Perform Disposition of Rejected Quantities for a Work Order Operation During Production Supervision

Operators complete or reject quantities based on the outcome of the manufacturing process, or post an inline inspection, based on the inspection results. The rejected quantities need to be reviewed for further action. Supervisors perform disposition of the rejected quantities and decide on the next course of action based on the available details. With this update, supervisors can perform the following disposition actions from the production supervisor workbench:

- Reverse rejected quantities to Ready state to allow re-processing of operation quantities.

- Move rejected quantities to scrap.

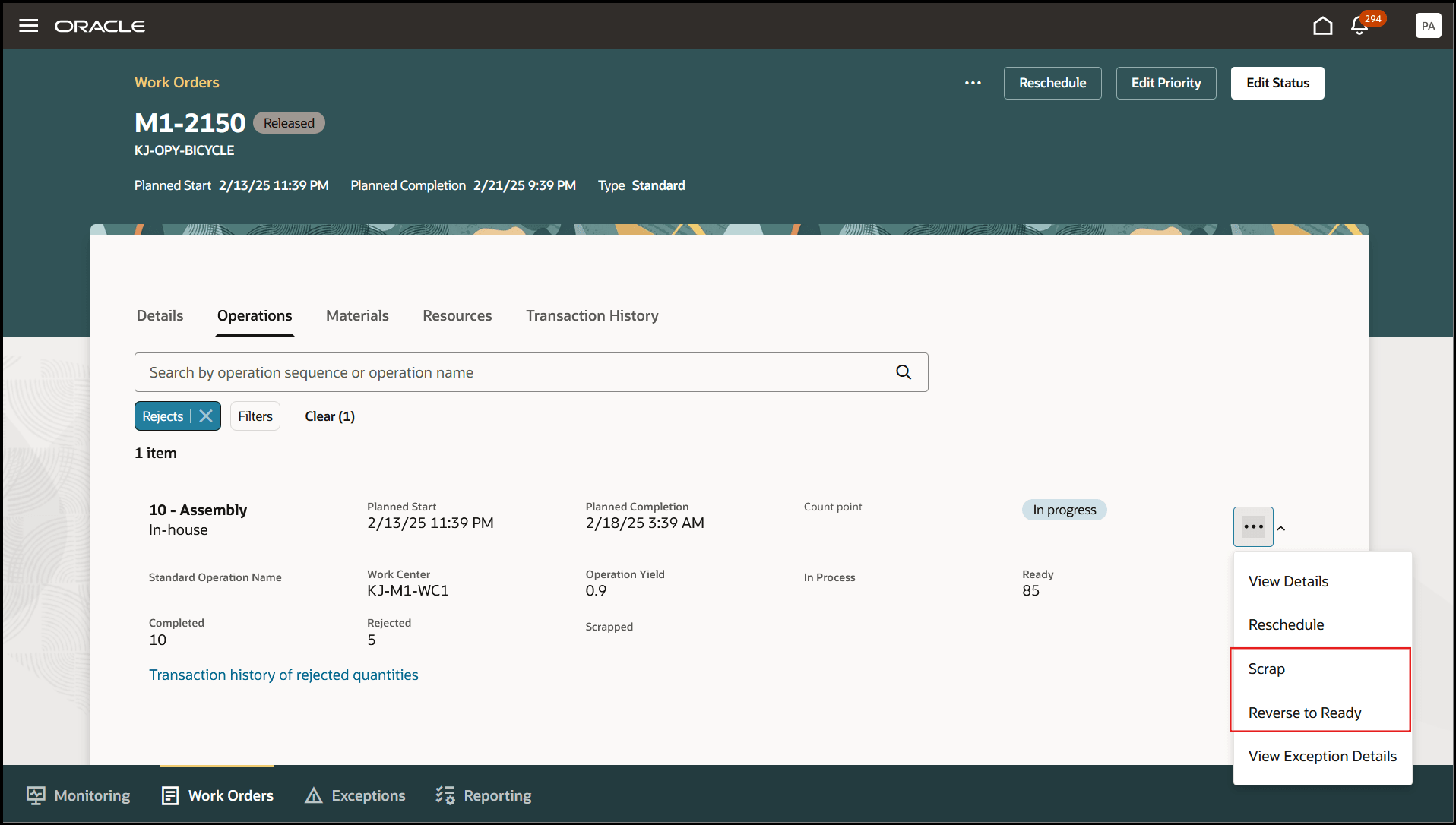

As a production supervisor, you can manage rejected work order operations by performing disposition actions. On the View Work Order page, navigate to the Operations tab and apply filters to view operations with rejects. For a selected operation, you can take one of the following disposition actions:

Scrap – Permanently discard the rejected items.

Reverse to Ready – Return the rejected items to a ready state for further processing.

