Redwood: Perform Cycle Counts Using Locators

Redwood: Perform Cycle Counts Using Locators

Maintaining precise on-hand inventory quantities is crucial for effective inventory management, sustaining high service standards, and efficient production planning. Cycle counting is used to maintain accuracy of inventory records by reconciling discrepancies between the recorded and actual on-hand stock. This process allows for targeted counts based on item rankings or specific categories, providing control over which items are counted irrespective of their warehouse location.

However, there are instances when a more systematic cycle count approach is required. This approach would allow warehouse operators to count a predetermined number of locations regardless of the goods stored there. You can now address this need by creating location-based cycle counts by specifying the frequency of counts for each location annually.

You can also include or exclude specific locators, and tailor the counting process to your operational needs. This allows for greater flexibility in ABC-based and category-based cycle counts.

Cycle Count now supports both item-based and location-based counting. You can exclude specific locators such as consigned or nonoperational ones to ensure accurate and efficient inventory management. This also ensures that restricted or irrelevant areas are not included in the count, keeping the focus on active and operational inventory locations.

Cycle Counting Approaches

You can choose between two counting modes:

- Create by Item

- Create by Location

Create Cycle Count

Create by Item: It focuses on counting items and allows users to exclude specific locators during the count sequence generation.

Count Location

By default, all locators are included. Users can specify which locators to exclude. Item selection is based on existing criteria such as ABC class or Item Category.

Locators Selection

Create by Location: The focus is on counting by locator, regardless of items stored. This is useful in scenarios with a low number of items or when targeting specific locations for counting.

When defining a new cycle count by location, follow these steps:

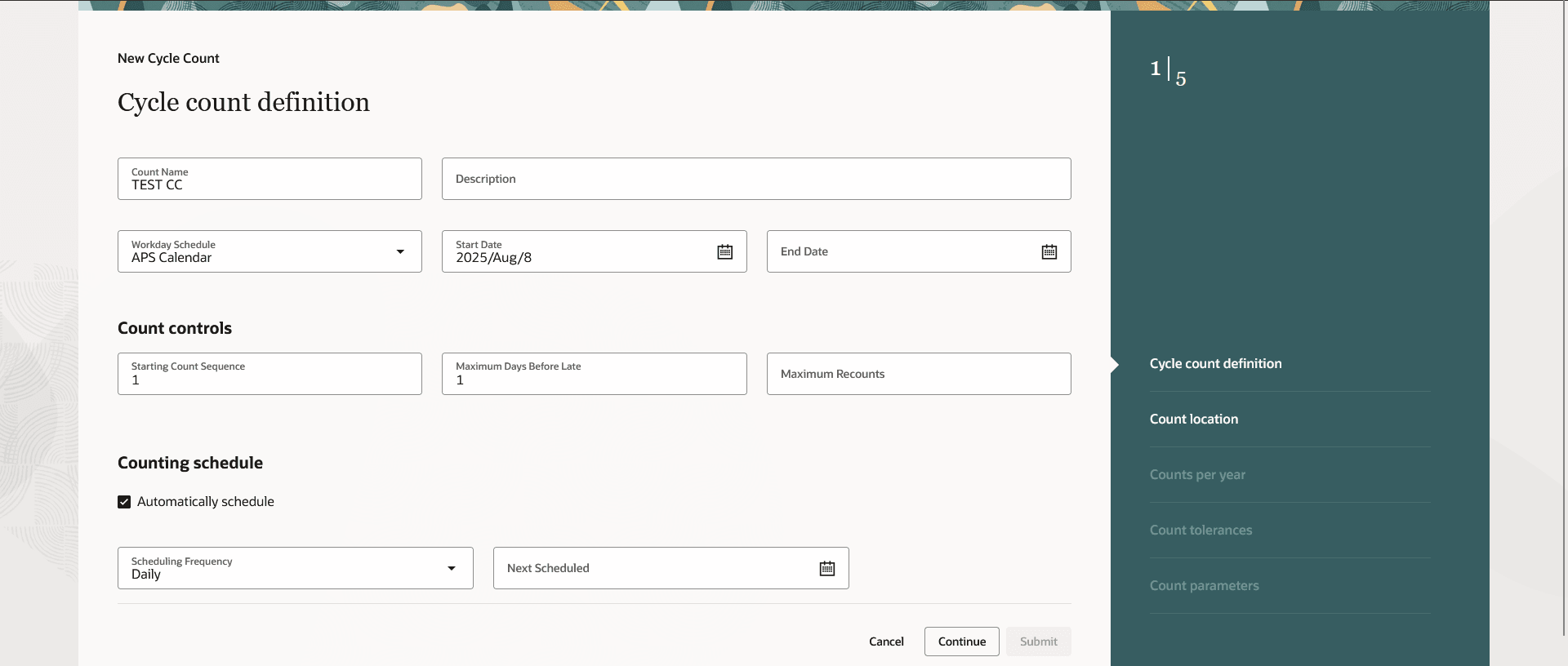

- Cycle count definition: This step is similar to the Create by Item process.

