Redwood: Define Pull Sequences and Generate Supplier and Intraorganization Kanban Cards

Kanban is typically used as a just-in-time inventory replenishment method to manage material supply based on actual consumption. A Kanban card accompanies a standard size bin that signals when material needs to be replenished from an internal or external source. In a flow manufacturing environment, continuous production is run at a constant rate to meet customer demand and requires material replenishment only when more material is needed. Often there are physical space limitations for storing materials at a work center or workstation, minimizing overstocking situations and the associated cost with holding inventory.

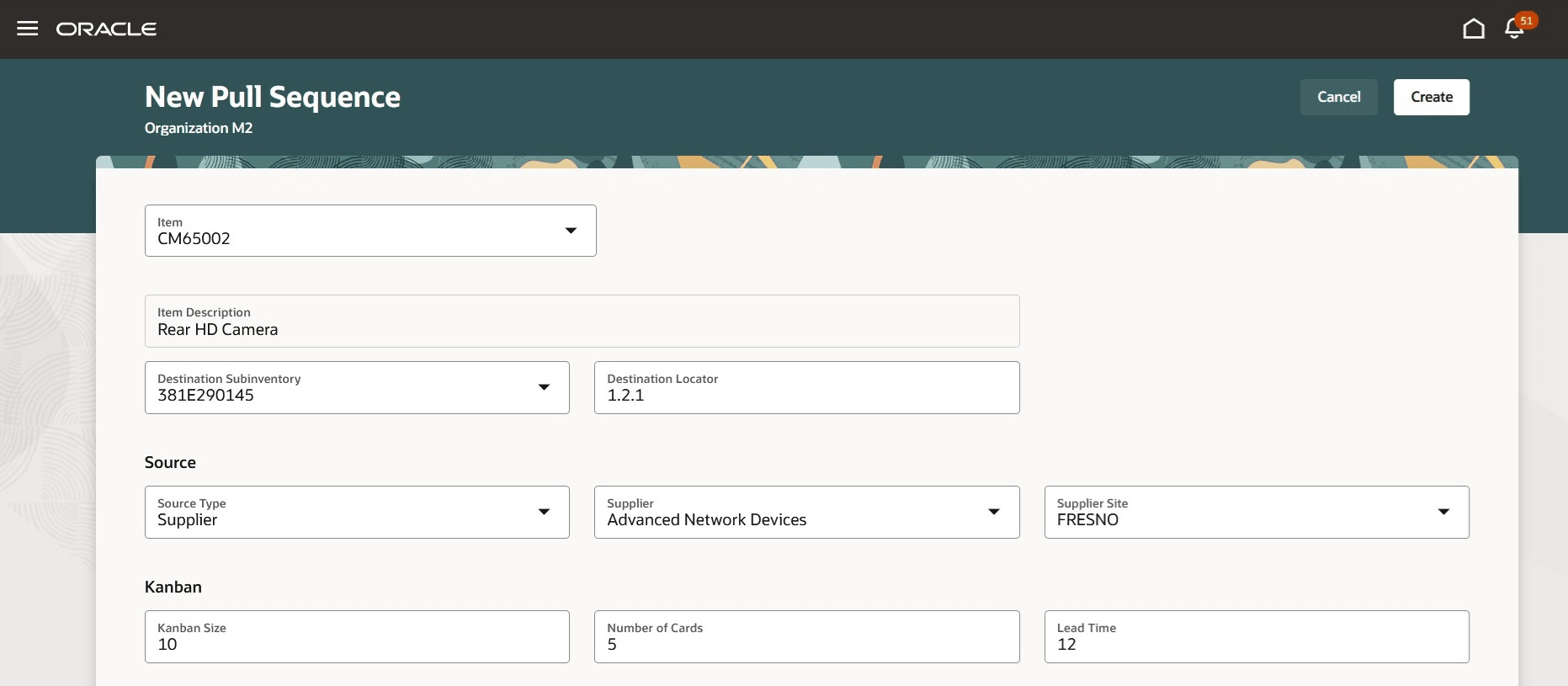

For items replenished using Kanbans, you can define replenishment chains as the series of pull sequences that pull materials between the point of supply and point of use. For example, you can replenish materials from another Kanban location in the organization or supplier to the supply subinventory for an operation in a flow production line.

For each pull sequence, you can define, generate, and print a number of Kanban cards that act as electronic visual signals used in coordinating the replenishment process. The Kanban card accompanies a bin of material to help track the bin status and replenishment supply status.

