Report Ad Hoc and Planned Additional Outputs for Discrete Manufacturing Work Order Operations When Executing Production at a Workstation

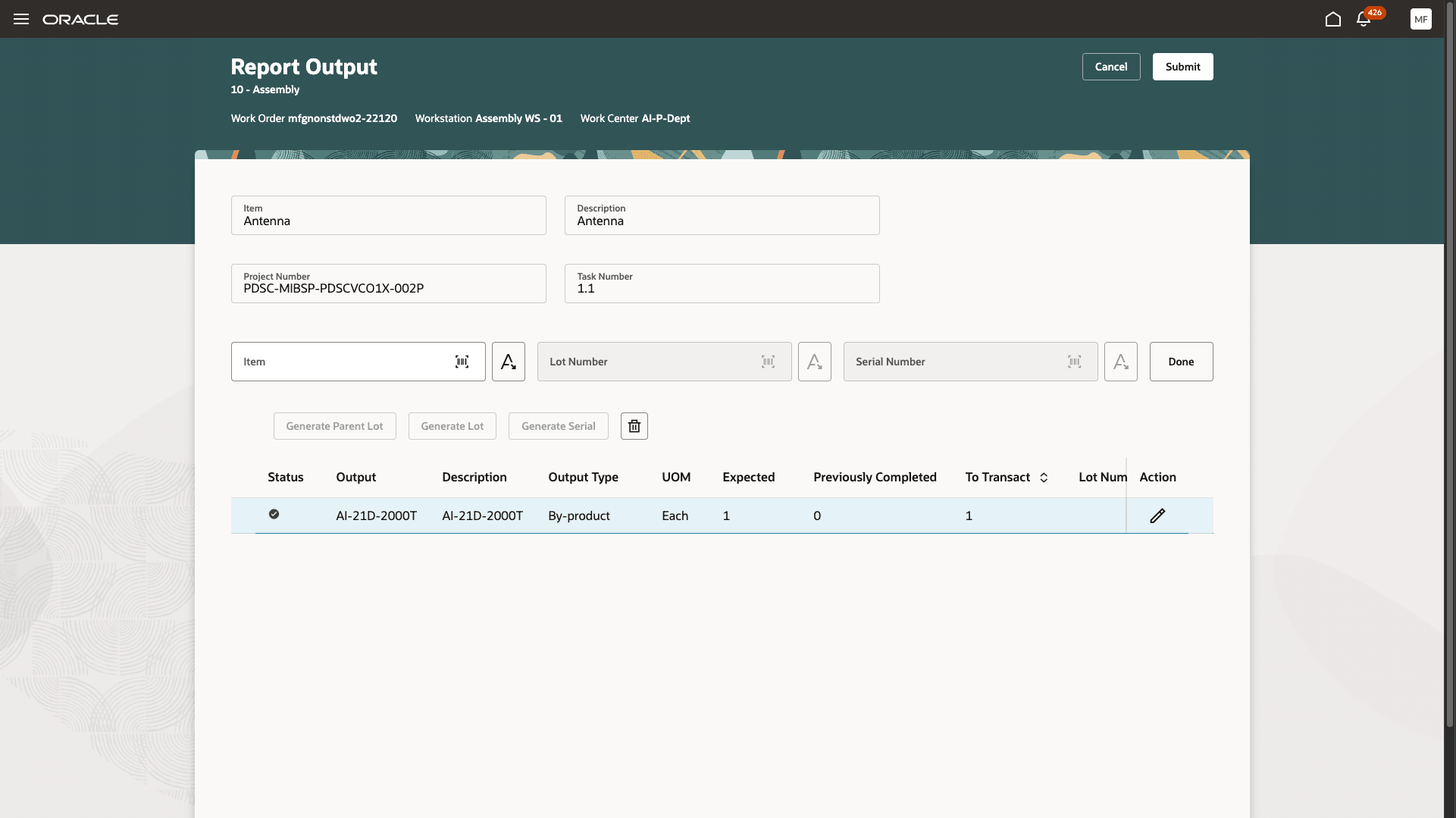

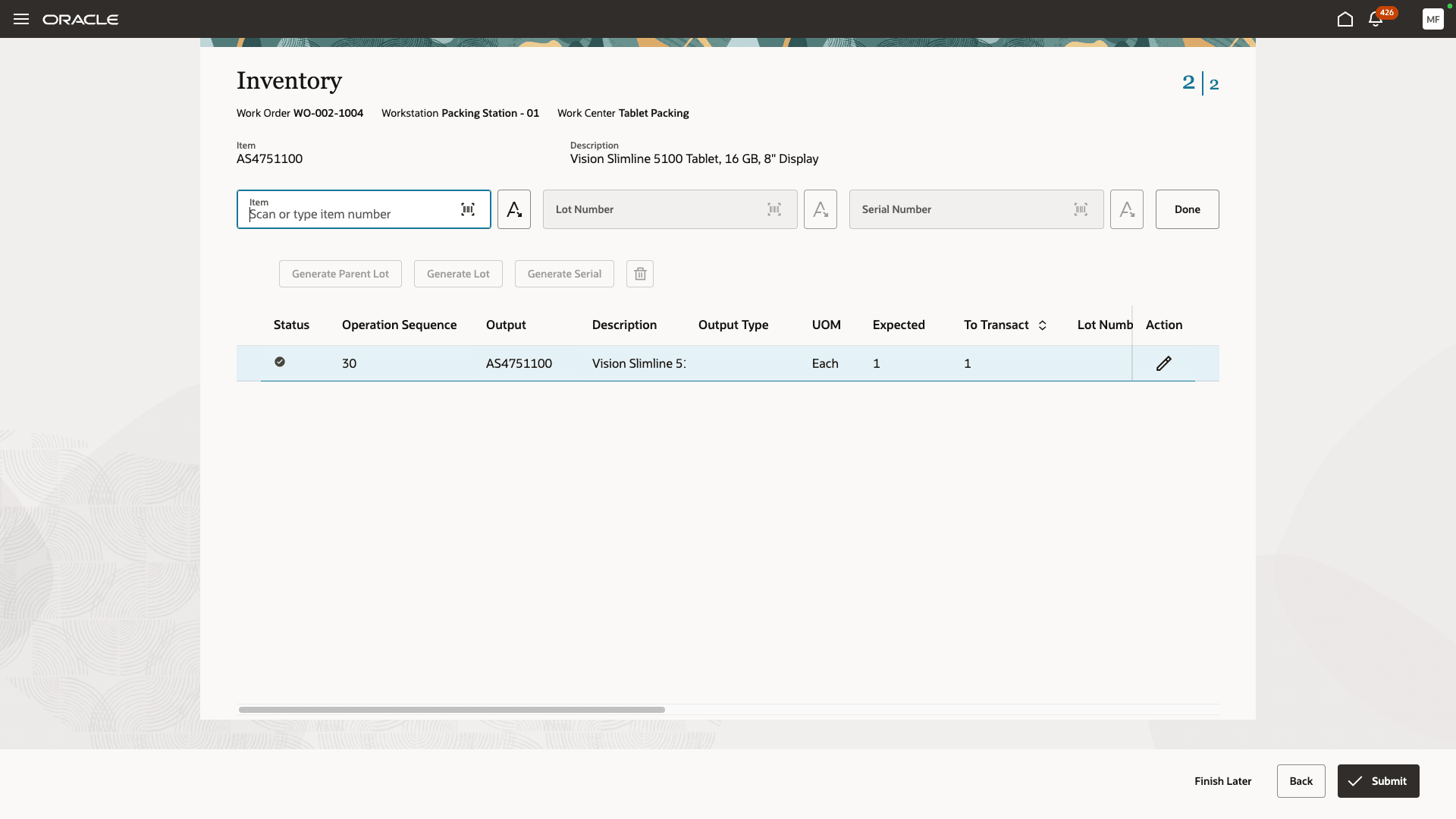

Discrete manufacturing processes can sometimes include more than one output. These additional production outputs are reported into inventory as supply, as reusable material for subsequent work orders, or as recoverable scrap sold as a separate item. With this update, operators can now report additional outputs, both co-products and by-products, during operation execution at a workstation. As an operator, you can also report ad hoc outputs to a specified completion subinventory when reporting the transaction.

Report Ad Hoc and Planned Additional Outputs When Executing Production at a Workstation

Report Ad Hoc and Planned Additional Output of Type Manual

Report Ad Hoc and Planned Additional Output of Type Automatic While Reporting Operation Transaction

Operators can leverage the unified user experience to perform output transactions, as part of the real-time operation execution. This helps save time for the operator and enhances overall operator productivity.