Work Order Operations tab: Disposition Actions

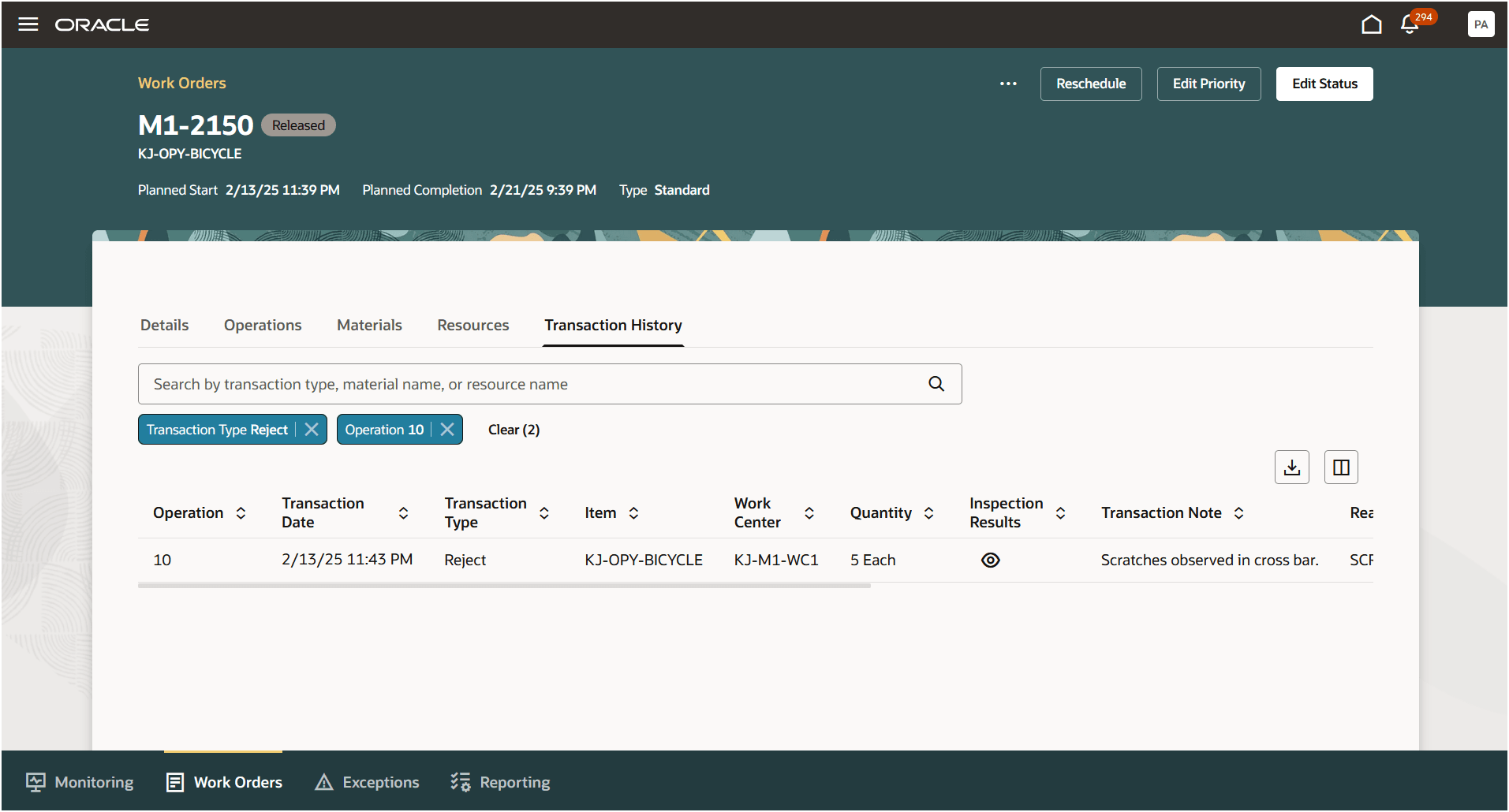

To help determine the appropriate disposition action, click 'Transaction History of Rejected Quantities' to review the background details of the rejected items. This takes you to the Transaction History tab of the work order where you can view the operation transaction history for the reject transaction.

The filter is automatically applied based on the operation context with Transaction Type = Reject. You can access details such as transaction notes, reject reasons, and inspection results captured by the operator during execution.

In this update, the following additional attributes have been added to the Transaction History tab:

