Load Point on Location now used in Container Optimization Planning.

Load Point on Location now used in Container Optimization Planning.

Prior to this enhancement, OTM would treat load points on a location as separate internal locations by bundling based on the location and then the loading point. CONOPT worked on bundles. Now CONOPT has to be able to consider using packing items from all load points and using a new Penalty Matrix to determine which items should be packed together. A new Planning parameter, USE LOAD POINT PENALTIES IN PACKING, has been introduced to enable the feature. It will also disable the criteria in bundling for bundling by load point.

Let's look at an example.

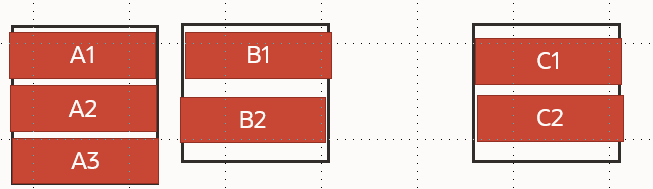

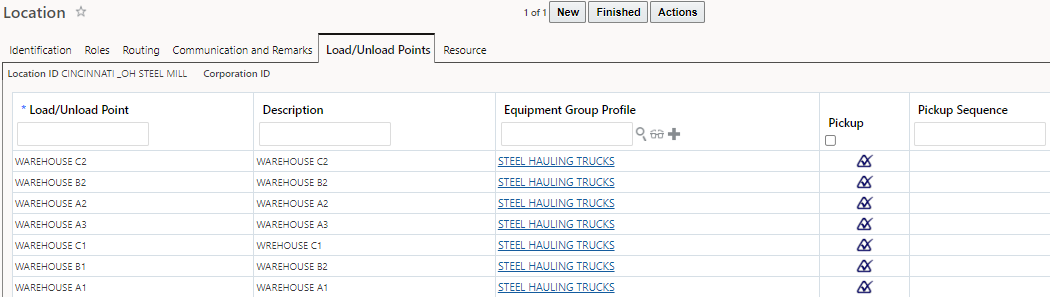

Here is a location. It has multiple load points. Some are clustered together and others are more distant. These could represent different warehouses or more commonly known as Loading Halls. Usually, a "Loading Hall" is defined by a large overhead crane on rails that has access to a finite area.

Loading Hall Layout

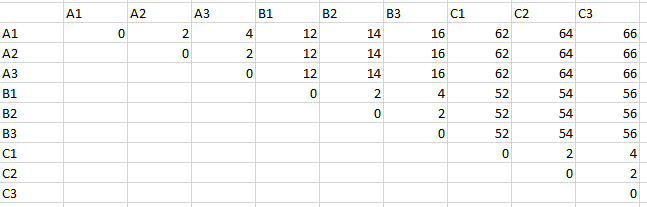

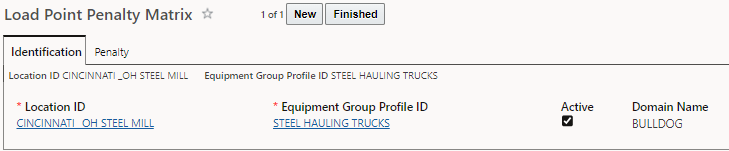

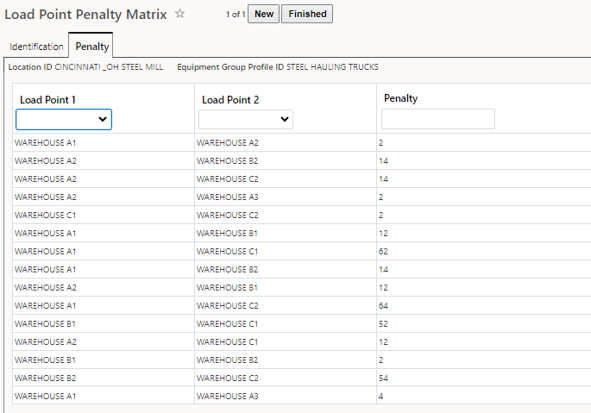

A Penalty Matrix is configured to put a value on the difficulty of traveling between "Loading Halls". The values in each cell are part of client configuration and are intended to represent distance between the points. One can easily see the logic that A cluster is close to the B cluster but more distant from the C cluster. B seems to be in between.