Here's the demo of these capabilities:

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

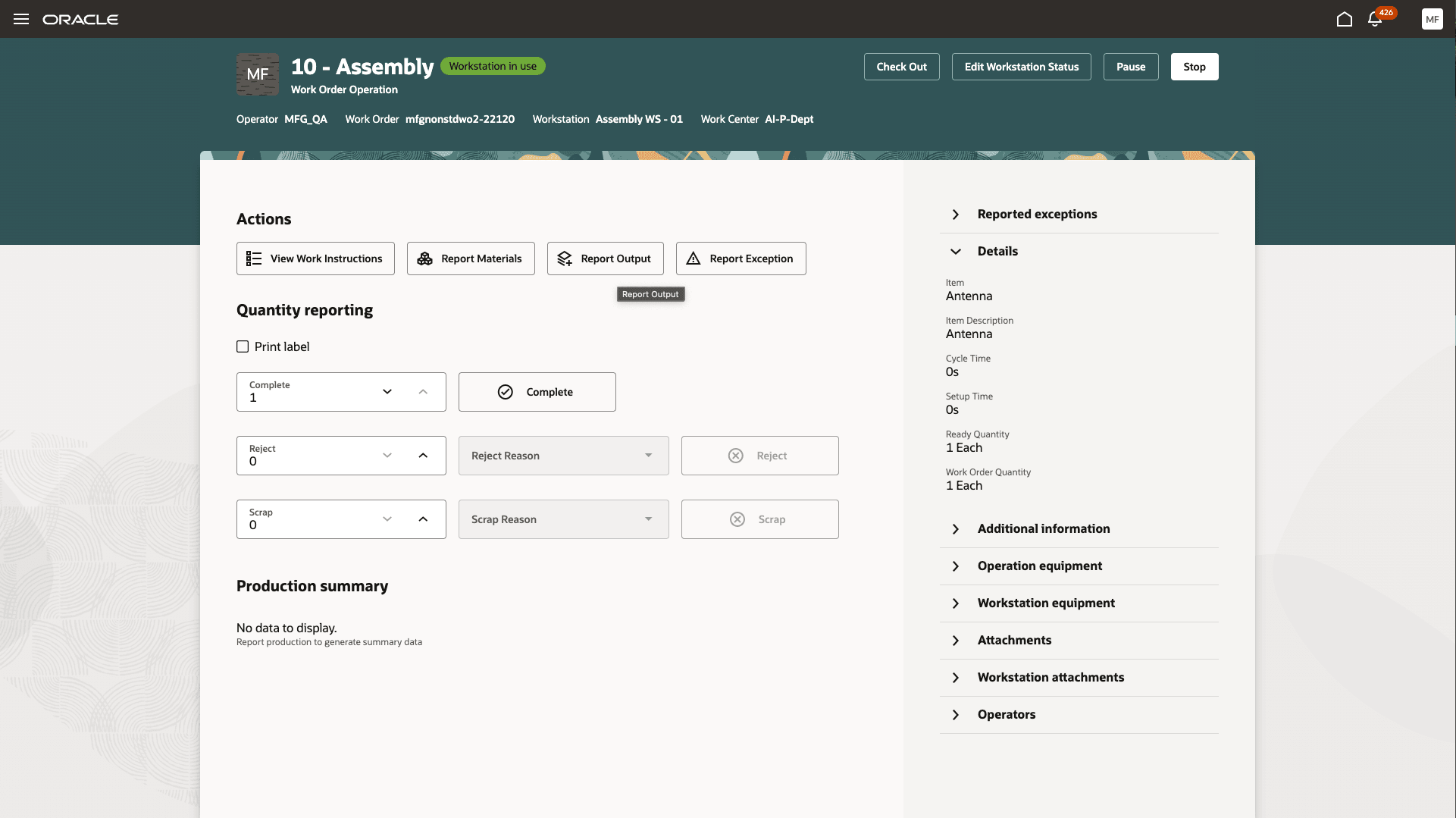

- "Report Output" button is visible if any operation in the discrete work order contains additional outputs.

- To make the "Report Output" button always visible, set "Always Show Report Output" page property in "Start Work Order Operation" page to "true" in Visual Builder studio.

- Ad hoc outputs can be reported by clicking the "Report Output" action or in conjunction with operation transaction reporting.

- Additional output of type "manual" defined in the work order operation can be reviewed by clicking "Report Output" and subsequently reporting to inventory.

- Additional output of type "automatic" defined in the work order operation can be reviewed while reporting operation transactions.

Key Resources

- Watch the Report Ad Hoc and Planned Additional Outputs for Discrete Manufacturing Work Order Operations When Executing Production at a Workstation demo.

- Watch the Complete Work Order Operation Quantities into Inventory During Work Execution at a Workstation demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can use this feature:

- Report Material Transactions (WIP_REPORT_MATERIAL_TRANSACTIONS_PRIV)

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

In addition to the preceding privileges, users should have item class data security configured with the View Item Basic action set to allowed.