Redwood: Plan Production Targets for a Flow Manufacturing Production Line

Oracle Manufacturing enables you to define a rate-based production line and execute supply orders, referred to as flow schedules, on that production line. This update includes planning support for enterprises that have rate-based manufacturing production lines. For example, you may have defined a production line that can make 10 pieces of various products on the production line per hour. Oracle Supply Planning honors this definition, including the production calendar of the organization where this production line exists, to generate the planned production requirements. These requirements are generated based on the demand for products built on this production line and the production capacity of this line.

If you’re running in an unconstrained mode, exceptions are generated when the planned production exceeds the production capacity of the production line.

If you’re running in a constrained mode, the system evaluates the ability to support the demand on alternative production lines if demand exceeds capacity. Depending on the constrained planning mode, when demand exceeds capacity, some planned production may be scheduled late, or the production line may be overloaded to enforce the demand due date.

You can release the planned production to Manufacturing. Manufacturing will recognize the requirements as flow schedules. After the release of planned production from Supply Planning, the system refines the flow schedules using intraday sequencing to ensure alignment to takt time goals.

Flow production lines have a defined constant capacity based on a line rate or its reciprocal, a takt time per unit of production. The product mix that can be manufactured on the flow production line is not only dependent on the demand but must also be producible at a near-constant takt time considering other constraints on the line.

Planners would like to slot daily production on the production line based on demand signals from the customers. They also need to get insights on material requirements for components and subassemblies for long-term supplier negotiation and other business reasons, even if the day-to-day replenishment is managed using Kanban replenishment. Finally, planners want to anticipate overcapacity situations.

To start with, you need to understand some terms and how they're calculated.

Production Line

- A production line is specified by its name, description, and code. A production line is modeled as a resource in planning.

- Line rate is maintained in the production line definition and represents the number of units produced by the line in 1 hour.

- For example, if the line rate is 10, then the production line produces a product or a mix of products at the rate of 10 units per hour.

- Takt time is the reciprocal of the line rate.

- Line rate doesn’t have to be a whole number. For example, 1.5 or 0.5 are valid line rates.

- Line rate UOM and Capacity UOM are Each per hour.

- Number of operations (Number of workstations) is an attribute of the line.

- Line operation sequence indicates the sequence of operations and is displayed in the Operations table.

- Line capacity is calculated based on the line rate and the total daily working hours of the organization based on the organization’s Manufacturing calendar.

Work Definition

The work definition header for the supply that’s produced on a flow production line (called a flow schedule) has an additional attribute named Production Line.

Line Operation Sequence is an attribute on the operation of a work definition brought over from the Production Line, and it indicates the stage at which the material is consumed on a Production Line.

Only the last operation of a flow schedule has an end date, which becomes the due date in planning (called the “completion date” in Manufacturing).

Flow Schedule

A flow schedule in Manufacturing doesn’t have a start date on any operation. Planning determines the start time based on the due date, number of steps (operations), and the takt time.

Example

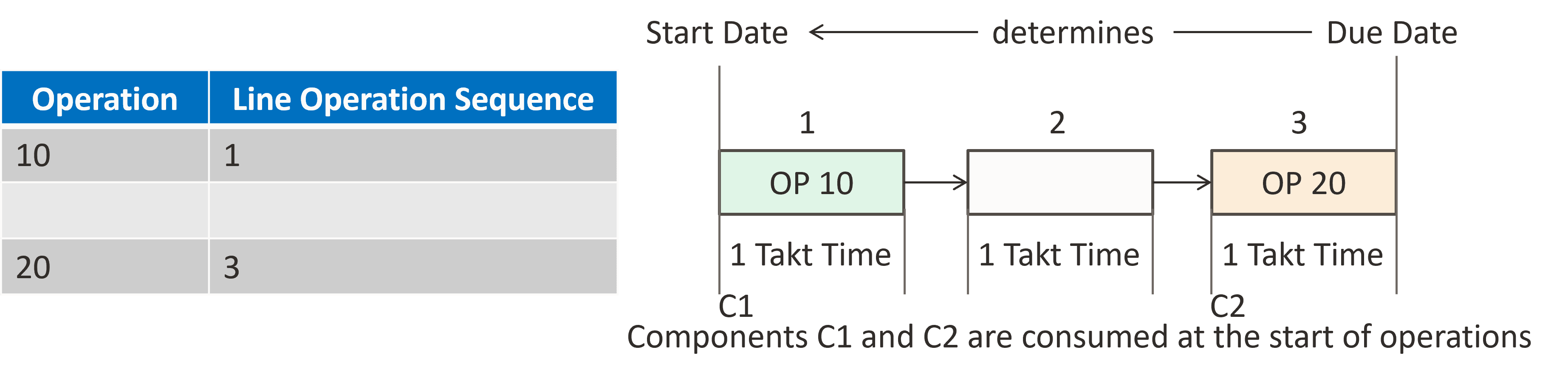

The line has 3 steps. A specific work definition on the line uses only 2 steps.

In this work definition, the Line Operation Sequence is 1 for Operation 10 and the Line Operation Sequence is 3 for Operation 20. This means that the materials are consumed in Operations 10 and 20, respectively.

Flow Schedule Work Definition with Line Operation Sequence

If a user doesn’t specify the line operation sequence for all operations, then the blank operation in the preceding example will be considered as the last operation.

