Honor Supersession Item Relationships

Efficient product lifecycle management processes sometimes necessitate the replacement of a product with a new product. This can be done by you or by the supplier of components required for your products and it can happen multiple times over your product’s lifecycle. This chain of replacements is referred to as a supersession chain. With this update, when you run a plan in the unconstrained mode, the planning process will meet demand by first consuming the supply of the on-hand and on-order supply across the entire supersession chain before generating planned orders using the latest revision of an item in the supersession chain. This enables you to reduce your inventory exposure by using up all available inventory that can be used to satisfy demand.

This feature allows you to:

- Plan considering supersession relationships of items.

- Review allocation of supplies to demands for the items in a supersession relationship.

This feature is applicable to:

- Unconstrained supply plans and unconstrained demand and supply plans

- Oracle Fusion source systems and external source systems

To use this feature, perform the following steps:

- Collect item supersession relationships.

- Create an unconstrained supply plan and set the parameter override PlnItemRel to true for that plan. To set the parameter override, in the plan options:

- Navigate to the Supply: Advanced Options dialog box, Technical tab.

- In the Parameter Overrides field, enter PlnItemRel=true and click Done.

- Run the plan.

- Review and analyze plan output.

Collect Supersession Item Relationships

You can collect item supersession relationships from Oracle Cloud SCM or from external sources.

To collect item supersession relationships from Oracle Cloud SCM:

- Define either master-organization-controlled or organization-controlled supersession item relationships in Oracle Product Hub.

- Select the Item Relationships reference data entity in Collect Planning Data.

- Run net change or targeted refresh to collect supersession item relationships to Oracle Fusion Cloud Supply Chain Planning.

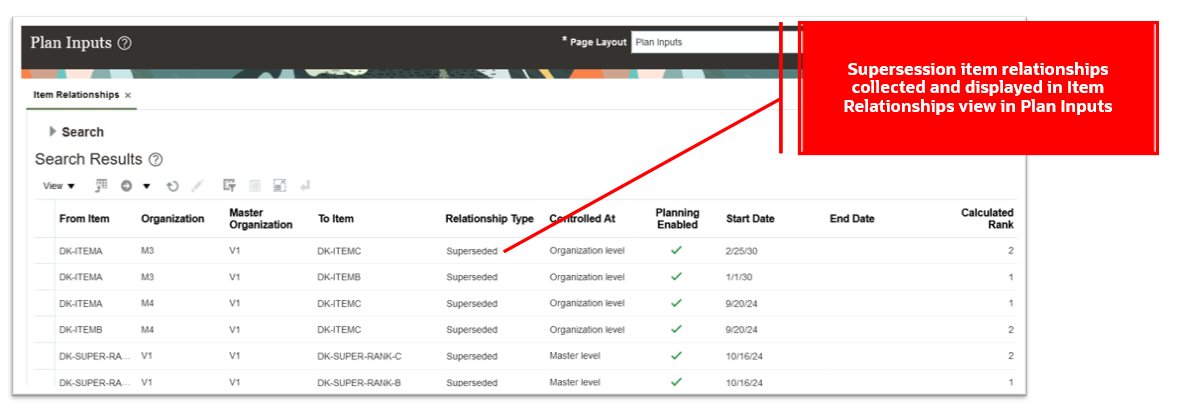

- Review the collected supersession relationships in the Item Relationships view in Plan Inputs. The Relationship Type column for the item will have a value of Superseded.

Collected Supersession Item Relationships Displayed in Item Relationships Table

To collect item supersession relationships from external sources:

- Prepare supersession relationships using the Item Substitute file-based data import (FBDI) template.

- For extracting supersession item relationships from Oracle E-Business Suite to Oracle Cloud Supply Chain Planning, run Extract Data for Supply Chain Planning Cloud with the parameter End Item Substitution set to Yes.

- Run net change or targeted refresh of Load Planning Data from Flat Files to collect supersession item relationships to Oracle Cloud Supply Chain Planning.

