Support Formula-Based Work Definitions in Costing

If you use process manufacturing work method in your manufacturing plant and have formula-based work definitions, you can now roll up the costs of the products when using standard cost method to value your inventory.

To calculate the costs, the Roll up Costs process will pick up work definitions based on the work definition selection criterion in cost scenarios as of the scenario effective date. Because formula also allows you to manage and track product effectivity, the rollup logic will only calculate the costs of products that are effective as of the scenario date.

As an example, imagine that your enterprise makes tofu to be packaged and sold directly and also used for other packaged products.

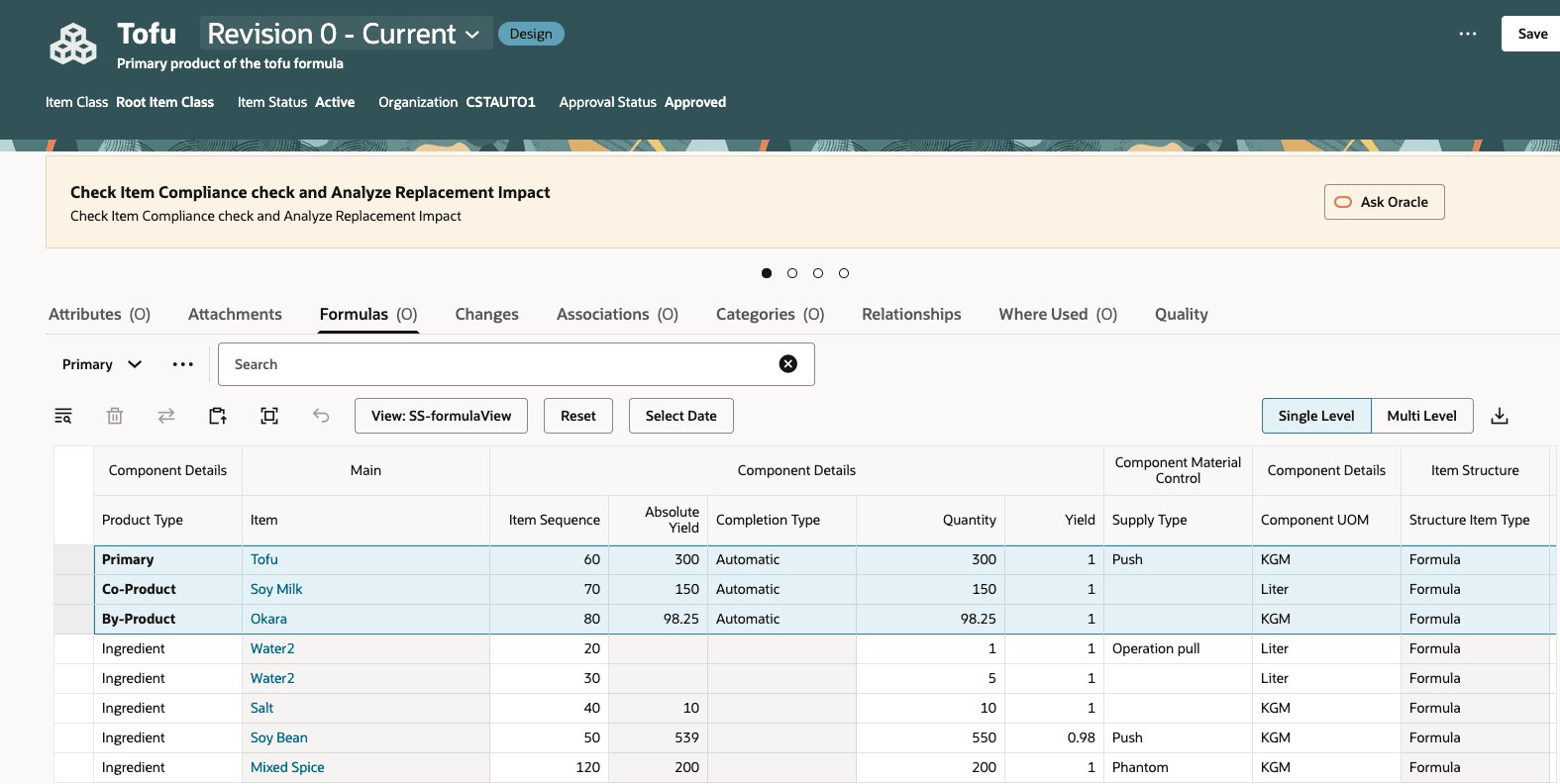

Screenshot of formula of a product

Note that the formula specifies soy milk (co-product) and okara (by-product) yielded from this formula. Assume that due to some planned process changes, soy milk won't be yielded after 8/31 from this formula (note the end date).