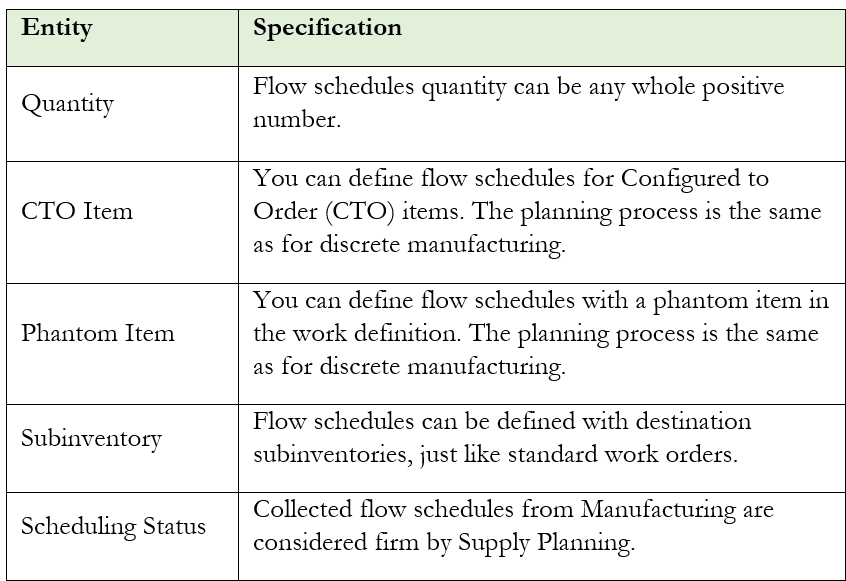

Flow Schedule Specifications

The following table lists some of the significant entities of a flow schedule.

Aggregation of Flow Schedules

Collected flow schedules for an item-org that have the same work definition in each day (dock date) are aggregated by quantity for planning purposes.

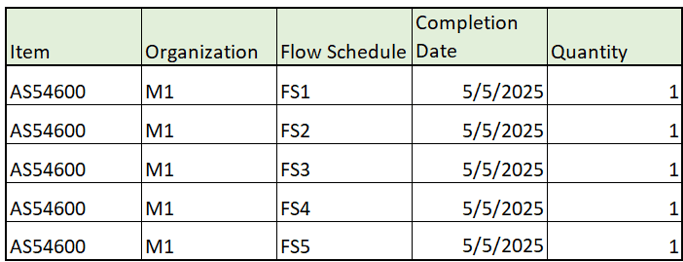

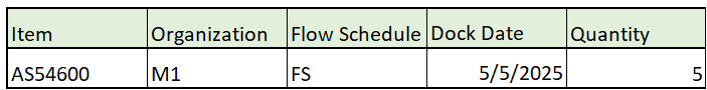

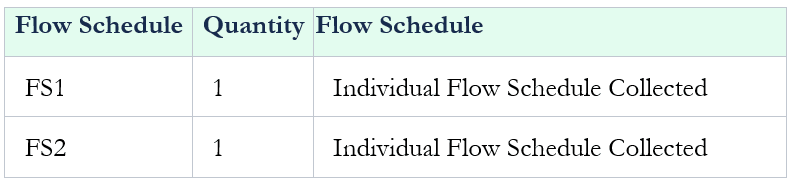

Example – There are 5 flow schedules in Manufacturing with the same item, organization, and completion date.

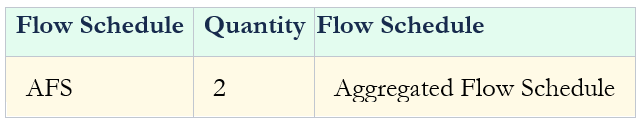

Planning aggregates the flow schedules for the same item, organization, and same completion date. The following table shows the aggregated flow schedule for the flow schedules in the preceding table:

The complete list of aggregation criteria is as follows:

- Item

- Work Definition

- Organization

- Subinventory

- Status (Released)

- Completion Date (End Date)

Planning uses a unique ID as the order number for the aggregated flow schedule.

Flow Schedules Planning

The following steps summarize the planning process for flow schedules:

- Plan day-level flow schedules as firm.

- Create net new supplies (planned flow schedules).

- Create line capacity requirements.

- Create planned order demands for components.

Duration Calculation

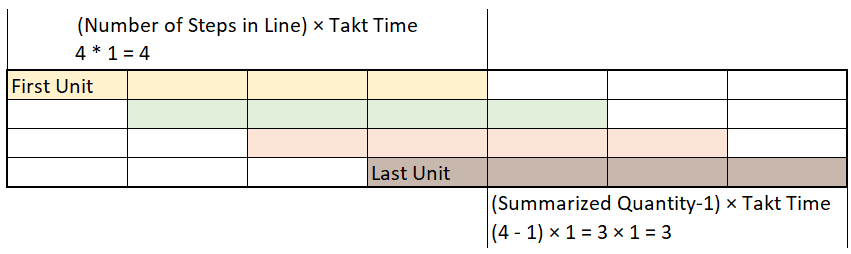

The following example shows how the production line duration is calculated.

In this example, there are 4 production slots per day and 4 steps in the flow line. The first unit exits the line after 1 production slot. The last unit exits the line after 4 production slots.

Planned Order Duration Calculation

Takt Time = 1 Hour

Duration = (Number of Steps in Line) x Takt Time + (Summarized Quantity-1) x Takt Time

Duration = 4 + 3 = 7 Hours

Constrained planning will apply order modifiers and lead-time lot size if applicable to the summarized (aggregated) flow schedule quantity.

Planning

Supply planning creates make planned orders for the assembly based on the total demand and the flow schedule supplies. Additionally, supply planning creates planned order demand for all components in the assembly’s item structure.

Example

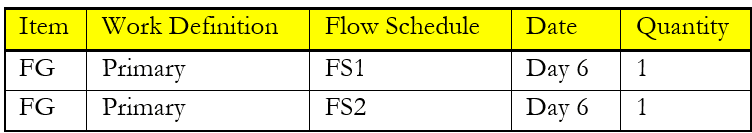

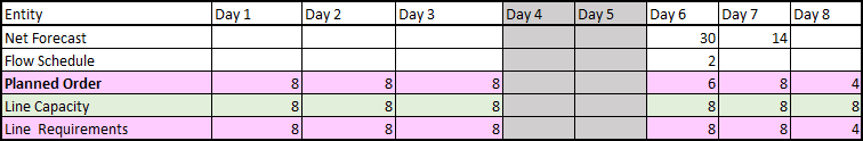

FS1 and FS2 are the flow schedules.

