Handle Intermediate Operations Completion in a Production Line

Previously, you could model and plan for rate-based production lines. In some situations, you may want to complete intermediate operations on the production line as part of your manufacturing execution processes so that you can gain real-time visibility to the manufacturing status. This capability is now available in Oracle Manufacturing. Oracle Supply Planning has been enhanced to include this increased visibility so that the appropriate remaining lead time can be calculated. Additionally, any materials that have been issued for a component and subassembly are also accounted for, so that the dependent demand is calculated correctly.

To support this enhancement, a new attribute called Last Completed Operation has been added to the Supplies and Demands table in plans and Plan Inputs, and to the list of selectable fields in the search panel. This column is hidden by default.

This column is relevant only to the order type of flow schedule. It displays the last completed operation of the flow schedule if there is one. It’s null for all other order types.

To plan the flow schedule, the supply planning process calculates the duration, starting from the operation after the last completed operation, based on the work definition attached to the flow schedule. Components required by an operation are planned to be available at the start of the operation.

Example 1: Process With or Without a Completed Operation

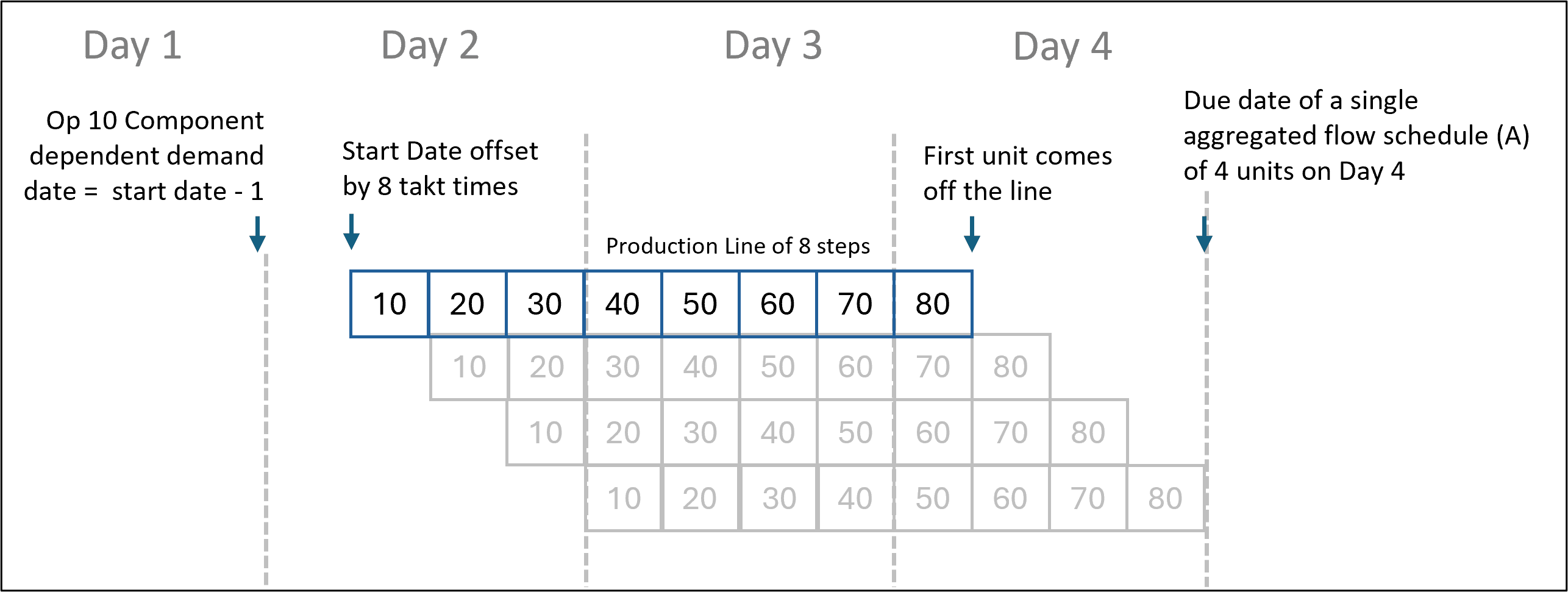

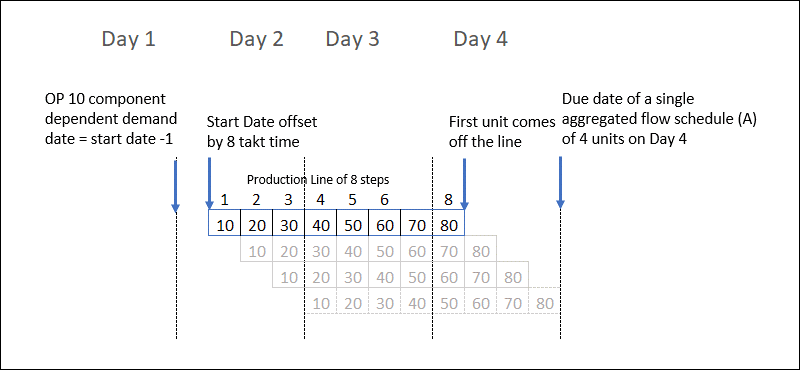

In this example, there’s a production line with the following attributes:

- Daily Available Hours = 8 Hours

- Number of Steps = 8

- Line Rate = 0.5 Units/Hour = 4 Units/Day

- Takt Time = 1 / 0.5 = 2 Hours

- Flow Schedule Quantity = 4

The following figure shows production started without any completed operation.