Here, you define key details such as Cycle Count Name, Count controls, and Counting schedule.

- In the Create by Location flow, you can set the Scheduling frequency to either Daily or Weekly.

Cycle Count Definition

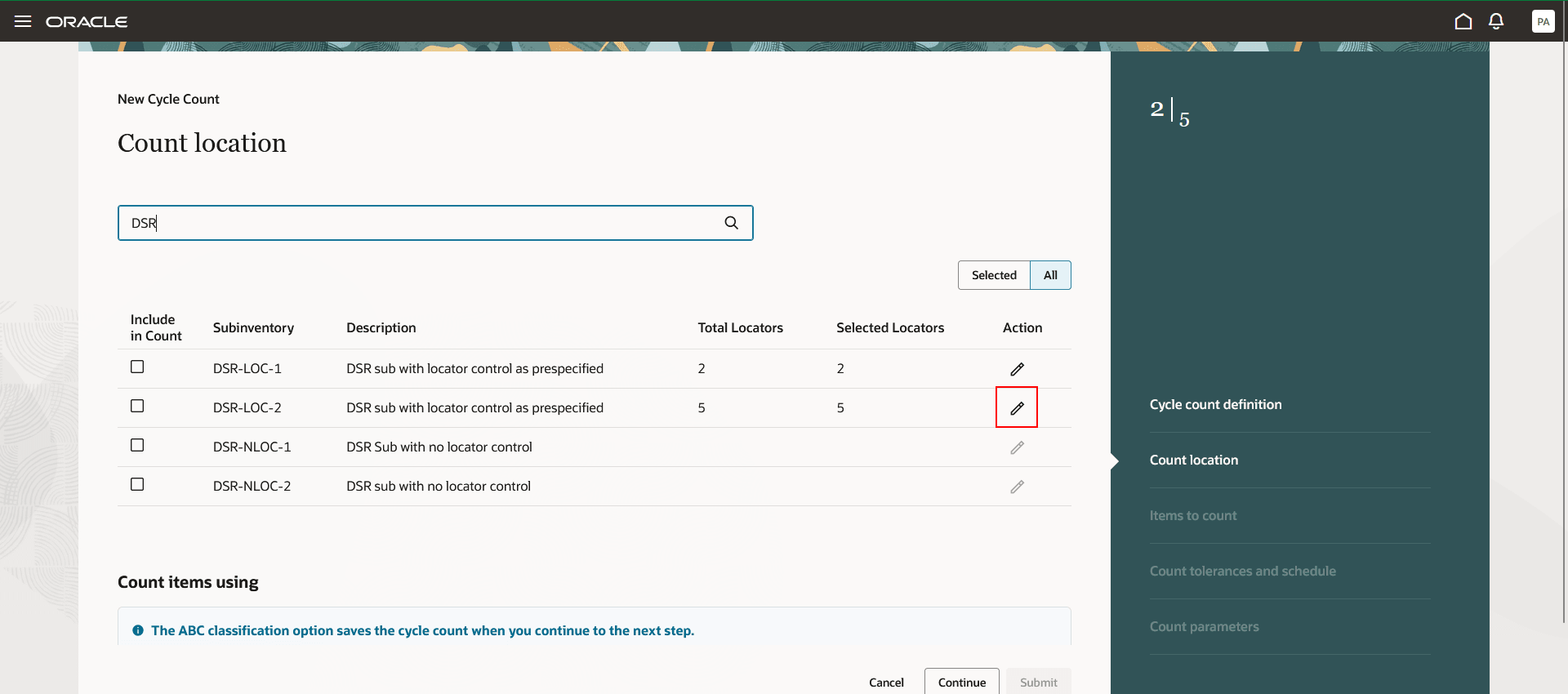

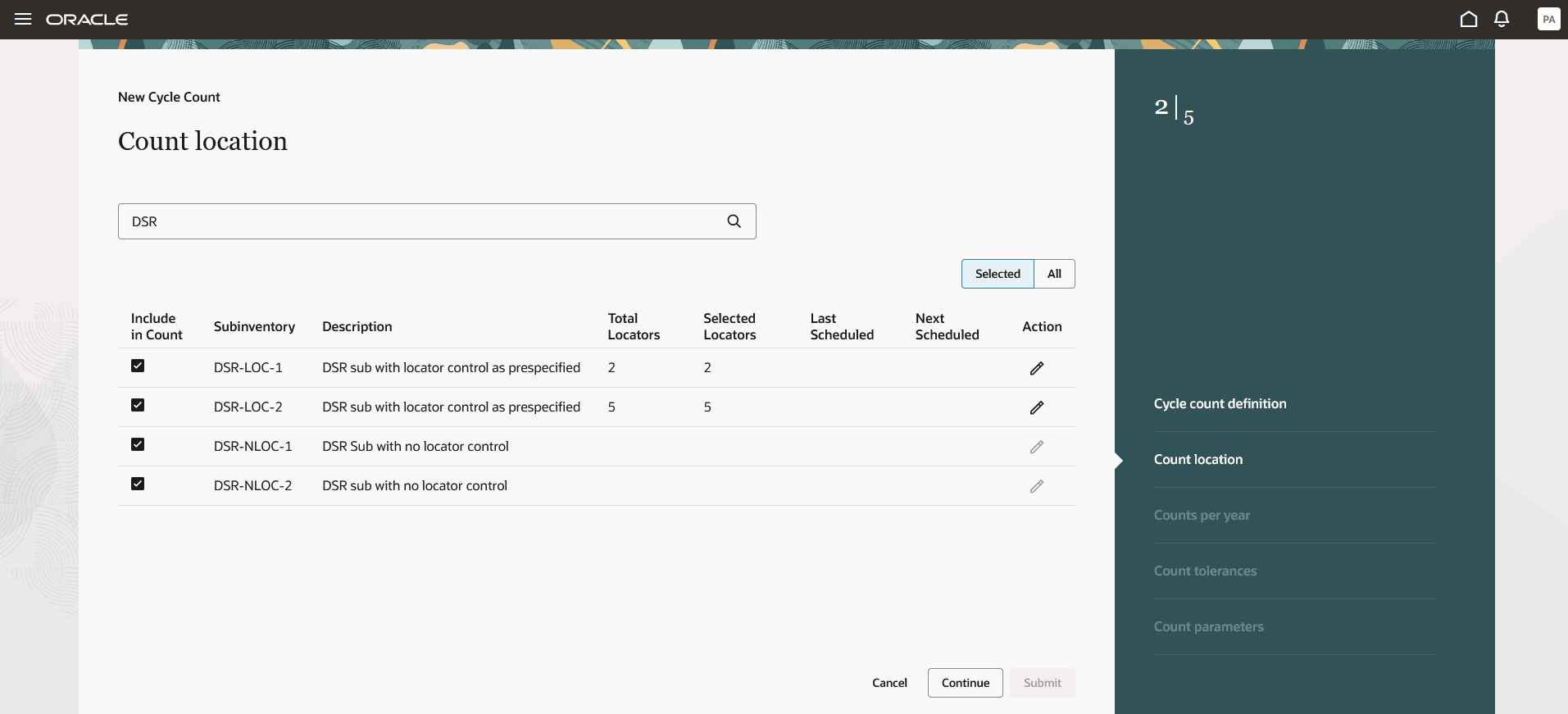

- Count location: Choose the subinventory to be counted.

