Execute Production at a Workstation and Automate Resource Transactions

Execute Production at a Workstation and Automate Resource Transactions

When you execute a work order operation at a workstation, you can see all the required information for the work order in one place. You can also track work order progress against the production targets. With this update, you can:

-

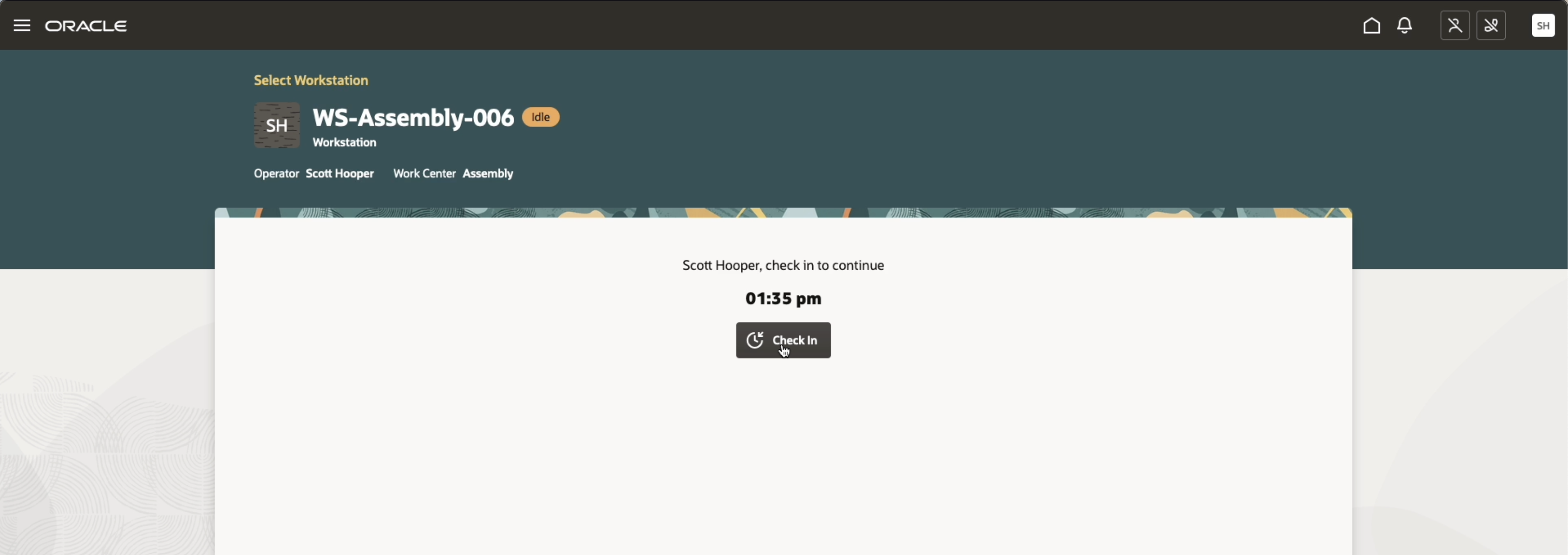

Track the time an operator spends at an assigned location, as all check-ins and checkouts are recorded.

