Execute Maintenance for Asset Routes

Asset routes allow you to centrally plan, execute, and record maintenance for a collection of assets using a single work order. Asset routes are useful for repetitive or routine maintenance such as inspections and preventative maintenance that eliminates the overhead of creating multiple work orders for the same activity. For example, you can use asset routes to:

- Inspect and maintain fire extinguishers in each floor of a building.

- Maintain hospital beds by room in each ward of a hospital.

- Perform basic preventative maintenance on forklifts in a production facility.

You use logical hierarchy to define routes and forecast them using a maintenance program. You can manage a maintenance program from the Maintenance Supervision page and record for compliance in the My Maintenance Work page.

NOTE: You can't reference routes in a manually created work orders.

You define routes using a logical hierarchy based on a maintainable asset that represents an activity or a physical location such as a plant, building, floor, or a production line. When you define a hierarchy’s name, you give the asset route details and reporting options. In the reporting options, you can make asset-level reporting mandatory to complete a work order and allow technicians to skip assets. You then update the hierarchy with the collection of applicable assets. The assets must only be modeled at the first child level under the hierarchy’s name. You can line up assets in a logical sequence for easy reporting.

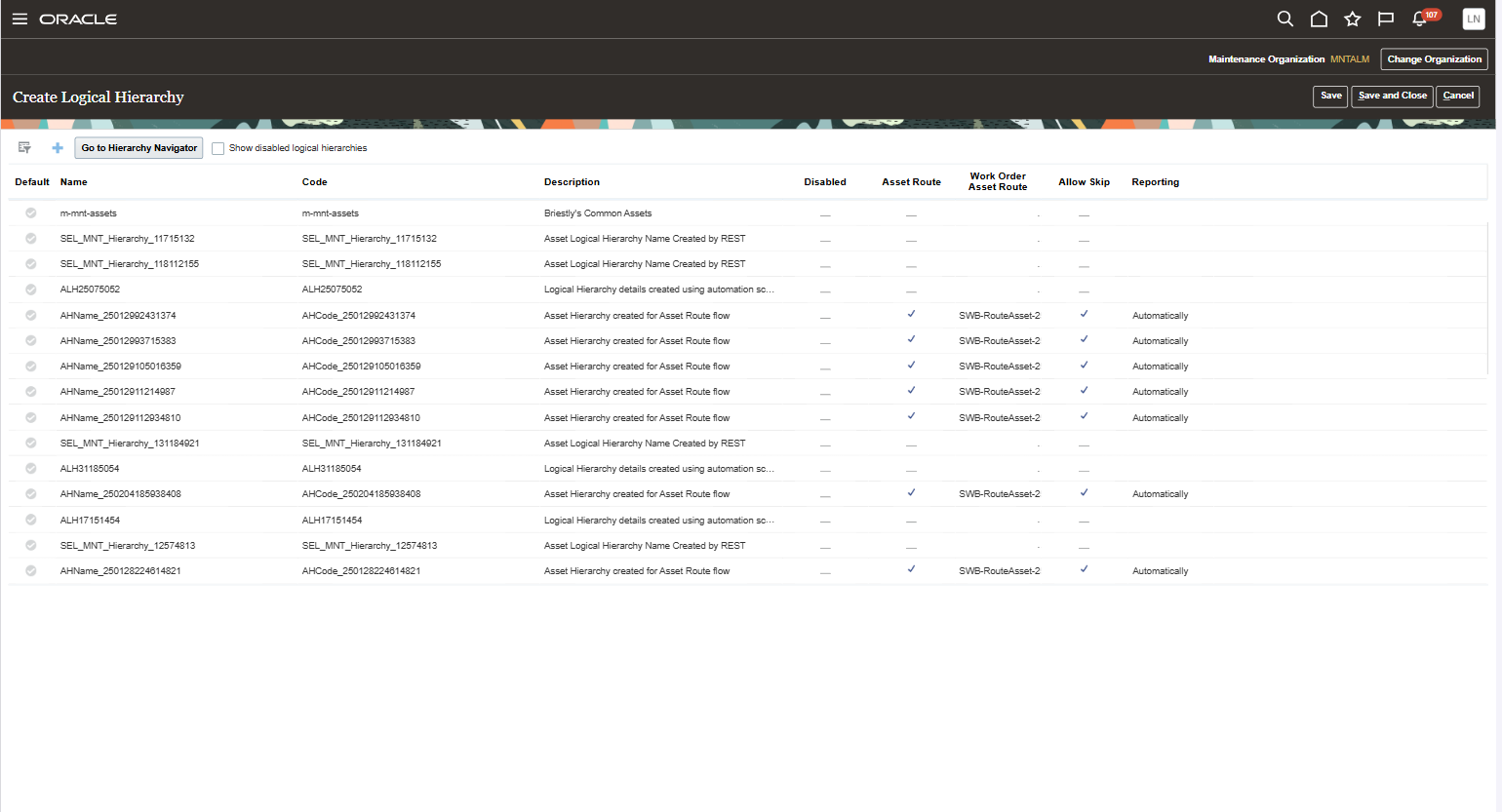

Here's a screenshot of the Create Logical Hierarchy page that shows a list of logical hierarchies and new parameters, Asset Route and Work Order Asset Route.