Count Location

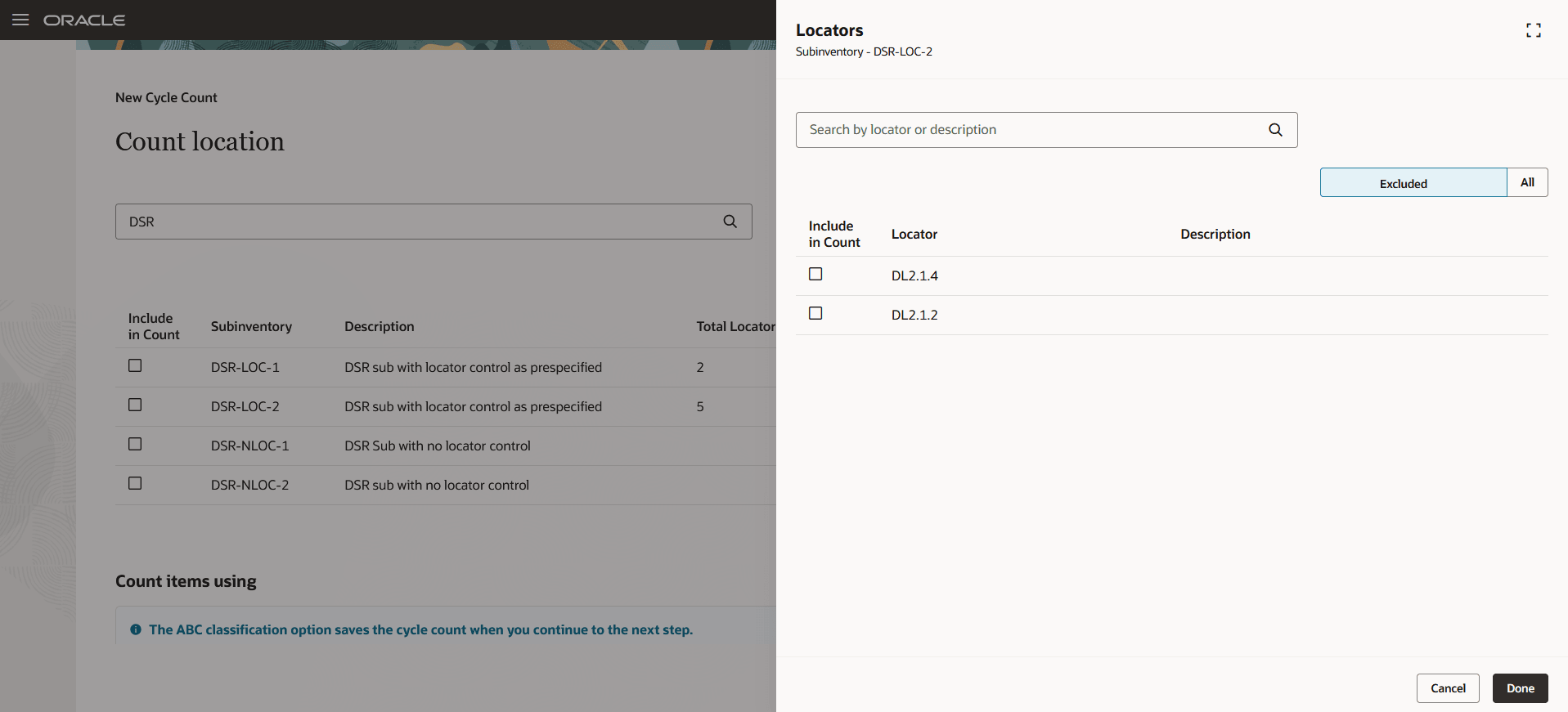

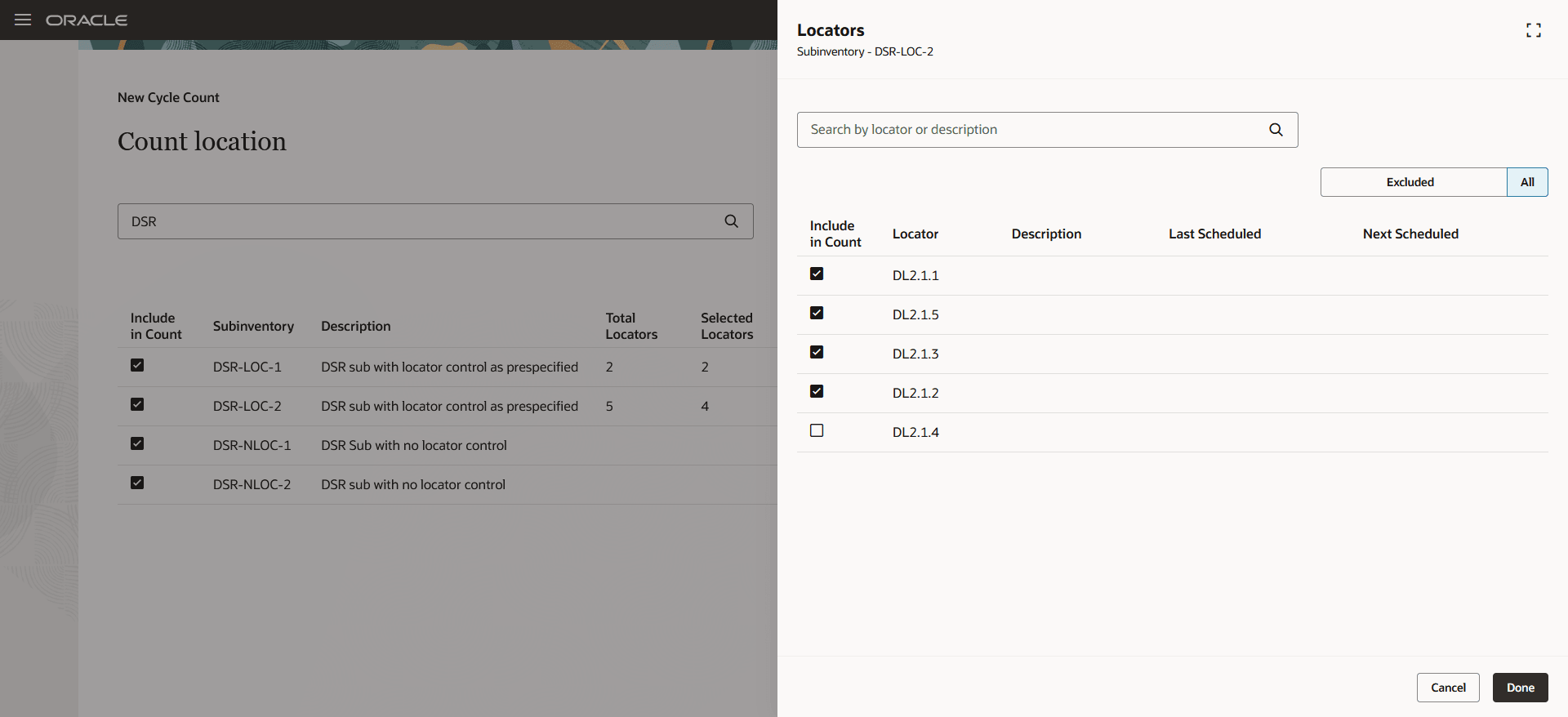

Specify the locators to include in the count. Use the Excluded toggle button to view the excluded locators.

