Redwood: Search and Perform Mass Actions for Work Orders Using a New User Experience

Redwood: Search and Perform Mass Actions for Work Orders Using a New User Experience

Production supervisors typically manage work orders by exception, coordinating activities for smooth operational performance during manufacturing execution. Using a Redwood user experience, you can now manage work orders with greater ease and efficiency.

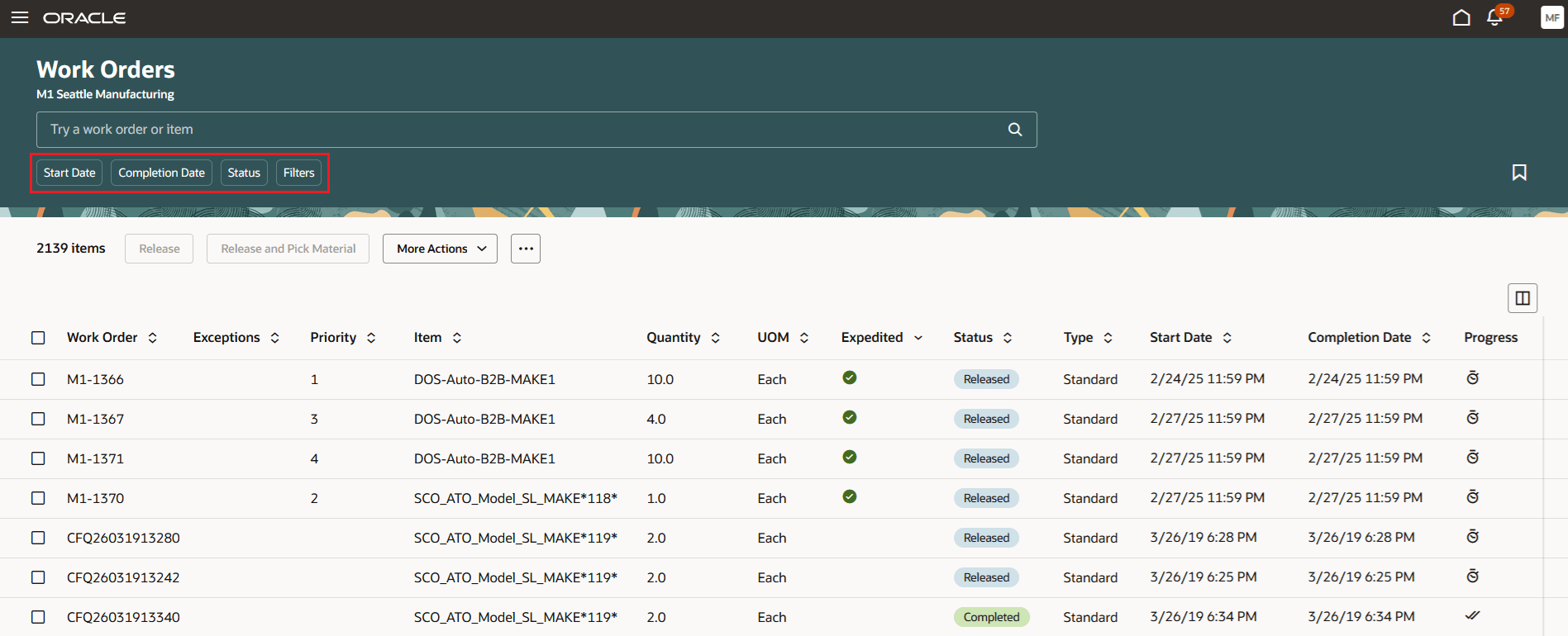

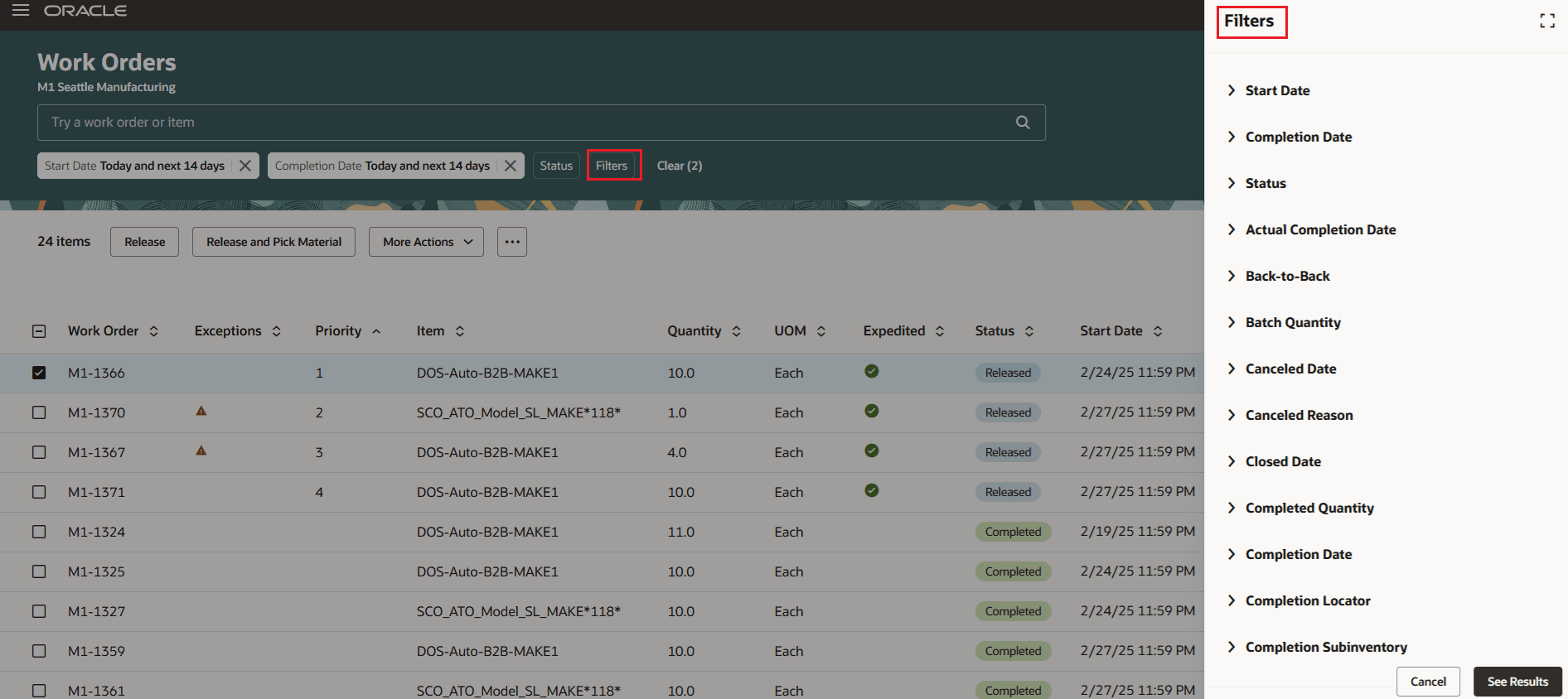

- Faster search and filter work orders – Use keywords and commonly used filters to quickly find and view work orders based on a powerful, index-based search engine. You can also use an extensive set of filter criteria, such as customer, project, and work definition version to narrow down the list of work orders.

- Saved search for frequent access - Create and run a saved search for retrieving work orders. You can configure settings for sharing and defaulting a saved search.

- View more work order information at a glance - View work orders with exceptions and work orders based on priority or expedited state. Track work order status, progress, and other work order header information including descriptive flexfields in a table format. You can also customize columns in the table of search results to rearrange, show, and hide information.

