Redwood: Use the New Supervisor Workbench

Overview

Maintenance supervisors are responsible for ensuring the smooth operation of maintenance teams. Maintenance supervisors manage work orders, assign tasks to technicians, and ensure compliance with safety and operational standards. Supervisors also handle inventory control, budgeting, and vendor relationships to ensure the timely procurement of parts and materials.

With this update, Oracle Fusion Maintenance includes the new Redwood Maintenance Supervision workbench. The Maintenance Supervision workbench uses a unified, modern interface to simplify maintenance management by consolidating the essential maintenance management tools in one place.

Key Capabilities

The Maintenance Supervision workbench includes the following key capabilities to help supervisors efficiently manage maintenance operations:

- View and Manage Work Orders

- Schedule Work Orders

- Assign Work Orders

Once enabled, you can access the Maintenance Supervision workbench from the Tasks menu on the Maintenance Management landing page. Enabling the workbench does not disable the existing Manage Maintenance Work Orders page.

View and Manage Work Orders

When you navigate to Maintenance Supervision, the Work Orders tab appears by default. You can use the following features from the Work Orders tab:

- Organization Context Switcher: Select an organization to view its associated work orders. The page metrics and results refresh based on the selected organization.

- Key Metrics Dashboard: Displays work order metrics such as Open, Unreleased, Past Due, and Completed work orders for real-time visibility.

- Search and Filter: Use keyword searches, suggested filters, and saved searches to refine results by work order status, priority, or planned start dates.

- Edit Work Orders: Update status, priority, or other details directly within the page.

- Create Work Orders: Quickly create new work orders, including single or multi-asset options, using the Create Work Order action.

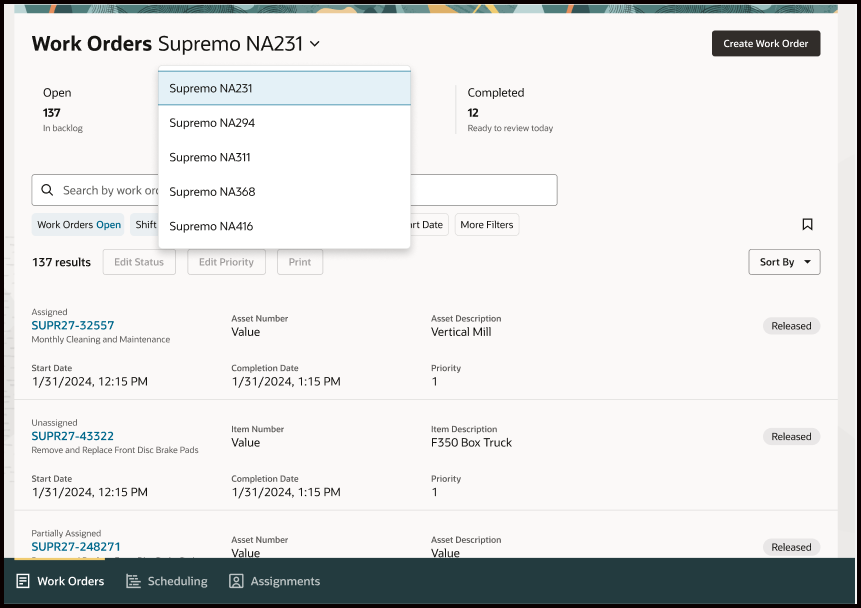

Select Organization

The organization context switcher near the top of the page lets you select an organization to view its associated work orders. The context organization defaults to your default maintenance organization in Maintenance Management. You can select other maintenance organizations to which you have access.

The following screenshot shows the Work Orders tab with the organization context switcher:

Maintenance Supervision Work Order Tab Organization Switcher

View Key Metrics

The Work Orders tab includes a static scoreboard of key operational metrics for your selected organization, such as the open, unreleased, past due, and completed work order counts. The following metrics are included by default:

- Open: The number of open work orders, as on the current date. The work orders can be in the Released, Unreleased, or On Hold status. All open work orders have a planned start date on or before the current date.

- Unreleased: The number of unreleased work orders, as on the current date. All unreleased work orders have a planned start date on or before the current date.

- Past Due: The number of work orders with a planned completion date before the current date and a status of Released, Unreleased, or On Hold.

- Completed: The number of work orders completed today that are available for review and closure.

The following screenshot shows the metrics or Key Performance Indicators (KPIs) that appear on the Maintenance Supervision Work Orders tab:

Work Order Tab Showing the List of Work Orders and KPIs

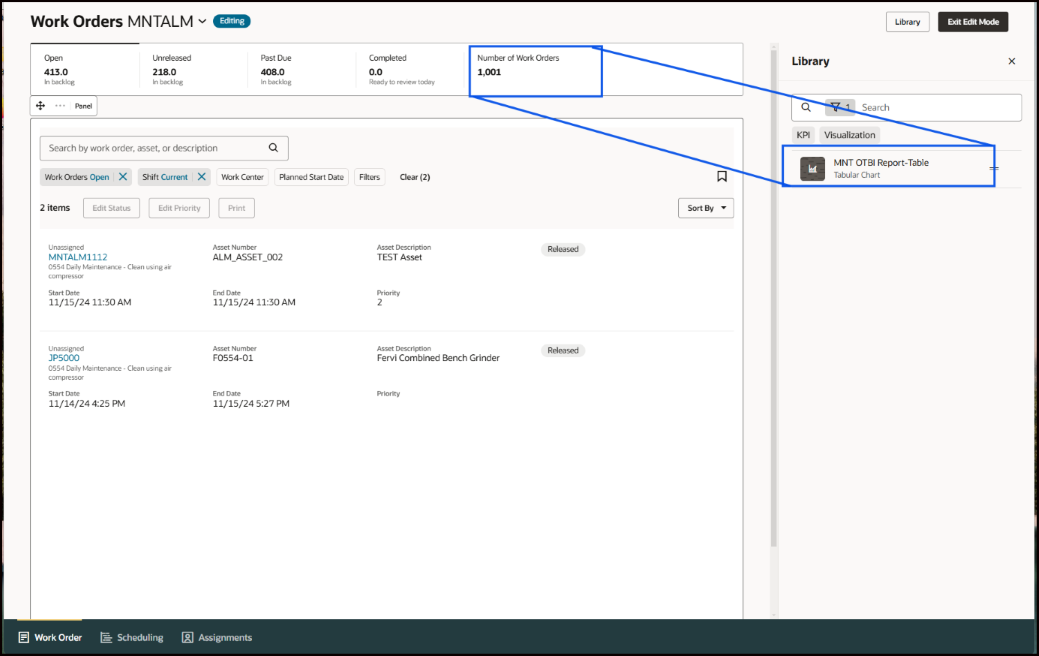

Edit Page Layout

Supervisors can personalize the Maintenance Supervision workbench by embedding Oracle Transaction Business Intelligence (OTBI) visualizations.

To personalize the layout:

- Click Edit Page Layout.

- Drag your KPI content to the scoreboard region.