Count Location Excluded Locators

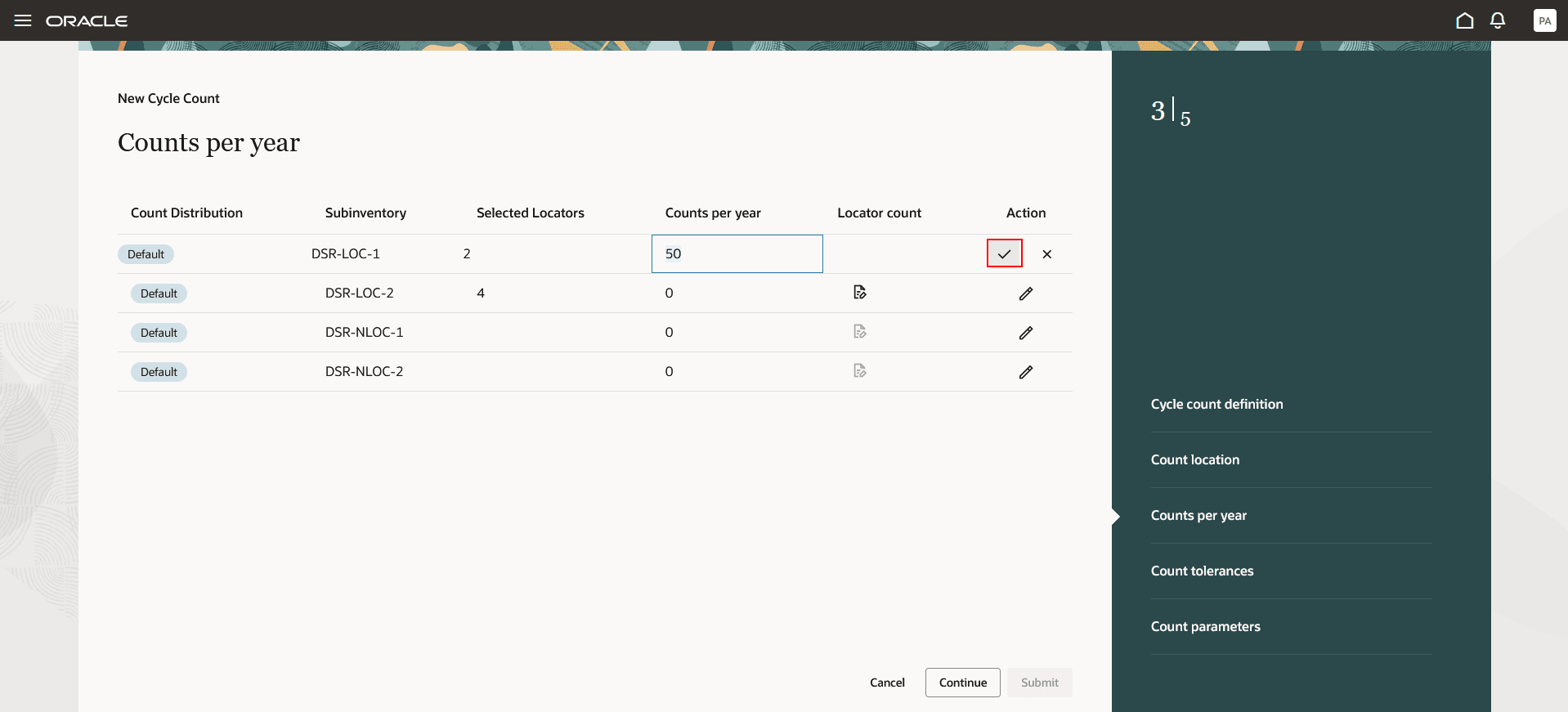

- Counts per year: Enter the number of counts per year for the selected subinventory or its locators. If you provide the count at the subinventory level, it defaults to all associated locators.