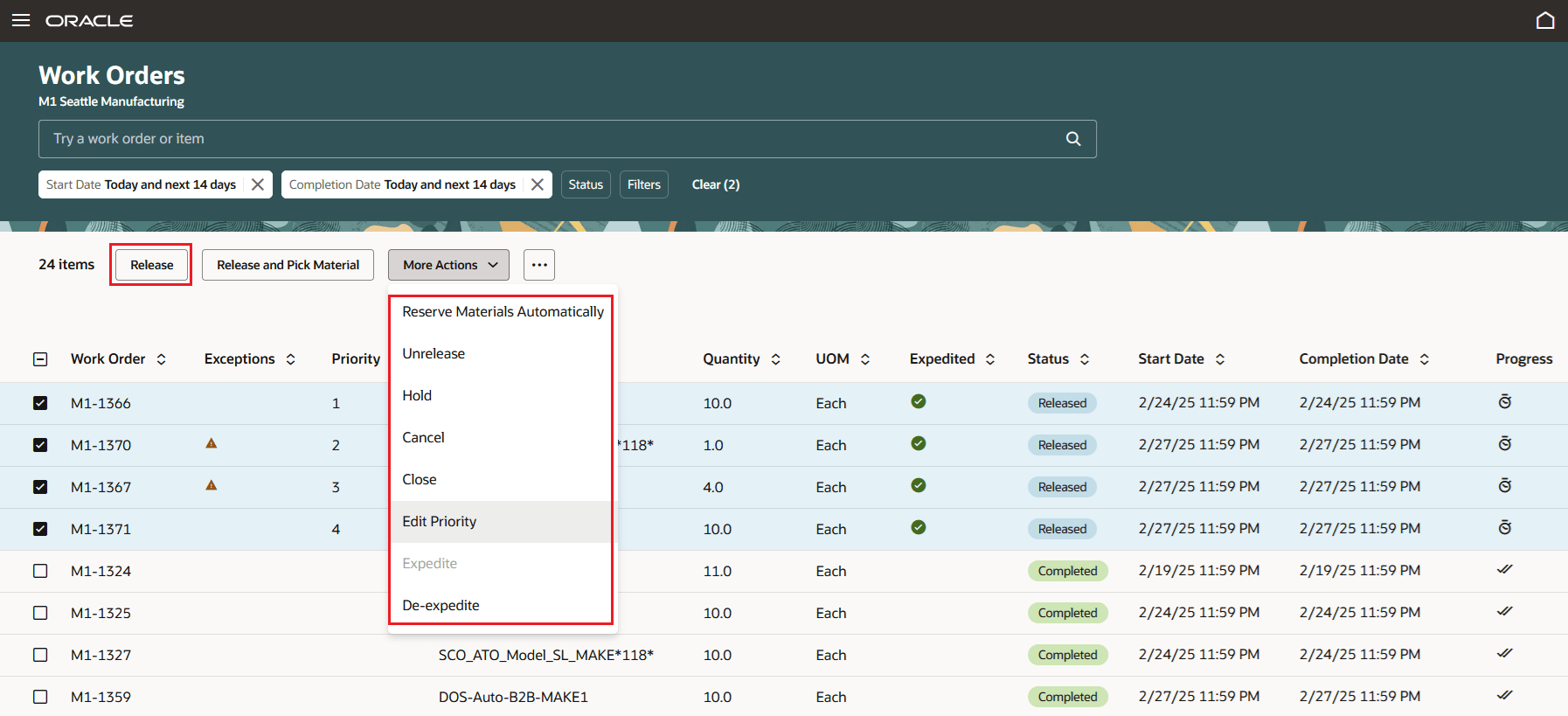

- Apply actions on multiple work orders – Select one or more work orders and take bulk actions like changing the work order status, picking materials, reserving materials automatically, editing the priority, expediting work orders, and printing reports and labels. The processing of multiple work orders is atomic: If all work orders are error free, then they are processed successfully. Even if one of the work orders cannot be processed successfully, then none of them are processed.

