Enable Parallel Processing in Cost Preprocessor

The Create Cost Accounting Distributions Process, also called as Cost Processor, calculates the cost and generates distributions for all supply chain transactions, such as inventory material transactions resulting from purchase order receipts or work order completions, resource transactions from work orders, and so on. You can now enable parallel processing in the Create Cost Accounting Distributions process so that the eligible transactions are spread across multiple subprocesses to achieve a much higher throughput during the Cost Preprocessor stage. Features from prior releases for parallel processing in quantity preprocessing and distribution processing stages are now enabled by default.

When enabled, during the Cost Preprocessor stage of the Create Cost Accounting Distributions process, multiple subprocesses are automatically spawned to process the transactions in parallel. The main process groups the transactions such that each of the subprocess can independently cost those transactions without any contention with the other subprocesses that may be running in parallel. The feature is specifically tailored for high to very-high volume cost processing and the throughput improvements will be significant in those scenarios. For low to medium volume cost processing, there will be improvements in throughput, but it might not be noticeably higher as the current processing times will usually be optimal to begin with.

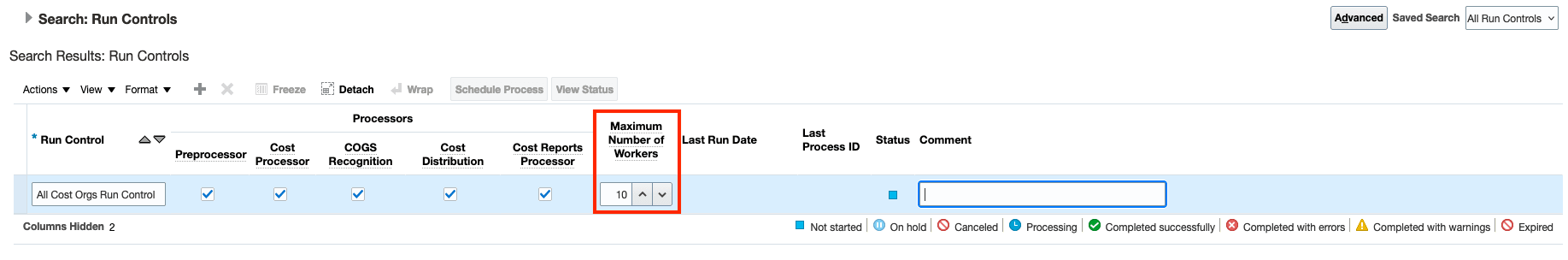

After you opt in to the feature, you can use the Maximum Number of Workers indicating the maximum number of subprocesses that would be used by the Create Cost Accounting Distributions process. If you haven't configured this setting before, you can enter a value between 2 and 20 to indicate that you want to use parallel processing.

Create Cost Accounting Distributions

To ensure that the Create Cost Accounting Distributions process does not consume a lot of resources that will otherwise be required for other processing elsewhere in the system, some restrictions are placed on the number of workers that will be launched by the system. Regardless of the value for maximum workers set in the run control parameter, during runtime, the system dynamically reduces the number of concurrent workers that are run based on the data volume being processed to ensure that the processing times are optimized. Currently, the threshold is set to 100,000 transactions or distribution lines and a maximum of 20 workers.

Workers identified dynamically based on load

| Incoming Cost rows during Cost Pre-Processor | Maximum Number of Workers | Actual Number of Subprocesses Launched (including the parent process) |

|---|---|---|

| 1000 | 10 | 1 |

| 100,000 | 10 | 1 |

| 400,000 | 10 | 4* |

| 1,000,000 | 10 | 10* |

| 2,000,000 | 10 | 10* |

* - Actual subprocesses may vary slightly from the number indicated based on actual volume and mix of transactions processed.

The main advantage from such parallel processing is to allow for dividing the load irrespective of the cost organization structure or variations in data volume in the cost organization or set of cost organizations. The parallel processing will also make better use of the available hardware. Customers that have a very high volume of transactions and are running a consolidated process will benefit through significant improvement in processing times with this feature. Ultimately, the reduced processing time will help speed up period close processing.

Steps to Enable and Configure

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25D

Tips And Considerations

- The feature is specifically tailored for high to very-high volume cost processing and the throughput improvements will be significant in those scenarios. For low to medium volume cost processing, there will be improvements in throughput, but it may not be noticeably higher as the current processing times will usually be optimal to begin with.

- For initial setup, we recommend a setting of one sub-process for every 100,000 transactions or 250,000 distribution lines that you generate today on a regular run of the Create Cost Accounting Distributions process. Use the greater of the values you determine based on the transaction and distribution volumes processed.

Key Resources

- Oracle Fusion Cloud SCM : Implementing Manufacturing and Supply Chain Materials Management Guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Supply Chain Cost Management, available on the Oracle Help Center.

Access Requirements

-

Users who are assigned a configured job role that contains these privileges can access this feature:

- Create Cost Distributions (CST_CREATE_COST_DISTRIBUTIONS)