Manage Process Manufacturing Work Orders in the Production Supervisor Workbench

Production supervisors can now manage process manufacturing work orders from the production supervisor workbench and perform work order related actions. Supervisors can view all process-related information, including the outputs and batch quantities for a work order operation. As a production supervisor, you can also monitor workstation performance for work centers executing process manufacturing work orders in your shift. You can view standard metrics, such as workstation and work center OEE during the shift.

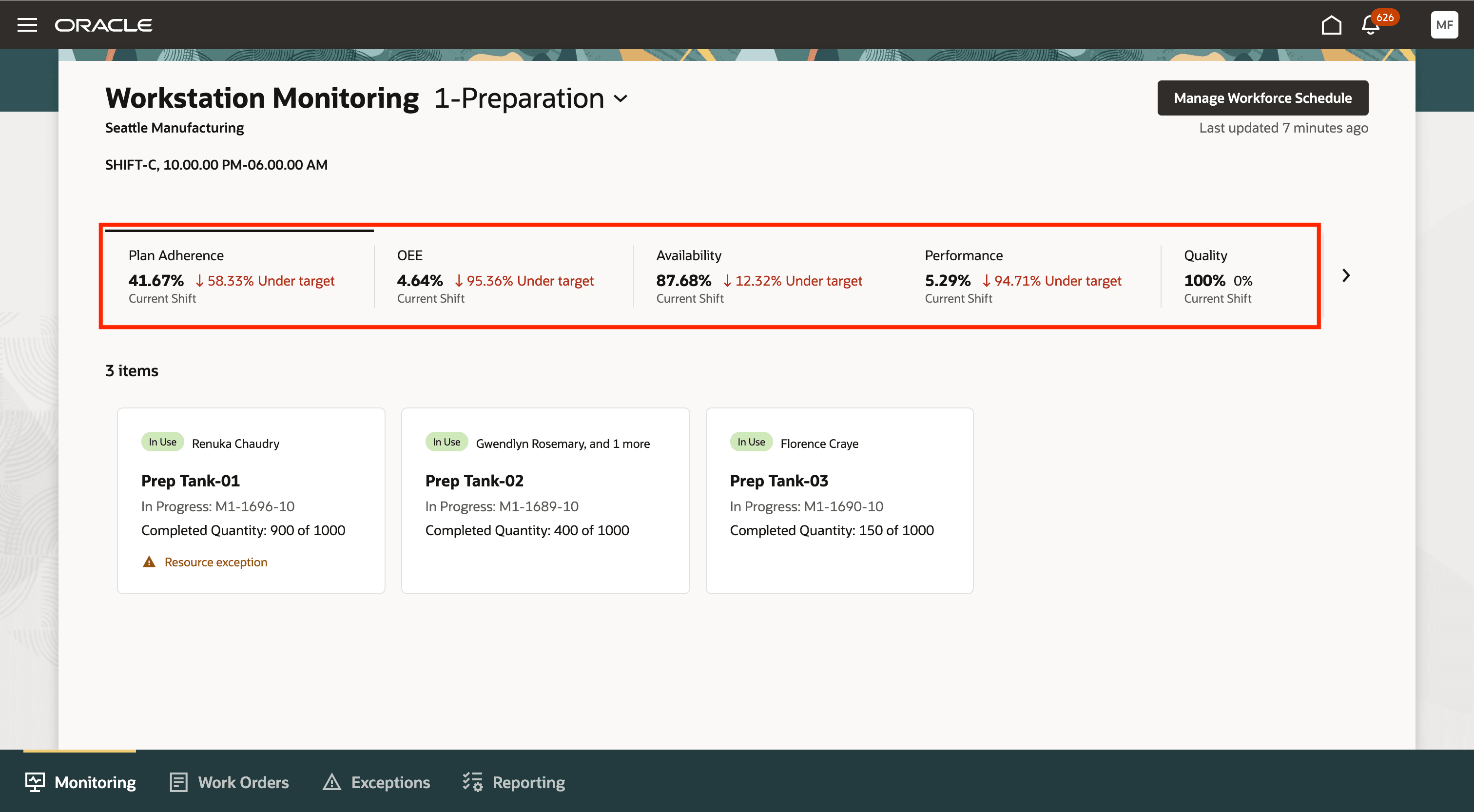

Monitoring Tab

The Monitoring Tab in the Production Supervisor Workbench provides real-time insights into workstation performance, including Plan Adherence, OEE, completed quantity, downtime, and operator assignments. It helps supervisors track deviations, monitor exceptions, and ensure production continuity with scorecards and workstation-specific data, enabling proactive decisions to maintain efficiency and productivity on the shop floor.

The following key metrics can be monitored at both the work center and workstation levels:

Plan Adherence: Represents the percentage of actual batch completion compared to the target completion for a workstation over the duration of the current shift. The displayed value is an average of the computed adherence values from all process workstations within the work center.

Overall Equipment Effectiveness (OEE): OEE, a key efficiency metric in process manufacturing, is determined using Availability, Performance, and Quality. It measures equipment efficiency at a specific workstation for the current shift. Expressed as a percentage, OEE is calculated by multiplying its components for the shift. The workstation values are then averaged to determine the work center’s overall OEE.