Check In to a Workstation

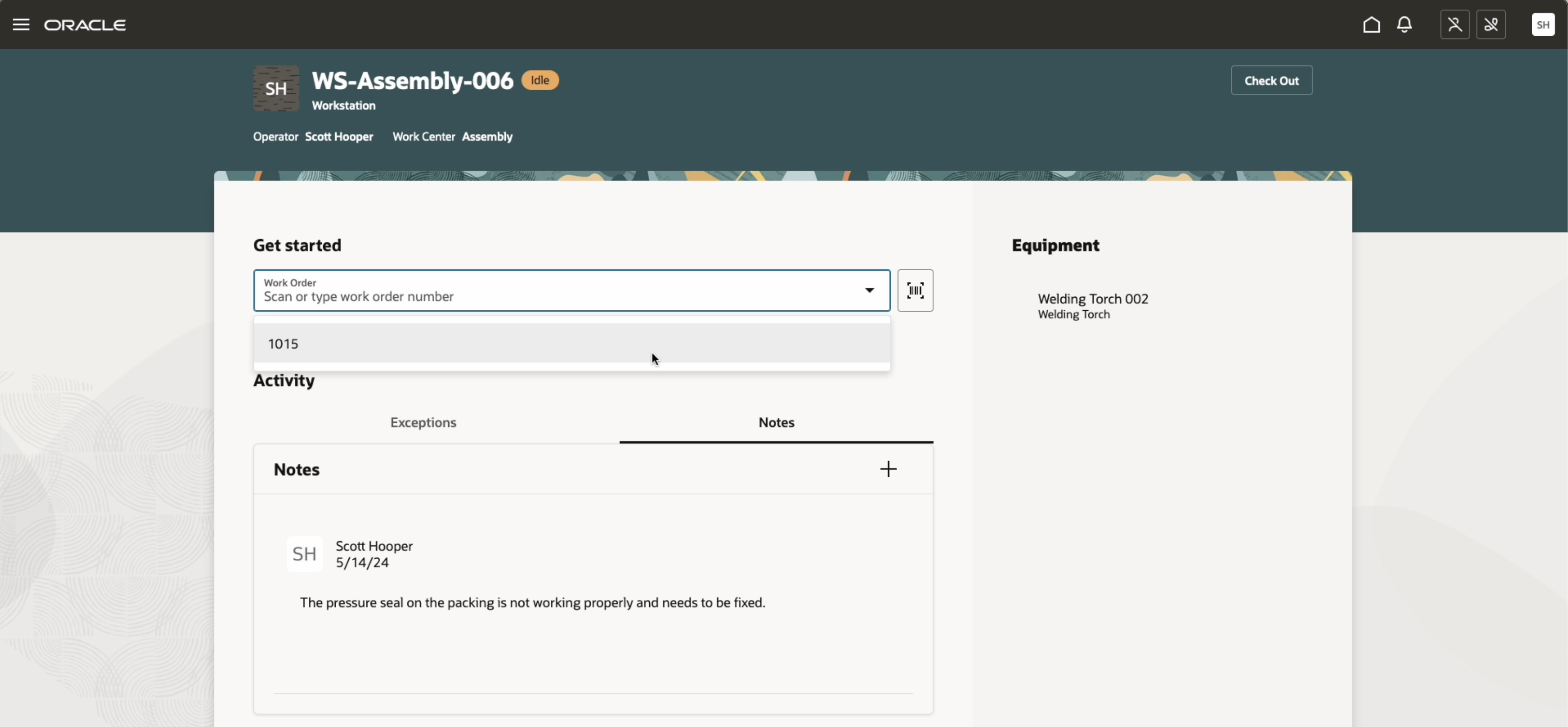

- Scan or enter a work order number to identify the work at a workstation.