AFS is the aggregated flow schedule.

- Line Rate = 1 Per Hour

- Takt Time = 1 / 1 = 1 Hour

- There are 8 working hours/day, and the line rate = 1 hour, so the daily capacity is 8 eaches.

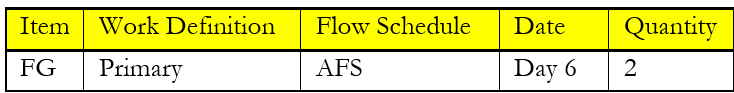

Flow Schedule Planning – Unconstrained Supply Planning

According to the preceding table, unconstrained supply planning overloads production by 22 units on Day 6 and 6 units on Day 7 to fulfill forecast requirements on schedule. However, when these planned orders for 22 and 6 units are released to manufacturing, they are disaggregated and rescheduled again. See the Release section later in this document to understand the behavior during release.

The Resource Availability in the preceding table is the line resource capacity per day, in eaches. The Resource Requirements in the preceding table are the line resource requirements, in eaches.

Flow Schedule Planning – Constrained Supply Planning

According to the preceding table, constrained supply planning prevents production overload but incurs a 1-day delay in fulfilling 4 units of Day 7 demand, which is satisfied on Day 8.

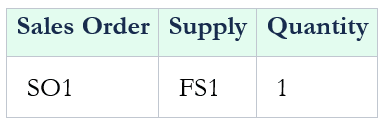

Flow Schedule and Reservations

Planning process (Collections) replaces the individual flow schedules from the source with their corresponding aggregated flow schedules.

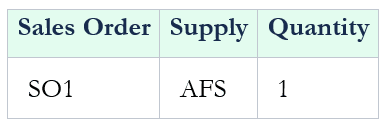

Example

Reservations can be created only through a Back-to-Back process. Manual reservations aren’t supported.

In this example, there are 2 flow schedules:

The flow schedules are aggregated, and the aggregated flow schedule is shown in the following table:

Collected reservation from source:

Planning replaces the individual flow schedule FS1 with the aggregated flow schedule AFS:

Release

Planned orders created by Supply Planning can be released to Manufacturing through Oracle Supply Chain Orchestration.

The Action for these planned orders is defaulted to Release and can’t be modified (Action: Release).