Availability: This metric provides information on the workstation's availability in the current shift. Availability calculates the percentage of runtime divided by the planned production time. The planned production time is calculated as the shift duration minus breaks, if any. Runtime is calculated as the difference between planned production time and all downtime, both planned and unplanned. Availability is calculated at the workstation level and aggregated across all workstations to compute the average availability for the work center.

Performance: This metric assesses the workstation’s performance by considering the impact of factors that can slow down manufacturing, namely slow cycles and minor stops. The performance percentage is calculated as follows:

Performance % = ((Ideal Cycle Time x Total quantity)/RunTime) x 100

The ideal cycle time for an operation is obtained from the resource usage of the work order operation being executed for the batch quantity at the workstation. Runtime is calculated as the difference between planned production time and all downtime, both planned and unplanned. Performance is calculated at the workstation level and aggregated across all workstations to compute the average performance for the work center.

Quality: This metric calculates the percentage ratio of good quantity to total quantity of the batch produced during the current shift. It assesses the quality of manufactured products produced during the current shift. Products that do not meet the quality standards, including products that need rework, lower the quality metric value. Quality is calculated at the workstation level and aggregated across all workstations to compute the average quality for the work center.

Downtime: Represents the total time, in minutes, that workstations within the work center have been non-operational during the current shift. This metric helps supervisors identify production bottlenecks and take corrective actions to minimize delays.

Completed Quantity: Tracks the batch quantity successfully processed at a workstation during the shift. At the work center level, this metric represents the total completed quantities across all workstations.

Open Exceptions: Displays the total number of reported deviations or issues that remain unresolved across all workstations within the work center, allowing supervisors to proactively address potential disruptions.