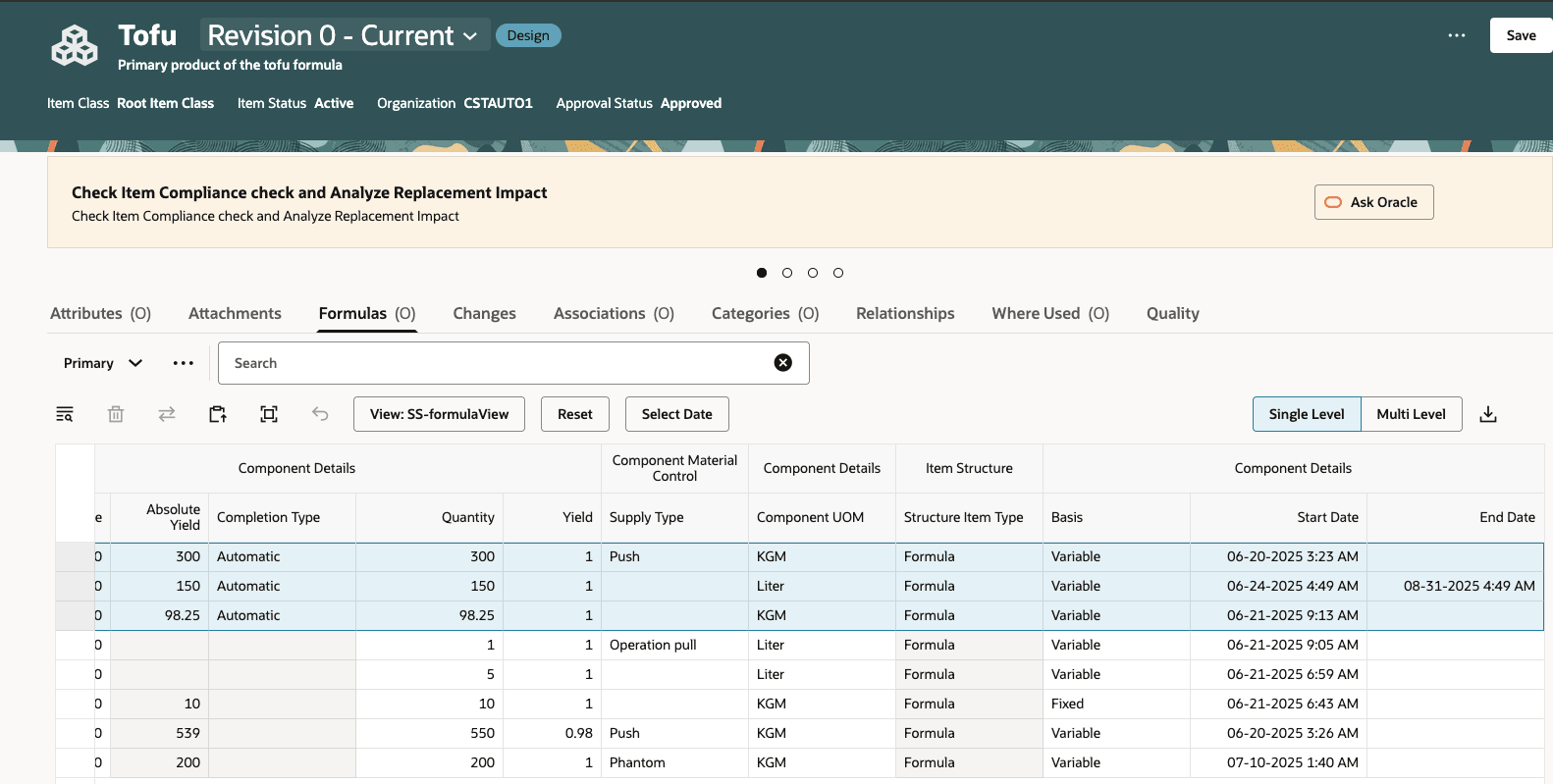

Formula with end-dated product

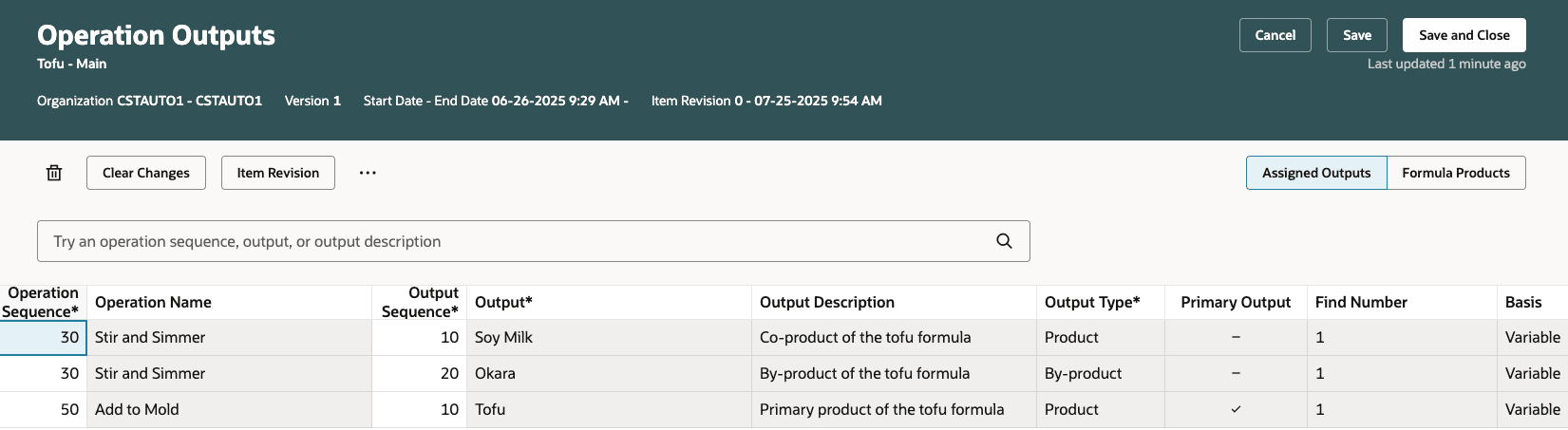

In the work definition, you'll assign all ingredients and products to operations. You also assign the cost allocation (fixed or percentage) and costing priority to the products to be used by the Roll up Costs process.

Screenshot of operation outputs for a process manufacturing work definition referencing a formula