- Review the collected supersession relationships in the Item Relationships view in Plan Inputs. The Relationship Type column for the item will show a value of Superseded.

How Supersession Item Relationships Are Used in Planning

Supply planning does the following when planning items that are related by supersession:

- Selects supersession item relationships that are valid based on the plan horizon start and end dates.

- Plans item supersession relationships with the goal of maximizing allocation of excess supplies from lower items to higher items in the supersession relationship, while minimizing demand lateness.

- Minimizes projected available balance across the items in the supersession chain.

- Respects one-to-one and one-to-many supersession relationships. Only unilateral relationships are honored. In the case of reciprocal supersession relationships, supply planning honors only the forward relationship from the lower to the higher item.

- Relationships aren’t valid if the end date occurs before the horizon start date or after the horizon end date.

- Breaks loops in a supersession chain by discarding relationships that cause the loops.

When allocating excess supplies in the item supersession chain:

- Supply planning allocates the supplies of an item first to its demands across the planning horizon.

- Supersession relationship effectivity dates aren’t considered while managing safety stock levels for higher items in a supersession chain.

- Supersession relationship date effectivity is considered while allocating supplies to non-safety-stock demands of higher items.

- Supersession relationships are respected while allocating excess supplies from a lower item to multiple higher items, and when a higher item has a relationship to multiple lower items.

- With respect to ranks in supersession relationships:

- Ranks are respected for allocation within an item-organization.

- Planning allocates excess supplies from lower items (also known as supplying items) to higher items (also known as receiving items) based on the relationship ranks. For example, if there’s an excess of 100 units in a lower item, and both higher items have 100 units of demand, then the 100 units of excess supply will be allocated to the higher item with the lowest-numbered rank (that is, rank 1 comes before rank 2). This is applied irrespective of whether a relationship is explicitly modeled, inherited (from a master organization to a child organization), or implied (in the relationship chain A -> B -> C, the relationship A -> C is implied).

- Excess supplies are allocated one supply planning bucket at a time.

- If there are multiple, higher-item demands in a planning bucket with valid supersession relationship effectivity, then supply planning allocates the excess supply starting with the higher item with the lowest rank number (considered as higher priority) and moves forward in the planning bucket in the ascending order of the rank of the higher items to allocate the remaining excess supply from lower items.

- Similarly, if there are excess supplies available from multiple, lower items for a higher item in a planning bucket, then the lower item’s excess supply with the lowest rank number will be allocated first, and supply planning allocates the excess from other lower items, in ascending order of rank, to the higher item demand.

- For example, supersession relationship A -> C is rank 1 and supersession relationship B -> C is rank 2, so supply planning first allocates excess supply to higher item C from item A, which has the lowest rank number, and then, if required, excess supply from item B is allocated to item C.

- The relationship ranks for supply allocation are validated for demands in each bucket. Preference is provided in supply allocation for unmet and past due demands from previous buckets prior to allocating to current bucket demands.

- Ranks are respected for allocation within an item-organization.

- Supply allocation based on ranks will be honored either for excess existing supplies or for excess planned orders.

- Supply planning creates planned order supplies for demand quantities that are still not satisfied even after allocating existing supplies from the item and from excess supply from its lower item.

- Supply planning recommends a planned order at a specific item in a planning bucket for satisfying demand quantity. Demand quantity across a supersession chain isn’t aggregated to recommend a planned order for a lower item.

