12 In-season Planning

This chapter details the In-season Planning process.

Typical Business Users

The typical business user who completes this task will be an Assortment Planner. The Planner usually will have completed the Item Planning process, and is now ready to update that plan based on actuals and trends.

Step 1: Trend Analysis

The first step in the In-season Item Planning process is Trend Analysis. You can select KPIs to review for Season To Date (STD), which are elapsed periods and Balance to Achieve (BTA), which are the remaining unelapsed periods in the segment. Based on these trends, Keep/Add/Drop decisions can be made for existing and new items.

Tab and Views in this Step:

Trend Analysis Tab

The Trend Analysis tab is used to analyze/review the trends and you can view style/ color.

Filters and Parameters View

The Filters and Parameters view is used to select the KPIs that will be used in the Trend Analysis view.

The steps to complete this process:

-

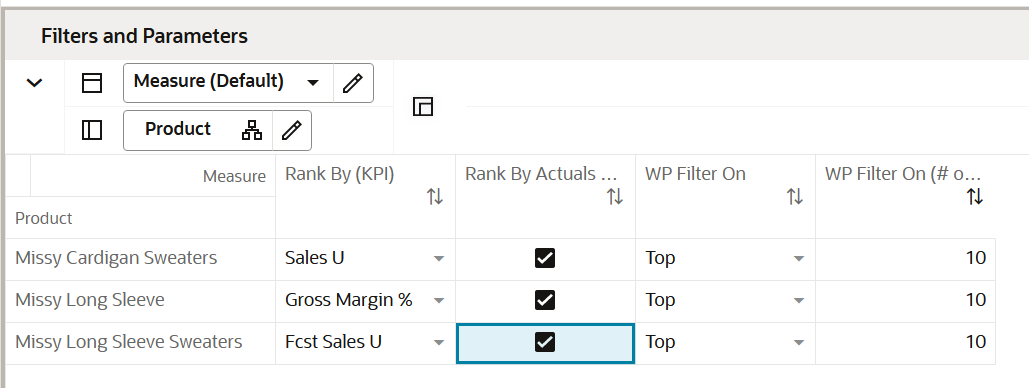

In the Rank by (KPI) measure, select the KPI that you wish to review in Trend Analysis.

-

If checked, the Rank by Actuals Only Boolean flag measure will rank items by actual sales results only.

If left unchecked, the ranking will be based on actuals and plan.

-

The WP Filter On and WP Filter On (# of Items) measures default to Top and 10, which will show the top 10 items in the Trend Analysis view.

You can also choose to show the lowest ranked items by selecting Bottom from the WP Filter On measure drop-down list.

-

Click Calculate to set your selections for view in the Trend Analysis view.

Figure 12-1 Filters and Parameters View

Measure Table

Table 12-1 Filters and Parameters View Measures

| Label | Definition |

|---|---|

|

Rank By (KPI) |

Key Performance Indicators that can be used to rank items in the Trend Analysis view. |

|

Rank by Actuals Only |

When this Boolean flag is selected, the Trend Analysis view will only show Season To Date actuals. |

|

WP Filter On |

Drop-down list that allows the planner to select whether to rank the top or bottom items in the Trend Analysis view. |

|

WP Filter On (# of Items) |

A planner-entered number to display the selected number of items in the Trend Analysis view. The default is 10. |

Measure Profile

Default Profile

The Default profile is used to select KPIs and set parameters for review in the Trend Analysis view.

Trend Analysis View

The Trend Analysis view is used to view Season To Date (STD) or Balance To Achieve (BTA) sales data to view variance to plan, as well as to facilitate focusing on exceptions through the top and bottom item performance reviews.

The steps to complete this process:

-

Review the performance of the items by the parameter and filters that were defined in the Filters and Parameters view, using the variance measures to compare to Working Plan, Current Plan (Approved version), and LY.

-

Update the KPIs, filters, and parameters as necessary and review the results in the Trend Analysis view.

-

These reviews can be done by cluster or channel.