- Transaction Note

- Reason

- Inspection Results

- Sub Inventory

- Locator

- Project and Task

- Country of Origin

- Product Serial Number

- Material Serial Number

- Lot Number

Work Order Transaction History Tab

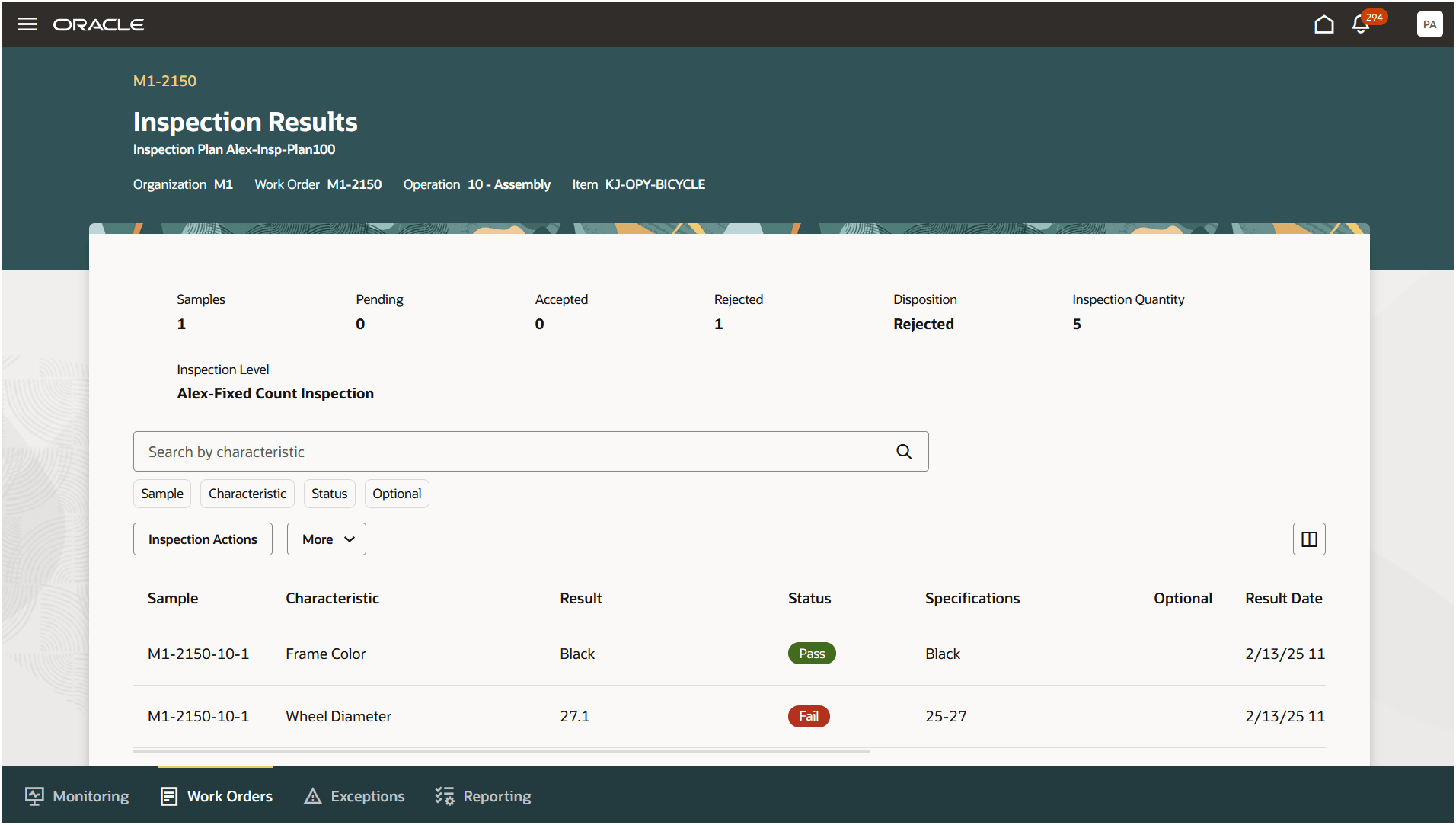

You can view the inspection results to check the value of inspection characteristics that caused the product to be rejected. You can optionally view inspection attachments and actions.

Inspection Results Captured During Operation Transaction

With this information, you have the necessary details to determine the appropriate disposition action.