Metrics in the Monitoring Tab

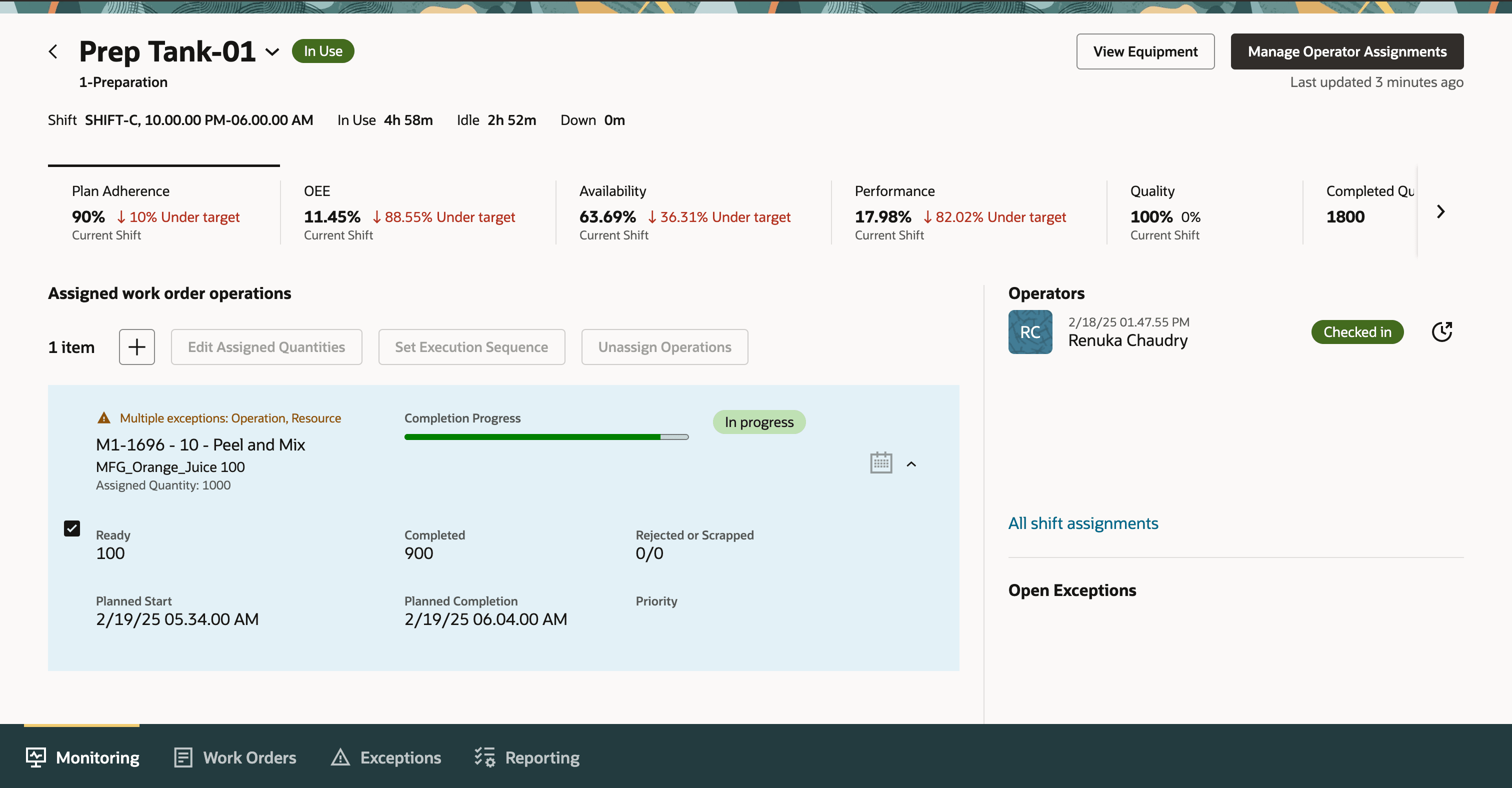

You can now assign process work order operations to workstations and monitor their progress.