Measure Table

Table 12-2 Trend Analysis View Measures

| Label | Definition |

|---|---|

|

WP Sales R, U, ROS GM R% |

Working Plan Sales Retail, Units, Rate of Sales, and Gross Margin percent. |

|

ROS |

The weekly rate of sales for the item/cluster/calendar periods that were selected in the wizard process. |

|

Keep/Add/Drop |

Drop-down list measure used to make In-season assortment changes. |

|

Keep/Add/Drop Comments |

Comments added for the status Keep/Add/Drop. |

|

CP Sales R, U, ROS, GM R% |

Current Plan Sales Retail, Units, Rate Of Sales, and Gross Margin percent. |

|

LY Sales R, U, ROS, GM R% |

Last Year Sales Retail, Units, Rate Of Sales, and Gross Margin percent. |

|

WP Sales R/U Var CP % |

Working Plan Retail, Units Variance to Current Plan. |

|

WP Sales R/U Var LY% |

Working Plan Retail, Units Variance to Last Year. |

Measure Profile

Default Profile

The Default profile is used to view trends using selected KPIs.

Step 2: Sales and Margin

The next step in the In-season Planning process is Sales and Margin. This step is used to assign like items, seed sales if necessary, and replan sales and margin based on actual results.

The steps to complete this process:

-

Define item parameters.

-

Replan regular and promotional sales and margin based on actuals and updated information.

Tabs and Views in this Step:

Sales and Margin Tab

The Sales and Margin tab is used to replan Regular and Promotional sales by item and cluster based on actuals and known trends.

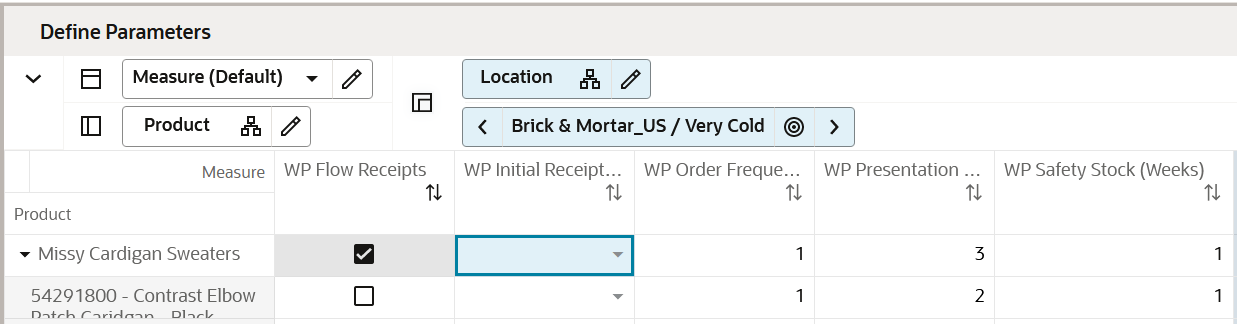

Define Parameters View

The Define Parameters view is used to review Assorted Items, Seed Sales, and assign like items by location cluster. If all clusters will receive the same data, you can rollup to All Location in the location hierarchy.

The steps to complete this process:

-

If you have a new item, or an item that you would like to re-seed, select the WP Seed Sales Boolean.

-

If you selected the Seed Sales Boolean, select the seed source from the WP Seed Source drop-down list measure:

-

Original Plan - the source for this data is from the Item Planning approved plan. If this option is selected, all the sales metrics will be seeded from the OP measures. This also includes Receipts, Customer Returns, Transaction, and Traffic measures.

-

Current Plan - the source for this data is from the In-season Planning approved plan. If this option is selected, all the sales metrics will be seeded from the CP measures. This also includes Receipts, Customer Returns, Transactions, and Traffic measures.

-

Forecast - the source for this data is Forecast Sales. If this option is selected, only the forecast sales will be copied to the regular sales.

-

Last Year - the source for this data is Last Year (if the item has data from the previous year). If this option is selected, only the total sales from last year will be copied to the regular sales. This does not include Receipts, however will include seeding of Customer Returns, Transaction, and Traffic measures.