Planned Order Disaggregation by Manufacturing

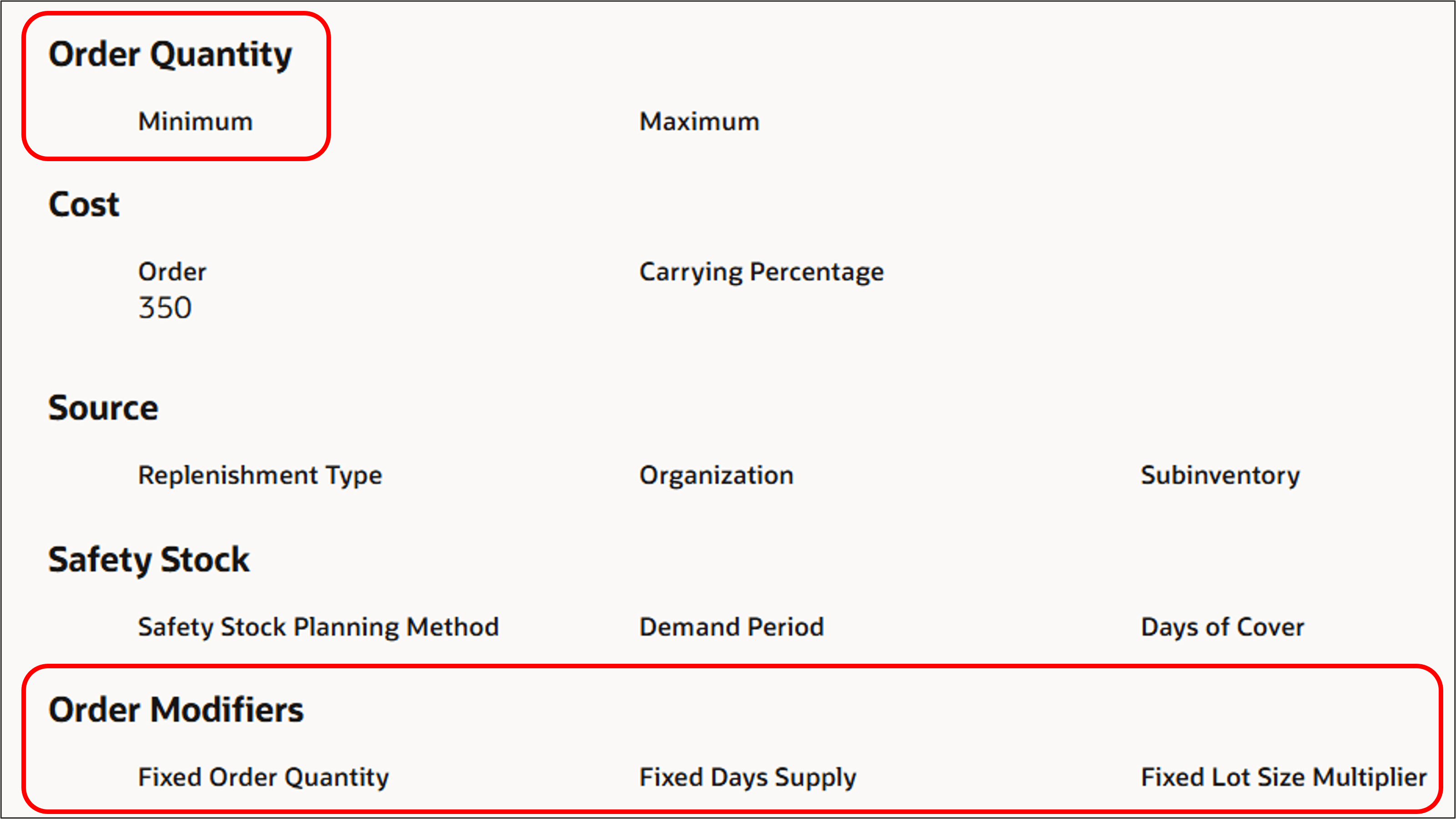

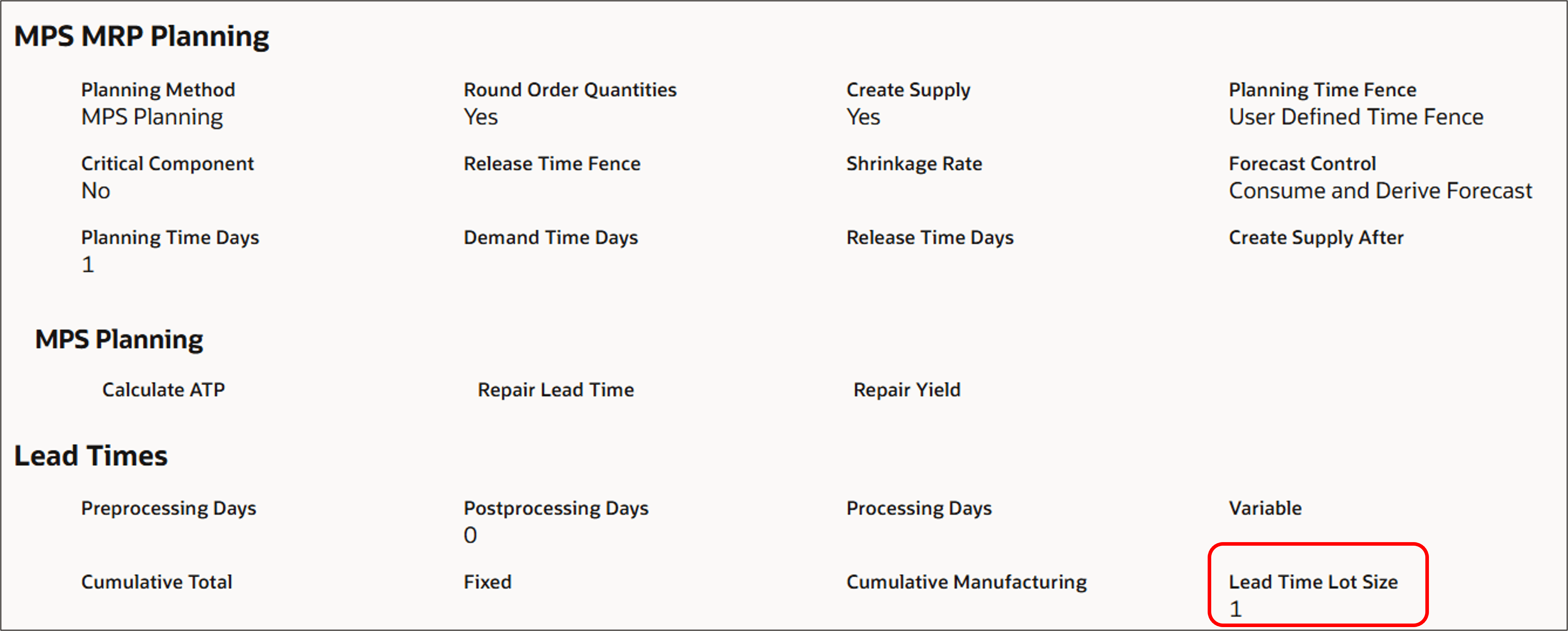

Typically, flow schedules are executed with a unit quantity except in a few special circumstances. But planned orders are always created for the net requirement in the planning bucket based on the item’s order modifiers. Hence, when the planned order for a flow schedule is released to Manufacturing, the item’s Lead Time Lot Size attribute is used to decide whether to disaggregate to unit quantity.

If the value of Lead Time Lot Size is null or 1 (which is the default value), then individual flow schedules are created for quantity of 1 each in Manufacturing.

If the value of Lead Time Lot Size is greater than 1, then the planned order quantity is retained as is and the flow schedule is created for the quantity of the planned order, subject to the line rate. If it exceeds the line rate, it may be split and moved to earlier dates to fit the available line capacity.

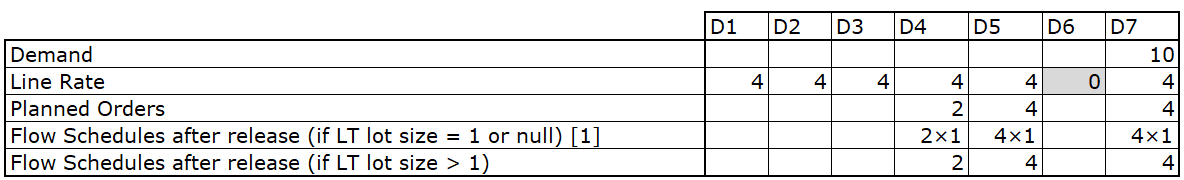

Example 1

Minimum Order Quantity = 2 Processing Lead Time = 1 Day

Table Showing Disaggregation of Planned Orders for Example 1

[1] - In this case the flow schedules are created in Manufacturing for a quantity of 1 each.

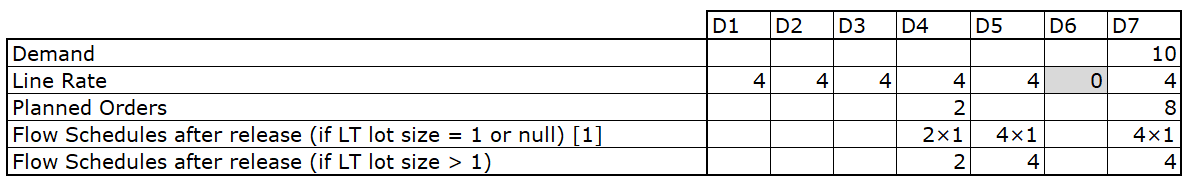

Example 2

Minimum Order Quantity = 2 Processing Lead Time = 2 Days

Table Showing Disaggregation of Planned Orders for Example 2

[1] - In this case the flow schedules are created in Manufacturing for a quantity of 1 each.