Substitute Demand and Substitute Supply

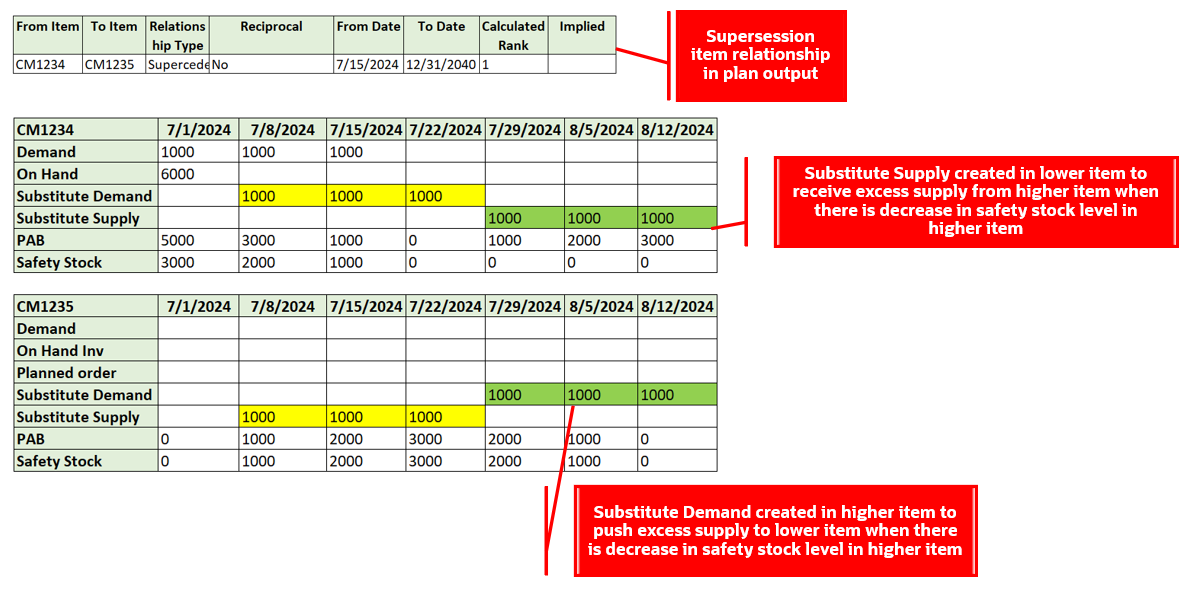

Excess supplies that are allocated across the supersession chain are linked to the receiving items by the Substitute Demand and Substitute Supply order types.

- Substitute Demand is the demand created on the lower (supplying) item that has excess supply. Substitute Demand will be pegged to the lower (supplying) item supply.

- Substitute Supply is the supply created on the higher (receiving) item. It will be pegged to the higher (receiving) item’s demand.

Substitute Demand and Substitute Supply are created in matching pairs.

Supply planning performs a pullback of substitute supply from higher items to lower items. Substitute supply that’s allocated to manage the safety stock level for a higher item is pulled back to a lower item by creating a reverse substitute demand on the higher item and a substitute supply on the lower item. Supply planning does this when the safety stock level of the higher item decreases in the succeeding planning bucket, and it uses this pulled back excess supply from lower items to allocate to higher item demands in subsequent planning buckets. Pullback also happens when supply planning allocates an existing supply in a planning bucket to safety-stock or non-safety-stock demands. For example, a firm supply of a higher item can be allocated to its demands, and supply planning pulls back supply to a lower item.

In the example shown in the following image, supply planning created a pullback substitute supply of 1000 units in a lower item on 7/29/2024, 8/5/2024, and 8/12/2024 planning buckets due to a decrease in safety stock levels in a higher item.

Pullback Supply Created from Higher Item Due to a Decrease in Safety Stock Levels