Loading Hall Penalty Matrix

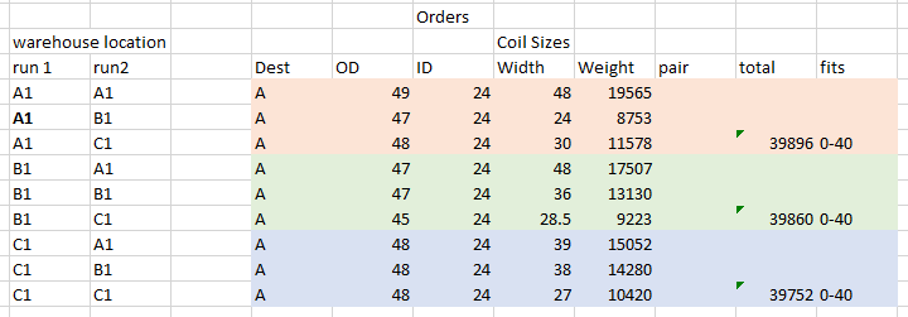

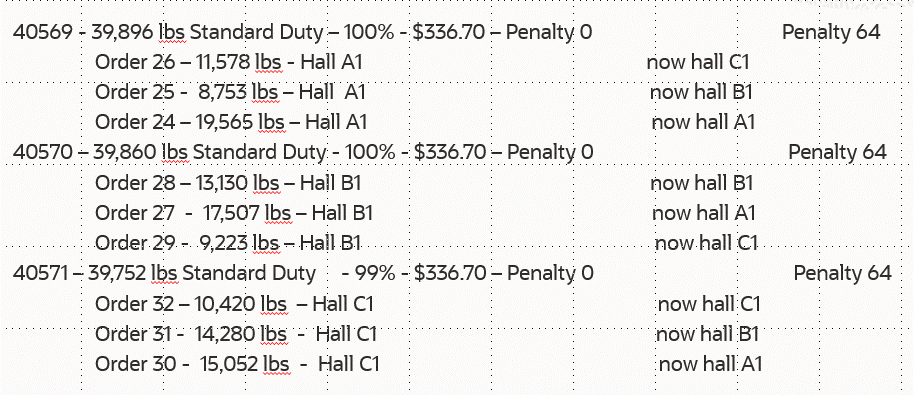

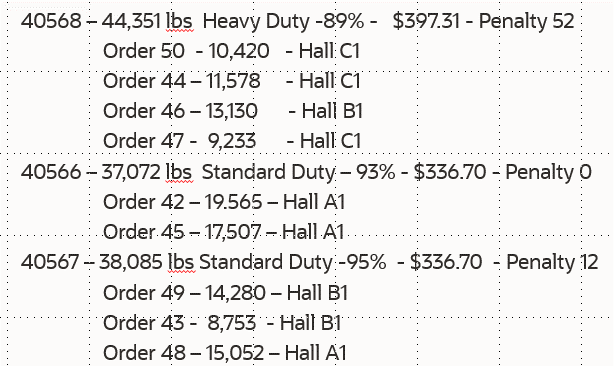

A simple test case with 9 orders is used to show that the location of the coils by way of the Penalty Matrix is used by Conopt to pack the equipment. The first run is designed to provide an optimized solution where there are no penalties. Then the locations are changed and the "inconvenience" to build the same optimized shipments as in the first case is now quantified by a penalty.

Run 1 and Run 2 do not use the same exact orders. Run 1's orders were copied and now have new IDs. The weight are unique across the orders and that is how to interpret the results. OD is Outside Diameter and ID is Inside Diameter. A real steel coil weight calculator was used to obtain the weights and dimensions.

The colors represent the ideal truckloads.

Loading Hall Test Example

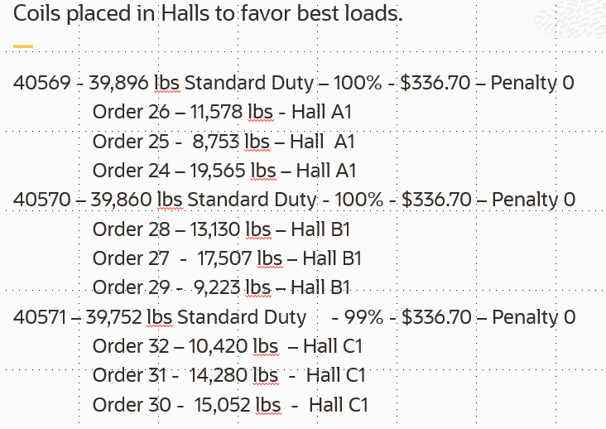

The first run is done and these are the results. Notice no penalties.

Loading Hall Optimal Example

Next Run has the Locations shifted. But before doing so, an estimated penalty cost is calculated based on the first solution with the trucks packed optimally. This was done outside OTM so the order numbers are the same. The "what if" was based on a lookup of the penalty table. This provided the "inconvenience" cost if the coils were placed in the worst possible positions and not using any of the new logic.

Estimated Penalty

Now the logic is used to run the second run.

Second Run

This Run is more expensive. It used a more expensive equipment and each equipment has good utilization, but not optimal utilization. The Penalty cost to not use the new logic would be very severe and this solution has made the trade-off of slightly higher transport cost as compared to loading cost.

Business Benefit

Business Benefit is that there is a cost to loading trucks at a large facility where materials may be spread out over a large area. The logic with the Penalty Matrix is designed to minimize the internal movement withing the plant while still planning an optimal loaded equipment.

Steps to Enable

A new Container Optimization Logic Parameter is required to activate the feature. USE LOAD POINT PENALTIES IN PACKING.

Bundling is recommended to be set to a very high value.

Load Points within a location are required. Loading Sequence is not used.

Load Points for a Location

The Penalty Matrix is also required.

Load Point Penalty Matrix Header

Load Point Penalty Matrix Details

Tips And Considerations

The Load Point Penalty Matrix can be loaded by CSV but there are no checks employed when this is done.

Capacity Limits is also required to manage the scenario where there are fewer, more expensive, high capacity trucks to handle the heaviest coils.

Quick Packing and Column Generation are recommended for this approach.

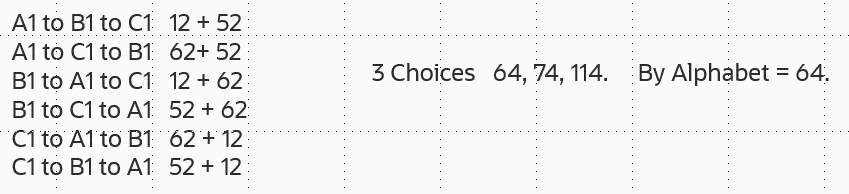

Penalty Cost Calculation

Penalty Cost Calculation

The conclusion is that sequence of direction of stops between Halls is not calculated as OTM does not keep track of that. Instead a method using the Alphabet is used to calculate the cost. The method to calculate the penalty may change in the future.