Workstation with Metrics

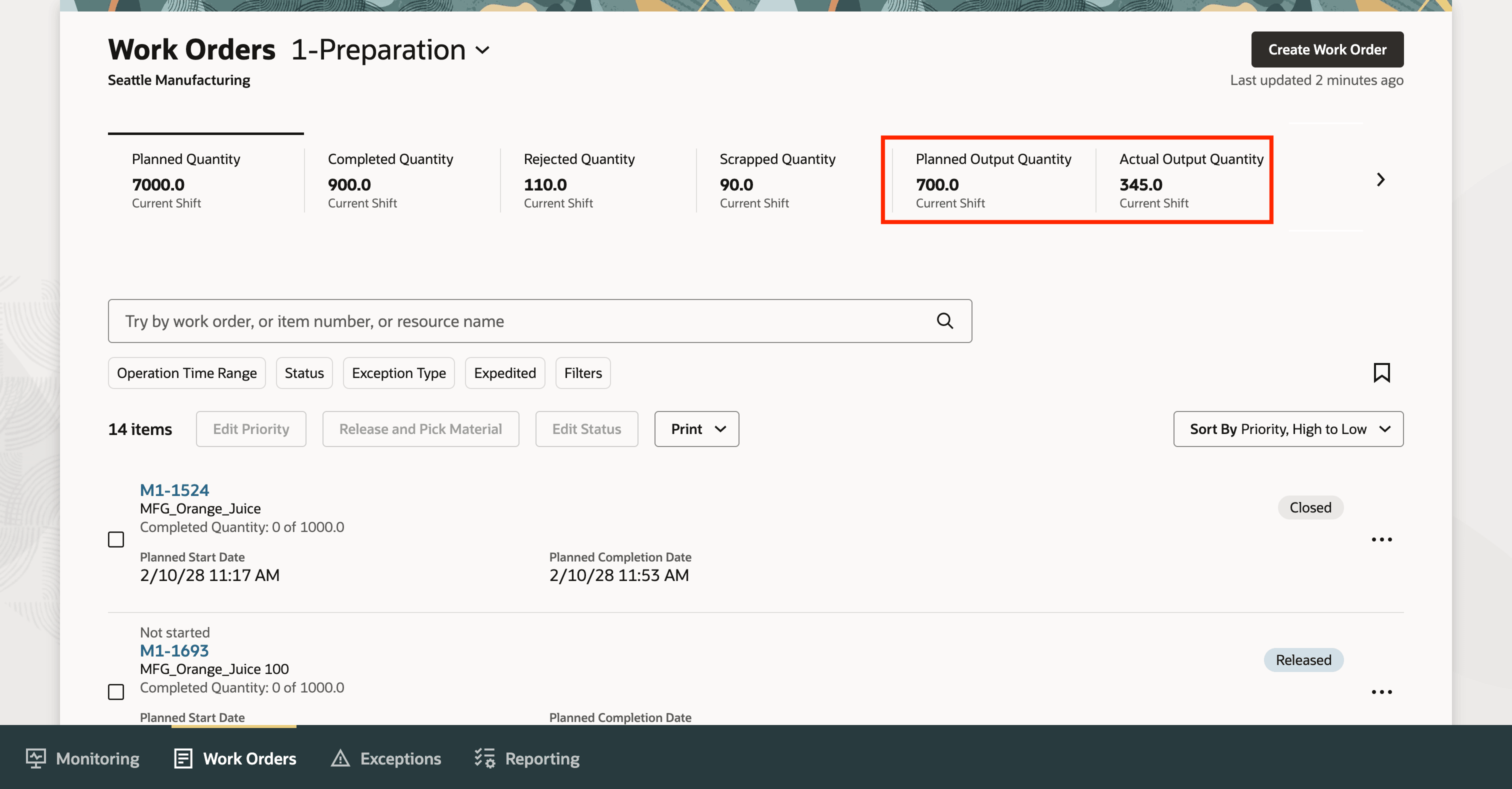

Work Orders Tab

With this update, the production supervisor workbench has been enhanced to support process manufacturing work orders and display new data fields and improved tracking capabilities across multiple tabs.

To improve tracking and management of process manufacturing work orders, new metrics have been introduced that provide deeper insights into production output, quality losses, and process deviations. These metrics help supervisors maintain batch consistency, optimize material usage, and ensure that production stays aligned with planned targets.

Planned Output Quantity: Defines the expected amount of finished product to be generated from a process work order. As process manufacturing often involves ingredient-to-finished-product transformations, this metric helps supervisors compare actual production against expected yields. It ensures that batch formulations and production parameters are followed correctly.

Actual Output Quantity: Represents the true quantity of finished product produced at the completion of a work order. In process manufacturing, variations between planned and actual output can occur due to evaporation, spillage, processing inefficiencies, or unexpected chemical reactions. Tracking this metric helps identify inefficiencies and optimize production processes for better yield and resource utilization.

