Use Different Components, Materials, and Resources Depending on Start and End Dates

Align the start dates and end dates for each manufacturing component and resource in your bill of resources with the dates that your fulfillment flow uses.

You can use more than one instance of the same component or resource in the same operation.

The way that you manufacture an item might evolve over time depending on the season, varying material properties, new regulations, design improvements, expected downtime, or other planned changes. You can manage these production changes in a single bill of resources. Promising will apply the lead time for each operation, then select the components, materials, and resources that are available and that are currently in effect according to their start dates and end dates.

Use this feature to help manage more than one instance of the same component or resource during different time intervals.

Try It

- Make sure you have these privileges.

- MSP_SCHEDULE_ORCHESTRATION_ORDER_FULFILLMENT_LINE_PRIV

- MSC_EDIT_BILLS_OF_RESOURCES_PRIV

- MSC_VIEW_BILLS_OF_RESOURCES_PRIV

- Go to the Setup and Maintenance work area, then select the Supply Chain Planning offering.

- Specify the start date and end date for each component and each resource in your work definition.

- Collect data. See Collect Data for Global Order Promising.

- Run the Create Bills of Resources scheduled process. This scheduled process will add the dates that you specified for each component from your work definitions into the bill of resources. Promising can then use this data to determine what components and resources are available according to their start dates and end dates, and will schedule sales orders so these components and resources can meet the order's demand dates. See Create a Bill of Resources.

Guidelines

- You can assign more than one instance of the same component to the same operation or to different operations. Use different date ranges for each of these assignments.

- You can set up more than one instance of each resource. Specify a different usage and different dates for each instance.

- The scheduled process will process each primary resource, each alternative resource, and each substitute component. The scheduled process sets the effective dates for each alternate or substitute to the primary's dates.

- If the scheduled process encounters more than one work definition for a component or resource that has the same effective dates, the same usage, and the same basis, then it will combine them into a single work definition.

- If an operation has more than one instance of the same component, then the scheduled process will use the Find Number attribute in the item's structure to uniquely identify each instance. For details about the find number, see View Structure Details—Classic.

- If the work definition's end date already happened, then the scheduled process won't include that work definition in your bill of resources.

- If the end date for a component or resource already happened, then the scheduled process won't include that component or resource in your bill of resources.

Introduction to the Examples

Assume your work definition has this hierarchy:

M1

AS301

CM201

CM202

R3

SB111

CM364

CM365

R4

where

- M1 identifies the manufacturing facility.

- The AS301 is an assembly that you will build in the M1 manufacturing facility.

- CM201 and CM202 are each components that you need to complete the AS301 assembly.

- R3 is the resource that you use to assemble the AS301.

- SB111 is a subassembly in the AS301.

- CM364 and CM365 are each components that you need to complete the SB111 subassembly.

- R4 is a resource that you need to assemble the SB111.

Here's the nomenclature that this example uses:

- AS means assembly.

- SB means subassembly.

- CM means component.

- R means resource.

Same Component, Different Levels, Dates, and Basis

In some business scenarios, you might need to have a lot of flexibility in your work definition.

Assume you sell an item named Glorious Bouquet, which is a bouquet of flowers. Your customers have very discerning tastes about what flowers they want to see in various parts of the bouquet, at different times of the year. Some types of flowers are always available and your customers always want them, regardless of season, so you consider them to be fixed. However, other flowers come and go with the season, so you view them as variable.

Assume your work definition has this hierarchy:

where

- Glorious Bouquet is your top level assembly.

- Focal Flowers, Secondary Flowers, and Leafy Greens are subassemblies.

- Sunflower, Tulip, Dahlia, California Poppy, Alstroemeria, Cala Lilly, Oregano, Verbena, and Basil are components.

For brevity, we'll focus on Secondary Flowers and California Poppy. Here's how we identify them:

| Item | Description |

|---|---|

| Glorious Bouquet | AS301. Top level assembly. |

| Secondary Flowers | SA1. A subassembly that contains components. |

| California Poppy | C1. A component. |

Assume your work definition contains more than one instance of the same critical component at different levels in the work definition, and the component's basis is different depending on the effective date. The scheduled process will link each instance to the parent item. If the component's basis is:

- Fixed. The scheduled process will roll up the dates for each instance to the parent.

- Variable. If the dates between the subassembly and the component match, or if the component's dates are within the subassembly's dates, then the bill of resources will include that component. If not, then it won't include that component. This logic applies when you have a subassembly that isn't critical and it contains a component that is critical.