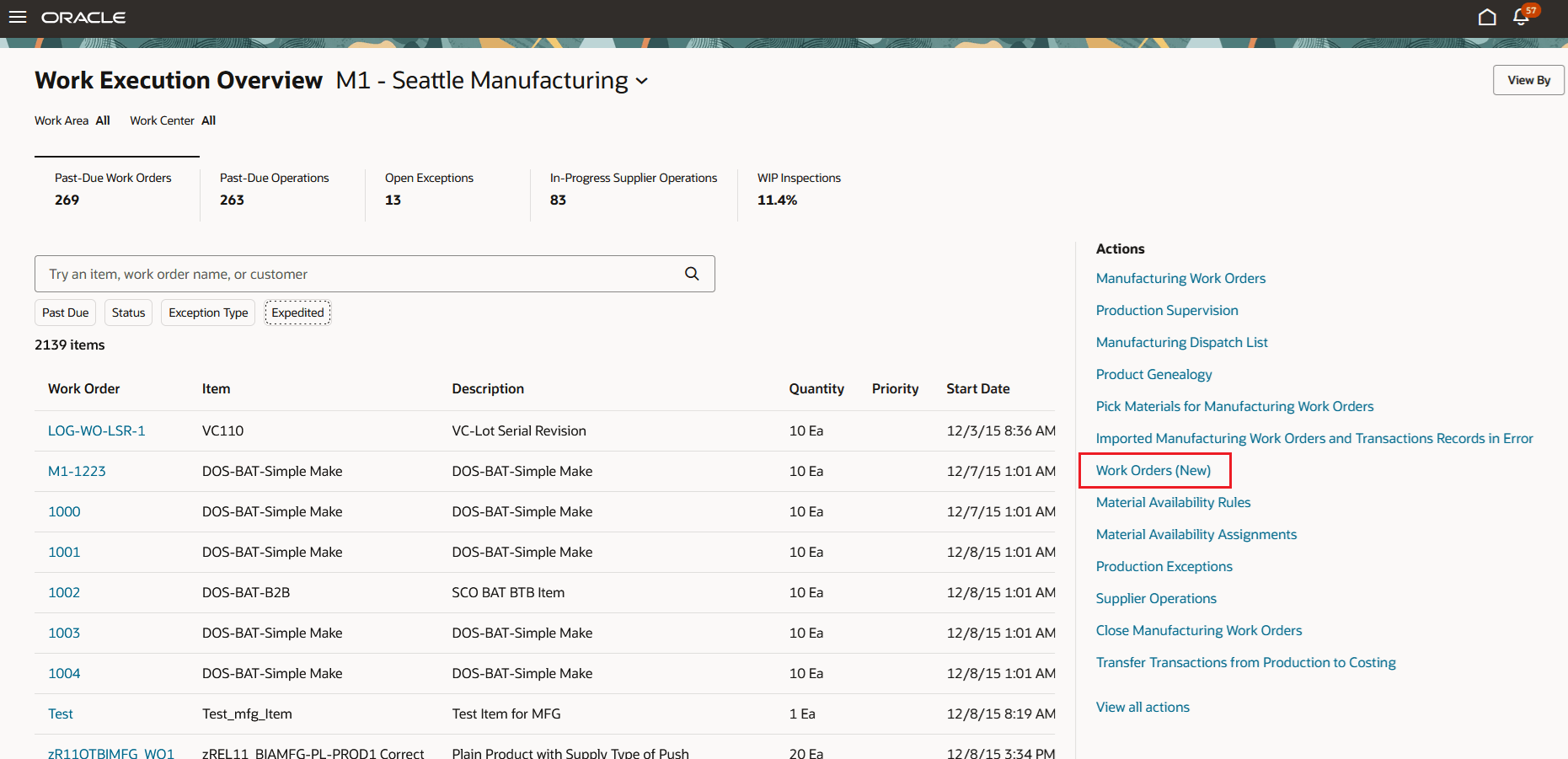

Work Execution Landing page

Manage Work Orders - Search

Manage Work Orders - Additional Search Filters

Manage Work Orders - Mass Actions

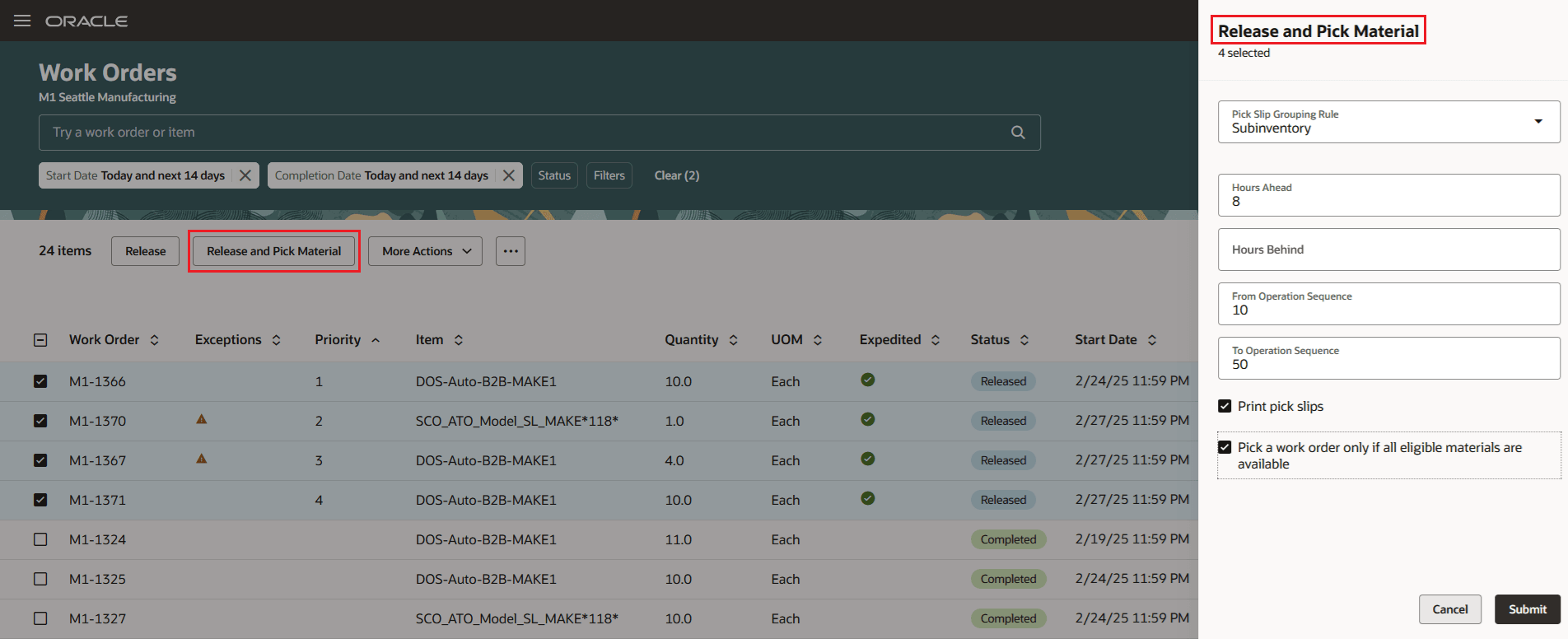