Counts per Year

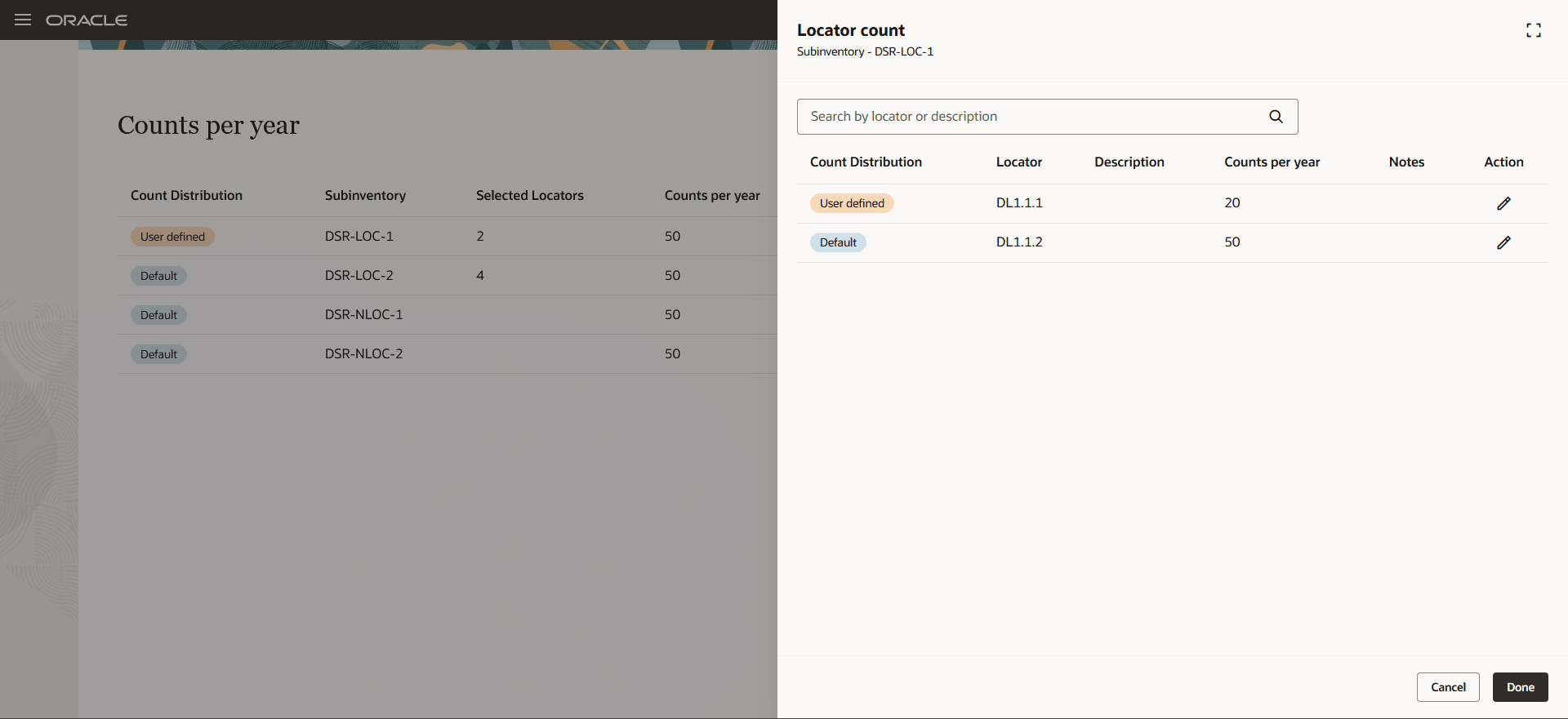

You can override these values at the locator level to assign different counts per locator.

Counts per Year Locators Override

NOTE: If the count remains unchanged at the locator level, it is marked as Defaulted. If modified, it is marked as User-Defined. This distinction helps identify whether the subinventory and its locators share the same count frequency.

- Count tolerances: Configure approval settings and count level tolerances.

- Count parameters: Provide any additional count parameters and submit the cycle count definition.

The location-based cycle count has been successfully created.

