Plan Process Work Orders for Material that is Both an Ingredient and an Output

In certain industries with blending operations where product yield and material consumption are optimized, it is common practice to capture off-spec product or rework material and blend it back into production to meet target product characteristics such as consistency and concentration. Another business process takes the product left over from one batch as a starting point for the next batch, for example, when filling the product into containers. In these dynamic scenarios, the same item can be used as an ingredient and a product of a batch. You can now specify these situations in the work orders in Oracle Fusion Cloud Manufacturing as ad-hoc items. Supply Planning considers these situations in the work order and calculates the output quantities considering time offsets appropriately. The quantity of the input of the same ad-hoc item isn’t planned.

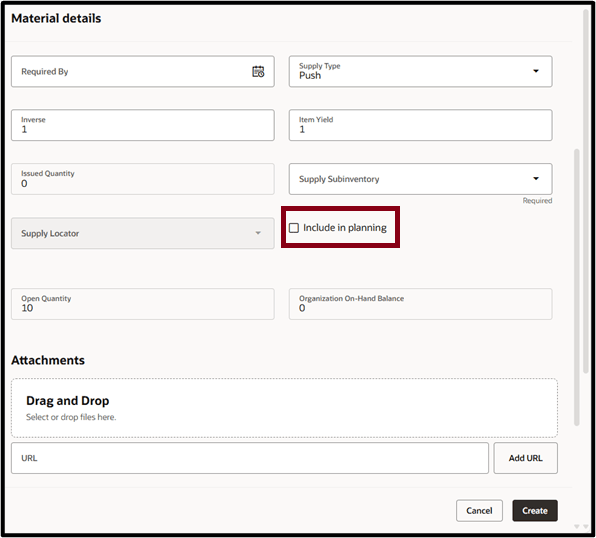

In Oracle Fusion Cloud Manufacturing, when you add an output item as an input item, the Include in Planning option shouldn’t be selected.

Defining Work Order Materials Details

As a result, the item isn’t collected as a component item in the plan inputs within the item structure. Consequently, Planning doesn’t generate any work order component demand for this item and plans only for the output item.

Steps to enable and configure

You don't need to do anything to enable this feature.

Access requirements

No separate privileges are required to this update.