Pull Sequence Definition

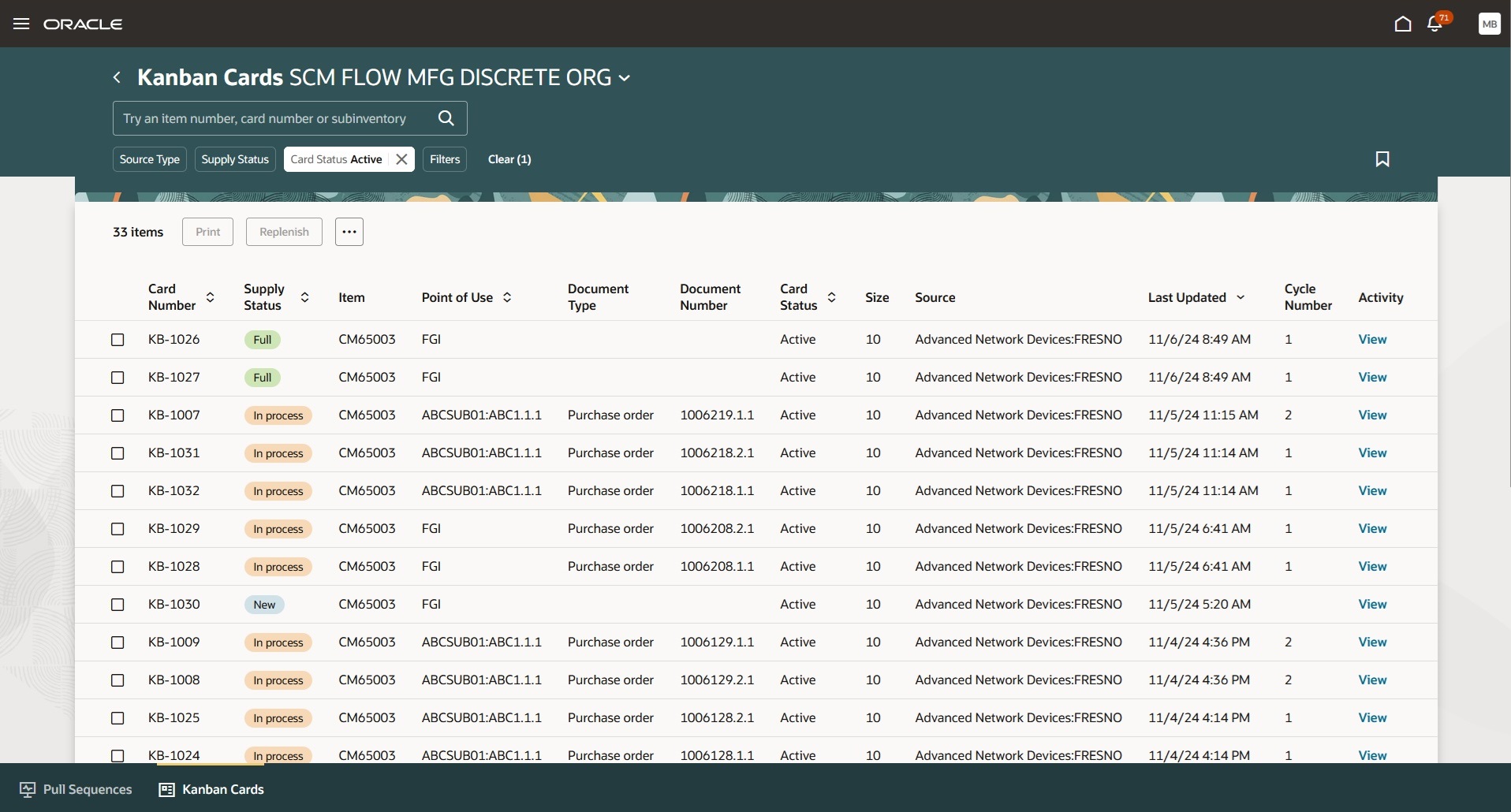

As an inventory manager, you can also track the status of kanban cards and the status of supply from supplier and intraorganization sources based on the automated replenishment process and expected lead time for the item. For a specific kanban card, you can view the activity with details such as the purchase order and line for a supplier kanban until the supply is fulfilled and the kanban card status is updated from empty to full.

Track the Status of Kanban Cards

Kanban card number is displayed in the replenishment documents movement request line and purchase order schedule. Requisition lines with Kanban numbers can be grouped into a single purchase order line with separate schedules. You can search movement request lines, expected shipments, orders to receive, or put away lines by kanban card number. You can view the kanban card number for a movement request line on the Confirm Pick mobile page.

Kanban replenishment based on actual consumption minimizes excess inventory and improves responsiveness to changing demand.