- Add corresponding visualizations below the scoreboard area.

The flexibility to add KPIs and visualizations enables supervisors to create dashboards that align with their unique workflows and operational goals.

The following screenshot illustrates adding KPIs and visualizations from your library:

Work Order Tab Edit Mode

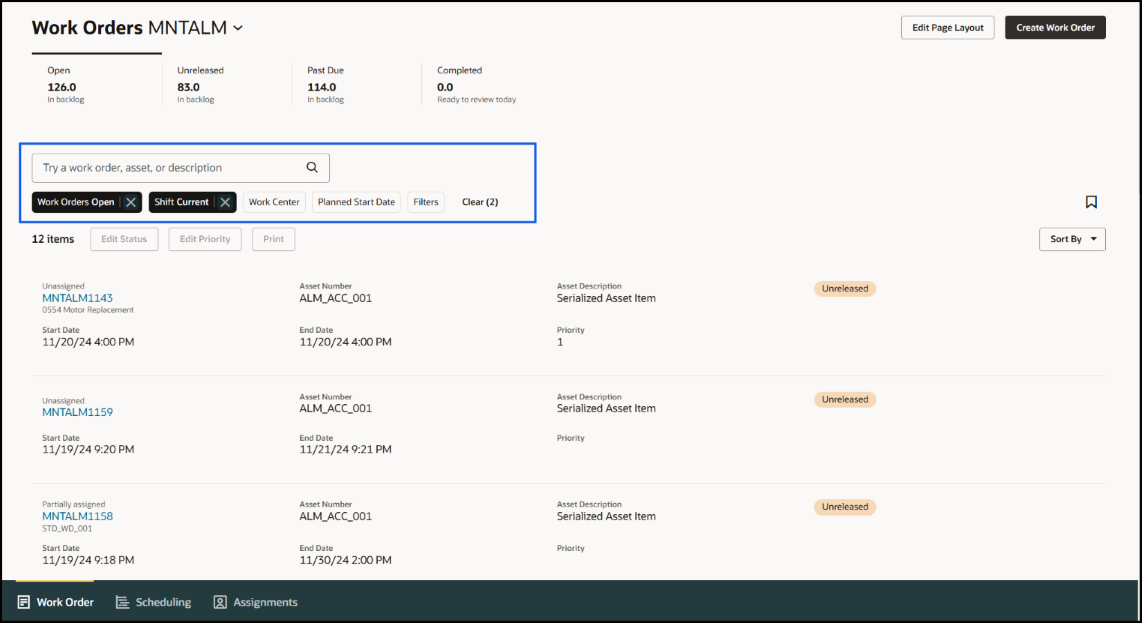

Search for Work Orders

The Work Orders tab displays open work orders for the current shift by default. The default configuration focusses on orders expected to be completed by the end of the shift. You can customize and refine the results using suggested filters, keyword search, and additional filters. For example, you can choose to deselect the current shift selection and filter based on the planned start date and planned completion date to set a custom date range, such as the upcoming week.

The search function supports full-text searches across multiple attributes. The results appear in a sortable table for easy management.

Search Criteria

You can use the keyword search to filter results by attributes, such as:

- Work Order Number

- Work Order Description

- Asset Number

- Asset Description

- Asset Serial Number

- Asset Lot Number

- Item Number

- Item Description

Suggested Filters

Refine your results further using suggested filters:

- Work Orders: Filter by work order status options, namely Open, Unreleased, Past Due, or Completed.

- Shift: Filter by timeframes, such as Past, Current, Next, or Today, based on the shift setups defined in the organization's default calendar.

Additional Features

Saved Searches: Save frequently used criteria and filter settings for quick access. You can create both personal and shared search configurations, enabling you to set a default or select a saved context for future searches.

Sort Options: Organize results using the following criteria:

- Priority (High to Low or Low to High)

- Planned Start Date (New to Old or Old to New)

The results are displayed by date and priority for clarity, with each row corresponding to a specific work order and asset. This approach enables you to manage one or multiple assets linked to a single work order, as each row provides a detailed view of the work order and the associated asset.

The powerful search and filtering functionality enables you to efficiently locate, prioritize, and manage work orders based on your operational needs.

The following screenshot shows the search bar and search options:

Work Orders Tab Showing Search Capabilities and Suggested Filters

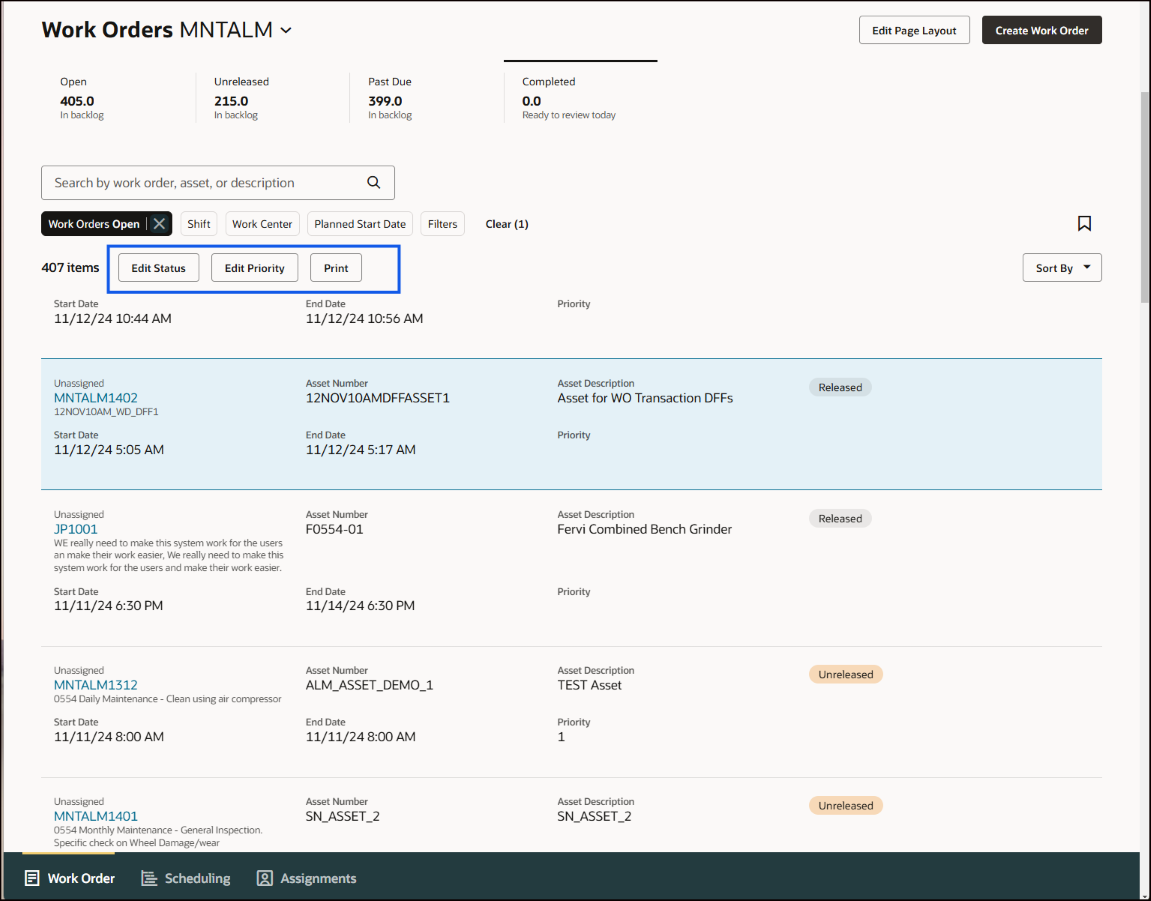

Perform Quick Actions

You can select a work order row and use one of the available quick actions to edit the work order status, edit the work order priority, or print the work order.