Scan or Enter a Work Order Number

-

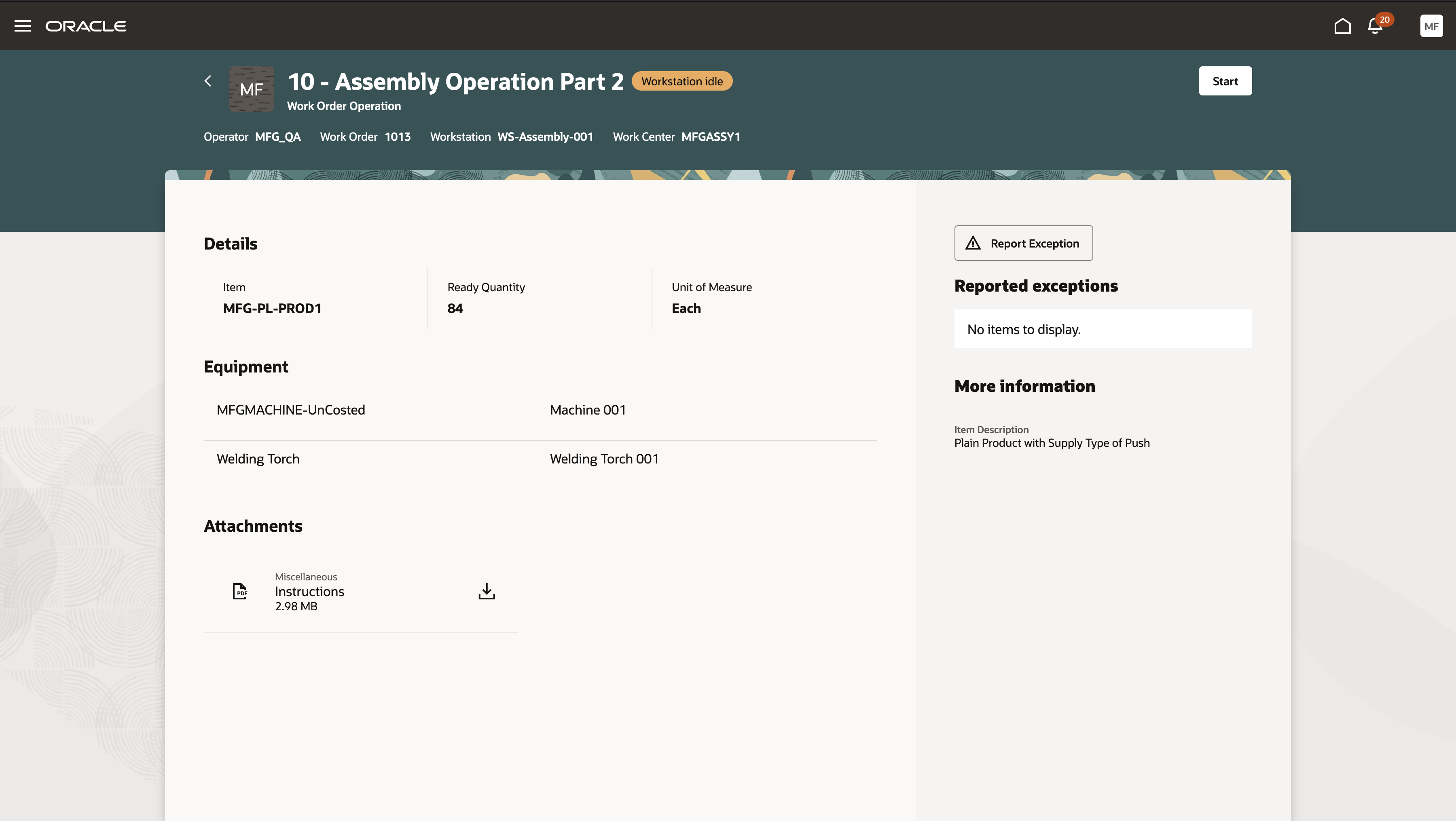

View all work order related information from a single page, including operation attachments and previous shift activity.