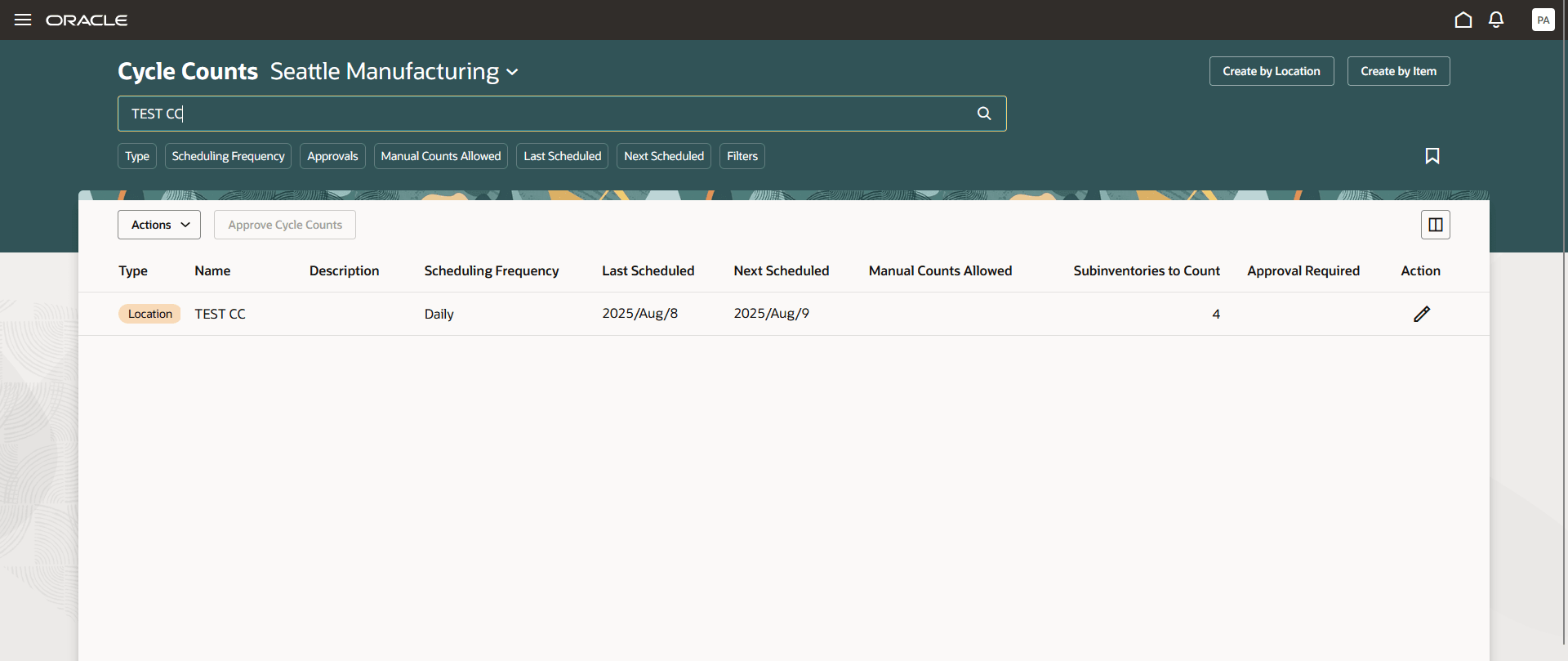

Cycle Count by Location

You can now generate count schedules and sequences for this location-based cycle count, and proceed to record the count sequences.

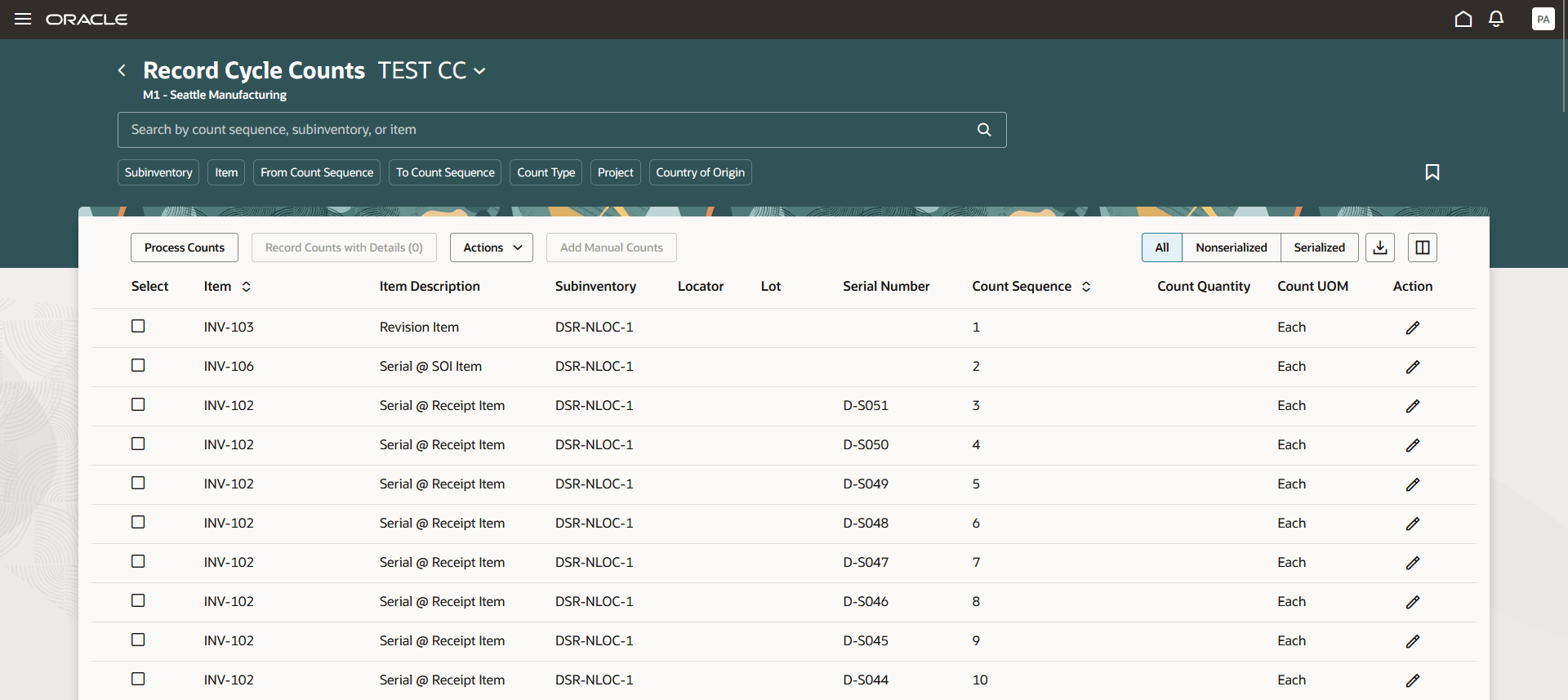

Record Count Sequences

You can now perform cycle counts based on your specific needs with more flexibility. This features reduces disruption to daily warehouse operations and provides improved inventory accuracy.

