Update Workstation Availability Status for a Workstation Along with Reason Codes

During production at a workstation, operators often need to spend time on preparation activities in addition to actual work execution. For example, operators may spend time setting up equipment, performing changeovers when preparing the workstation to produce product variants, or pausing for intermediate adjustments. Such activities impact the availability and performance metrics of the workstation. The time spent on these activities needs to be tracked accurately to report workstation availability and to calculate OEE.

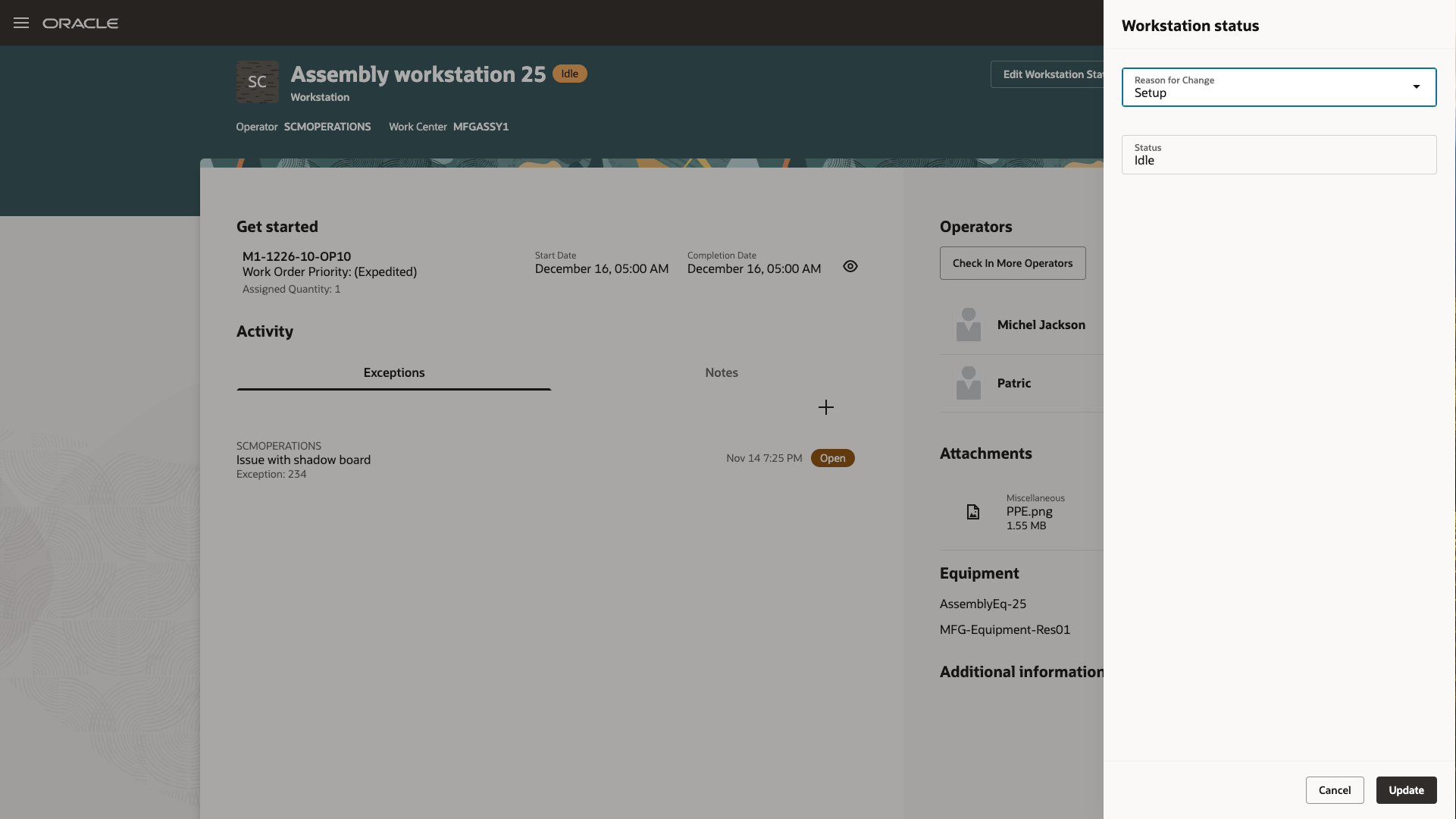

Edit Workstation Status by Selecting a Reason for Change

With this update, operators can now change the workstation status by selecting a predefined reason code for the status update. Computation of OEE components, such as availability and performance, are influenced by workstation reason codes entered by operators when they change workstation statuses.

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25C

You must opt in the Monitor Workstation Performance When Supervising Production feature (25A) to automatically enable this feature.

To use this feature, you need to set up workstation reason codes under the Smart Operations Configurations task in the Work Execution work area with the following details:

- Workstation Reason Codes: Specify workstation reason codes, detailing their associated statuses and their impact on Overall Equipment Effectiveness (OEE) calculations.

Tips And Considerations

- Production supervisors can configure workstation status change reasons and the corresponding workstation statuses under the Smart Operations Configurations task in the Work Execution work area.

- If an operator edits the workstation's status to Down during execution, the work order operation execution is stopped and the workstation becomes unavailable for execution until the status changes to idle. The work order operation resource transactions for the stopped execution are reported when the execution is stopped.

- The following status change reasons are predefined in the application: Setup, Corrective Maintenance, Shift Break, and Break.

Key Resources

- Watch the feature demo for Update Workstation Availability Status for a Workstation Along with Reason Codes.

- Watch the feature demo for Configure and Manage Performance Metrics for Your Workstations.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges can edit the workstation status with reasons:

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

- View Smart Operations Parameters (WIP_VIEW_SMART_OP_PARAMETERS)