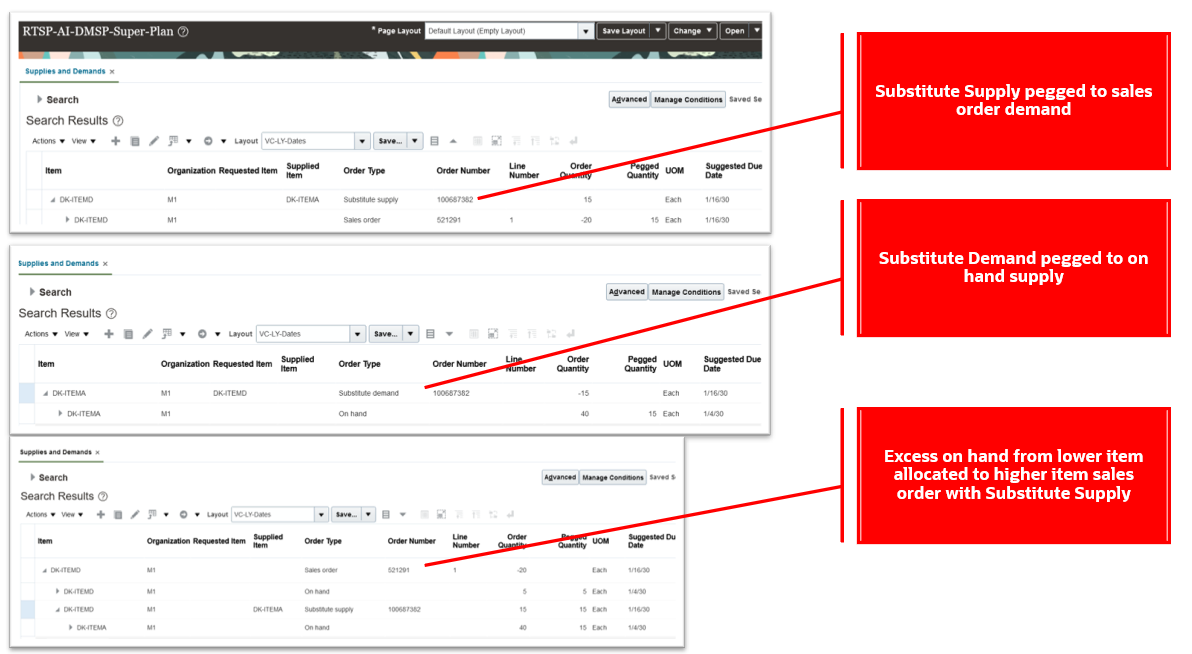

The Supplies and Demands view has been enhanced to show Substitute Demand and Substitute Supply order types, as shown in the following image. These new order types appear in Demand Pegging and Supply Pegging.

Supplies and Demands Displays Pegging Details of Substitute Demand and Substitute Supply