Rejected Quantity: Represents the batch quantity that failed to meet quality standards during production. In process manufacturing, rejection may occur due to variations in raw material quality, improper mixing, or deviations in process conditions. High rejection rates indicate quality control issues that need to be addressed to minimize waste and rework.

Work Orders Page

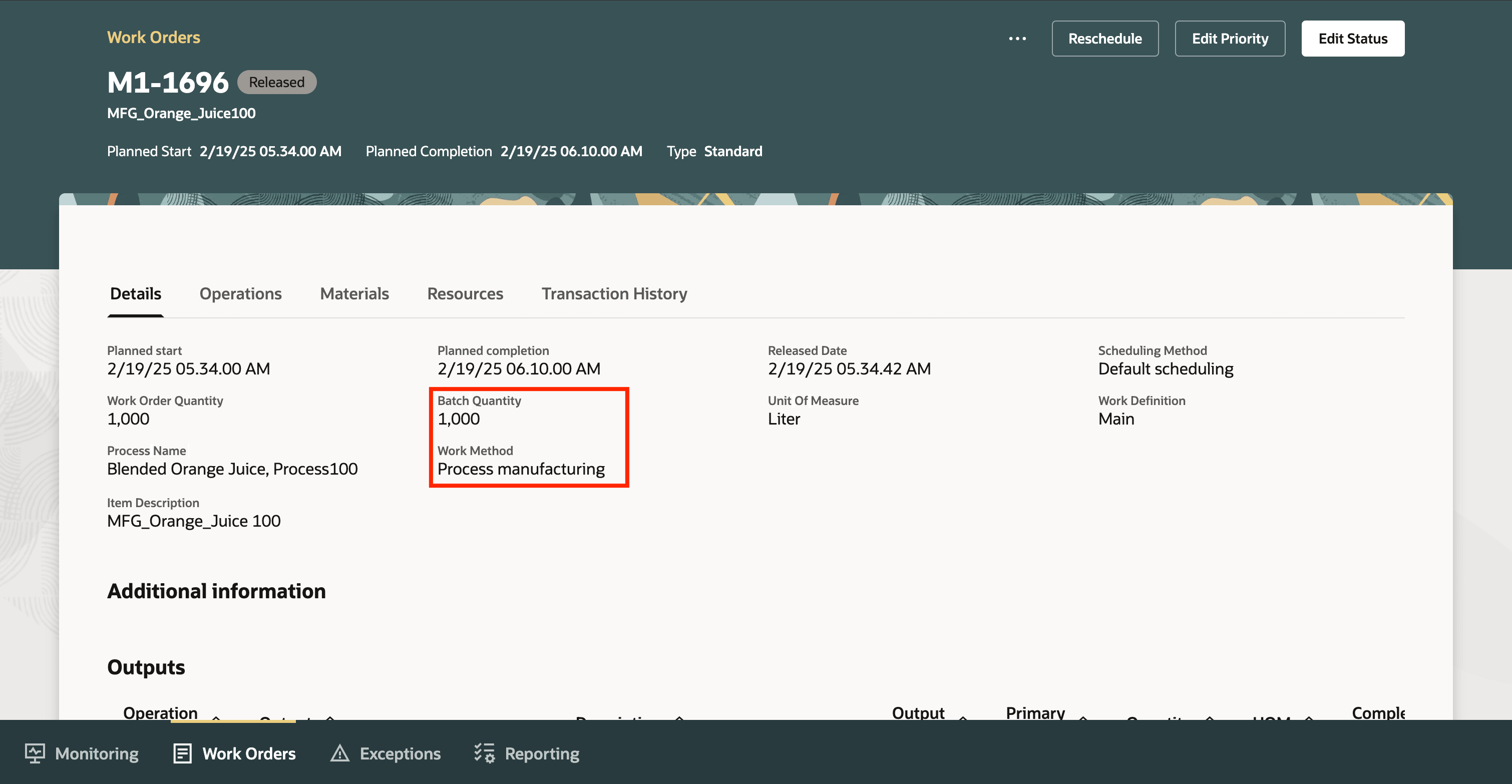

Changes in the Work Order Details Page - Details Tab

The following details have been added to the work order details page:

Batch Quantity: Total units in a process work order batch.