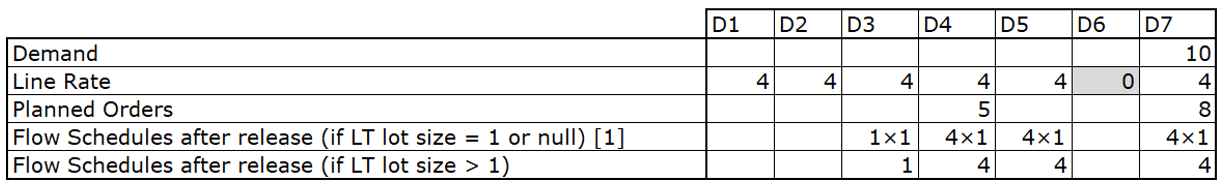

Example 3

Minimum Order Quantity = 5 Processing Lead Time = 2 Days

Table Showing Disaggregation of Planned Orders for Example 3

[1] – In this case the flow schedules are created in Manufacturing for a quantity of 1 each.

For more details about rescheduling logic in Manufacturing, see the What’s New documentation of this feature in Manufacturing.

In addition, when the item doesn’t have any order modifiers (that is, all of its 4 modifier attributes, Fixed Order Quantity, Fixed Lot Size Multiplier, Minimum Order Quantity, and Fixed Days of Supply are blank) then the flow schedules are also created for a unit quantity. The 4 modifier attributes mentioned here can be set up in the Planning section of the Product Management application.

Order Modifier Setup

Navigation: Product Management > Planning > General Planning

Lead Time Lot Size Setup

Navigation: Product Management > Planning > MPS MRP Planning > Lead Times

Back-to-Back flow schedules are created automatically with a quantity of 1.

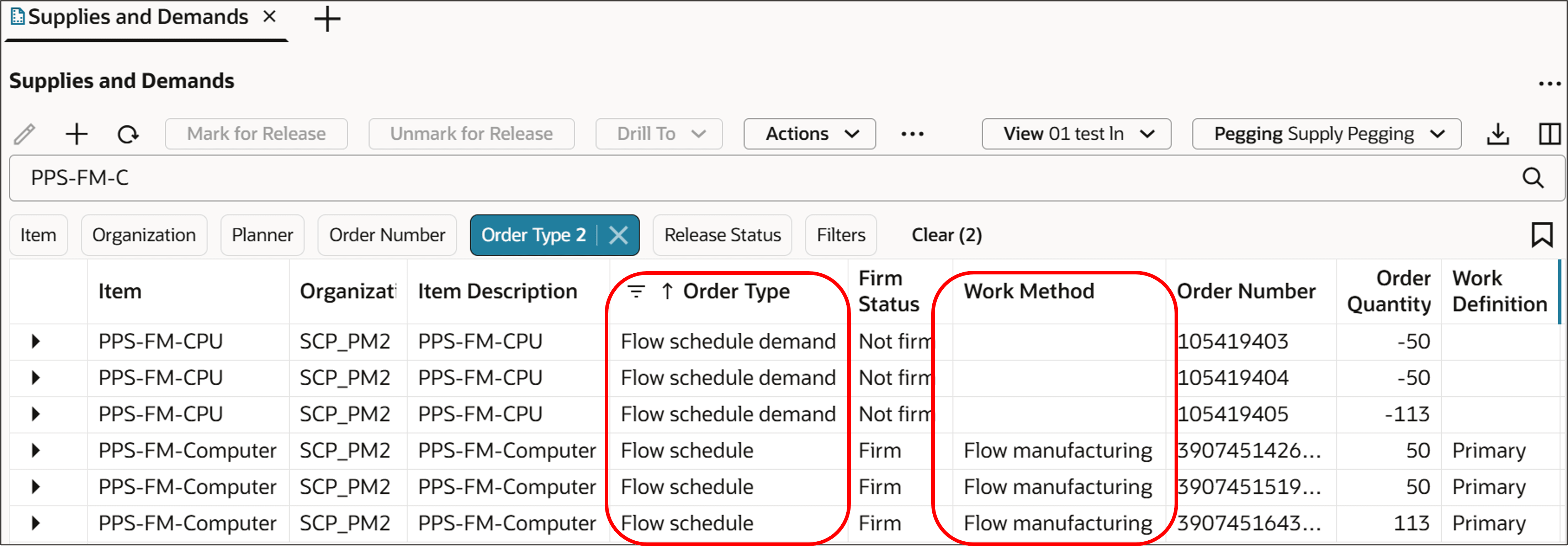

Supplies and Demands

Planning for flow manufacturing is supported only for customers who have opted into the Redwood user experience available with the 25B release. Some of the following capabilities are not available in the classic (non-Redwood) user experience.

There are two new order types in the Supplies and Demands table named Flow Schedule and Flow schedule demand.

In addition, there’s a new column named Work Method, which is displayed by default. As mentioned earlier, the new work method is called Flow manufacturing. The Work Method column is also available in Plan Inputs.