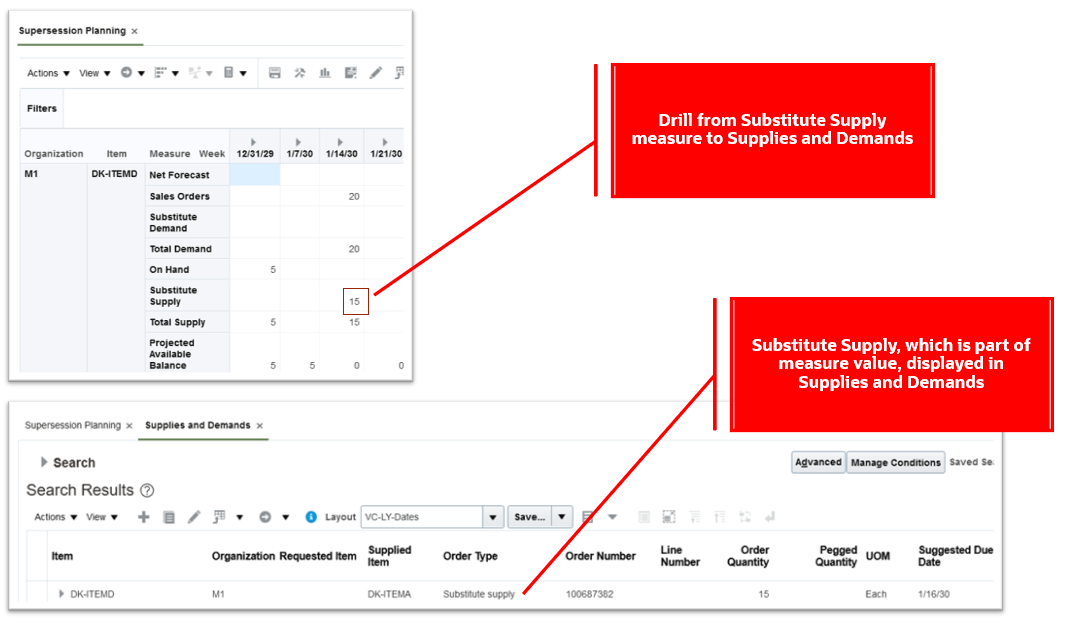

Substitute Demand and Substitute Supply order types are available as measures for analyzing the supersession planning in planning analytics. You can drill from either of these measures to the Supplies and Demands page, as shown in the following image.

Drill from Substitute Supply Measure to Supplies and Demands

Total Supply, Total Demand, and Projected Available Balance are some of the measures where Substitute Demand and Substitute Supply measures are included in computation by supply planning.

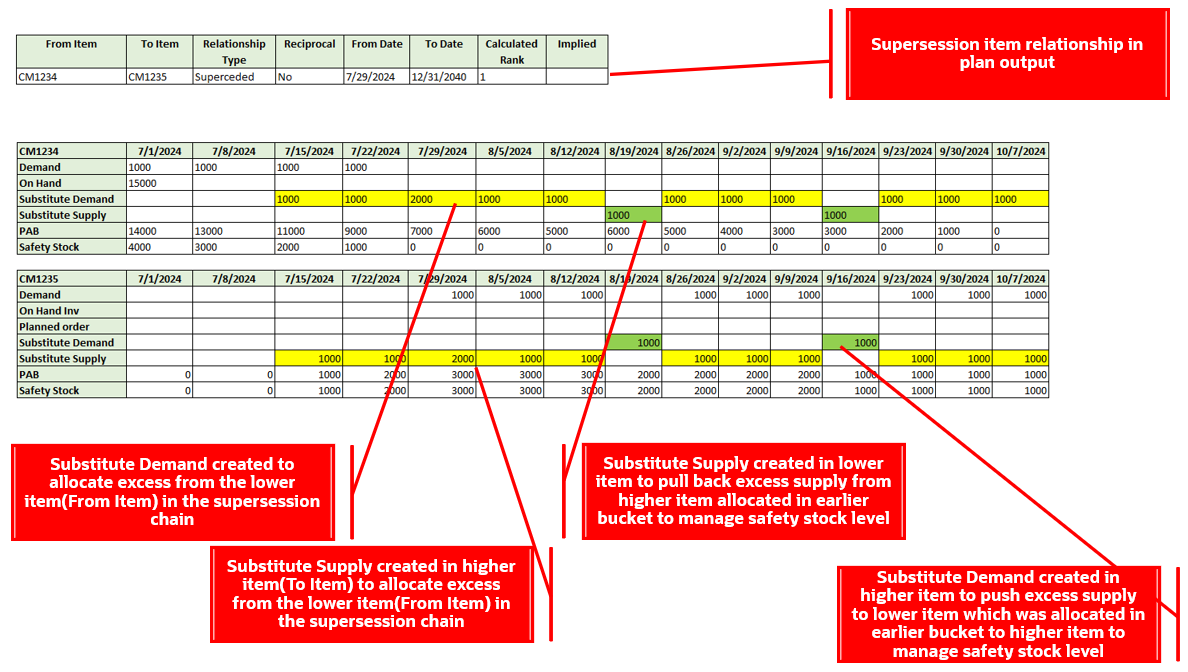

Example 1: Allocation of Supplies to Demands for Items in a Supersession Chain

In this example we have a lower item (From Item) superseded by a higher item.

- CM1234 is superseded by CM1235 with rank 1 with an effective start date of 7/29/2024 to an effective end date of 12/31/2040.

- Plan start date in this example is 7/1/2024.