Here's the demo of these capabilities:

Steps to Enable

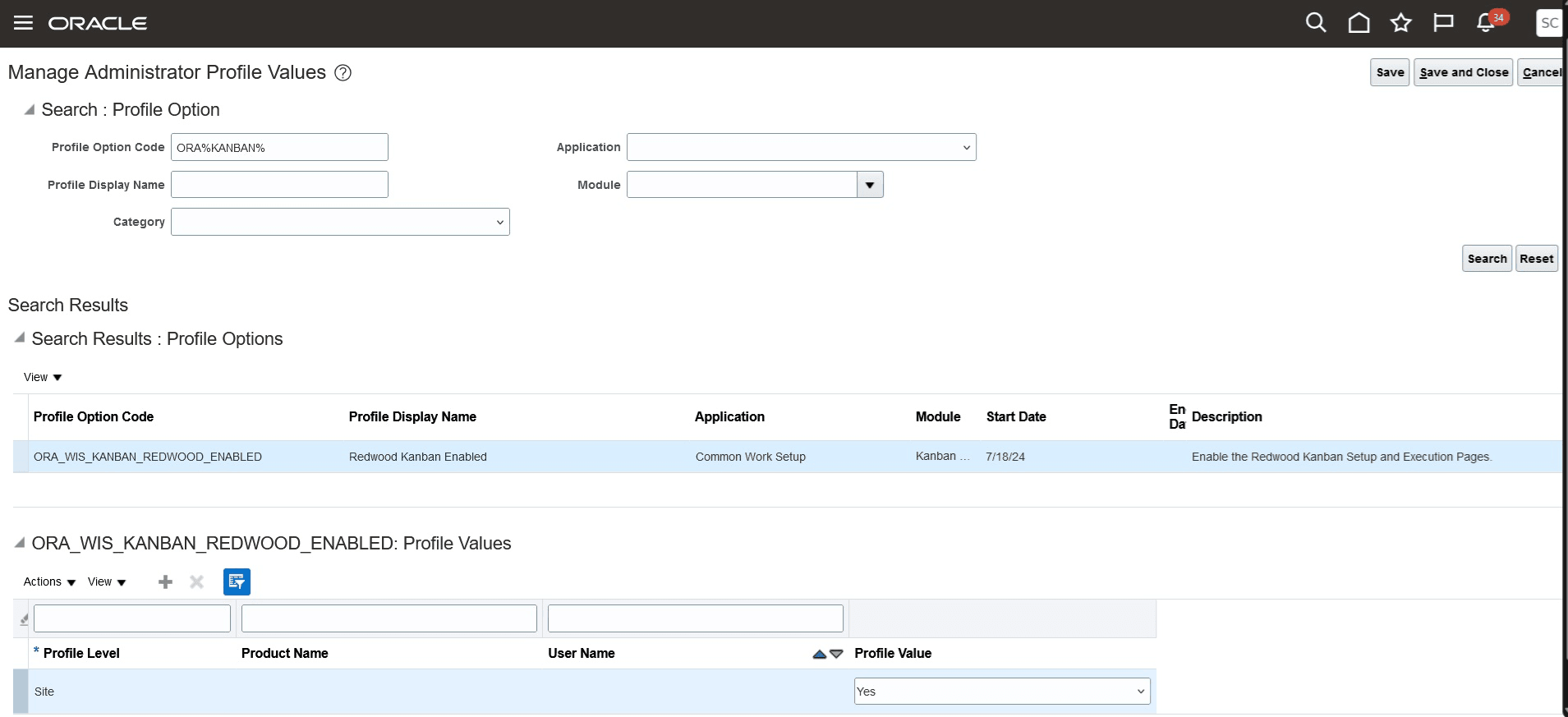

Follow these steps to enable or disable this feature:

- In the Setup and Maintenance work area, search for, and select the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIS_KANBAN_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is N.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

You'll have the option to enable or disable this feature from 25A update.