The Create Logical Hierarchy Page with New Parameters

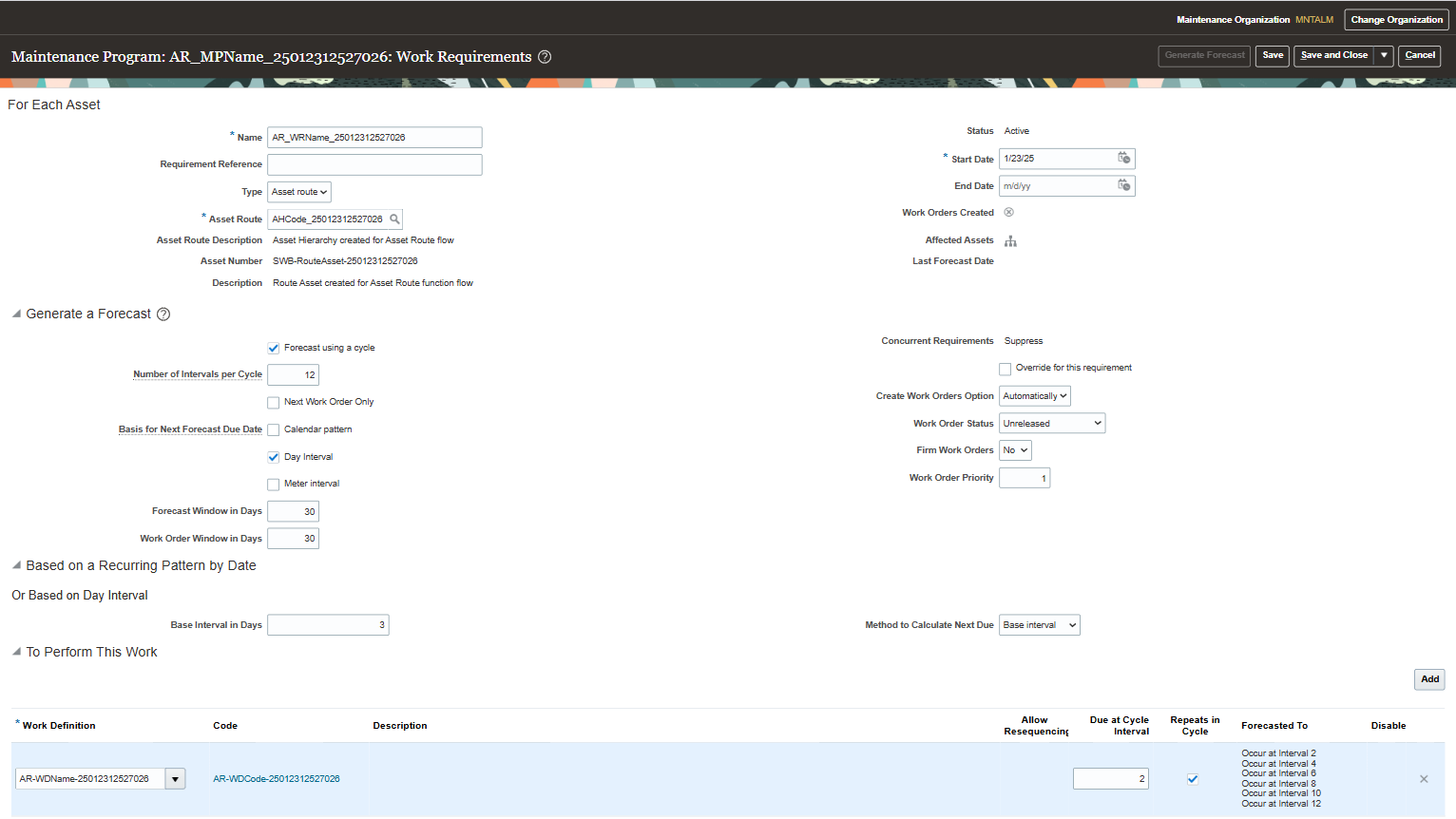

After a hierarchy is defined for a route, reference it in a maintenance program. To reference the asset route, select Type as Asset Route and select the logical hierarchy’s name that represents the asset route. After you select, the maintainable asset defined in the hierarchy is shown. This asset is used to forecast and create the maintenance work order.

Here's a screenshot of the Maintenance Program page for work requirements that shows a maintenance program of type asset route, wherein you associate the maintainable asset defined in the hierarchy.