Steps to Enable and Configure

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management

Tips And Considerations

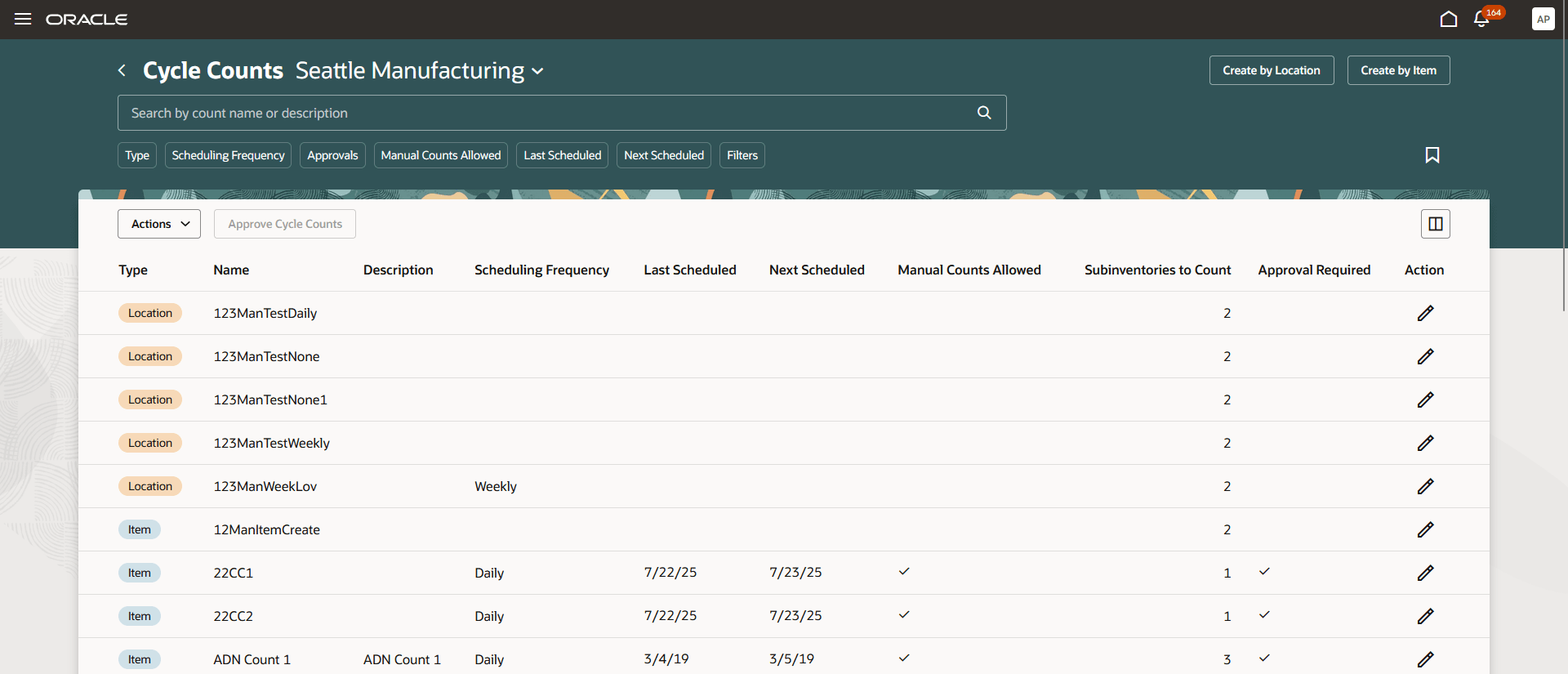

- On the landing page, you can identify whether a cycle count was created by Location or by Item using the Type column.

- A Location type indicates a location-based cycle count.

- An Item type indicates an item-based cycle count.

- Handling Different Subinventory Types:

- Locator Controlled Subinventories:

- Users can select specific locators for the count.

- Counting is executed at the locator level.

- Non-Locator Controlled Subinventories:

- Counting is performed at the subinventory level, as locators are not applicable.

Key Resources

- Oracle Fusion Cloud SCM: Using Inventory Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Redwood: Create Cycle Counts Using a Redwood Page available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Create Cycle Count Using Responsive Inventory (INV_CREATE_CYCLE_COUNT_RESPONSIVE_PWA_PRIV)

This privilege was available prior to this update.