The following screenshot shows a highlighted work order row and the action buttons:

Work Orders Tab Showing Work Order Actions

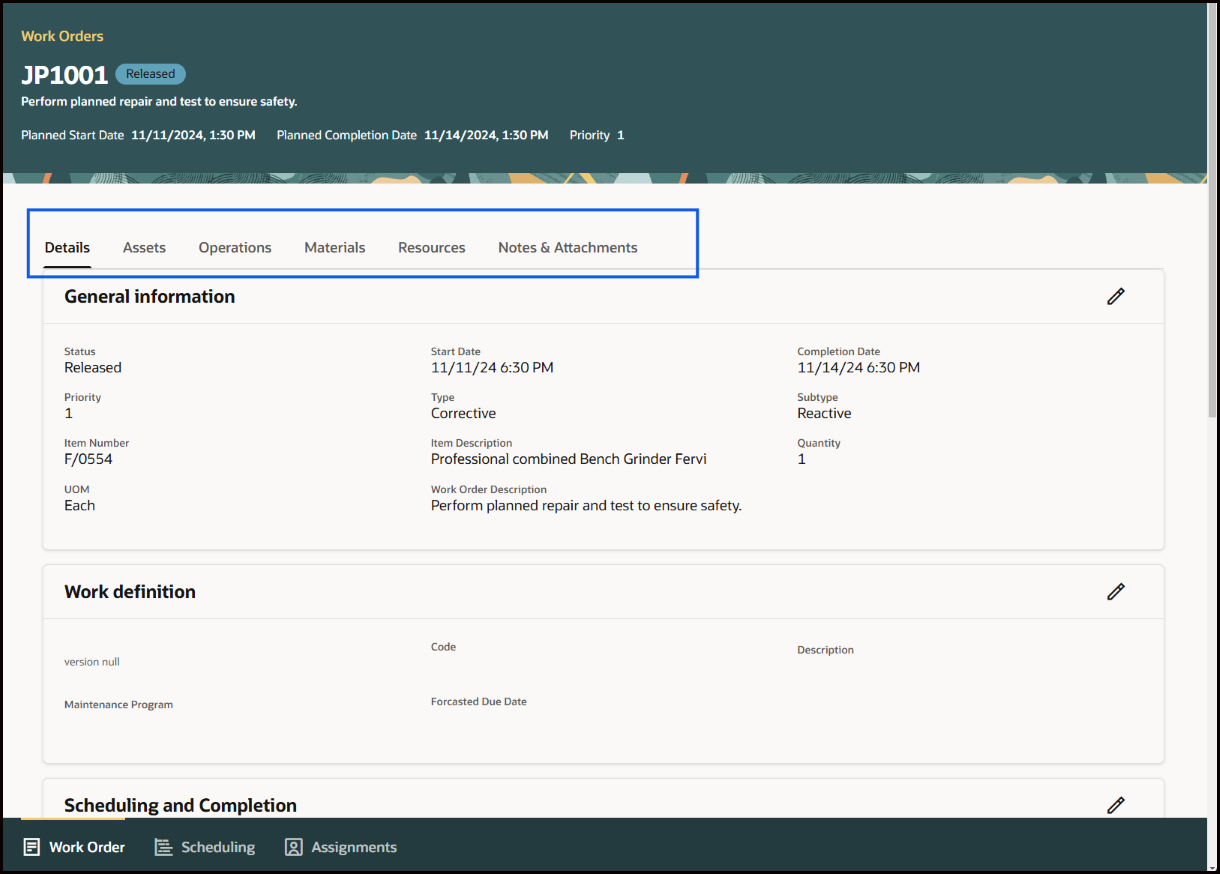

View And Edit Work Order Details

You can navigate to the details page of any work order by clicking the work order number for more information. The Details tab includes general information, work definition details, scheduling and completion, additional information, and attachments.

You can also access the Assets, Operations, Materials, Resources, and Notes & Attachments tabs. You can edit the information on each tab. The Assets tab shows the work order asset information and its associated meters, which can be updated. The Operations tab lets you add an operation if the work order is in an Unreleased Status. You can update and add planned Materials and Resources on the respective tabs. You can edit or add Notes and Attachments to the work order.

Certain attributes can be updated depending on the status of the work order. For instance, you can edit the work definition if the work order is in an unreleased status. However, you cannot update the work order operation attributes if the work order is in a released status.

The following screenshot shows the work order Details tab:

Work Order Tab Showing Work Order Details

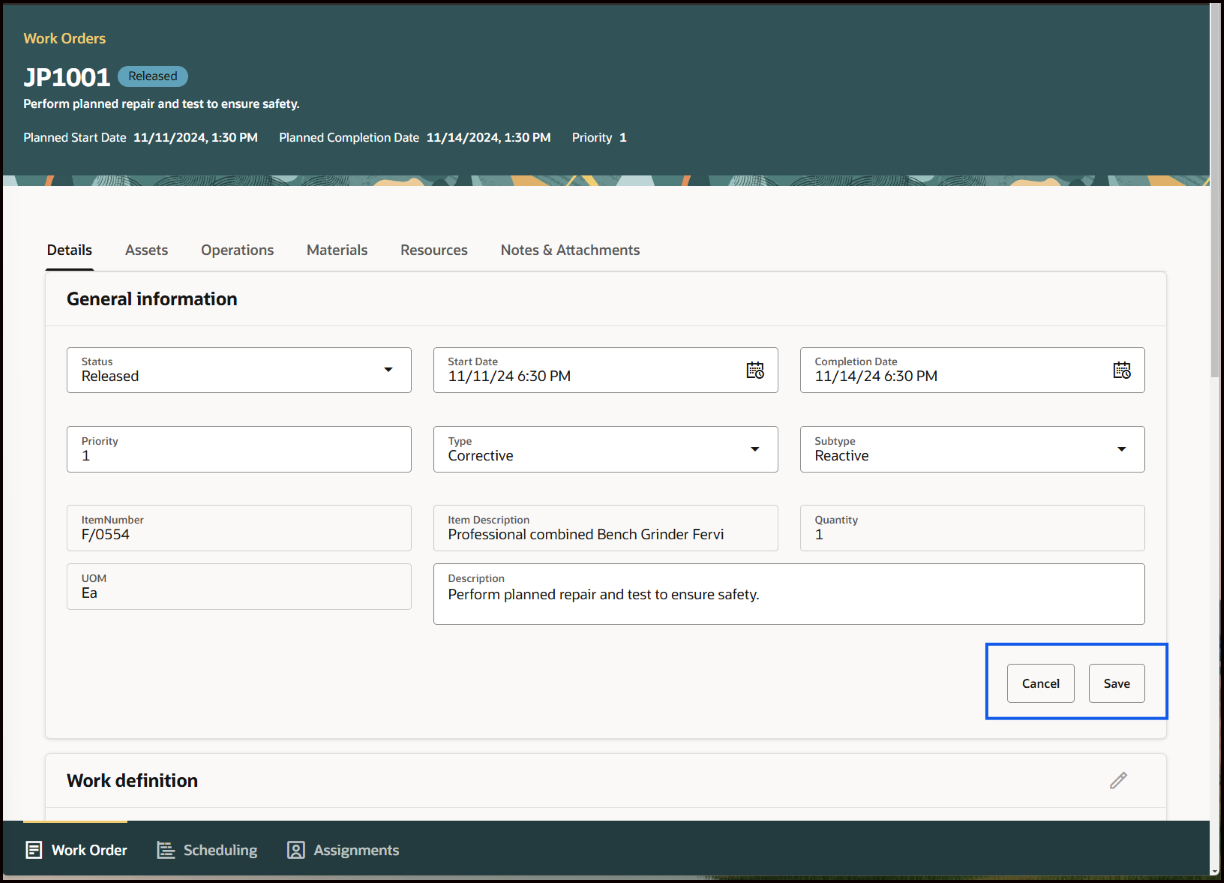

The following screenshot shows the General Information section in edit mode, with the Cancel and Save buttons:

Work Order Details General Information in Edit Mode

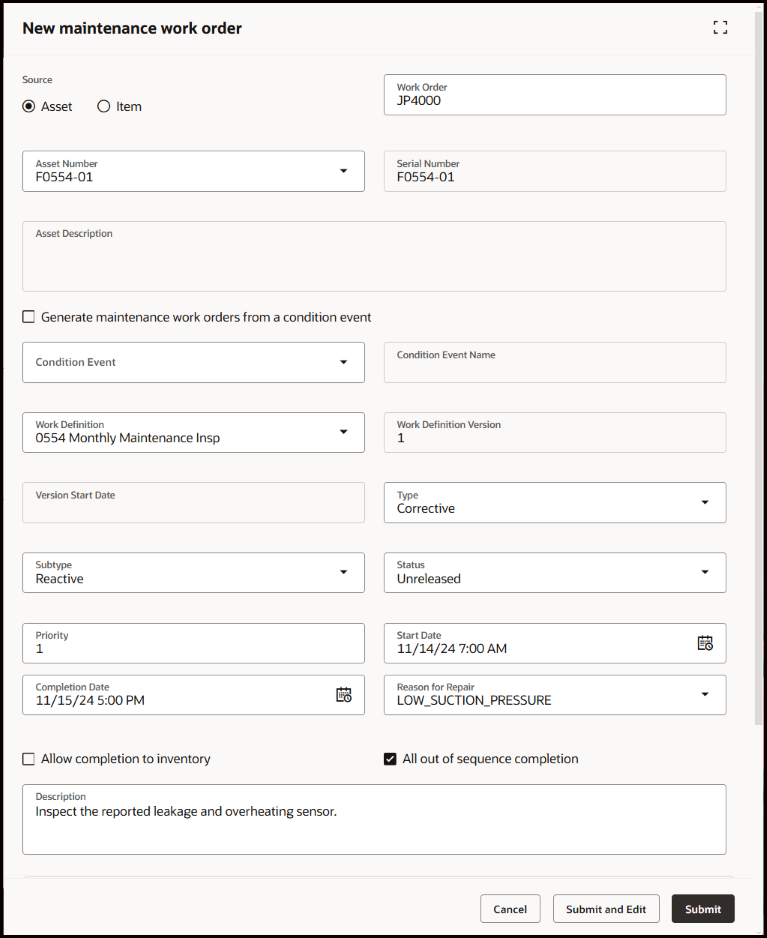

Create a Work Order

You can create a work order by clicking Create Work Order. A drawer opens up that lets you specify the details for a single or multi-asset work order.

The following screenshot shows the Create Work Order button:

Work Order Tab: Create Work Order Button

You have flexibility in the way you create a work order. After you enter data, you have the option to Submit and Edit and continue editing the work order.

The following screenshot shows the New Maintenance Work Order drawer:

Work Order Tab: New Maintenance Work Order Drawer

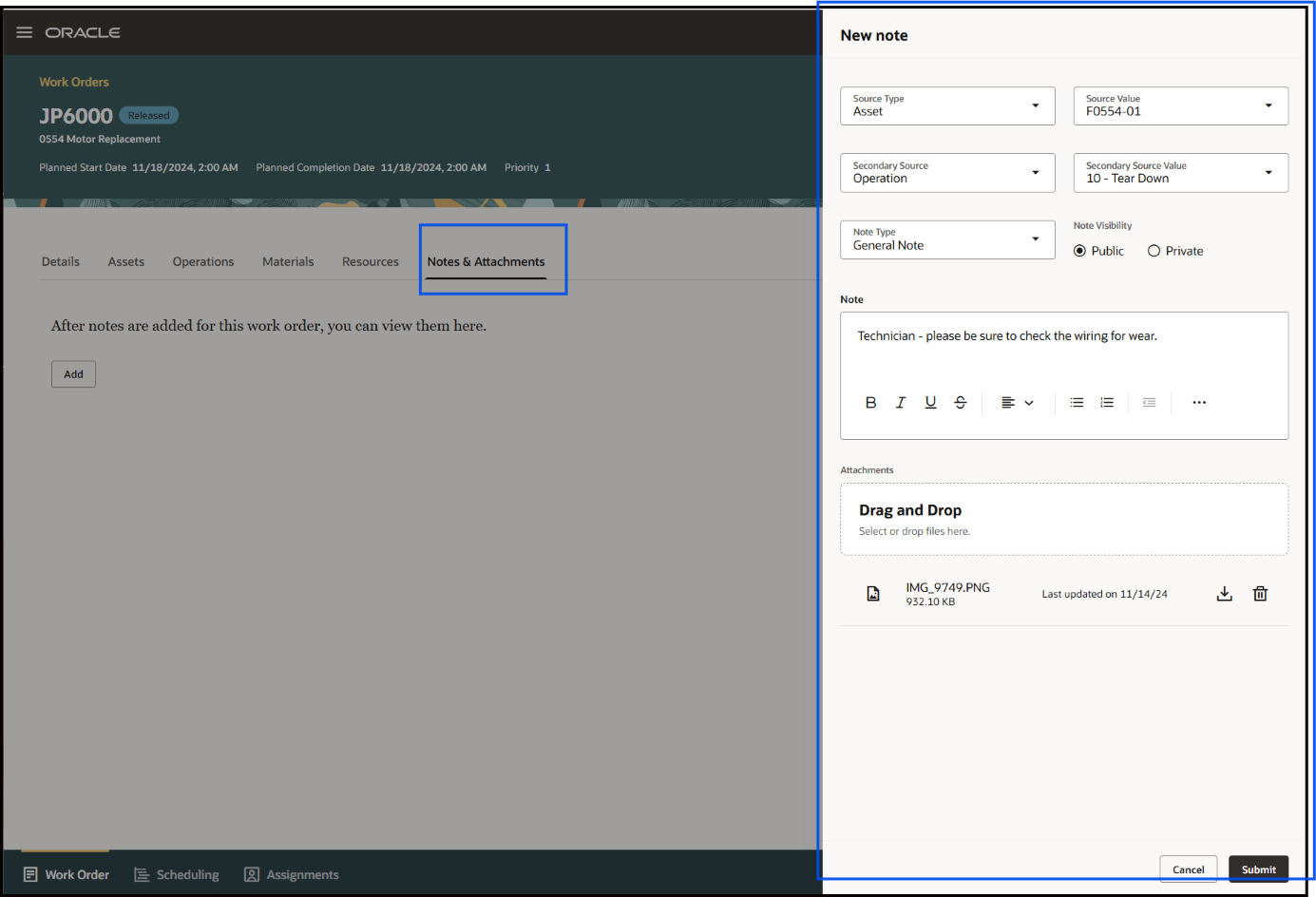

To support collaboration, you can create Notes & Attachments for the work order. This information then becomes available for the maintenance technician.

The following screenshot shows the New Note drawer:

Edit Work Order Note

Schedule Work Orders

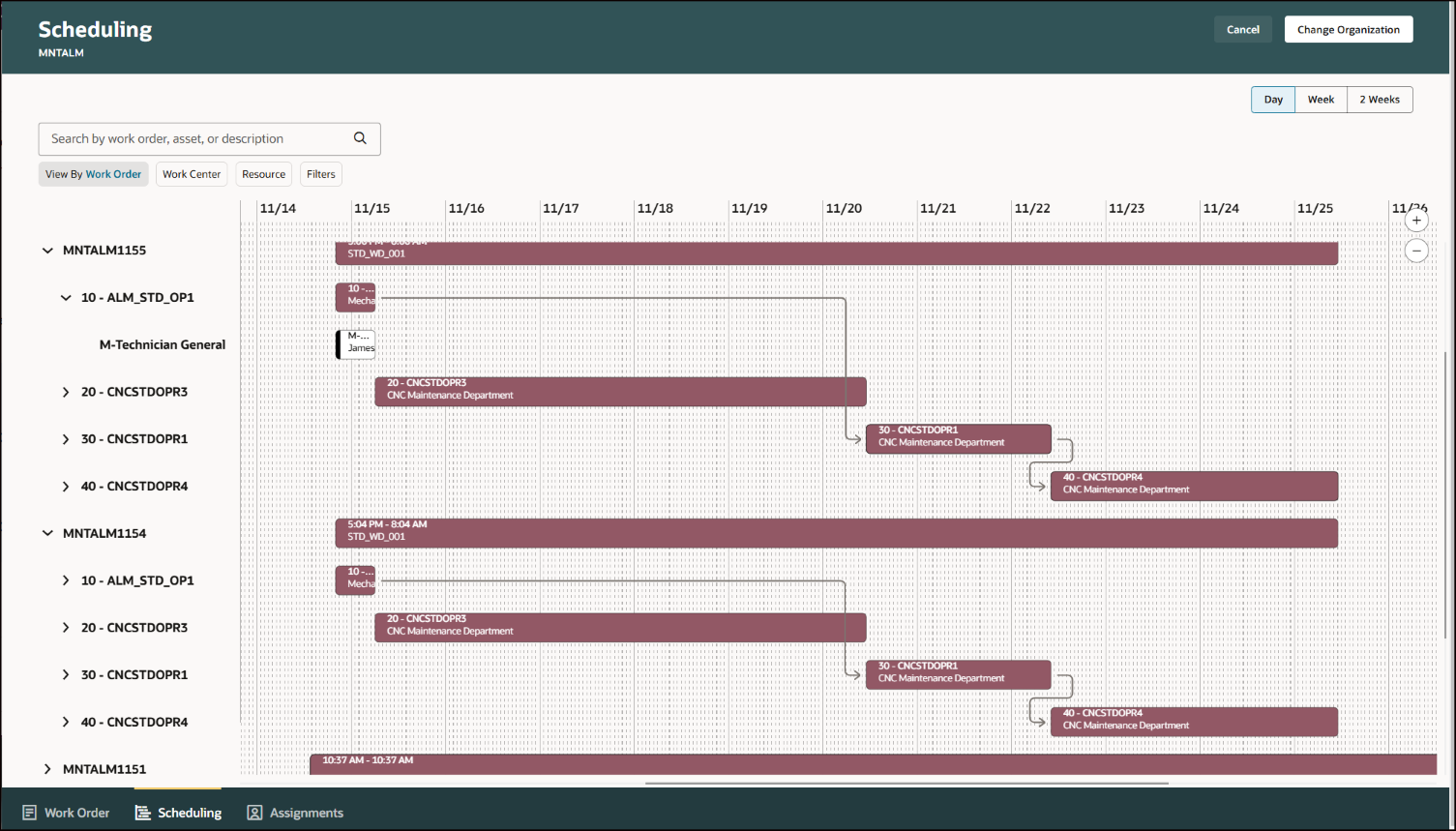

Supervisors can use the Scheduling tab to evaluate and adjust workloads, ensuring work orders are completed on time without causing disruptions to the organization. Scheduling includes an intelligent Gantt Chart, which lets you view work orders or assignments for a specific shift, day, or week. You can also choose to change the organization if you manage more than one organization.

The default View By Work Order view helps managers see whether the work orders for a shift, or the selected time period, have been assigned.

The visual representation makes it easy to identify the status of work orders within the selected timeframe. Color-coded indicators highlight work orders as Assigned, Partially Assigned, or Unassigned, enabling quick identification of gaps or overlaps. Supervisors can also expand individual work orders to analyze the sequence of their operations for better planning and execution. You can use the mouse to hover over areas on the Gantt chart to get details on the work order, operation, or the resources.

You can use smart search to search for work orders. You can use the suggested filters and additional filters to refine your search. You can filter work orders by work center, resource, status, priority, work order type, work order subtype, and asset work center.