You need to prepare for the upcoming Summer and Fall bouquet selling season, which runs July 21 through December 1. You need to promise differently depending on some seasonal variation in supply, so you create this work definition:

| Row | Description | Assembly | Subassembly or Component | Effective Date | Quantity | Basis | Find Number |

|---|---|---|---|---|---|---|---|

| 1 | Glorious Bouquet | AS301 | SA2 | July 21 | 1 | Fixed | 1 |

| 2 | Secondary Flowers | - | SA2 | July 21 through September 30 | 5 | Variable | 2 |

| 3 | Secondary Flowers | - | SA2 | July 21 through November 1 | 6 | Variable | - |

| 4 | Secondary Flowers | - | SA2 | November 2 | 10 | Variable | - |

| 5 | California Poppy | SA2 | C1 | July 21 through December 1 | 1 | Fixed | 1 |

| 6 | California Poppy | - | C1 | August 1 through October 1 | 2 | Fixed | 2 |

| 7 | California Poppy | - | C1 | July 21 through November 1 | 2 | Variable | - |

Note that if there's no end date, then the Effective Date column in the table includes only the start date.

You create more than one instance of the Secondary Flowers subassembly in the Glorious Bouquet assembly to account for seasonal variations:

- Row 1. Contains Glorious Bouquet, your top level assembly. The dates run for the full duration of the selling season, July 21 through September 30.

- Row 2. Contains Secondary Flowers with July 21 through September 30 and a quantity of 5 to cover the early part of the selling season.

- Row 3. Contains Secondary Flowers with July 21 through November 1 and a quantity of 6 to pick up an increase in the supply that's typically available later in the season.

- Row 4. Vast batches of secondary flowers become available during the Fall harvest at the end of October, you know you'll have a surplus inventory of secondary flowers, so you create this instance of Secondary Flowers with a much larger quantity of 10, and you put it into effect on November 2.

- Row 5. The California Poppy is your trademark secondary flower, you always include at least one of them, so you add it as fixed, with a quantity of 1, July 21 through December 1. This covers most of the selling season.

- Row 6. You add the poppy with a quantity of 2, August 1 through October 1.

- Row 7. More poppies are available between August and November than they are July through December, so you increase the number of poppies that you include in your bouquet August through November.

Note

- The work definition specifies the Find Number attribute for Secondary Flowers and California Poppy.

- Assume all components and resources are critical except for SA2, Secondary Flowers.

- We're using "rows" here only to help describe the example. There's no such row in your actual work definition.

If the California Poppy has a variable basis, and if that poppy's date range:

- Matches or falls within Secondary Flowers' date range. The scheduled process will roll up that poppy's date range.

- Doesn't match or fall within Secondary Flowers' date range. The bill of resources won't include that poppy.

Assume you run the Create Bills of Resources scheduled process on July 20. The scheduled process will create this bill of resources:

| Assembly | Component | Effective Date | Quantity | Basis | Find Number |

|---|---|---|---|---|---|

| Glorious Bouquet, AS301 | California Poppy, C1 | July 30 through December 1 | 1 | Fixed | 1 |

| - | California Poppy, C1 | August 1 through October 1 | 2 | Fixed | 2 |

| - | California Poppy, C1 | July 21 through November 1 | 12 | Variable | - |

The bill of resources will include the C1 from these rows of the work definition:

- Row 5 because its basis is fixed. The bill of resources will include all fixed components. It will also include the exact quantity for each fixed component from the work definition. It doesn't adjust the quantity because the quantity is also fixed, not variable.

- Row 6 because its basis is fixed.

- Row 7 because the date range for the C1 poppy in row 7 is July 21 through November 1, and that date range matches the range for the SA2 Secondary Flowers that's in row 3.

Here's the math that the scheduled process applies to get a quantity of 12 poppies:

- Row 3 in the work definition has a quantity of 6, which means the Glorious Bouquet needs 6 Secondary Flowers subassemblies.

- Row 7 for the C1 California Poppy has a quantity of 2, so each Secondary Flowers subassembly on row 3 needs a quantity of 2 C1 California Poppy components.

- 2 California Poppy components multiplied by 6 Secondary Flowers subassemblies equals 12 poppies. That quantity also happens to be enough poppies to line each side of the yellow brick road.

