Plan Supplies Based on a Formula

Process manufacturing is guided using a formula, which is a listing of the ingredients needed for manufacturing and the expected products that are produced. With this update, Oracle Fusion Cloud Product Management enables you to manage formulas and this functionality is then used downstream to manage the work definition. Oracle Supply Planning can now use work definitions that may have multiple ingredients and output products.

You can plan supplies and demands based on a formula, which is a new item structure type. A formula contains Ingredients (inputs) and Products (outputs). The root item of a formula is considered the primary output and will be added programmatically as a product in the formula.

This feature is available:

- When there’s a work definition associated with an item structure.

- In discrete and process manufacturing.

- Only in constrained supply plans and constrained demand and supply plans.

- Only in the Redwood user experience.

Work Definition Based on a Formula

You can assign ingredients of a formula as work definition operation items. Similarly, you can assign products of a formula as work definition operation outputs. You can't override those attributes defaulted from the formula in the work definition except for supply type and completion type.

Component and Output Types in a Formula

There are 2 component types:

- Input

- Output

There are 3 output types:

- Product

- Co-product

- By-product

The basis type for a product can only be variable. This applies to all product types, that is, Primary, Co-product, and By-product.

A product can be repeated in a formula only if the find number is different.

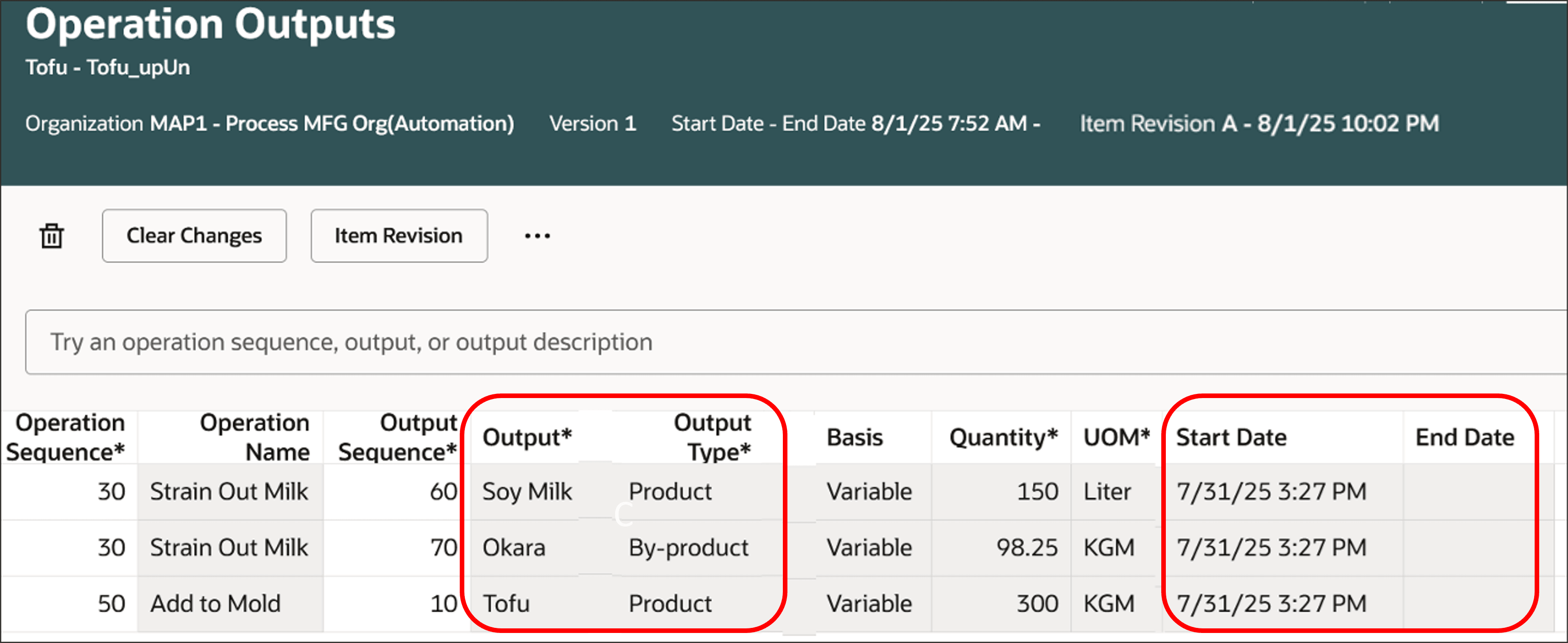

Output Effectivity Dates

Similar to input, an output can have effectivity dates: Start Date and End Date.

The output item start date can’t be null.

Outputs and Effectivity Dates

In this update, the collection process only considers operation outputs with the last effective start date.

When a change happens, the current entry is end-dated, and a new one is created. This approach eliminates the need to display additional attributes in the user interface because only the effective output is relevant. Consequently, there are no changes to the planning process.

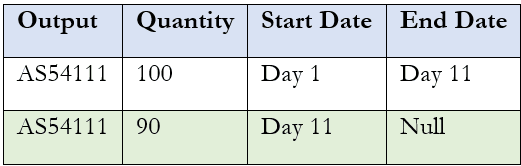

Example – Consider output AS54111 with the following effectivity date ranges:

- Output AS54111 quantity is 100 from Day 1 to Day 10 (Inclusive).

- Output AS54111 quantity is 90 from Day 11 and beyond.

Outputs and Effectivity Dates Example

If the plan run date is on or before Day 10, then the first row is collected with the output quantity of 100.

If the plan run date is on or after Day 11, then only the second row is collected with the output quantity of 90.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- Manufacturing automatically assigns a formula’s inputs and outputs to the work definition operations based on the suggested operation sequence.

- There isn’t a Usage field in the formula. There’s only Quantity, and it’s always positive.

- You can’t assign the same output to multiple operations within a work definition version.

- If there are multiple rows of the same output in a formula with different find numbers, you can assign only one of the rows to a work definition operation.

- If an item has no structure and it’s not used in any other structure as a component, then you can modify the item structure item type.

- If an item has structure but isn’t used in a work definition, you can delete the structure and then update the item structure type.

- If an item has structure and is used in a work definition, you can’t update the item. Create a new formula item instead.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supply Chain Planner (ORA_MSC_SUPPLY_CHAIN_PLANNER_JOB)

- Materials Planner (ORA_MSC_MATERIALS_PLANNER_JOB)

These privileges were available prior to this update.