Fix Problems and Improve Performance

Order Management automatically fulfills most sales orders. However, if you encounter a problem, you can use the Manage Fulfillment Lines page to view the cause and fix it. You can also use Manage Fulfillment Lines to improve fulfillment performance.

-

Manage Fulfillment Line Exceptions displays order line exceptions that are past due, in jeopardy, backordered, and on hold.

-

Most exceptions happen because an item isn't available.

-

More than one solution might fix an exception. How you fix the exception depends on your organization policies.

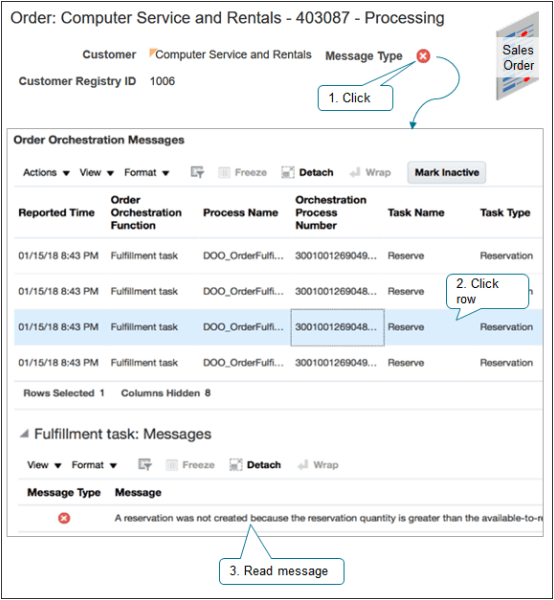

Assume you submit an order line that includes a quantity of 20, but inventory only has an on-hand quantity of 10. You open the sales order in a fulfillment view, click the icon next to Message Type in the order header, then notice the messages.

The Order Orchestration Messages dialog displays a message for the Reservation step of the orchestration process.

Orchestration couldn't create a reservation because the reservation quantity is greater than the available-to-reserve quantity.This error might happen when you create a sales order, change the quantity when you revise the order, or add a new order line to an order that already exists. You can reduce the ordered quantity on the order line to 15 and submit a revision, or inventory can increase the on-hand quantity and you can recover the order line. The orchestration process will then send another reservation request, inventory processes the line, and the line moves to the next orchestration process step.

Use the Manage Fulfillment Lines page.

-

Go to the Order Management work area, then click Tasks > Manage Fulfillment Lines.

-

On the Manage Fulfillment Lines page, search for your sales order.

-

In the search results, in the Order attribute, click the link.

-

On the Order page, try the solutions that this topic describes.

Do an Action on the Order Line

Do a manual action on the order line to fix an exception, improve performance, or do other tasks.

|

Action |

Description |

|---|---|

|

Schedule |

Schedule an order line if the orchestration process that references the line includes a manual scheduling step, or if the fulfillment line isn't scheduled. If you schedule an order line, then Order Management sends a request to the order promising process to schedule the fulfillment line. |

|

Unschedule |

Unschedule an order line to make supply available to a higher priority order line. If you unschedule an order line, then Order Management moves the orchestration process back to the scheduling step, sets the status to Awaiting Scheduling, and then releases supply so other order lines can use it. You must manually schedule an order line that you unschedule. |

|

Check Availability |

Use Check Availability to reschedule the fulfillment line. Use it to view the scheduling options that are available, see the best option, and get details you need to evaluate each option.

For redesigned pages, see Redwood: Check Availability. |

|

Split Line |

Split the fulfillment line to fulfill one part of the line from one warehouse, and another part from another warehouse. Use the analytics area to help identify the warehouse to use. For details, see Split Order Lines. |

|

Substitute |

Order Management displays the best substitution according to how your order administrator sets up substitution. Use the analytics area to help identify the item to substitute. To substitute an item that's part of a shipment set, you must remove the order line from the shipment set. |

|

Reserve |

Reserve supply to make sure its available only for a specific order line. If you reserve supply, then Order Management removes it from availability so other order lines can't use it, then reserves it for the order line that you select. |

|

Unreserve |

Release supply so some other order line can use it, such as a higher priority order line that has an exception. |

|

Hold |

Release a hold on an order line so processing can continue. If a hold exists on any part of an order line, then Order Management might not be able to complete the fulfillment process. A hold on part of an orchestration process can allow an order line to proceed, but it might arrive at a point where it stops and waits for a user to release it. For details, see Use Holds to Temporarily Stop Processing. |

Edit the Order Line

-

Edit attributes on the order line to fix exceptions or improve performance.

-

Remove the value from an order line attribute to allow Order Management to select the best fulfillment option without having to consider a specific value for the attribute.

-

Remove values when you want to use Check Availability but don't want Order Management to consider a specific fulfillment requirement.

Edit the order line.

|

Attribute |

Description |

|---|---|

|

Source |

Select Warehouse or Supplier in the Source option, then set the Warehouse or Supplier attribute. |

|

Warehouse or Supplier |

Change the Warehouse or the Suppler that Order Management uses to source the item. Use the analytics area to help determine the warehouse to select. For details, see Source Items from Different Warehouses. |

|

Shipping Method |

Change the Shipping Method to a faster method. You can also add a check mark to the Clear Contents option immediately next to Shipping Method to allow Order Management to select the shipping method. |

|

Demand Class |

The Demand Class determines the priority that Order Management uses when it schedules the order line. Change the demand class when you must.

Demand class applies only if the ATP (available to promise) rule uses supply chain search, and if Order Management uses allocation. |

|

Scheduled Ship Date or Scheduled Arrival Date |

Set Override Schedule to Yes, then set the value in one of the date fields, such as 12/22/19. The orchestration process will reschedule order fulfillment according to the date you set. The orchestration process calculates the shipping schedule when you create a sales order, including the Scheduled Ship Date and the Scheduled Arrival Date. If you're aware of an alternative to this schedule, and if you know the best date to schedule the fulfillment line, then you might consider overriding these dates. |

Improve Performance When You Search

If you find that it takes a long time for Order Management to search for your sales orders, then consider adding values to more attributes when you do your search. For example, if you search only on an address attribute and search takes a long time, then add values to other attributes on the order header, such as Customer or Order.