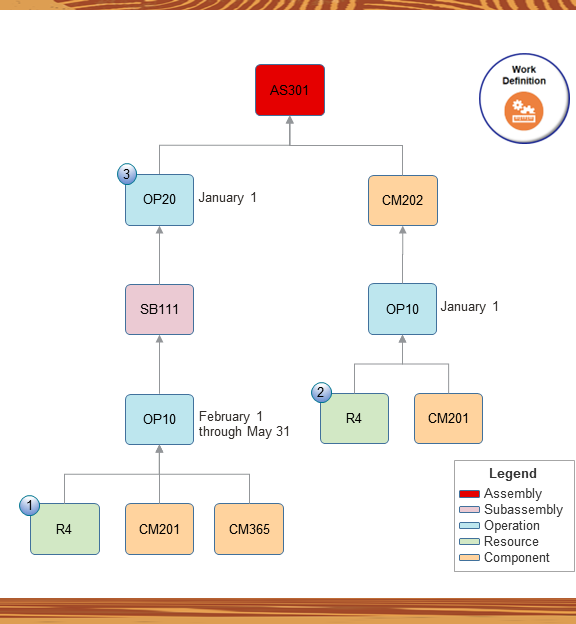

Same Components, Different Uses

Assume you have the same components but you apply them for different uses, and all components and resources are critical.

You run the Create Bills of Resources scheduled process on January 1, and it creates this bill of resources:

| Assembly | Component or Resource | Operation Sequence | Quantity | Effective Date |

|---|---|---|---|---|

| AS301 | SB111 | 10 | 1 | Jan 1 |

| - | CM201 | 10 | 1 | Jan 1 |

| - | CM202 | 20 | 2 | Jan 1 through May 31 |

| - | CM202 | 30 | 4 | Jun 1 |

| - | R3 | 10 | 0.5 | Jan 1 |

| SB111 | CM364 | 10 | 1 | Jan 1 |

| - | CM365 | 10 | 1 | Jan 1 |

| - | R4 | 10 | 0.5 | Jan 1 |

Note

- If there's no end date, then the Effective Date column in the table includes only the start date.

- The operation sequence specifies the sequence that we use to build the assembly. For example, we do operation 10 first, and then operation 20, and then operation 30.

For brevity, let's see how promising works only for the CM202. The bill of resources will use the CM202 for different operations, in different quantities, depending on the CM202' date ranges. If demand for the CM202 happens:

- January 1 through May 31, Promising will consume a quantity of 2.

- On or after June 1, Promising will consume a quantity of 4.

Same Components or Resources, Overlapping Dates

Now let's assume your work definition has a slightly different hierarchy:

M1

AS301

CM201

CM202

R3

R4

SB111

CM201

CM365

R4

Assume you have these values.

| Assembly | Component or Resource | Operation Sequence | Quantity | Basis | Effective Date |

|---|---|---|---|---|---|

| AS301 | CM202 | 10 | 1 | Variable | January 1 |

| - | CM201 | 10 | 1 | Variable | January 1 |

| - | R4 | 10 | 0.5 | Variable | January 1 |

| - | SB111 | 20 | 1 | Variable | January 1 |

| - | R3 | 20 | 0.5 | Variable | January 1 |

| SB111 | CM201 | 10 | 1 | Variable | February 1 through May 31 |

| - | CM365 | 10 | 1 | Variable | February 1 through May 31 |

| - | R4 | 10 | 0.5 | Variable | February 1 through May 31 |

Assume:

- All components and resources are critical except for SB111 and R3.

- The AS301 and SB111 both use the same CM201 component and the same R4 resource.

- The CM201 goes into effect on January 1 with no end date, and the R4's date range is February 1 through May 31, so the dates for CM201 and R4 overlap each other.

Assume you run the Create Bills of Resources scheduled process on January 1, and it creates this bill of resources:

| Assembly | Component or Resource | Quantity | Effective Date |

|---|---|---|---|

| AS301 | CM202 | 1 | January 1 |

| - | CM201 | 1 | January 1 |

| - | CM201 | 1 | February 1 through May 31 |

| - | R4 | 0.5 | January 1 |

| - | CM365 | 1 | February 1 through May 31 |

| - | R4 | 0.5 | February 1 through May 31 |

The scheduled process will roll up child SB111's components, resources, and dates to the parent AS301 in the bill of resources.

If demand for the CM202 component happens:

- February 1 through May 31, Promising will consume a quantity of 2

- January 1 through January 31, or on or after June 1, Promising will consume a quantity of 1

If demand for the R4 resource happens:

- February 1 through May 31, Promising will consume a quantity of 1 hour

- January 1 through January 31, or on or after June 1, Promising will consume a quantity of 0.5 hours

Note that you set the item's basis to Fixed or Variable.

This example will you give you a work definition with this hierarchy after you finish collecting data:

Note

- The R4 resource will do the OP10 operation to build the SB111 subassembly. It will use the CM201 and CM365 components. This OP10 can start as early as February 1 but must end no later than May 31.

- The R4 resource will do the OP10 operation and will use the CM201 component to assemble the CM202 component. This OP10 can start anytime on or after January 1.

- The R4 resource will do the OP20 operation to build the final AS301 assembly. It will use the SB111 subassembly and the CM202 component. This OP20 can start anytime on or after January 1.