Manage Work Orders - Release and Pick Materials

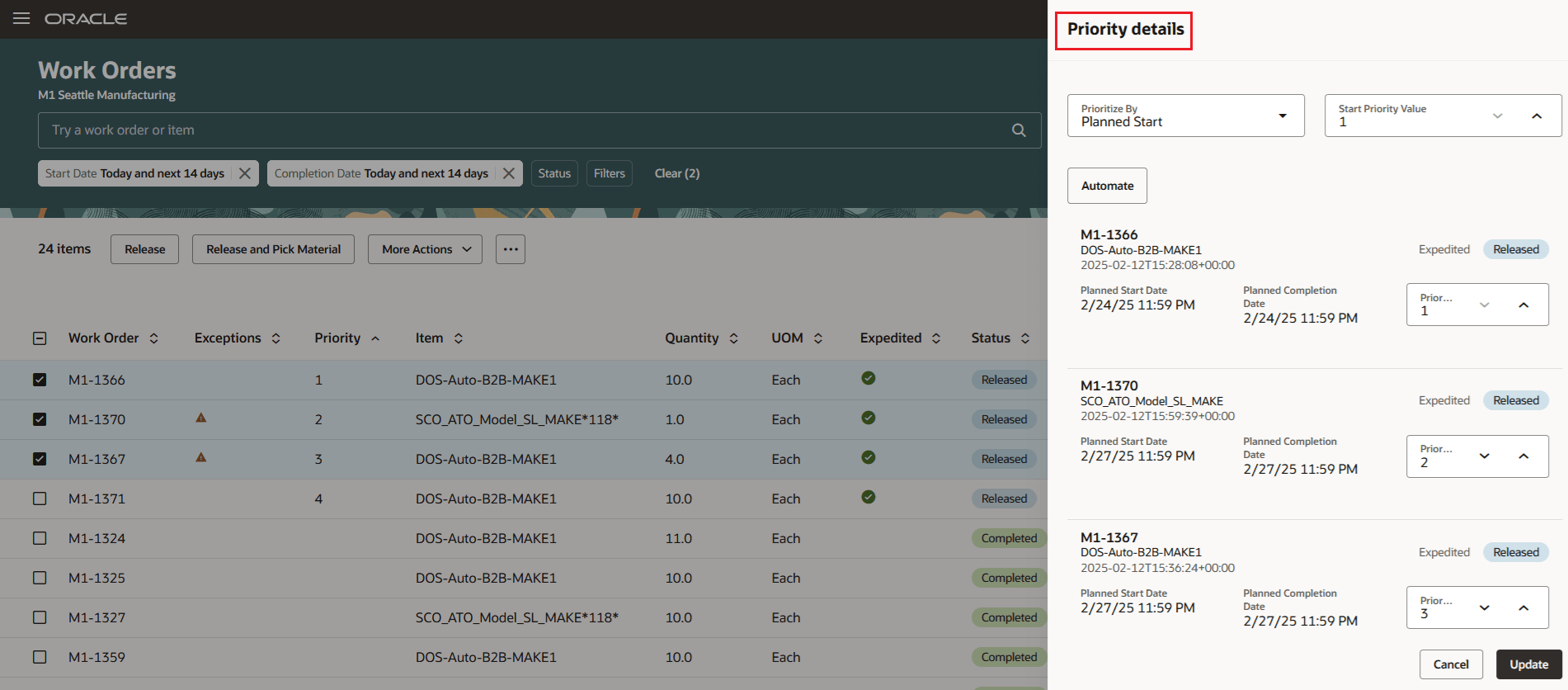

Manage Work Orders - Priority Details

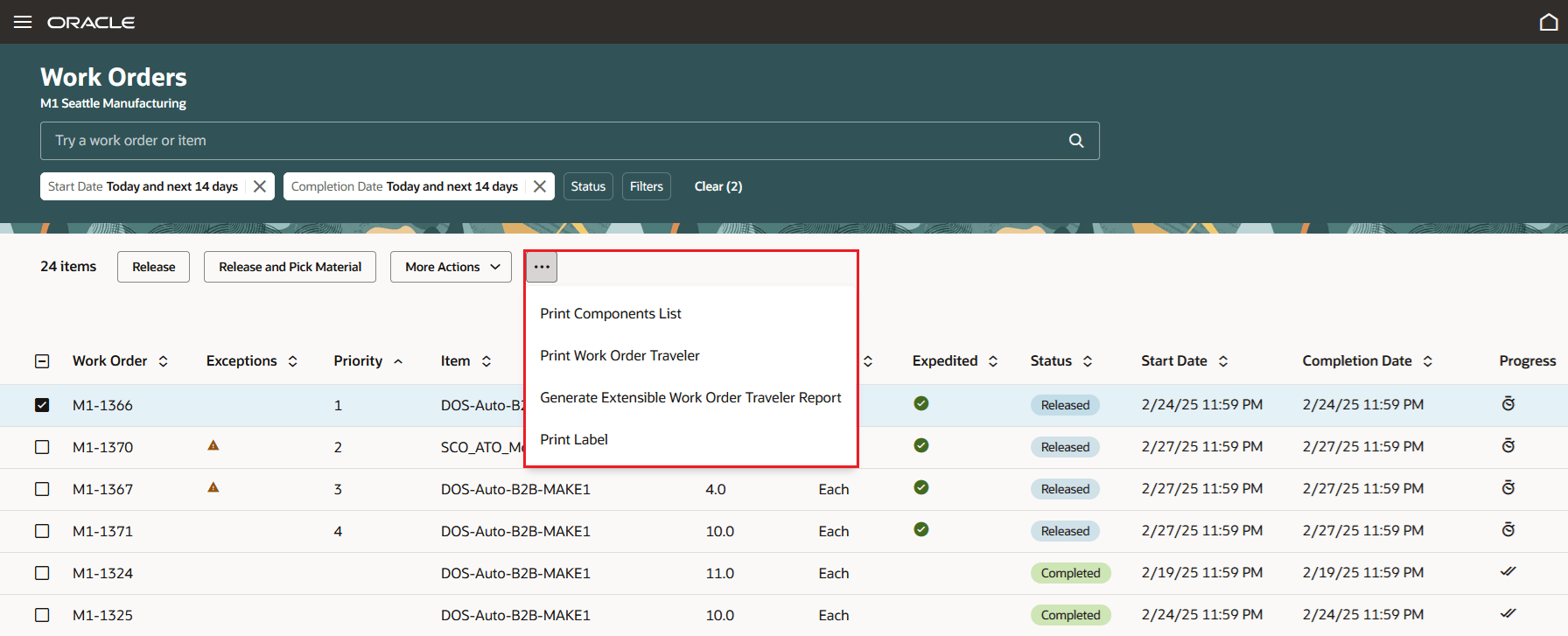

Manage Work Orders - Print Actions

The Redwood user experience simplifies work order management. Increased productivity and progress tracking capabilities help with the various administrative aspects of manufacturing.

Here's the demo of these capabilities:

Steps to Enable

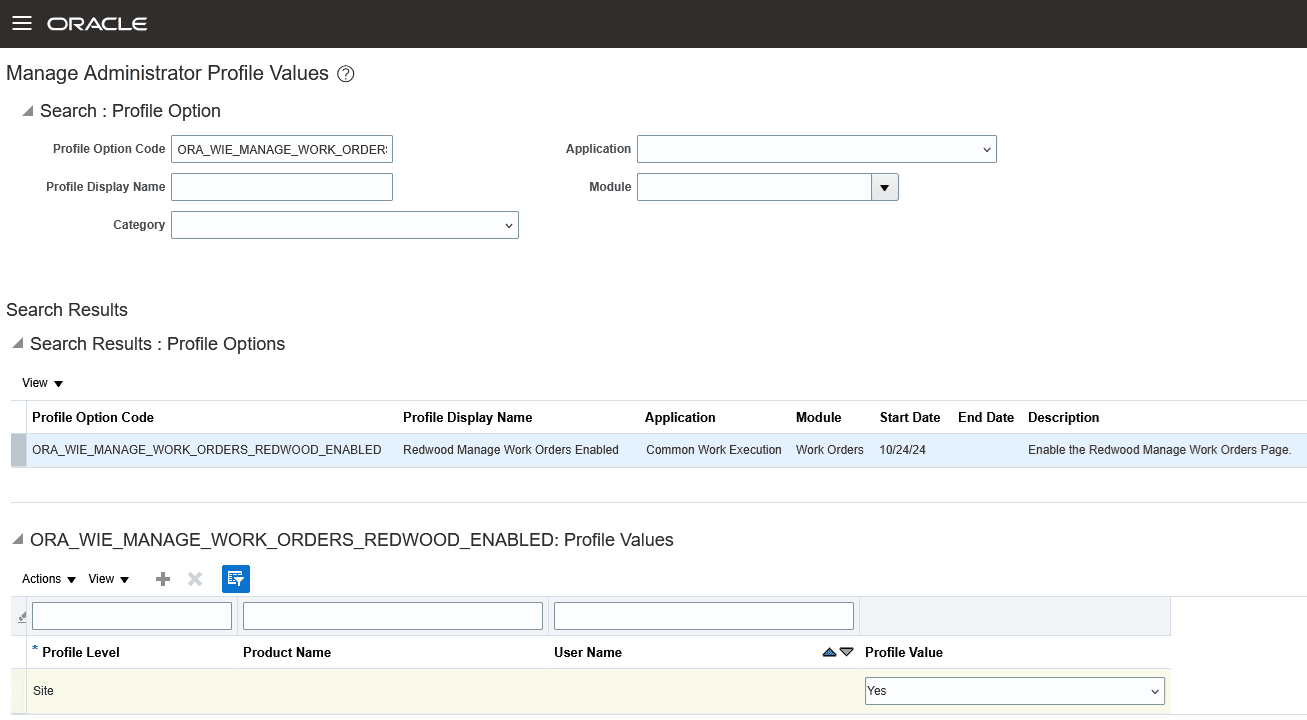

To get an end-to-end Redwood experience, it's recommended that you turn on the profiles for the Manage Work Orders feature. Follow these steps to enable or disable the feature:

- In the Setup and Maintenance work area, search for the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIE_MANAGE_WORK_ORDERS_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is N.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

Profile Option for Accessing Manage Work Orders Using the Redwood User Experience

Tips And Considerations

- You can continue to use the existing REST services and File-Based Data Import for discrete and process manufacturing work orders. You can then search and take action on the work orders using the Work Orders page in the Redwood user experience, based on the user privileges.

- You can't drill down on the Work Order page to view or edit the details of a work order at this time.

- You can't select all work orders in the search results to apply actions at this time.

-

Before using this feature, make sure that you submit the scheduled process to create the index definition and perform initial ingest to OSCS. You can also submit the process if the index is already created and you want to ingest it again. This clears the index and reingests the data.

-

Program name: ESS job to create index definition and perform initial ingest to OSCS

-

Index Name to Reingest: fa-scm-mfg-work-order

-

-

Work orders can be created or executed using the user interface, REST APIs, or File-Based Data Import (FBDI). Not all modes of work order creation or update trigger the near real-time ingest of the index. You can update the index by running a separate scheduled process. This scheduled process doesn't clear the index, but only updates the existing index with the changes from these transactions. Oracle recommends that you ingest these updates at least once a day, or as often as your business requires, to keep the index current.