Supplies and Demands Table

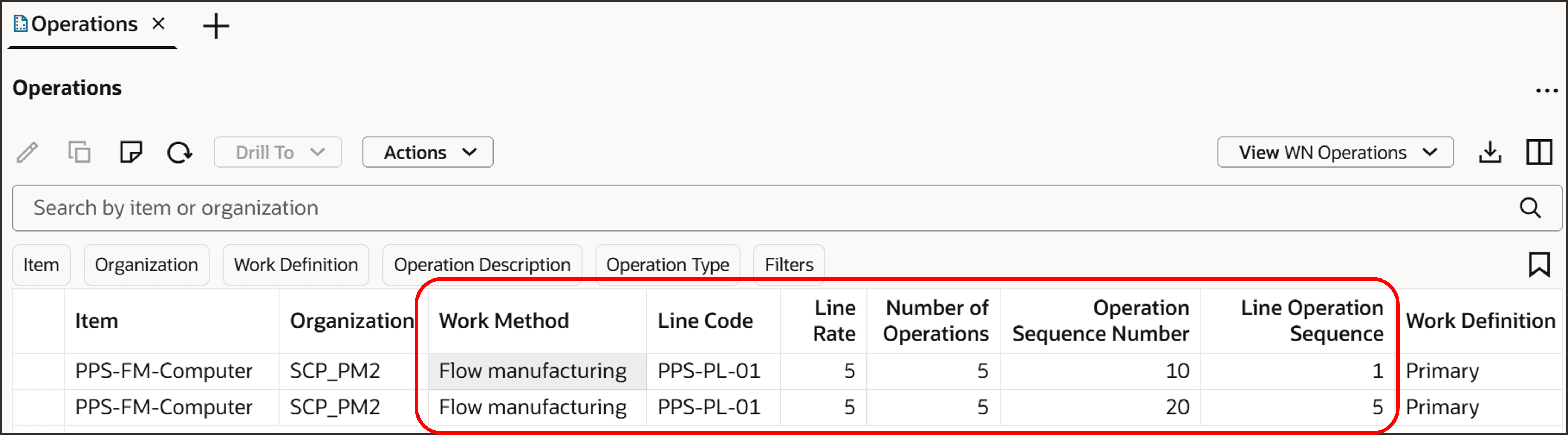

Work Definition and Operation Resources

There are 5 new columns in the Operations table:

- Line Code

- Line Rate

- Number of Operations

- Operation Sequence Number

- Line Operation Sequence

Operations Table

These columns are also available in Plan Inputs.

Routings table was renamed to Operations table.

Resources

The production line is defined independent of the work area and work center. It's only in the context of a work definition that the production line is associated at the work definition header level to apply to all operations (and their work centers).