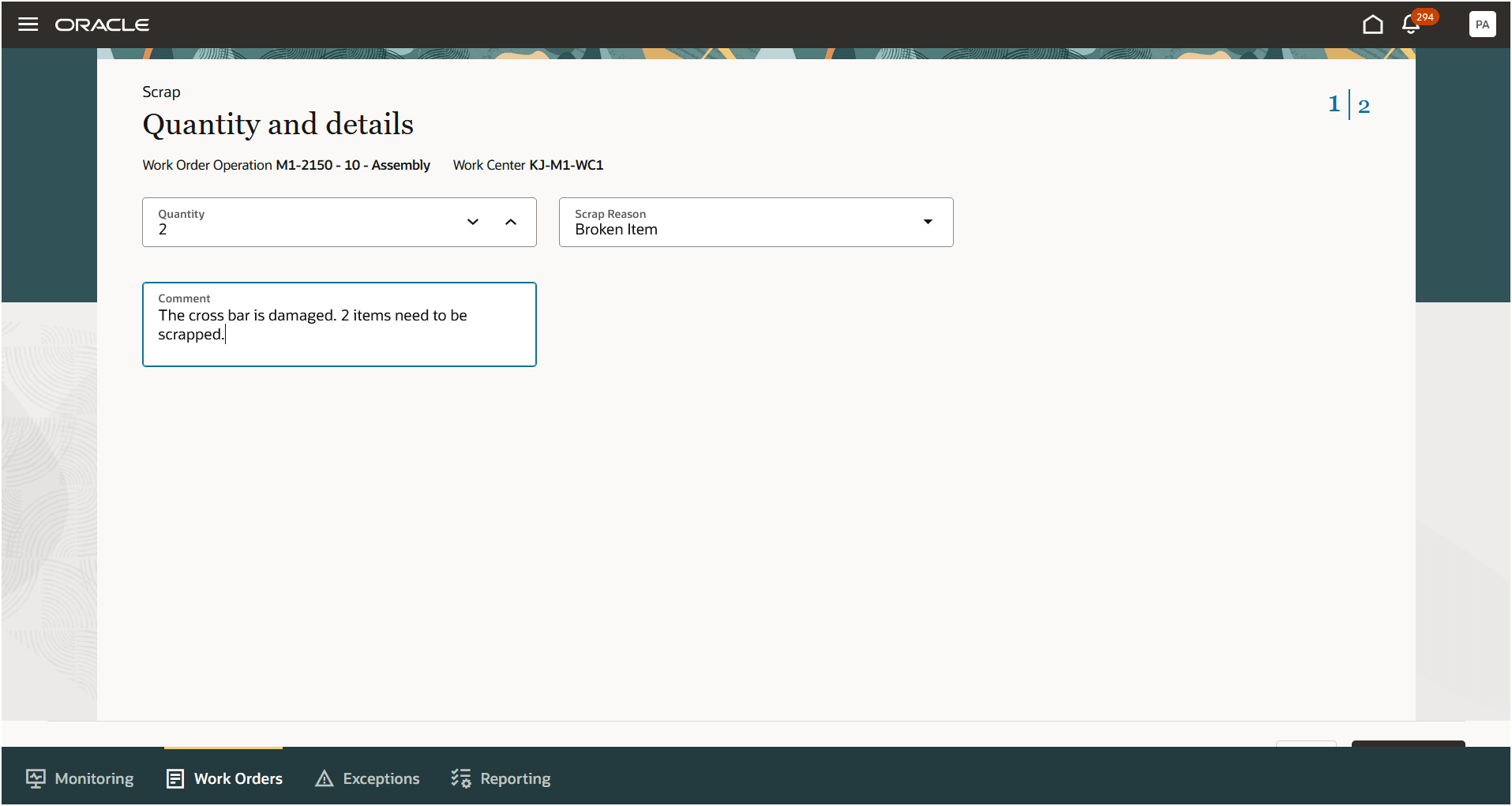

To scrap rejected items:

- In the Operations tab, select the Scrap action.

- Enter the quantity to be scrapped, select a scrap reason and, optionally, provide a scrap comment.

- For serialized execution, select the serial number of the item being scrapped.

- Click Save and Continue.

- In the Materials step, you can capture details such as lot or serial number of any assembly pull items required for the scrap transaction.

- Click Submit.

