Bulk Compartment Compatibility

Bulk material loading is quite different than loading a dry van with packaged items. Every item leave a residue. Every shipper is concerned that there is no contamination of product from one load to the next. This enhancement keeps a history of the prior loads and has logic to assign equipment that is compatible with the planned shipment.

Food Grade Tanker

Packing vs Asset Compatibility

It is very easy to confuse packing in bulk planning with equipment (asset) assignment. However, they are quite different.

This enhancement is about the assignment of compatible assets after a shipment is planned. Additionally, this enhancement is about bulk commodities and not about loading barrels and boxes onto dry vans.

Bulk planning uses the equipment group as a surrogate for the actual equipment. The instantiation is the Shipment S-Equipment where the shipment contents and the equipment are displayed. The physical equipment (asset) can be assigned to the s-equipment.

All bulk loadings leave a residue of the prior item that was loaded. Many shippers will not clean equipment compartments between loads as the mixing does not degrade the product. However, in this current logic, a washout resets the equipment to a fresh state so anything can be loaded.

The Process of Planning Bulk

Planning will only build shipments with the equipment group, which is a surrogate for the asset. It is a 2 step process to build shipments and then to assign a compatible asset. With dry vans, there is no concern for contamination like there is for bulk. The packing logic for BULK will only allow one item to be loaded at a time. (In OTM, the object is still called a packaged Item and with the concept that it can be thought of like an ERU and treated like an imaginary cubic form with weight and volume.) The ERU is very important for packing bulk since bulk will never pack with "water level" compartment volume. The ERU represents the quantity that typically is loaded.

- Step 1 is to build the shipment with the Equipment Group.

- Step 2 is to find an asset that is compatible with the planned shipment based on the matching of asset residue with the planned packaged item in each compartment.