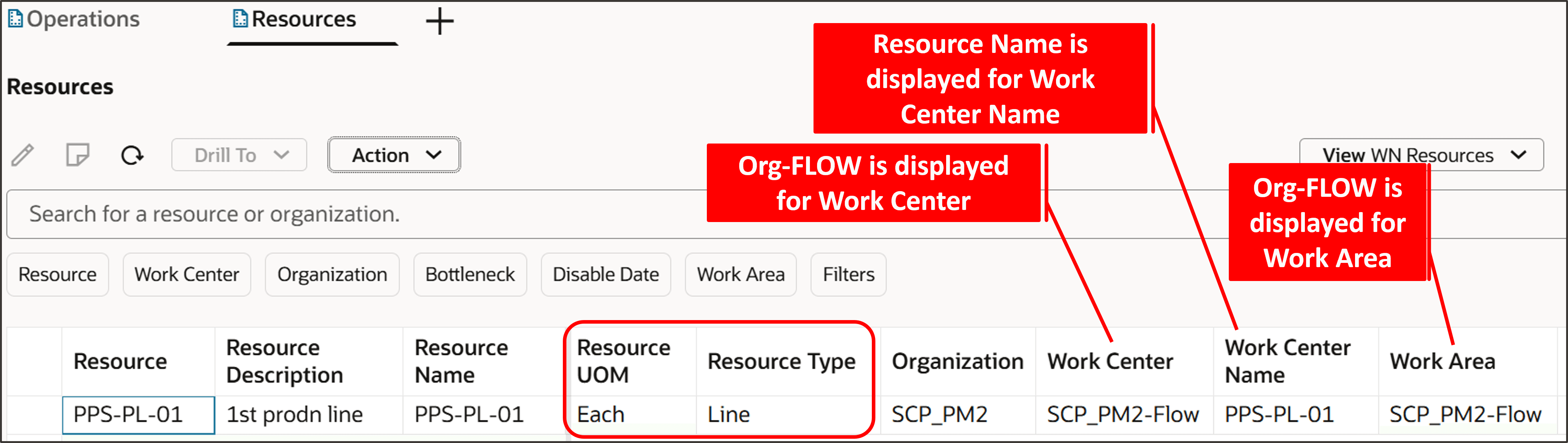

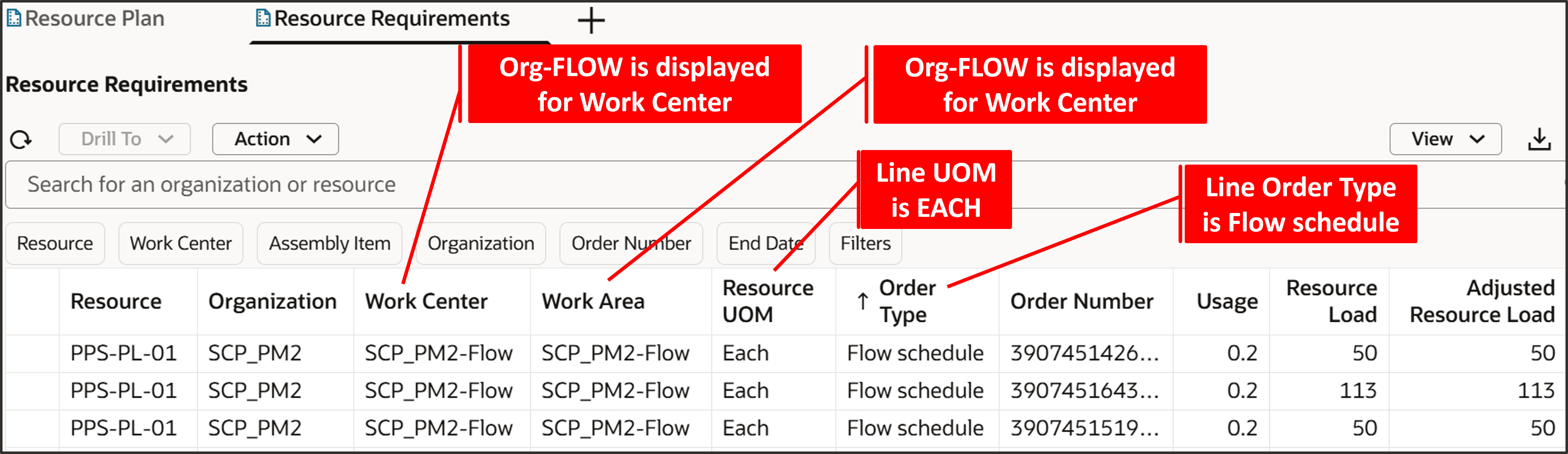

Since there are no work areas and work centers associated with production lines, the work area and the work center are displayed as Org-Flow for the line resources, as shown in the following screenshot and table.

Resources Table

The following table summarizes the specific column values and new columns because of modeling the production line as a resource:

Flow Manufacturing Impacts on Resource Columns

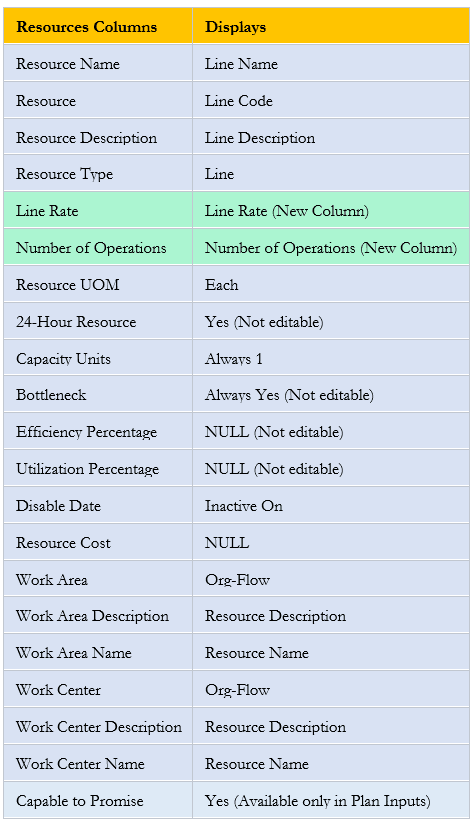

Resource Plan

In the Resource Plan table, the column Resource also includes the line resources.

For flow lines that are displayed as resources in pivot tables, the resource availability and resource requirements measures are not hours of usage but are instead units of production. The resource availability measure, though it’s editable, currently doesn’t use those edits in a replan as a change to the line rate. Instead, the line rate is always based on what’s specified in the source system.