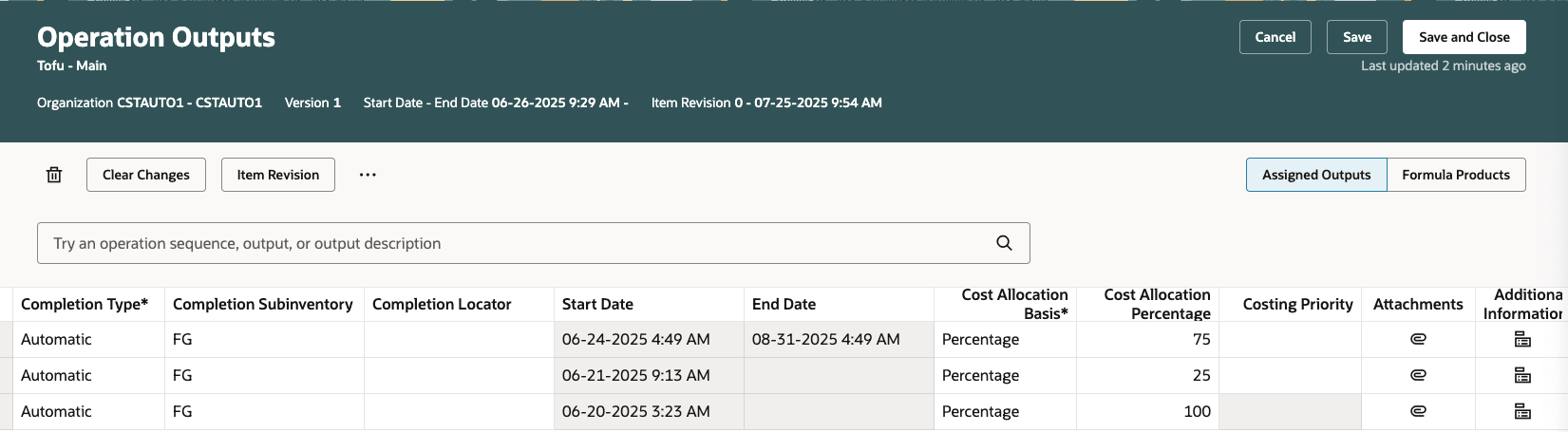

Screenshot with work definition outputs showing the date effectivity

Now, if your cost scenario is effective as of 9/1 (after the soy milk is end dated in the formula), the Roll up Costs process will only calculate the costs of active products with percentage cost allocation - okara and tofu.