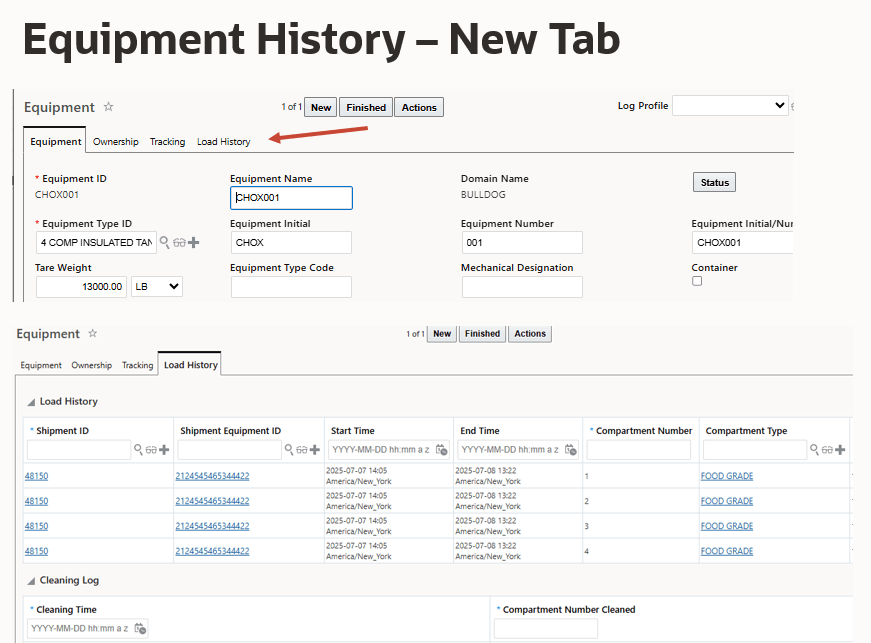

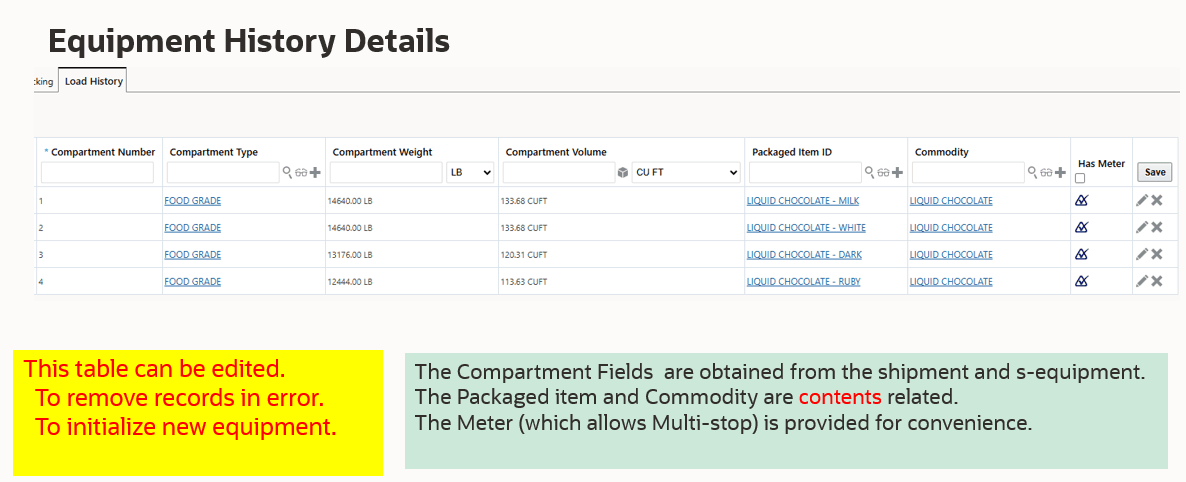

The new tab on the Equipment Table has many columns and will take 2 slides to see all of the columns.

Bulk Asset Compartment History

Second half of History Screen

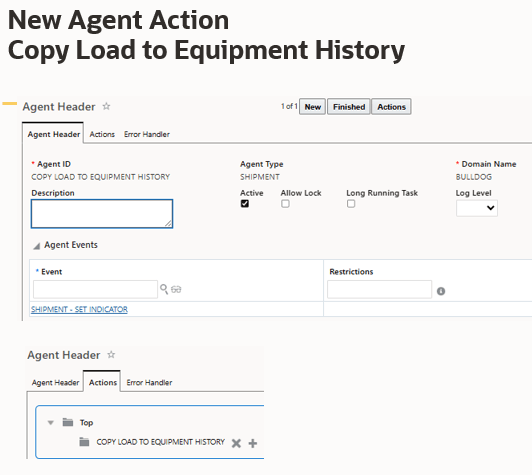

New Agent Action

A new agent action has been provided to simplify the work of copying the actual shipment contents to the assigned equipment when the client is absolutely certain that the equipment has been loaded and the "actuals" have been updated. The action is intended to be invoked by an event that happens when the equipment leaves the facility. It is not recommended to be done in planning after the assignment. If this step is done immediately after planning, there could be changes due to order cancellations, changes in items and quantities, as well as physical equipment that could not be loaded for mechanical and cleanliness reasons.

New Copy Action

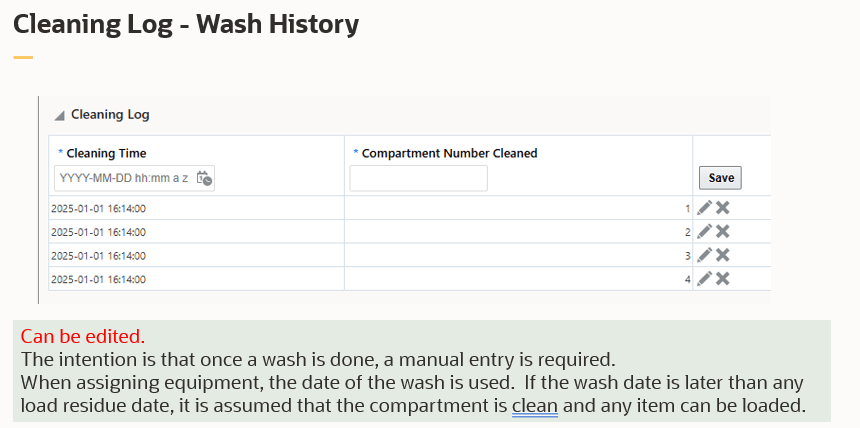

Washing Equipment will remove the residue constraint for the logic. OTM does not go back in history beyond the wash.