Profile to Enable Kanban

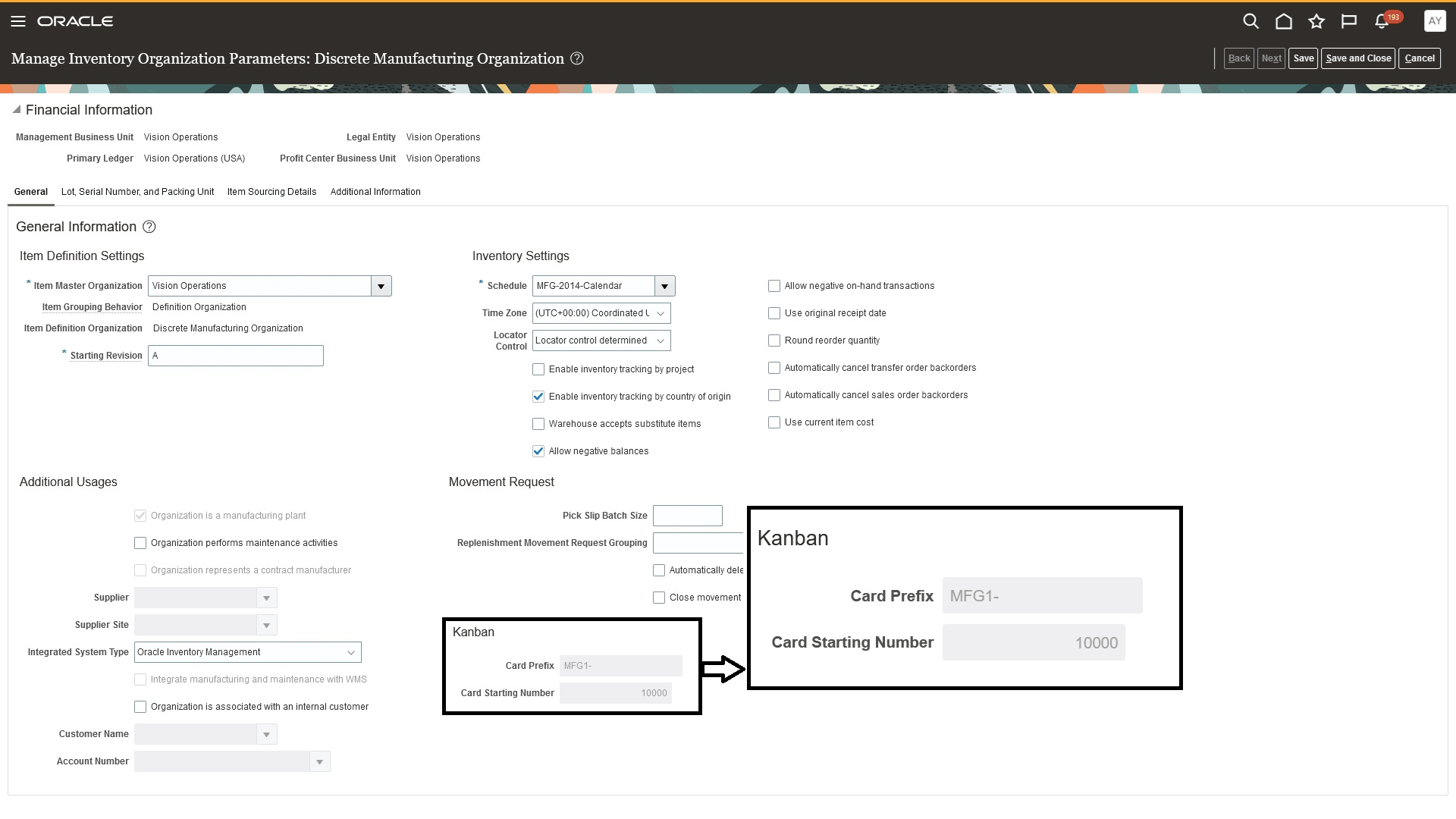

You will need to set up the inventory organization parameters to generate kanban cards:

- In the Setup and Maintenance work area, search for, and select the Manage Inventory Organizations task.

- On the Manage Inventory Organizations page, search for the required inventory organization.

- Select the required row of search results and click the Manage Organization Parameters action.

- Under the General tab of the Manage Inventory Organization Parameters page, enter values for the attributes Card Prefix and Card Starting Number in the Kanban section.

Inventory Organization Parameter for Kanban

Tips And Considerations

- You can use intraorganization and supplier kanbans to replenishment items that are used outside of flow production lines.

- As a recommended practice, an item replenished using kanbans must avoid other methods of inventory replenishment or supply planning.

- Item must be setup in the item definition with the Release Time Fence planning attribute as Kanban Item.

- You can't use production and interorganization kanbans currently.

- You can't use Kanbans in WMS-enabled organizations currently.

- You can directly specify the size of a Kanban card without Kanban planning based on the lead time and average daily demand currently.

Key Resources

- Watch the Define Pull Sequences and Generate Supplier and Intraorganization Kanban Cards demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges and codes can access this feature:

- Privileges :

- Manage Pull Sequences (WIS_MANAGE_PULL_SEQUENCES _PRIV)

-

Manage Kanban Cards (WIS_MANAGE_KANBAN_CARDS_PRIV)

These privileges are available from 25A.

- Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These roles were available prior to this update.