Process Name: Unique name that identifies the process work definition.

Work Method: Defines discrete or process manufacturing.

Output Details: Categorizes outputs as product or by-product.

Work Order Details Tab

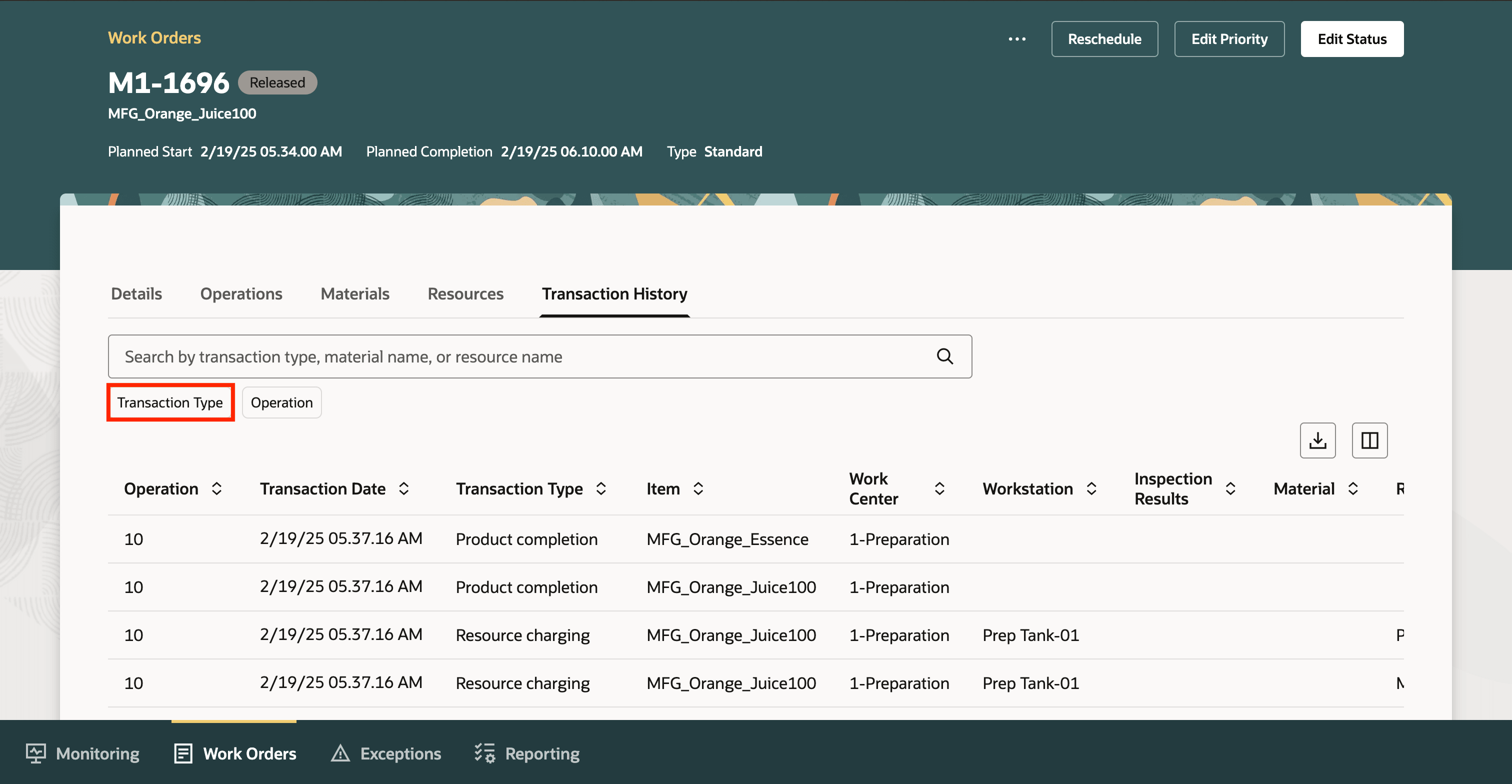

In addition to the changes in the Details tab, we also have enhancements across other areas in the work order, improving visibility