Maintenance Program for an Asset Route

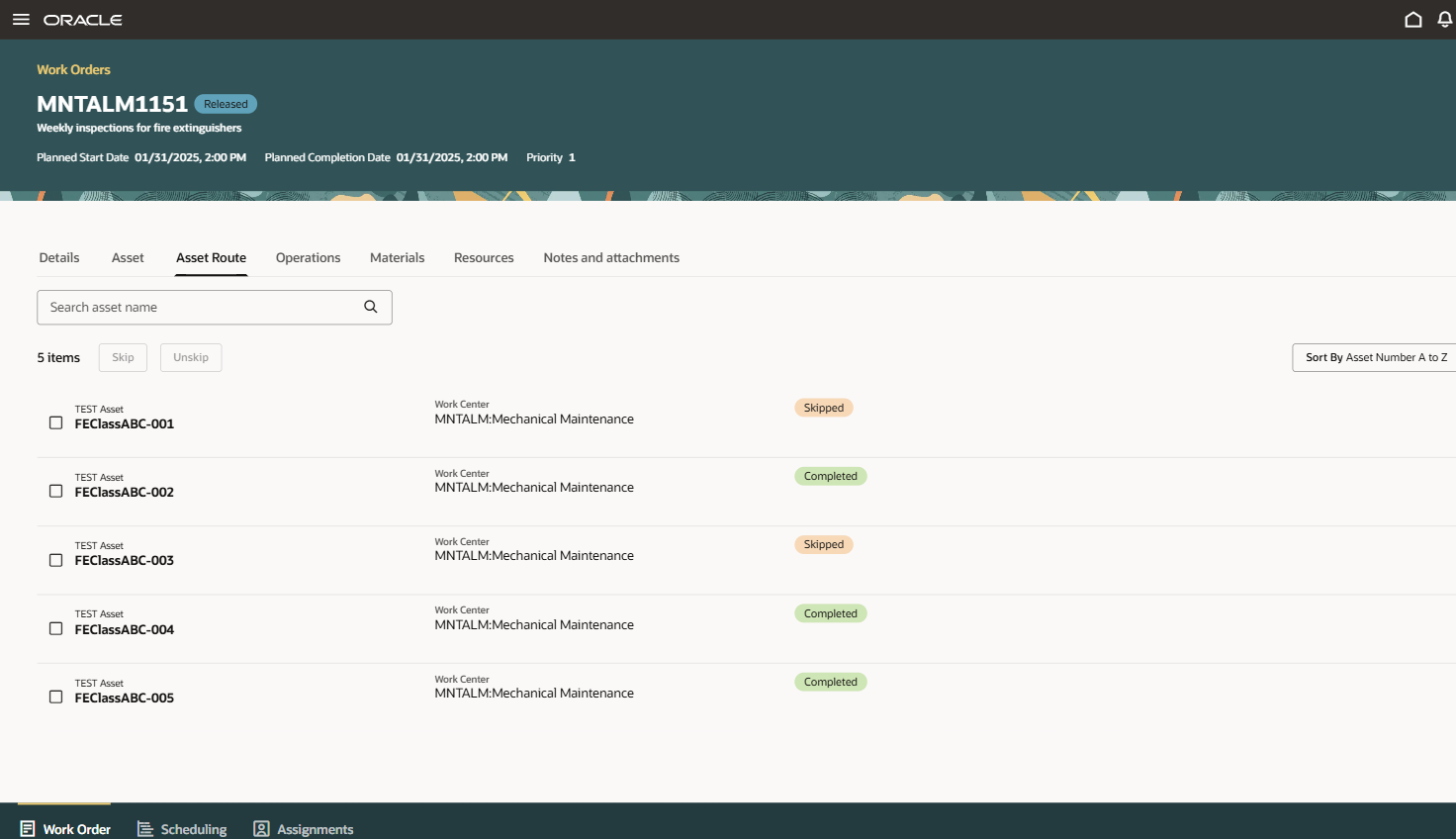

After the maintenance forecast is generated, you can view and manage the asset route due dates in the Maintenance Forecast page. Use the Maintenance Supervision page to manage the asset route work orders before release. You can view the collection of assets pending reporting on the Asset Routes tab. If your administrator allows, you can skip one or more assets before release. This can help your technicians decide the assets they can report or skip when they complete a work order.

Here's a screenshot of the Maintenance Supervision workbench shows how a maintenance supervisor can update a work order for an asset route.