Wash History

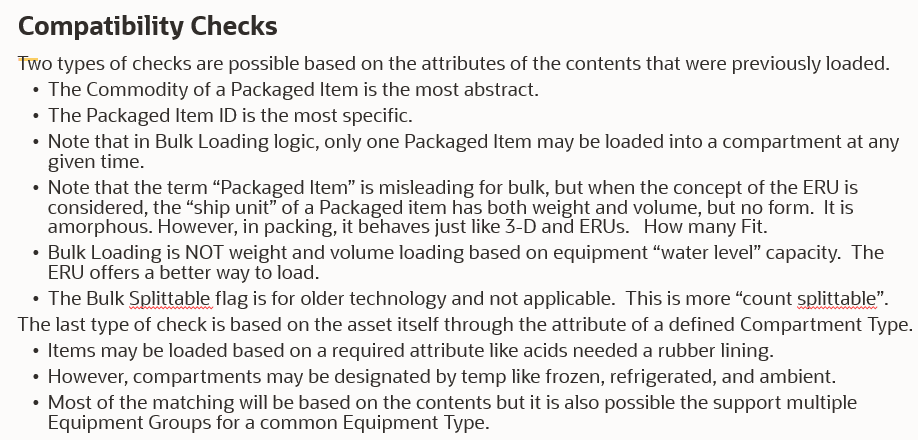

New Action to Validate Compatibility

Compatibility Checks

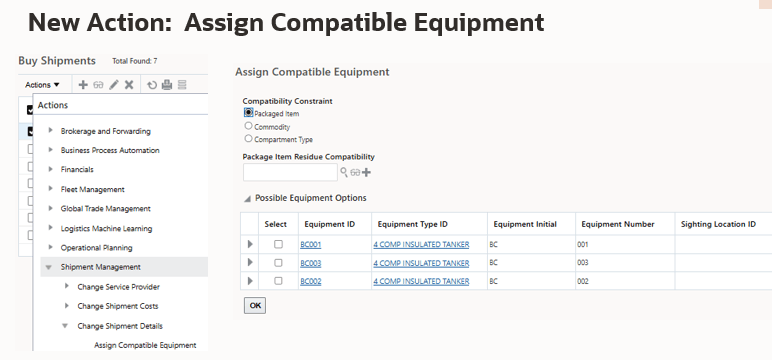

The new action to assign the Asset to the shipment is a Shipment Action and not a Fleet Action. The assets are assumed to be on site for loading and are not to be fetched from a distant location. While all dry vans of a given size are assumed to be equivalent, the bulk asset is unique because of the residue. The assignment process compares the asset to the planned shipment. The "link" is a search for the assets that share the same Equipment Type. You can use agents to fill in the Sighting Location and Arrive Date to filter the location. More than one asset may be available. You can check as many as you like and the first match will be selected. If a compartment is clean, any product may then be loaded.

New Action Screen

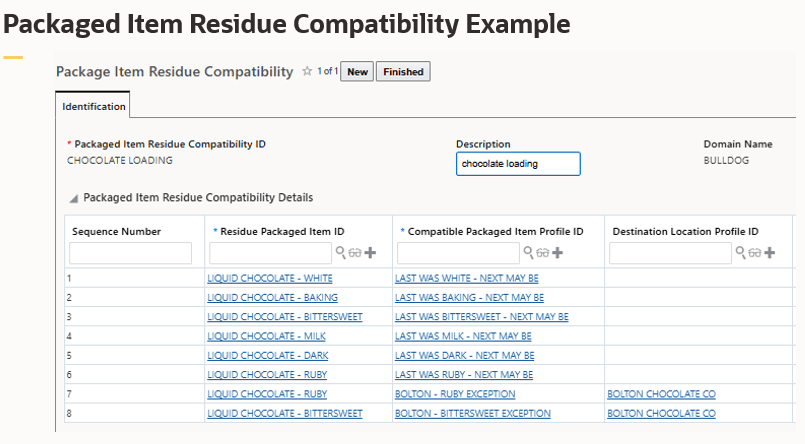

- Matching Criteria to determine if the planned new load is compatible with an asset that contains residue can be configured by using the Packaged Item Profile that contains the item to be loaded as it compares with the Packaged Item of the residue in the compartment. The check is done on the compartment level.

- The sequence number is part of the Primary Key but is also provided for easy reference to find a line to edit. It is not used in any logic.

- The Residue Packaged Item Column represents the item that was loaded in the equipment.

- The Compatible Packaged Item Profile is a general list of items that can be loaded on top of the residue for most customers.

- The Location Profile contains a list of locations where the Profile represents an "override profile". This may have fewer or more items or different items.

Packaged Item Residue Compatibility

This feature compliments the Bulk Planing Feature. It now allows you to manage the assets that are to be loaded to complete the planned shipments. All bulk loadings leave behind a residue that may or may not be compatible with the next planned item to be loaded. You are now able to set up matching criteria to test if the material to be loaded is compatible with the residue.

Steps to Enable and Configure

- Bulk Loading must be Configured by setting the Conopt Logic Configuration parameter for USE BULK EQUIPMENT GROUP LOGIC to TRUE.

- Shipments are then built.

- Next, the new Shipment UI action for Assign Compatible Equipment can be run. Only one shipment can be matched at a time.

- The action requires that the Packaged Item Residue Compatibility table must be setup. This is list of acceptable items that can be loaded on top of the residue.

- Every PI that can be loaded MUST have a list of compatible items that can be loaded after it.

- THERE IS NO WILD CARD that implied that NONE means that ALL can be loaded.

- Once an asset (equipment) has been selected, it will be added to the s-equipment of the shipment.

- If no asset is selected because none match, an asset should be washed and it will then be compatible.

- Manual entry of the wash history is required.

- The asset is then loaded and dispatched. It is essential to not copy the load to the history until the actual load can be confirmed.

- You must set up an agent that contains the new agent action to COPY LOAD TO EQUIPMENT HISTORY and this action will copy the newly dispatched load to the asset history.

Tips And Considerations

Compatibility or the next item is a FAIL SAFE process. This means that for every item that is loaded, there must be a record created with a profile of all compatible items. This is essential for product safety.

In dry van loading, there is an entity called Commodity Incompatibility. This is NOT FAIL SAFE. It is not used in the Bulk Loading logic.