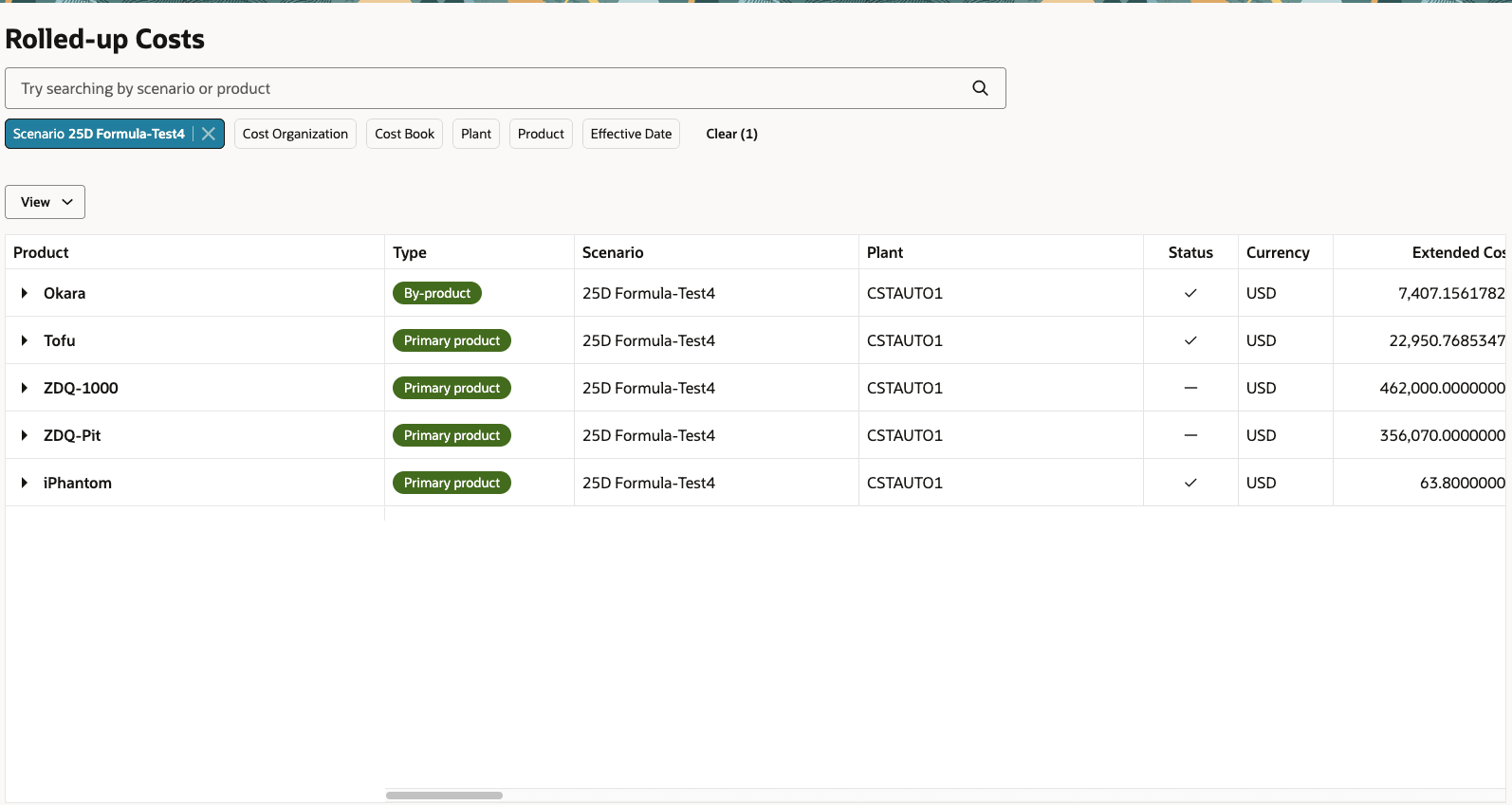

Screenshot of rolled-up costs page

Cost of product = Cost allocation Percentage * (Material costs incurred till the operation yielding the product + resource costs incurred till the operation yielding the product) + Manufacturing Overheads