Scrap Disposition Action: Select Scrap Quantity

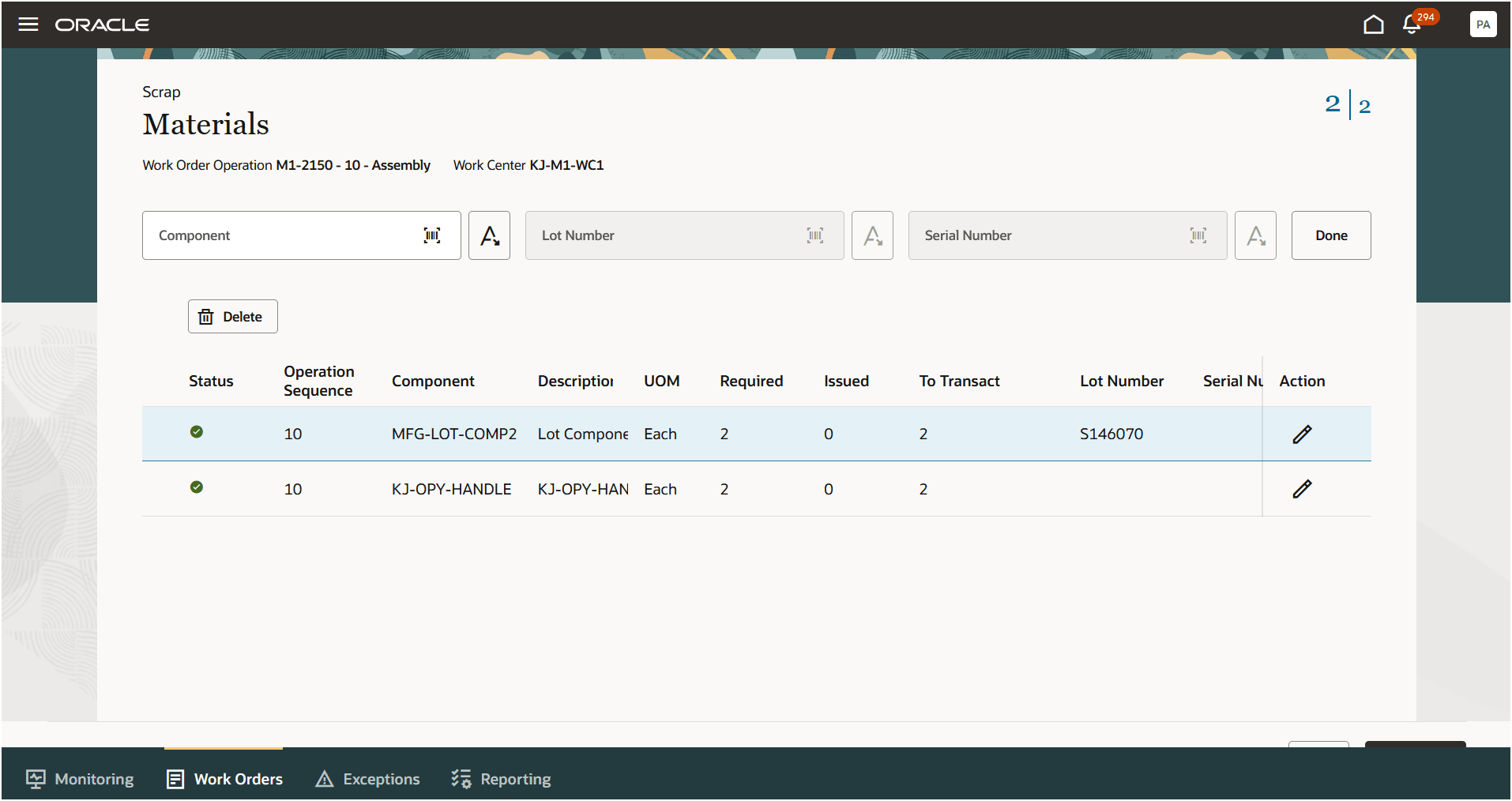

Scrap Disposition Action: Capture Assembly Pull Material Items to be Issued

To reverse rejected items to ready state:

- In the Operations tab, select the Reverse to Ready action.

- Enter the quantity to be reversed, workstation to assign this quantity for re-execution, and, optionally, provide a comment.

- For serialized execution, select the serial number of the item being reversed.

- Click Save and Continue.

- In the Materials step, you can capture details such as lot or serial number of materials to be returned.

- Click Submit.