Resources Plan Table

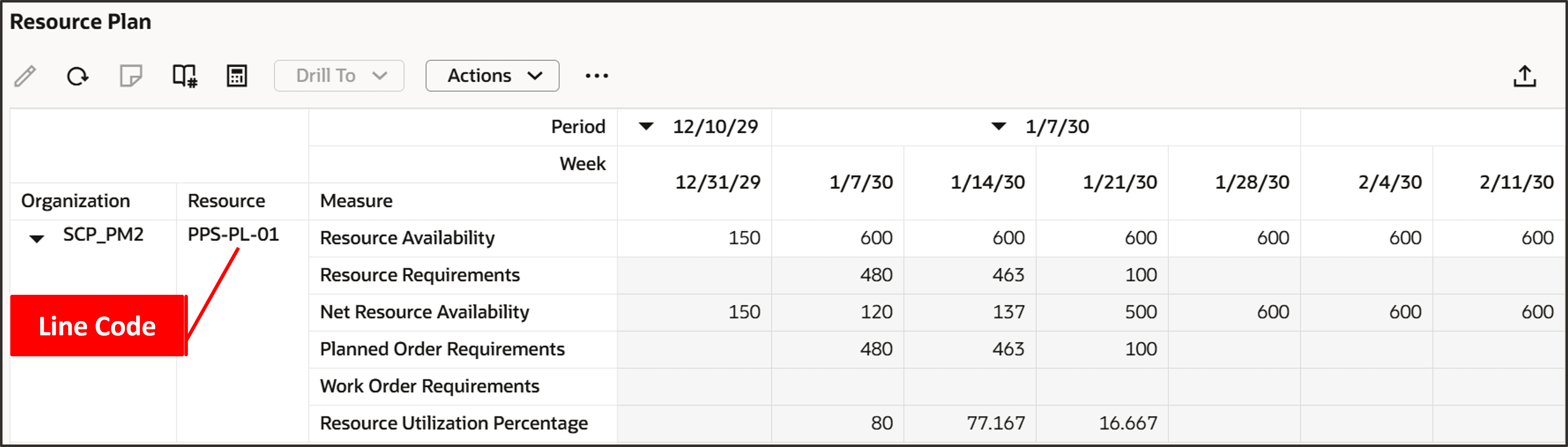

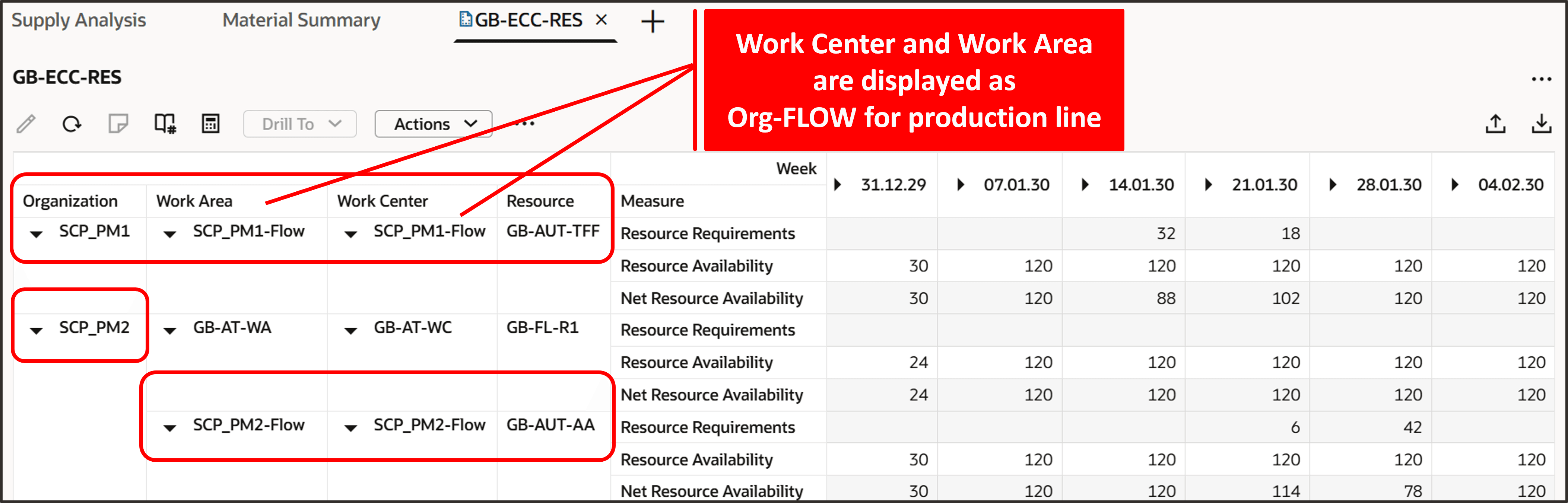

Configured Resource Plan

Similar to the Resource Plan, the work area and the work center are also displayed as Org-Flow for the line resources, as shown in the following image.

Configured Resource Plan Table

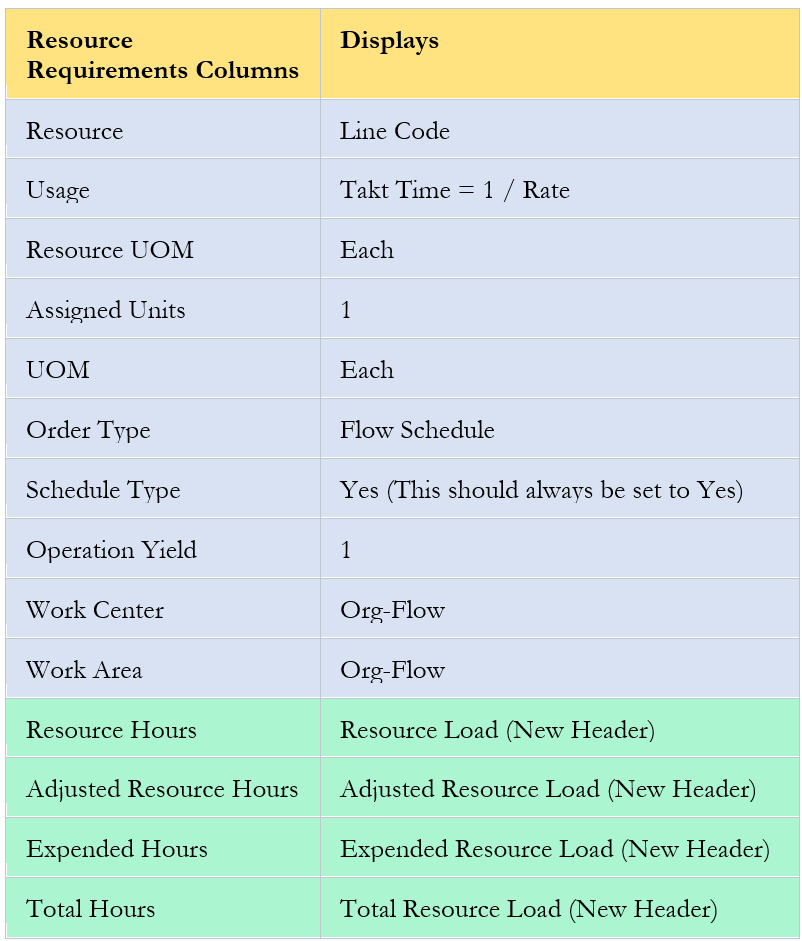

Resource Requirements

In the Resource Requirements, the work area and the work center are also displayed as Org-Flow for the line resources, as shown in the following screenshot and table.

Resource Requirements Table

The following table summarizes the specific column values and column header changes because of modeling the production line as a resource:

Flow Manufacturing Impacts on Resource Requirements Columns

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- Flow routing operation resources aren’t collected in this release.

- Planning considers component substitution when creating planned orders with a Work Method of Flow manufacturing. But substitute components can’t be released to the execution system.

- There’s no explicit production line cost in Manufacturing. The related cost are the resources’ costs assigned to the production line.

- You can determine the desired takt time of the production line outside of the system, based on the average daily demand and the working hours of the production line. Then determine the line rate (inverse of takt time) to store in the system.

- Back-to-Back flow schedules are created automatically for quantity of 1.

- There’s no shrinkage in flow manufacturing. Planning ignores the shrinkage factor even if it has been set up.

- Manual reservations aren’t supported.

- Minimum Transfer Quantity (MTQ) isn’t supported for flow schedules.

- Supersession isn’t supported for items having flow schedules in the initial phase.

- Flow schedules aren’t supported in contract manufacturing organizations.

- Project-Driven Supply Chain (PDSC) isn’t supported for items having flow schedules in the initial phase.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supply Chain Planner (ORA_MSC_SUPPLY_CHAIN_PLANNER_JOB)

- Materials Planner (ORA_MSC_MATERIALS_PLANNER_JOB)

These privileges were available prior to this update.