The following screenshot shows the Scheduling Tab Gantt Chart work order view:

Scheduling Tab Gantt Chart

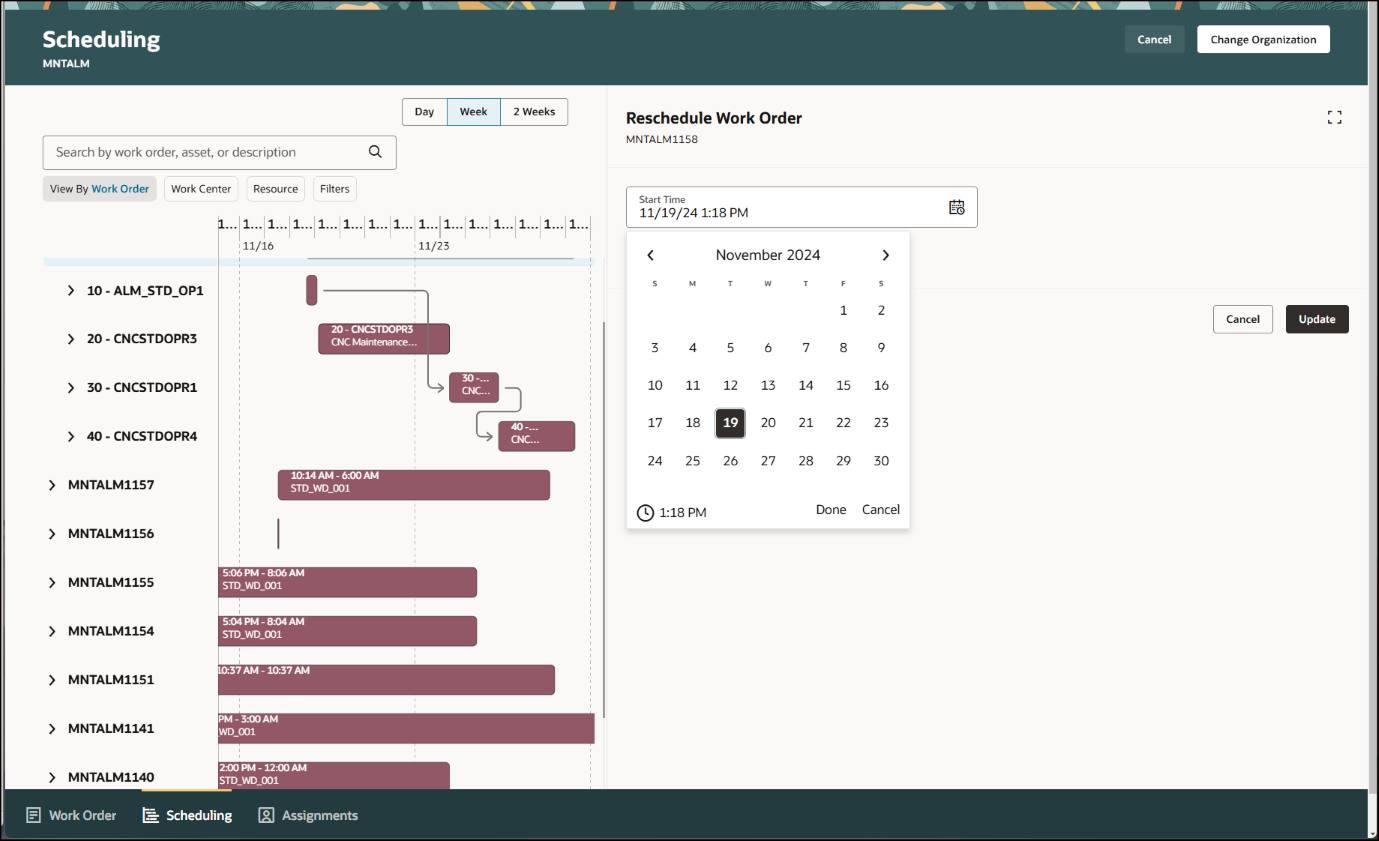

To adjust the work order schedule, right-click a work order in the Gantt Chart and select the Reschedule option.

The following screenshot shows the Reschedule Work Order drawer:

Reschedule Work Order Drawer

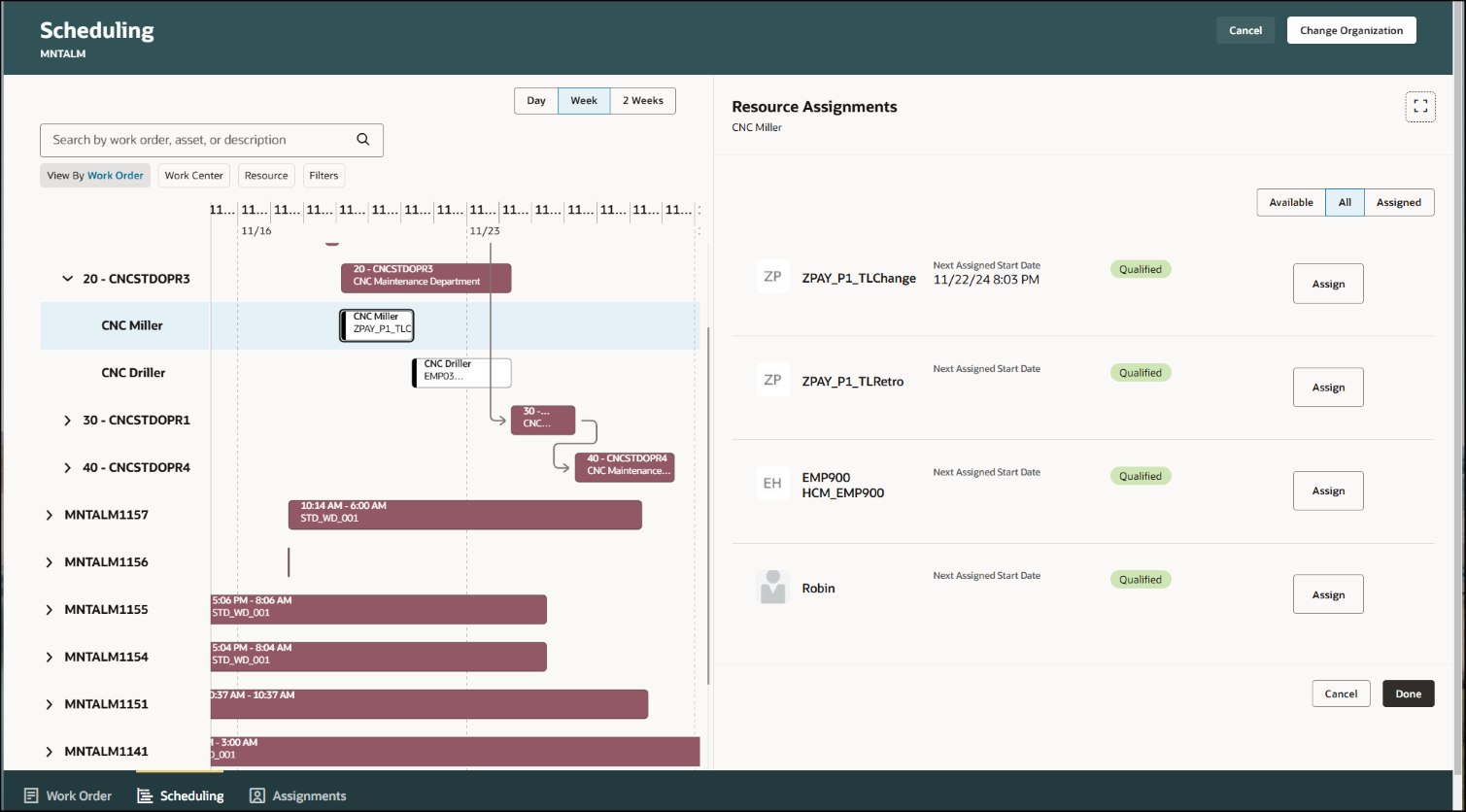

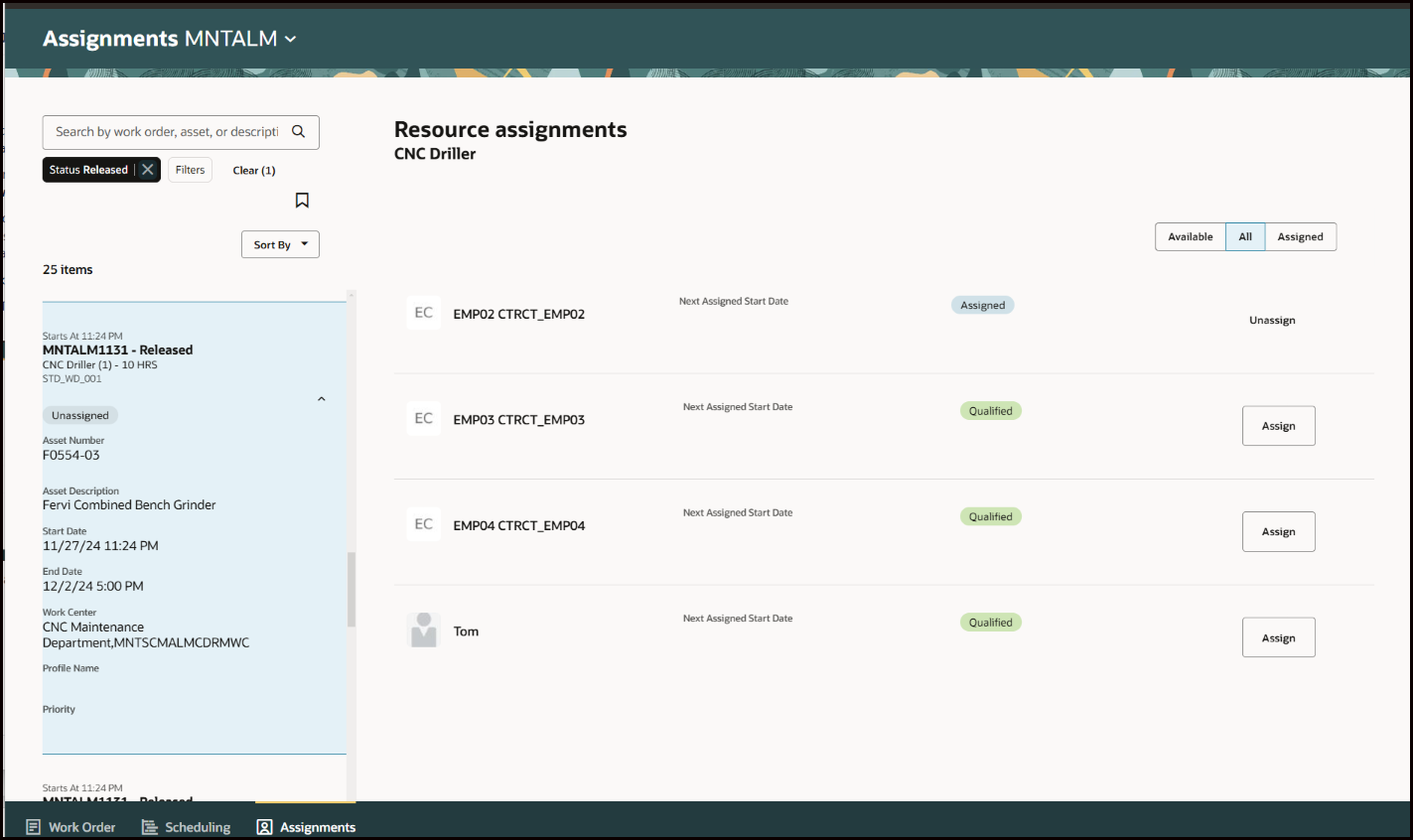

Supervisors can use the Gantt chart to assign users to work order operations. Expanding a work operation lets you see the resources for the operation. To assign a technician, right-click the resource, which opens the Resource Assignments drawer. You can see the people who are qualified and available to do the work. Click Assign against a resource to assign the person to the operation. You can also unassign a person from an operation and assign them to another operation.

The following screenshot shows the Gantt assignment drawer:

Resource Assignments Drawer

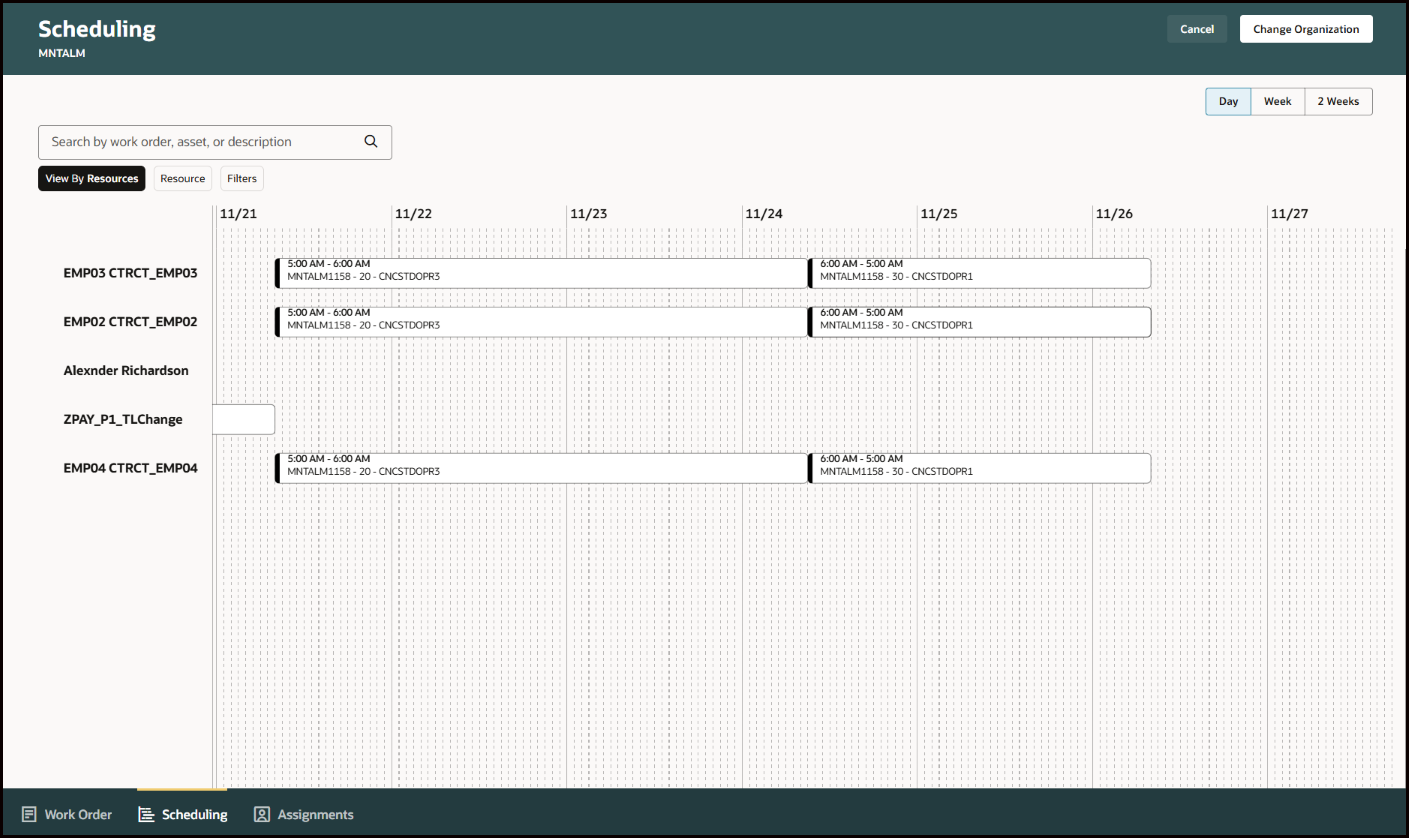

You can click View By and select Resources to switch the Gantt Chart view from the default work order view to the resource view. You can then view work assigned to each resource, which helps you gain visibility and investigate any conflicting work assignments for technicians.

You can reallocate tasks based on skill levels ensuring that each technician is working at their optimal skill level.

The following screenshot shows the Scheduling Tab Gantt Chart resource view:

Scheduling Tab Gantt Chart Resource View

Assign Work Orders

The Assignments tab in the Maintenance Supervision workbench enables you to efficiently allocate work orders ensuring that maintenance teams have a clear understanding of their work queues and priorities at the start of the shift. You can match technicians to work orders based on the specific resource requirements.

The Assignments tab displays the work orders for the current shift that need assignment. You can use suggested Status filter to filter the work orders by status or use Filters for advanced filtering options. The saved search functionality lets you quickly access frequently used search criteria, simplifying the process of managing work orders.

Each work order includes essential details, such as duration, status, and requirements. When you select a work order, you are presented with a list of qualified technicians. The default view highlights technicians that are available, but you also have the option to switch to the All view to see all qualified technicians, regardless of their availability. After making assignments, you have the flexibility to later make adjustments in the Scheduling tab if necessary.

When you make an assignment, the work order is removed from the view. The counter in the collection container updates to show the current number of work orders that need allocation.

The following screenshot shows the Assignments tab and a selected work order with available resources:

Assignments Tab Showing Selected Work Order with Available Resources

Maintenance supervisors can use the new Maintenance Supervision workbench to simplify maintenance activities, monitor key metrics, and manage work orders, schedules, and resources in one place. This intuitive, Redwood-based experience enhances decision-making, optimizes resource allocation, and helps supervisors focus on what needs attention now and next.

Steps to Enable

To enable the Maintenance Supervision page:

- Set the profile option ORA_MNT_SUPERVISION_REDWOOD_ENABLED to Y at the site level to enable the task Maintenance Supervision in the Maintenance Management landing page. This profile will not disable the existing Manage Maintenance Work Orders task.

- Ensure that users have the existing work order privileges:

- Manage Maintenance Work Orders

- MNT_MANAGE_MAINTENANCE_WORK_ORDER_HEADERS_PRIV

- Manage Maintenance Work Order Operations

- MNT_MANAGE_MAINTENANCE_WORK_ORDER_OPERATIONS_PRIV

- Close Maintenance Work Orders

- MNT_CLOSE_MAINTENANCE_WORK_ORDERS_PRIV

- Ensure that users have security access to each maintenance organization for which they need to report maintenance.

- Run the initial bulk ingestion of work orders and schedule routine bulk ingestion updates, as described in the rest of this section.

After you enable the profile option, you need to enable the Oracle Search Extension Framework to create indexes, ingest predefined indexes, and manage search capabilities:

- Set the Enable/Disable Search Ext Framework (ORA_FND_SEARCH_EXT_ENABLED) profile option to Yes.

- Make sure that you have the Manage Scheduled Job Definition (FND_MANAGE_SCHEDULED_JOB_DEFINITION_PRIV) privilege to run scheduled processes.

- Submit the scheduled process to create the index definition and perform initial ingest to the OSCS process for creating indexes and ingesting predefined indexes.

- Job Name: ESS job to create index definition and perform initial ingest to OSCS.

- Index Name to Reingest: fa-alm-work-order

Note:

If you don't specify any index names when submitting the process, the process runs for all predefined indexes.

Tips And Considerations

The following tips and considerations apply when enabling the Maintenance Supervision page:

- Make sure to submit the scheduled process to create the index definition and perform initial ingest to OSCS before using this feature. You can also submit the process if the index is already created, and you want to ingest it again. This process clears the index and reingests the data.

- Program name: ESS job to create index definition and perform initial ingest to OSCS.

- Index Name to Reingest: fa-alm-work-order

- Work orders can be created using the Manage Maintenance Work Orders or the Maintenance Supervision page in the Maintenance Management work area, using REST APIs, from maintenance programs, and created or updated using File-Based Data Import (FBDI). Not all modes of work order creation trigger the near real-time ingest of the index. You therefore need to update the index by running a separate scheduled process. This scheduled process doesn't clear the index, but only updates the existing index with the changes from these transactions. We recommend that you ingest these updates at least once a day, or as often as your business requires, to keep the index current.

- Program Name to Run Bulk Ingest: ESS job to run Bulk ingest to OSCS.

- Index Name to Reingest: MNT_WO_BULK_INGEST.

- Optionally, you can enable opt-ins that further expand the capabilities of maintenance work orders. You should enable these opt-ins only after you set the profile option to switch from the Maintenance Dispatch List to the My Maintenance Work page:

- Allow repair of one or more assets for an item: If enabled, you can optionally select an item as the context of the work order instead of a single asset. Once the work order header is created, you can navigate to the Assets tab to define one or more assets to be repaired. Once released, you can execute each work order by asset using the My Maintenance Work page.

- Allow completion of an asset to an inventory location: If enabled, then for an asset or item-based work order, you can issue and return an asset to a completion sub-inventory location. This location can be for serviceable or rejection (MRB) asset tracking.