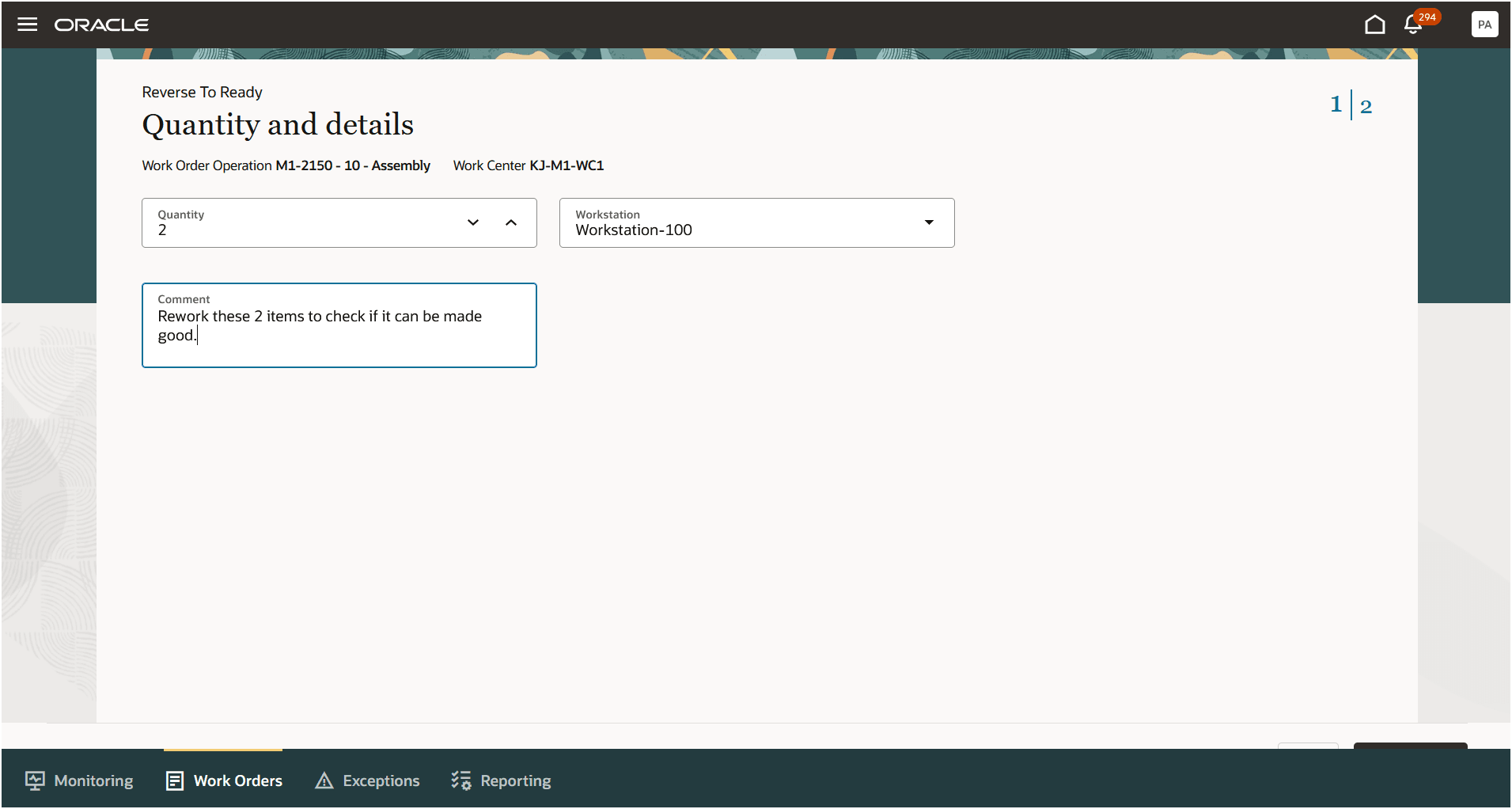

Reverse to Ready Action: Select Reverse Quantity

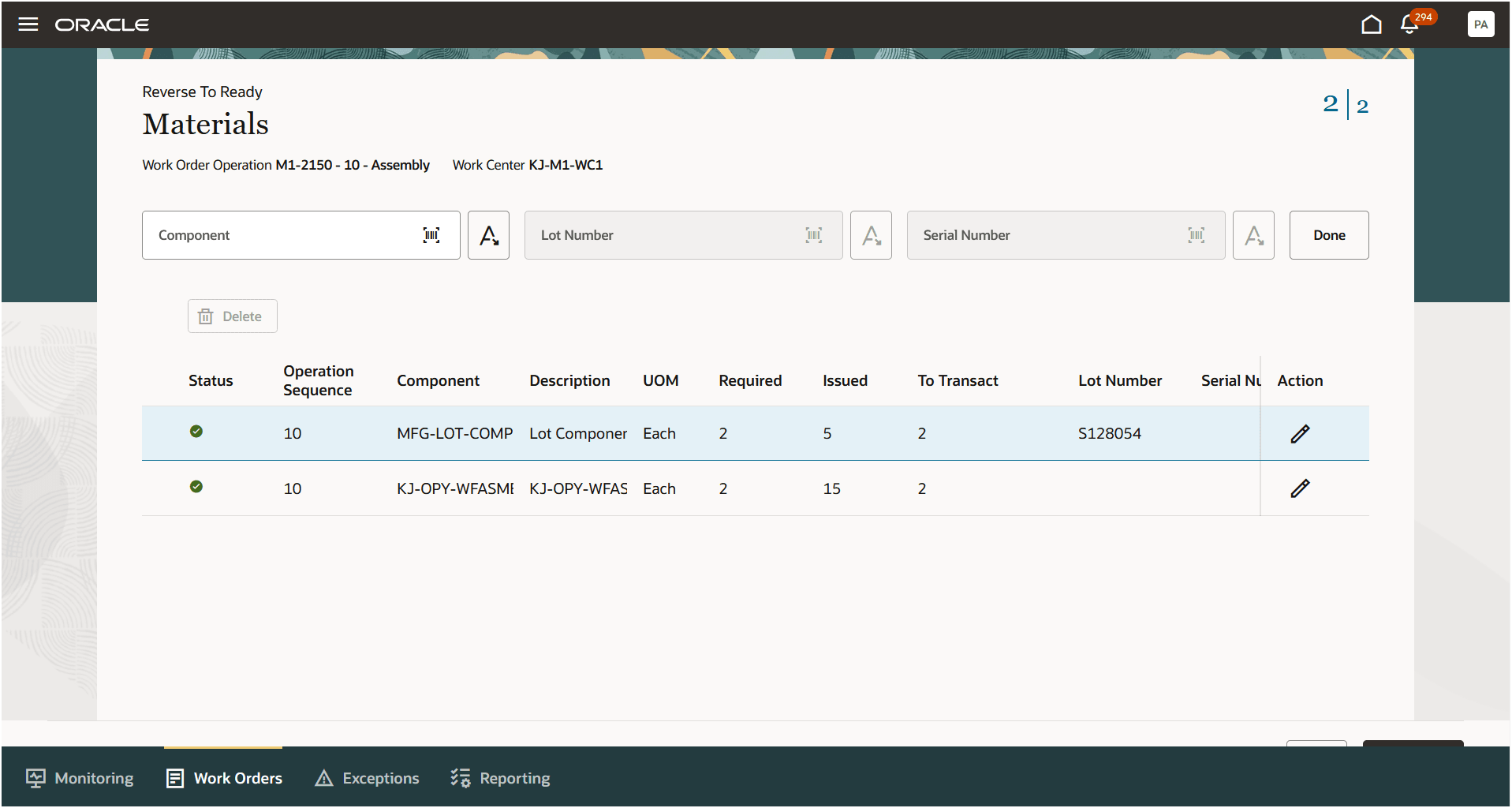

Reverse to Ready: Capture Materials to be Returned

Supervisors can leverage the unified user experience to manage dispositions and maintain accurate records of completions for work order operation quantities post execution.

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25D

Tips And Considerations

-

When you perform a disposition action as a supervisor, inspection results are not captured again even if they have been configured.

-

You can disposition partial quantities from a work order operation and adjust material consumption accordingly.

-

For a Reverse to Ready transaction, resource usages are completely reversed and cannot be modified.

Key Resources

- Watch the Perform Disposition of Rejected Quantities for a Work Order Operation During Production Supervision demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supervise Production (WIP_SUPERVISE_PRODUCTION_PRIV)

- Perform Disposition of Rejects (WIP_PERFORM_DISPOSITION_REJECTS_PRIV)

- Manage Work Orders by Service (WIP_UPDATE_WORK_ORDERS_SERVICE_PRIV)

- View Production Shift Details (WIP_GET_PROD_SHIFT_DETAILS_PRIV)

- View Production Quality Inspections (WIP_VIEW_PRODUCTION_QUALITY_INSPECTIONS_PRIV)

- View Inspection Plans (QA_VIEW_INSPECTION_PLANS_PRIV)

- Get Item Rest (EGP_GET_ITEM_REST_PRIV)

In addition to the preceding privileges, you should have the following data security configured for your role and user:

- Manufacturing plant data security: Set the security context value for the manufacturing plant to the manufacturing organization.

- Item class data security: Set the View Item Basic action to allowed.