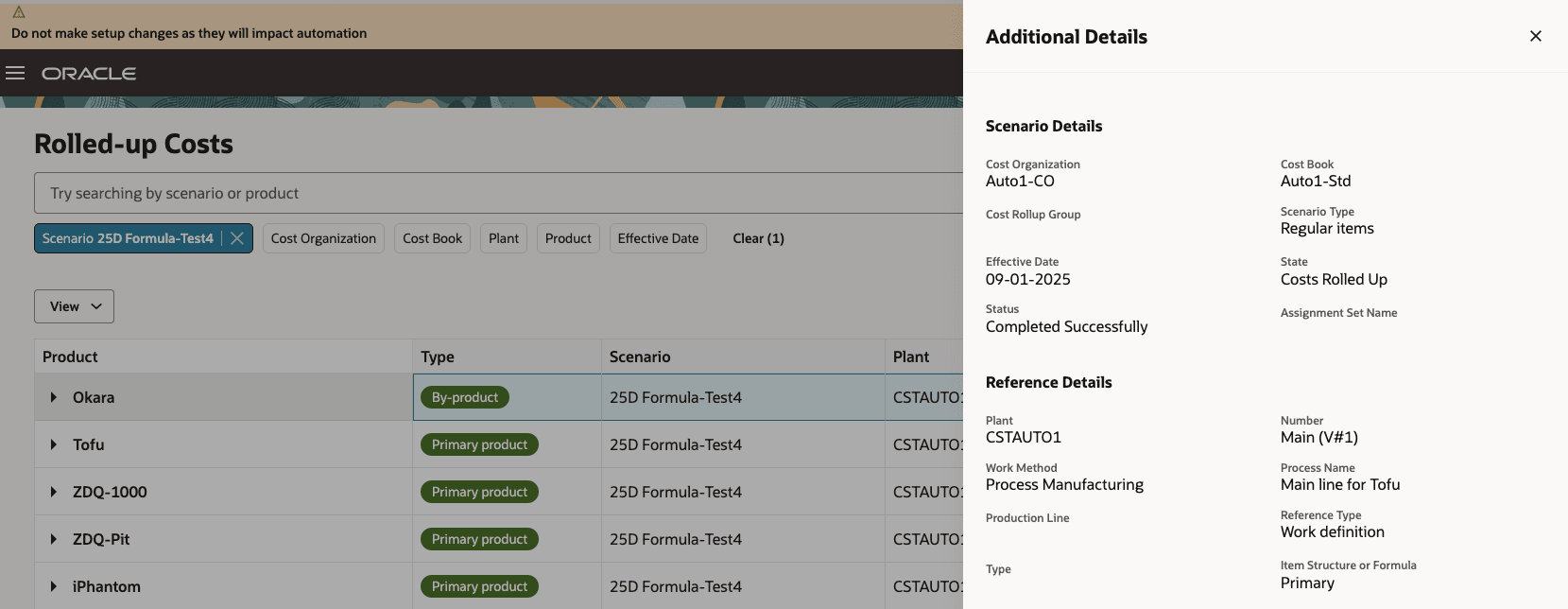

When you click on View - > Additional Details, you'll see the name of the formula referenced in the work definition of the product rolled up. Note that this attribute will also show the item structure name, if your work definition references an item structure. This attribute is introduced in this update, therefore, this information will only be available for products rolled up after the 25D update.

Additional details showing formula name

After you've validated your costs, you can publish the scenario so that these product costs can be used to cost your product completion transactions in Cost Accounting.

If your enterprise uses a cost method other than standard cost for inventory valuation, Cost Accounting will cost the transactions based on existing logic specific to the cost method you're using. There is no impact to the cost calculation logic or to any of the pages to review work order costs and costing transactions and distributions.

Some of the benefits this feature provides include:

- Increase accuracy of your enterprise's financial reporting by calculating costs based on your needs when using formula-based production.

- Enhance efficiency by validating your product costs quickly to avoid any expensive rework.

- Facilitate better decision making by tracking your actual production costs, performing what-if analysis, and so on to reduce supply chain costs for your enterprise.

Steps to Enable and Configure

If you want to use this feature, then you must opt in to its parent feature: Redwood: Create and Edit Formulas. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Tips And Considerations

- If you use phantom items in your production process and have additional products (co-products and by-products) defined in the formula of these phantom items, the Roll up Costs process will ignore all the additional products from the formula and allocate 100% of the ingredients costs to the primary product while exploding the phantom subassembly and use that cost to calculate the cost of finished products.

- The attribute to display the item structure or formula name is displayed in the Redwood page only.

- In the Rolled-up Costs Redwood page, the quantity for inputs or components is displayed in the costing unit of measure defined for the item.

- If you perform cost rollup for selected items, you need to use the Cost Scenarios Redwood page to select products with formula to roll up the costs.

Key Resources

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Supply Chain Cost Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges can access this feature:

- Manage Cost Planning Scenario Definition (CST_MANAGE_SCENARIO)

- Perform Cost Rollup (CST_PERFORM_COST_ROLLUP)

- Review Rolled Up Costs (CST_REVIEW_ROLLEDUP_COSTS)