The following occurs:

- On bucket 7/15/2024, supply planning allocates excess supply to maintain safety stock of the higher item. Supply can be allocated to maintain safety stock levels before the effective start date and after the effective end date of the supersession relationship.

- On buckets 7/15/2024 through 10/7/24, the lower item has sufficient excess to manage safety-stock and non-safety-stock demand of the higher item. For each non-safety-stock demand of the higher item, the planning process creates a distinct set of substitute demand and supply. This means that in bucket 7/29/24, there will be two sets of substitute demand and supply: one for meeting the safety stock increase of 1000 and another for allocation to 1000 units of demand.

- On buckets 8/19/2024 and 9/16/2024, supply planning creates a pullback of 1000 units from higher item CM1235 due to a decrease in safety stock from 3000 to 2000 units.

- For the remaining planning buckets, supply planning allocates excess supply from the lower item until it’s exhausted.

Allocation of Supplies to Demands for Items in a Supersession Chain

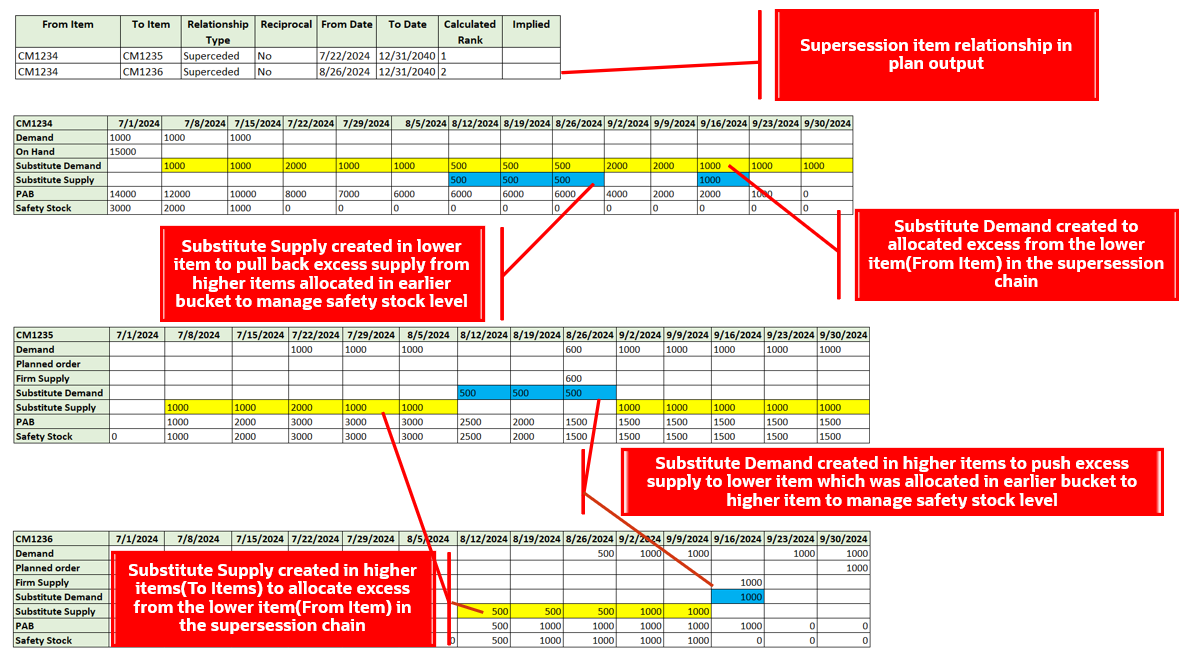

Example 2: Allocation of Supplies to Demands to Multiple Higher Items (To Items) in a Supersession Chain

In this example we have a lower item (From Item) superseded with multiple higher items.

- CM1234 is superseded by CM1235 with rank 1 with an effective start date of 7/22/2024 to an effective end date of 12/31/2040.

- CM1234 is superseded by CM1236 with rank 2 with an effective start date of 8/26/2024 to an effective end date of 12/31/2040.