Process Without Any Completed Operations

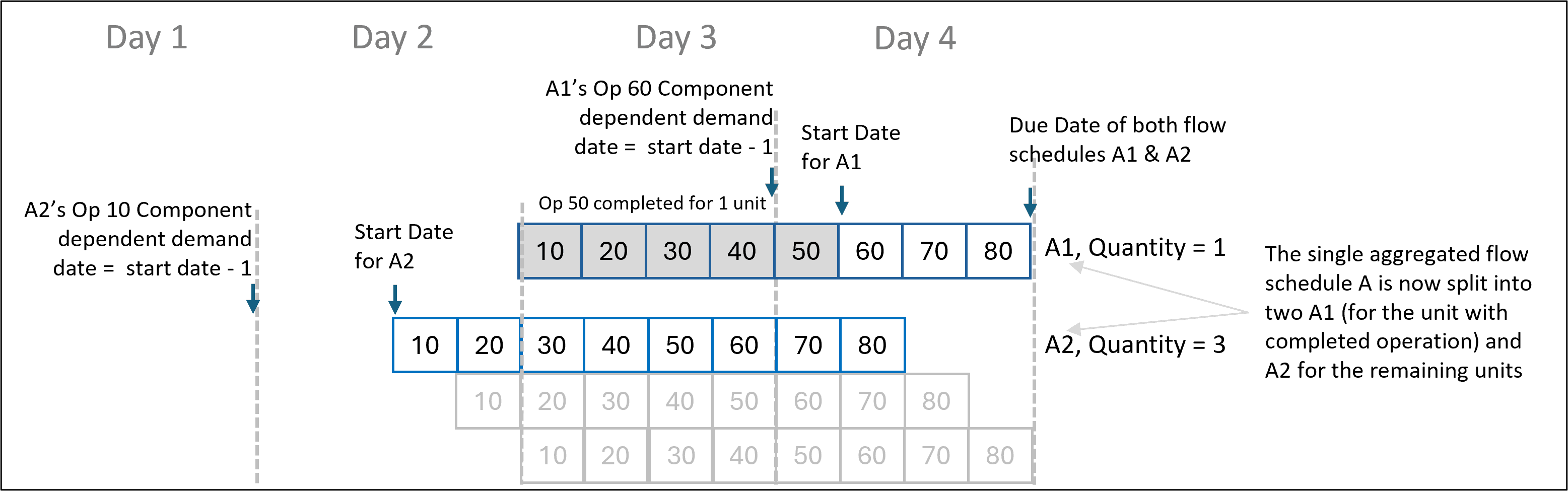

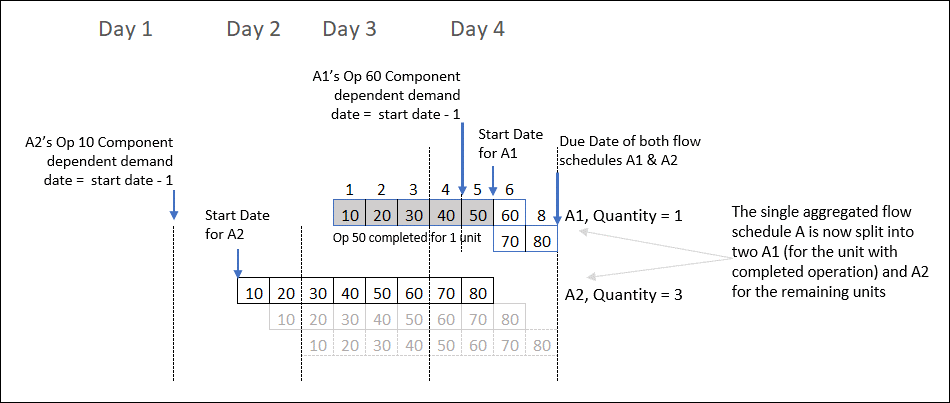

The following figure shows a situation where the first 5 steps are in a completed state for one unit.

Process with One Completed Operation

After the completion of the first 5 steps, the new start date for A1 is calculated based on the due date and the duration of the remaining steps. Here’s how the start date is calculated:

- The due date of the flow schedule aligns with the last slot of Day 4 (23:59).

- Since there are only 3 open operations, the start date is the second slot of Day 4.

Note: For the flow schedule A1, the component requirements for operation 10 through operation 50 aren’t considered as component demands.

For flow schedule A2, the start date is calculated as follows:

- The due date of the flow schedule aligns with the last slot of Day 4 (23:59).

- Since the flow schedule is for 3 units, the first unit comes off the line in the second slot.

- The start date of the first unit is offset from Day 4’s second slot by 8 Takt times. Therefore, the start date of the flow schedule is Day 2’s third slot.

Example 2: Process with a Completed Intermediate Operation and Another Operation That Isn’t Explicitly Mapped to a Flow Line Step

When a work definition on a production line has an operation that’s not associated with any step on the line, that is, the line operation sequence number is blank (as operation 70 is in the second diagram below) and has completed operations (operations 10 through 50 below), then operation 70 is assumed to be starting at the first step (after the last completed operation). This is the current behavior prior to this feature, and it hasn’t been changed. Such operations, which aren’t assigned to any step in the line, can’t be marked as complete.

Process with One Operation That Isn’t Explicitly Mapped to a Flow Line Step

Process with a Completed Operation and Another Operation That Isn’t Explicitly Mapped to a Flow Line Step

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- The aggregation process for flow schedules considers the completed operations and aggregates only those flow schedules that share identical completed operations, in addition to the following entities: item, organization, work definition, status (Released), and dock date.

- For instance, if there are two flow schedules with 5 operations that have the same entities as mentioned here, and operation 10 of the first flow schedule has been completed but operation 20 of the second flow schedule has been completed, they won’t be aggregated.

- If the line operation sequence number is null in the source, supply planning sets it to 1.

- An operation with a line operation sequence number equal to 1 is planned at the beginning or the start time of the supply.

- All component demands of operations are scheduled at the supply's start time.

- Product completions aren’t allowed in intermediate operations.

- Partial completions aren’t supported for flow schedules.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supply Chain Planner (ORA_MSC_SUPPLY_CHAIN_PLANNER_JOB)

- Materials Planner (ORA_MSC_MATERIALS_PLANNER_JOB)

These privileges were available prior to this update.