-

Program Name to Run Bulk Ingest: ESS job to run Bulk ingest to OSCS

-

Index Name to Reingest: MFG_WO_BULK_INGEST

-

Key Resources

- Watch the Search and Perform Mass Actions for Work Orders Using a New User Experience demo.

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

Manufacturing Privileges:

- Manage Work Order Headers (WIP_MANAGE_WORK_ORDER_HEADERS_PRIV)

- Manage Work Orders by Service (WIP_UPDATE_WORK_ORDERS_SERVICE_PRIV)

- Print Work Order Traveler (WIP_PRINT_WORK_ORDER_TRAVELER_PRIV)

- Print Components List (WIP_PRINT_COMPONENTS_LIST_PRIV)

- Print Product Labels (INV_PRINT_LABEL_REQUESTS_PRIV)

- Pick Components for Work Orders (WIP_MANAGE_WORK_ORDER_COMPONENT_PICKING_PRIV)

- Print Movement Request Pick Slip Report (INV_PRINT_MOVEMENT_REQUEST_PICK_SLIP_REPORT_PRIV)

- Reserve Materials Automatically for Work Orders (WIP_MANAGE_WORK_ORDER_MATERIAL_RESERVATIONS_PRIV)

- View Work Orders (WIP_VIEW_WORK_ORDERS_PRIV)

- View Production Exceptions (WIP_VIEW_PRODUCTION_EXCEPTIONS_PRIV)

HCM Privileges:

- Access HCM Common Components (HRC_ACCESS_HCM_COMMON_COMPONENTS_PRIV)

- Use REST Service - Guided Journey Responses (ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

- Use REST Service - Guided Journeys Read Only (ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

These privileges were available prior to this update.

In addition to the preceding privileges, you should have the following data security configured for your role and user:

- Manufacturing plant data security: Set the security context value for the manufacturing plant to the manufacturing organization.

- Item class data security: Set the View Item Basic action to allowed.