- Plan start date in this example is 7/1/2024.

The following occurs:

- Supply planning allocates excess supply from lower item CM1234 to the higher items CM1235 and CM1236 demands.

- On buckets 8/12/2024, 8/19/2024, and 8/26/2024, 500 units of substitute supply are pulled back from higher item CM1235 to CM1234 due to the decrease in safety stock of higher item CM1235 from 3000 to 2500 units, 2500 to 2000 units, and 2000 to 1500 units respectively, for each of those buckets.

- On bucket 8/26/2024, 600 units of firm supply of item CM1235 are allocated to its demand. As a result, excess supply from lower item CM1234 isn’t allocated.

- On bucket 9/16/2024, safety stock for item CM1236 decreases to 0. Hence, 1000 units of substitute supply are pulled back to lower item CM1234.

- On bucket 9/23/2024, the firm supply of 1000 units of item CM1236 is allocated to its demand. As a result, only 1000 units of substitute demand are created on lower item CM1234 to allocate supply only to higher item CM1235.

- On bucket 9/30/2024, because the supersession relationship between higher item CM1235 and lower item CM1234 has a calculated rank of 1, 1000 units of excess supply from lower item CM1234 are allocated to higher item CM1235. Supply planning recommends 1000 units of planned order for the rank 2 higher item CM1236 to satisfy its demand.

Allocation of Supplies to Demands from a Lower Item (From Item) to Multiple Higher Items (To Items) in a Supersession Chain

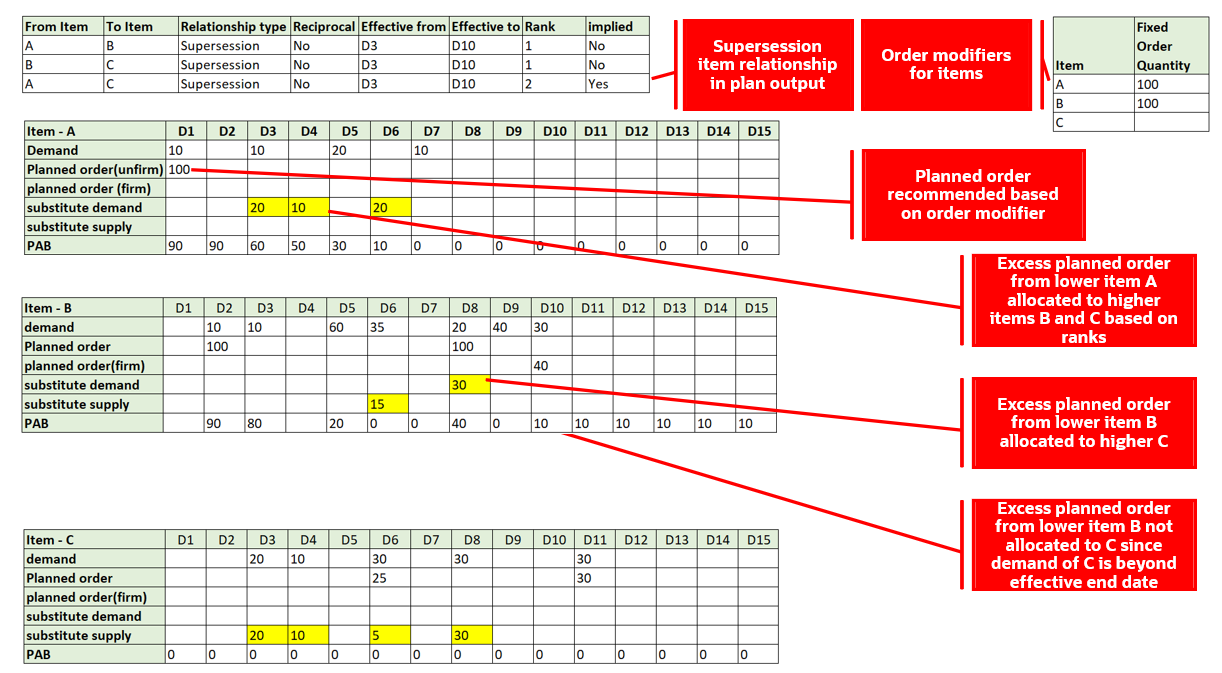

Example 3: Allocation of Supplies to Demands Across a Supersession Chain with a Planned Order Recommendation

In this example, item A is superseded by item B, and item B is superseded by item C.

