Display Manufacturing Details in New Web UI

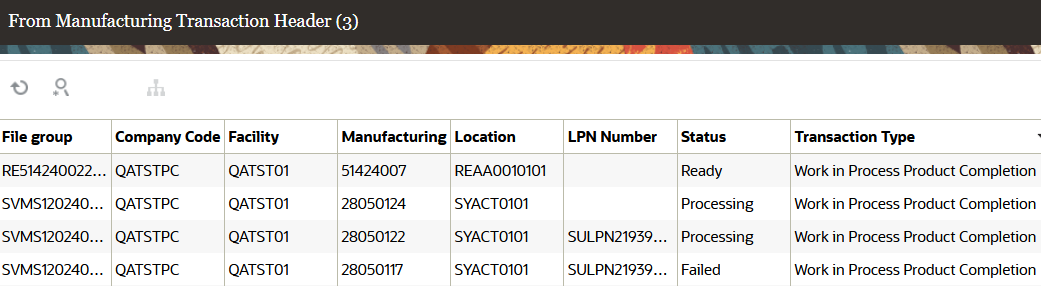

A new web UI, From Manufacturing Transaction Header has been added to display manufacturing transactions details including transaction type and status.

From Manufacturing Transaction Header

- The From Manufacturing Transaction Header UI allows you to view information regarding the inventory to be updated in a detailed page.

- You can filter and export the records.

- You can view manufacturing operations and if the item is serial tracked, its underlying serial number recorded as well.

INVENTORY HISTORY TRANSACTION UPDATES

Once the records are added to the From Manufacturing Transaction Header UI, the associated Ref Codes and Values for the TRAN_ID, TRAN_TYPE and WO-Ops Seq fields will be updated as per the following table for the following impacted Inventory History Transactions (IHTs):

- IHT-2 - Container Consumed

- IHT-4 - Inventory Adjusted pre verification

- IHT-22 - Lock Container - Before ASN Verification

- IHT-23 - Lock Container - After ASN Verification

- IHT-24 - Unlock Container - Before ASN Verification

- IHT-25 - Unlock Container - After ASN Verification

- IHT-29 - Create Allocatable Container

- IHT-49 - Lock Active

- IHT-50 - Unlock Active

| Field Name | New REF Code | New REF Value |

|---|---|---|

| TRAN_ID (TRA) | ref_code_15 | ref_value_15 |

| TRAN_TYPE (TRT) | ref_code_19 | ref_value_19 |

| WO-OPS Seq (WOD) | ref_code_20 | ref_value_20 |

The following updates are added for the Expense Destination field:

| Field Name | New REF Code | New REF VALUE |

|---|---|---|

| Expense destination (EXD) | ref_code_18 | ref_value_18 |

ATTRIBUTES ADDED TO MANAGE DATA SPANNING ACROSS MULTIPLE PAYLOADS

Due to manufacturing processes, sometimes a single LPN could have more than 1,000 products manufactured (yielding small products like Mouse, Medicine Vials, and so on.) In a scenario like this, the number of records planned per transaction could surpass the OIC Limit.

To address scenarios where data for a particular LPN/transaction comes in multiple payloads, we’ve added a mechanism to accept data for the same transaction across different payloads and the system will not initiate the transaction processing until we receive the complete data.

- Now, WMS can include a payload with data spanning multiple transactions. Additional attributes to indicate whether all the records are received or not will be at the transaction level.

The following attributes are now visible in the JSON payload:

| Attribute/Flag | Description |

|---|---|

| resend_flg |

When Inventory Management resends the transaction at the individual transaction level or work order level, this indicates to WMS whether to process the records or not to handle duplicate transactions. |

| ready_for_processing_flg |

This flag indicates whether all the records for a particular transaction is sent or not. If there are outstanding records for the same transaction, the value in the payload will be sent as "no", otherwise the value will be sent as "yes". |

| create_hdr_flg |

This flag indicates whether there is a new transaction record creation or an update to an to existing transaction. |

- If the transaction has the ready_for_processing_flg value set as "No", the corresponding records will be in "Not Ready" status.

- If the transaction has the ready_for_processing_flg value set to "Yes", then the intermediate record is updated with a status of "Ready" and further processing will be initiated.

PROCESS MANUFACTURING TRANSACTIONS AND UPDATES

Once the records are added into the From Manufacturing Transaction Header UI, the corresponding inventory history will be updated once the validations for the records are successful.

For manufacturing transaction records, the location can be drop/reserve/active and for a drop/reserve location, the LPN is mandatory.

- Once the records are picked up for processing, the system will update the status of the transaction to "IN-PROCESSING". Once the updates are successful, the system will update the status to "Completed/Success".

- Depending upon the quantity passed updates could differ for the inventory and corresponding serial numbers.

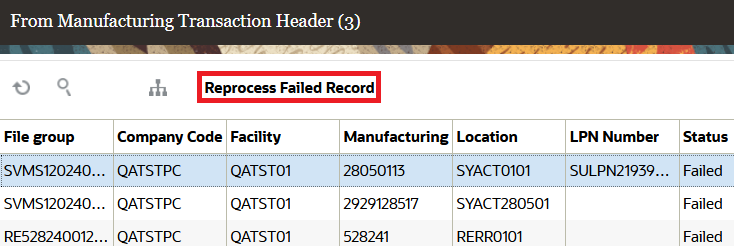

REPROCESS FAILED RECORDS

In certain situations, records sent by manufacturing systems via Inventory Management can fail due to missing items, unrequired quantities that are present in the application, or corresponding locations that are not configured.

To avoid having to resend failed manufacturing transactions, we’ve added a Reprocess Failed Record action button to the From Manufacturing Transaction Header UI.

Reprocess Failed Record

Steps to Enable

You don't need to do anything to enable this feature.