and control in process manufacturing. The Transaction History Tab now includes expanded filtering options for tracking material issues, returns, rejected items, and scrapped quantities, with the added ability to download transaction history to Excel for further analysis.

Transaction Type Filter

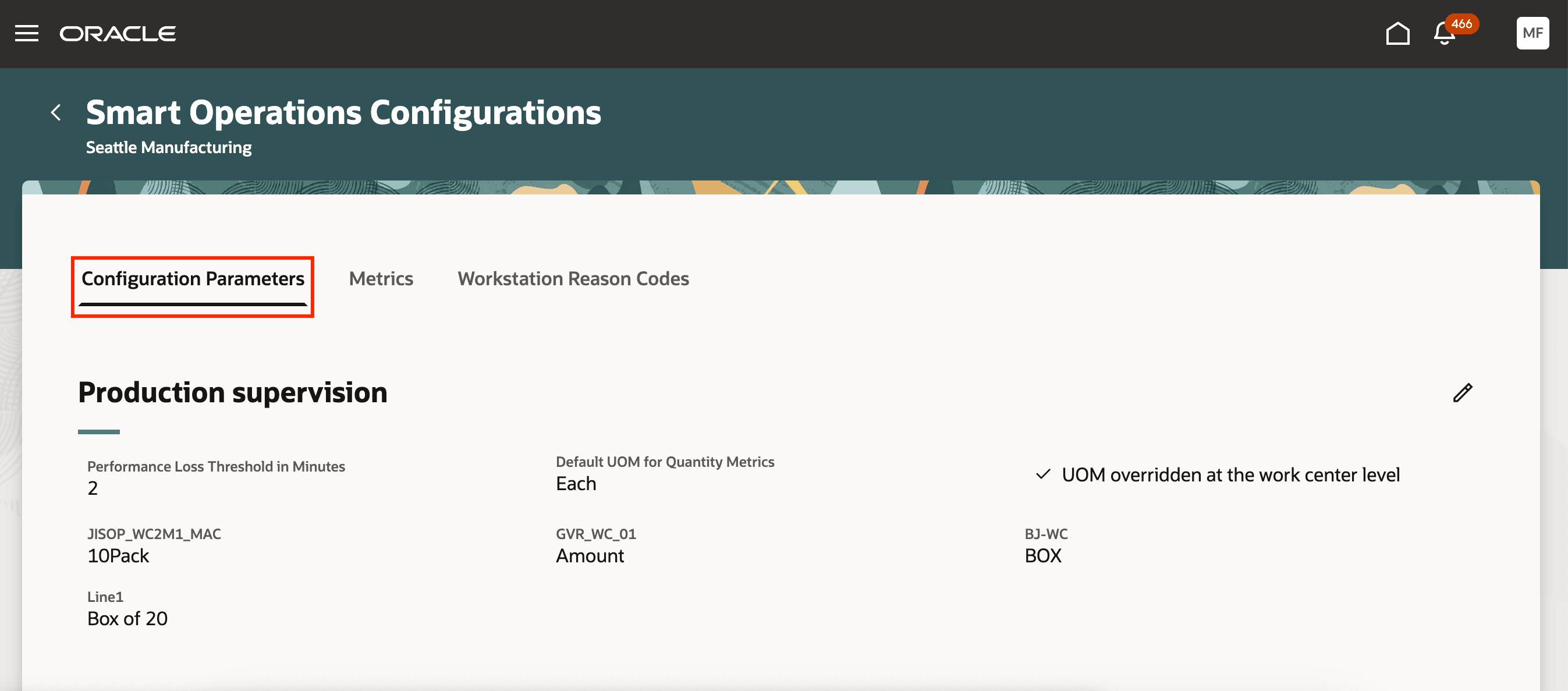

Configuration Parameters for Unit of Measure (UOM)

