Track Items in More Than One Unit of Measure

See how you can use the dual units of measure feature to order, price, manufacture, receive, pick, pack, and ship an item in the primary UOM but price it in the secondary UOM.

You might need to order, transfer, outsource, or buy an item in a unit of measure that's different from the unit of measure that you use to price and invoice it. For example:

-

You price fish by the pound but you sell the entire fish to your customers.

-

You price steel by the ton but ship and receive it by the sheet.

-

You price paper by the pound but ship and receive it by the roll.

-

You price apples by the pound but ship and receive them by the bag.

Consider an example.

Note

-

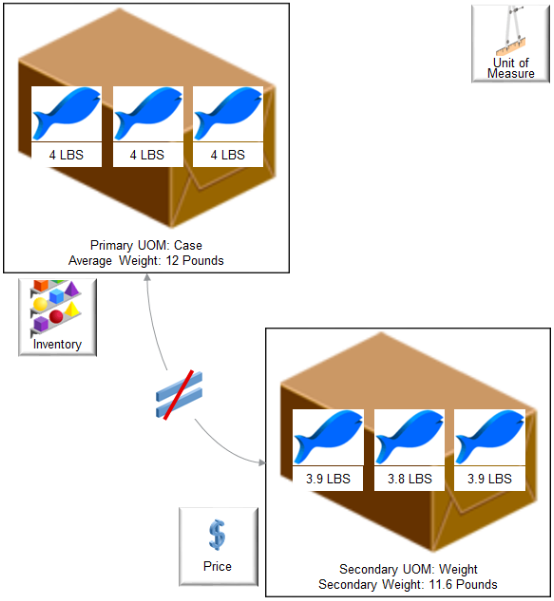

Weight for each fish is approximate because it naturally varies in size. For example, 10 different fish will each sell for a different amount because each one has a unique weight. You might need to use the primary UOM Case to stock your fish in inventory, but use the secondary UOM Pounds to price it.

-

The total weight of an average case of fish is 12 pounds, and that's how you stock it.

-

The actual weight of the case that you weigh just before you ship is 11.6 pounds, and that's the price you charge your customer.

You can use the dual units of measure feature to meet this requirement. It's an end-to-end, integrated solution that works across Oracle Applications:

-

Use this feature to simultaneously track an item in the primary UOM and secondary UOM throughout your order-to-cash process and procure-to-pay process, including in Order Management, Inventory Management, Procurement, and Manufacturing.

-

Capture the actual weight of the item that you sell, transfer, or purchase so you can accurately price, invoice, and cost the item.

-

Provide a price estimate at the time of sale or purchase and maximize value according to the exact weight that you ship or receive. In some cases, the weight might change between the time you acquire the item and sell it. For example, produce might lose some of its weight through evaporation while it sits in inventory, so you weigh it just before you ship, and price it at the Weight secondary UOM.

You can use Order Management to create a sales order in the item's primary unit of measure or in another unit of measure that's in the primary UOM class, such as Each, then use the standard conversion or item conversion to automatically calculate quantity in the secondary UOM, such as Pound.

-

Track the item in a UOM that's different from the UOM that you use to stock the item. For example, use the primary UOM Cases to stock and track the quantity that your customer orders, and use the secondary UOM Pounds to track the secondary quantity that you price and actually ship. You can use Case and Pounds simultaneously to track the item.

-

Use an automated flow to update the order line and invoice it according to the quantity or the secondary quantity that you ship.

-

Use and view two units of measure throughout your end-to-end supply chain. For example, start with the primary unit of measure for the ordered quantity on the order line, then price and invoice in the secondary unit of measure. Reserve, allocate, plan, produce, and ship in the primary.

-

If you're doing an internal transfer of goods, then you can create and fulfill the transfer order in the item's primary UOM, and calculate transfer pricing according to the secondary UOM.

-

Select the lot to use to fulfill the item during shipping.

-

Revise a sales order. Add a new order line that has a dual units of measure item to an existing order, or change the quantity on a line that has a dual units of measure item.

-

Cancel an order line that has a dual units of measure item.

-

Cancel a sales order that has dual units of measure items. Order Management will automatically set the quantity and secondary quantity on all order lines to zero.

Realize these benefits.

-

Improve the accuracy of the price that your charge your customers. Charge them according to the quantity that you actually ship, in the secondary UOM.

-

Bill accurately so you can increase profitability.

-

Improve the accuracy of your reports. Use secondary attributes in your reports, such as the secondary quantity and the secondary unit of measure.

-

Increase revenue and improve customer satisfaction.