View Work Order Operation Details

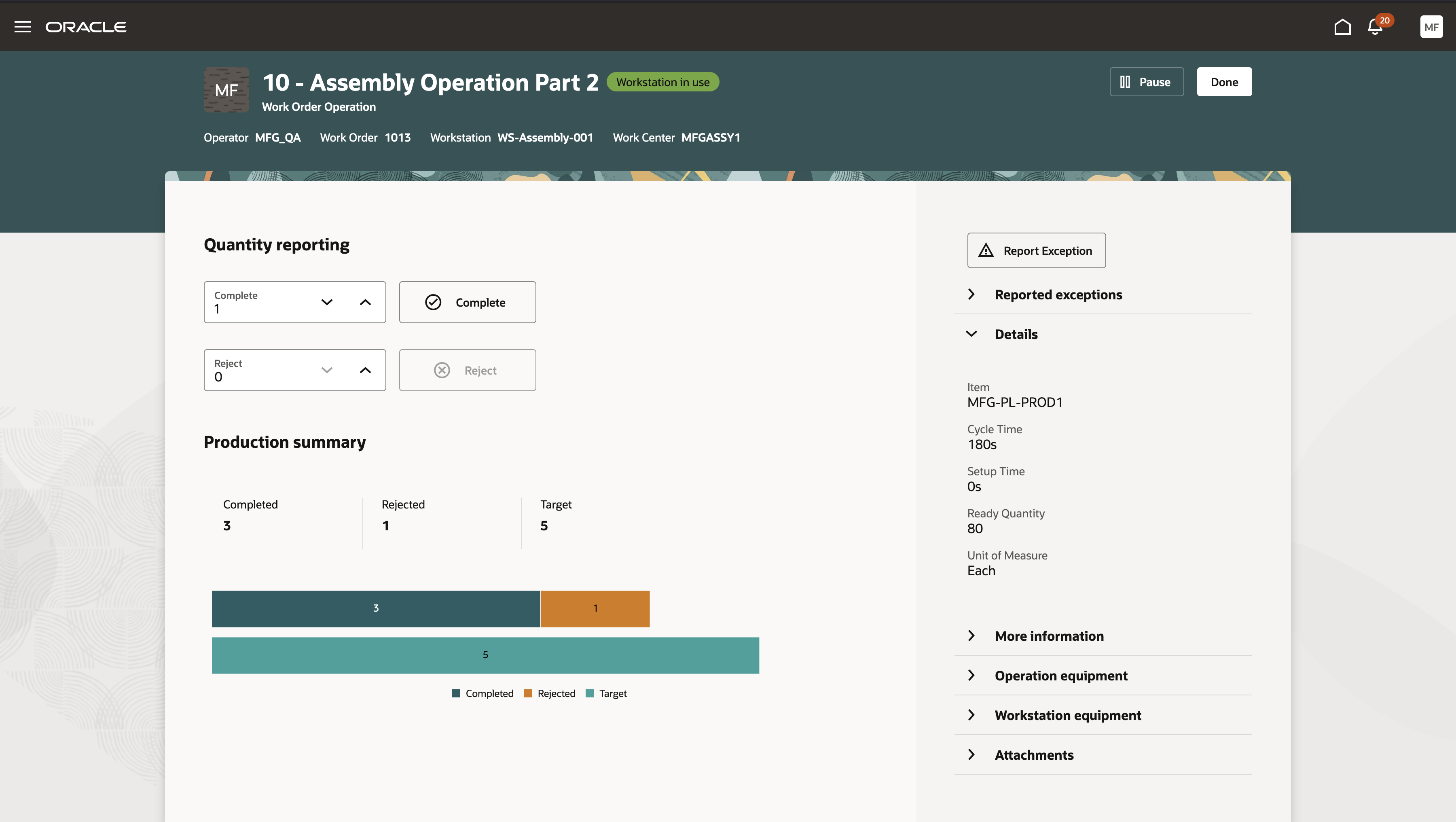

- Report completed and rejected quantities during execution.

- View real-time progress towards operation completion with automated transaction updates of completed quantities.

Work Order Operation Progress

- Automate resource usage reporting for operator and equipment resources based on the time spent executing work order operations.