To enhance flexibility in reporting and metric calculations, the system now supports work center-level overrides for unit of measure (UOM) while maintaining default values at the plant level. Currently, UOM conversion is managed at the plant level for reporting, but with this update, the system first checks if a work center-specific override exists. If found, the system applies the designated UOM, else it defaults to the plant-level conversion. Each work center can have a different UOM based on production needs—for example, a juice production work center may use litres, while a packaging work center may use Each for individual units. When new work centers are created, they inherit the default UOM from the Default Unit of Measure for Quantity Metrics setting at the organization level. Selecting the override checkbox enables customization while keeping the default UOM available for adjustments.

During metric calculations, the system verifies whether the Default Unit of Measure for Quantity Metrics Override checkbox is selected. If enabled, the specified UOM for each work center is applied, else the default UOM is used. If the Override Unit of Measure at Work Center Level checkbox is deselected, work centers disappear from the screen, but previously defined UOM values remain stored in the database if they differ from the organization UOM. Reselecting the check box restores these values while all other work centers display the default UOM.

All metrics are calculated based on the reporting UOM in Smart Operations Configurations.

Unit of Measure (UOM) Configuration Parameter

Supervisors can leverage the unified user experience to manage and monitor process manufacturing work orders for their work centers and ensure production continuity during the shift.

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25D

To use this feature, follow these steps:

- Access the setup options to enable process manufacturing:

- Click the profile icon and navigate to Setup and Maintenance.

- Select Manufacturing Master Data > Manage Plant Parameters.

- Check the Enable Process Manufacturing check box.

- Configure the unit of measure (UOM) settings at the organization and work center levels:

- Open the Smart Operations Configurations page.

- In the Configuration Parameters tab, enter a value for the Performance Loss Threshold field.

- Select a unit of measure from the Default UOM for Quantity Metrics dropdown list.

- To set a specific UOM for each work center, select the Override UOM at Work Center Level option and enter the appropriate UOM for the work center.

Tips And Considerations

- Using the extensibility features of VB Studio, you can edit the page to:

- Modify the default ordering of tabs.

- Hide or display seeded scorecard metrics.

- If your role has the Configure OTBI Reports on Landing Page privilege, you can add custom KPI metrics and visualization reports to the dashboard pages after creating them with Oracle Transactional Business Intelligence (OTBI).

Key Resources

- Watch the feature demo for Manage Process Manufacturing Work Orders in the Production Supervisor Workbench.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supervise Production (WIP_SUPERVISE_PRODUCTION_PRIV)

- Manage Workstation Queue (WIP_MANAGE_WORKSTATION_QUEUE_PRIV)

- Manage Assignment of Operators to Workstation (WIP_MANAGE_WORKSTATION_OPERATORS_PRIV)

- Get Manufacturing Plant Set Up Data by Service (WIS_GET_MFG_PLANT_SETUP_SERVICE)

- View Production Shift Details (WIP_GET_PROD_SHIFT_DETAILS_PRIV)

- Configure OTBI Reports on Landing Page (WIS_CONFIGURE_OTBI_REPORTS_LANDING_PAGE_PRIV)

Visualization Configurations:

- View Service Manager Dashboard (SVC_VIEW_SERVICE_MANAGER_DASHBOARD_PRIV)

- View Service Representative Dashboard (SVC_VIEW_SERVICE_REPRESENTATIVE_DASHBOARD_PRIV)

Guided Journeys : Role Codes:

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

All privileges and roles were available prior to this update.