- Supersession relationship between item A and B is effective from Day 3 to Day 10 with rank 1. (Days are all abbreviated to “D1,” “D2,” and so on in the image.)

- Supersession relationship between item B and C is effective from Day 3 to Day 10 with rank 1.

- Implied relationship between item A and C is effective from Day 3 to Day 10 with rank 2.

- Plan start date in this example is Day 1.

The following occurs:

- On Day 1, supply planning creates a planned order of 100 units for lower item (From Item) A, respecting the order modifier of a fixed order quantity of 100 units. However, the excess planned order is not allocated to higher item B demand on Day 2 because the relationship effective start date is Day 3.

- Excess planned order from item A is allocated to higher items B and C, respecting ranks and effectivity on Day 3, Day 4, and Day 6.

- For item B, supply planning recommends a planned order on Day 2 for 100 units, respecting the order modifier of a fixed order quantity of 100.

- On Day 6, 15 units of excess planned order are allocated from item A to item B and 5 units to item C, respecting supersession relationship ranks.

- On Day 8, 30 units of excess planned order are allocated to higher item C from lower item B.

- Ten units of an excess firm planned order from item B remain unallocated, because the real demand for higher item C is beyond the effective end date of Day 10 for the supersession relationship between item B and C.

Allocation of Supplies to Demands Across a Supersession Chain with Planned Order Recommendations Respecting Order Modifiers

Here's a demo of these capabilities:

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- Supply planning assumes the unit of measure (UOM) of all the items in the supersession chain are the same. In case of different UOMs, the UOM of the supersession item is taken as reference for allocating supply quantity from the lower item in the chain.

- Attribute-based planning and Project-Driven Supply Chain aren't supported while planning supersession item relationships.

- Supersession item relationships defined among a primary product, co-product, and by-product are ignored.

- Change granularity isn’t supported for Substitute Demand and Substitute Supply measures.

- Demand plans with forecasts based on a supersession relationship can be provided as an input demand schedule to a supply plan. However, the supply plan considers the reciprocal supersession relationships in demand plans as unilateral relationships and plans the forecasts for items in the supersession chain.

- Only master-controlled supersession item relationships can be collected from external source systems.

- Item Revision Start Date and Item Revision End Date measure values of supersession forecasting in demand plans aren't considered by supply planning as supersession item relationships’ date effectivity.

- Substitute supply created for maintaining a safety stock level for higher items in the supersession relationships won’t have any pegging reference to a demand.

- Substitute Supply and Substitute Demand pairs created for managing the return of supply from a higher item to a lower item in case of safety stock allocations won’t have pegging relationships to lower item supplies.

- A Demand and Supply type plan doesn’t support supersession forecasting. You can run supersession planning for a Demand and Supply plan by using an external forecast as a demand schedule.

Key Resources

- Refer to update 22B feature Respect Organization-Specific Item Substitution Rules (Including Rank) for details related to master organization and organization-controlled relationships and computation of calculated ranks while collecting item relationships.

- Refer to update 23C feature Forecast Using Supersession Relationships for details related to forecasting based on supersession relationships.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Monitor Supply Planning Work Area (MSC_MONITOR_SUPPLY_PLANNING_WORK_AREA_PRIV)

- Monitor Demand and Supply Planning Work Area (MSC_MONITOR_DEMAND_AND_SUPPLY_PLANNING_WORK_AREA_PRIV)

These privileges were available prior to this update.