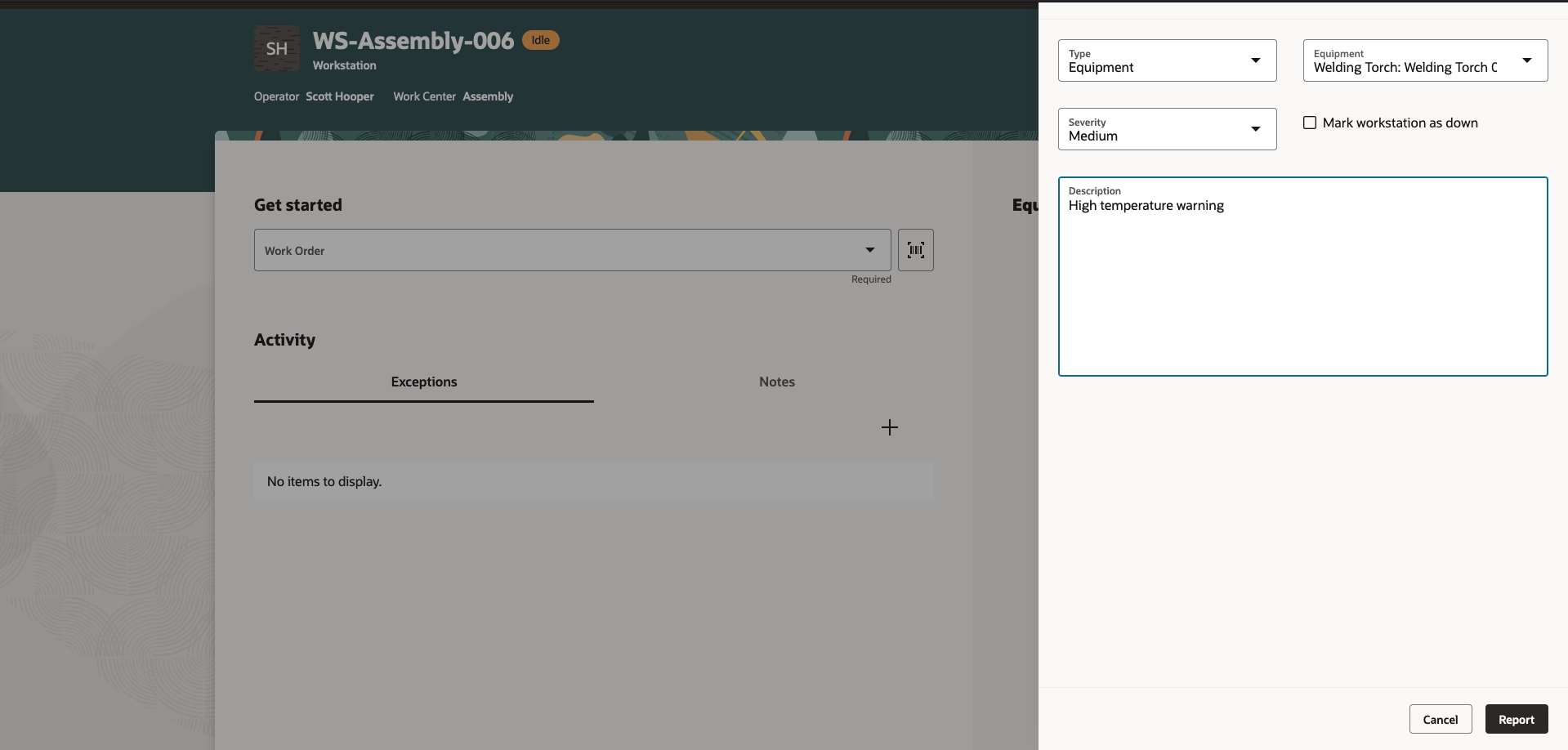

- Report an exception directly from the workstation to help identify issues that may disrupt production and request support.

Report Production Exception

Operators can access production execution capabilities from their workstations through a single user interface that provides a smooth and intuitive digital experience. Operators can focus on their manufacturing tasks with handy access to all the information required to efficiently perform these tasks.

Steps to Enable

Make the feature accessible by assigning a configured job role that contains the required privileges. Details are provided in the Access Requirements section below.

In the Work Definition work area, you can model workstations that are part of a work center and associate equipment resource instances to perform in-house operations. These workstations are available for selection in the Work Execution work area for users to check in and execute work order operations.

Tips And Considerations

- A user can check in to only one workstation at a time. Also, only one user can check into a workstation at a time.