Asset Route Shown on Maintenance Supervision Workbench

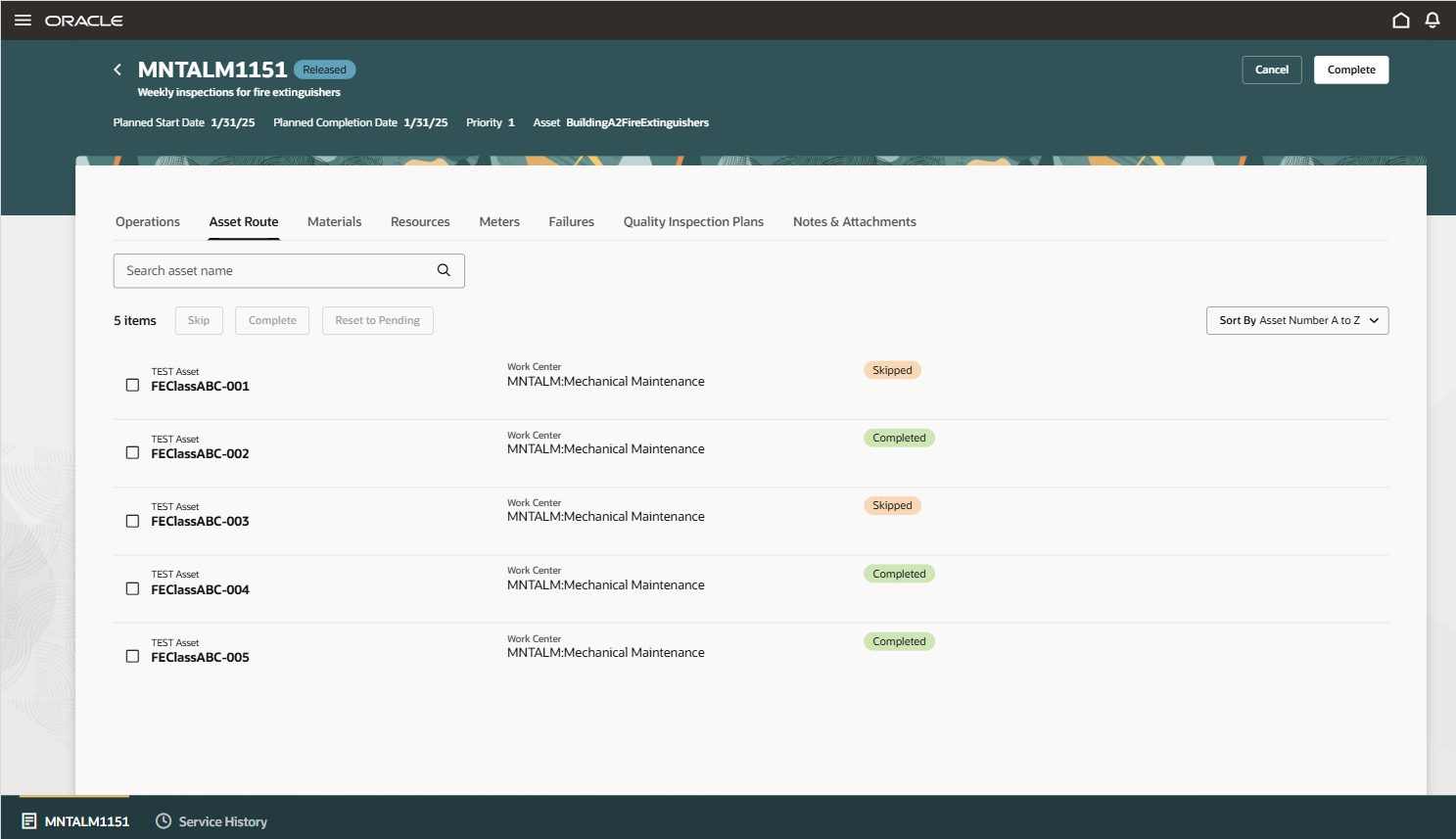

After release, your technician previews, reports, and completes the work order using the My Maintenance Work page. On the Asset Route tab of the reporting page, you can view the assets that are pending for reporting. Mark an asset as completed or skipped, depending on the options defined for the hierarchy. This provides a compliance record within work order history for each asset in the collection of the route.

Here's a screenshot of the Asset Route tab that shows how a technician completes reporting for each asset from My Maintenance Work.

Asset Reporting on My Maintenance Work

After reporting on assets, your technician use the Complete page to finalize the work order. There is a new KPI card for the asset route that details pending actions and provides a navigation back to the Asset Routes tab.

Let your maintenance teams use a single maintenance work order through asset route to complete same kind of preventive maintenance tasks on a group of assets. This improves work efficiency. Your maintenance planners can use maintenance programs to set up work orders for a route using predetermined intervals. By doing so, they can comply with safety standards with less or no manual effort.

Here's the demo of these capabilities:

Steps to Enable and Configure

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management

Tips And Considerations

The functionality is limited to Redwood so you must enable the Maintenance Supervision and My Maintenance Work pages.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Manage Customer Assets (CSI_MANAGE_CUSTOMER_ASSETS_PRIV)

- View Customer Assets (CSI_VIEW_CUSTOMER_ASSETS_PRIV)

- Manage Enterprise Assets (CSE_MANAGE_ENTERPRISE_ASSETS_PRIV)

- View Enterprise Assets (CSE_VIEW_ENTERPRISE_ASSETS_PRIV)

These privileges are available prior to this update.