- If you want to report the actual time spent by a resource executing a work order operation, then set the charge type for the work order operation resource to manual and add equipment instances to the workstation.

- During execution of a work order operation, an operator can pause and resume execution at any time.

- Actual time spent executing an operation is calculated as the time elapsed between start and end minus the pause time.

- If you want to report the checked in user's actual time spent executing a work order operation as a labor resource transaction, then configure the production operator as a labor resource instance belonging to the work center that the workstation is part of.

- For automated resource usage transactions, the execution time is converted from time elapsed unit of measure (seconds) to the resource's unit of measure using the profile Hour Unit of Measure (ORA_RCS_HOUR_UOM). The UOM set in this profile and the resource must belong to the UOM class specified in the other profile, SCM Common: Default Service Duration Class (RCS_DEFAULT_UOM_CLASS_CODE_FOR_SVC_DURATION). We recommend that you set this profile to a UOM class that represents units of measure for time.

- Operation cycle time, setup time, and real-time target displayed while executing a work order operation also rely on the UOM configuration described above.

- Real-time target is the quantity a user should have produced based on execution time elapsed and the cycle time of the operation.

- Users who are assigned a configured job role that contains the privilege WIP_CHECKOUT_OVERRIDE_WORKSTATION can check out any other user.

The following prerequisites and conditions currently apply when executing production at a workstation:

- Only work order operations belonging to discrete manufacturing work orders can be executed at workstations. Process manufacturing work orders cannot be executed at a workstation.

- Work order operations that are enabled for serialization can be executed at a workstation only if the assembly serial numbers are pre-assigned to the work order.

- Work order operations for lot-controlled items can be executed at a work station only if the lot numbers are pre-assigned to the work order.

- Work order operations with serialized or lot-controlled operation materials cannot be executed at a workstation.

- Work order operations with resources requiring equipment or labor qualifications cannot be executed at a workstation.

- Product completion transaction for items that are serialized at receipt cannot be completed at a workstation.

- Work order operations for organizations with project tracking, country of origin tracking for inventory, or with warehouse management integration cannot be executed at workstations.

Key Resources

-

Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges can execute production at a workstation:

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

- Override Existing Check In of an Operator at a Workstation (WIP_CHECKOUT_OVERRIDE_WORKSTATION)

The preceding new privileges are introduced in this update.

Other Privileges:

- Get Manufacturing Plant Set Up Data by Service (WIS_GET_MFG_PLANT_SETUP_SERVICE_PRIV)

- Get Work Orders by Service (WIP_GET_WORK_ORDERS_SERVICE_PRIV)

- Report Operation Transactions (WIP_REPORT_OPERATION_TRANSACTIONS_PRIV)

- Report Production Exceptions (WIP_REPORT_PRODUCTION_EXCEPTIONS_PRIV)

- Manage Work Execution Work Area (WIP_MANAGE_WORK_EXECUTION_WORK_AREA_PRIV)

- Report Resource Transactions (WIP_REPORT_RESOURCE_TRANSACTIONS_PRIV)

- View Workstations (WIS_VIEW_WORKSTATIONS_PRIV)

- View Work Orders (WIP_VIEW_WORK_ORDERS_PRIV)

- Get Work Definitions by Service (WIS_GET_WORK_DEFINITIONS_SERVICE_PRIV)

- Use REST Service - Guided Journey Responses (PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES_PRIV)

- Use REST Service - Guided Journeys Read Only (PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO_PRIV)

- Manage HCM Non-Person Note (HRT_MANAGE_HCM_NON_PERSON_NOTE_PRIV)

- Get Item Rest (EGP_GET_ITEM_REST_PRIV)

- Access HCM Common Components (HRC_ACCESS_HCM_COMMON_COMPONENTS_PRIV)

- Configure Inventory Barcode Formats (INV_CONFIGURE_INVENTORY_BARCODE_FORMATS_PRIV)

In addition to the preceding privileges, users should have item class data security configured with the View Item Basic action set to allowed.