-

-

If you want to assign a like item, in the WP Like Item measure, select the existing item to assign to the new item

-

Like Item CP - the source for this data is the Current Plan from the selected Like Item. If this option is selected, all the sales metrics will be seeded from the CP measures. This also includes Receipts, Customer Returns, Transactions, and Traffic measures.

-

Like Item LY - the source for this is Last Year data from the selected Like Item. If this option is selected, only the total sales from last year will be copied to the regular sales. This does not include Receipts, however will include seeding of Customer Returns, Transaction, and Traffic measures.

-

In the Like Item % measure, assign an adjustment ratio for the existing item sales to be copied to the new item.

-

-

Run the Seed Plan Application Action.

Running the Seed Plan Application Action creates the following logic for each Assorted Item:

-

Source Sales Units are spread to week based on the source selected.

-

Units are multiplied by the Base Unit Price and Base Unit Cost to get Retail and Cost.

-

Base Unit Price and Cost are interfaced from a source system for existing items and entered for placeholder items in the Item Administration segment.

-

Wp plans can be cleared only for the un-elapsed periods.

-

Note:

Only un-elapsed periods will be updated with seeded data.

Measure Table

Table 12-3 Define Parameters View Measures

| Label | Definition |

|---|---|

|

Wp Assorted item |

Boolean measure to highlight the assorted item. |

|

Wp Start Week |

Item Selling Start Week |

|

Wp End Week |

Item Selling End Week |

|

WP Seed Sales |

A Boolean flag measure that if selected, creates a weekly sales plan for assorted items. |

|

WP Seed Sales Source |

A drop-down list used to select the seed source for an item's sales. |

|

WP Like Item |

An item used to populate the Sales R, U, and GM R of a new item being added to the assortment using an adjustment ratio. |

Measure Profiles

Default Profile

The Default profile is used to assign item parameters before seeding sales.

Application Action

Seed Plan

The Seed Plan Application Action populates an item's weekly sales based on the sales source selected.

Plan Sales and Margin View

The Plan Sales and Margin view is used to replan Regular and Promotional sales by item and location cluster.

The steps to complete this process:

-

Use each of the Real Time Alerts to identify and locate items that need immediate attention. Resolve the alerts as appropriate.

-

Review the Regular Sales for item/cluster/week combinations that are performing outside of expectations and make adjustments as necessary.

-

Review ROS and Sell Thru % to ensure that sales and inventory are in line with expectations.

-

Review the WP Sell Thru U var CP measure to understand the unit variance between your WP Sell Thru and CP Sell Thru.

-

Review the WP Needed Sales Lift % measure to understand the sales lift % necessary to bridge the gap between your WP Sell Thru and CP Sell Thru.

-

Review AUC and Gross Margin measures to ensure the financial viability of the plan.

-

Repeat this process for each item and cluster in the assortment.

-

Once all item/clusters/weeks have been planned, utilize the measure profiles to compare to LY, OP, and CP, as well as to reconcile to MFP.

Measure Table

Table 12-4 Plan Sales and Margin View Measures

| Label | Definition |

|---|---|

|

Selling Weeks |

Boolean Measure |

|

Fcst Sales Reg + Promo U |

Forecasted Regular & Promotional Sales Units from AI Foundations Lite. |

|

Base Unit Price R |

An item's retail value that can differ by location. |

|

WP ROS |

The weekly rate of sales for the item/cluster/calendar periods that were selected in the wizard process. |

|

WP Sales Reg+Promo R, U, AUR |

Regular and Promotional Sales Retail, Units, and Average Unit Retail. |

|

WP GM R, GM % |

Gross Margin value and Gross Margin percent for an item. |

Measure Profiles

Default Profile

The Default profile is used to plan Regular and Promotional sales by item and cluster.

Last Year Profile

The Last Year profile is used to review last year regular and promotional data compared to the working plan.

Original Plan Profile

The Original Plan profile is used to review the most recently approved Item Plan Original Plan (OP) Regular and Promotional data compared to the working plan.

Current Plan Profile

The Current Plan profile is used to review the most recently approved Item Plan Current Plan (CP) Regular and Promotional data compared to the working plan.

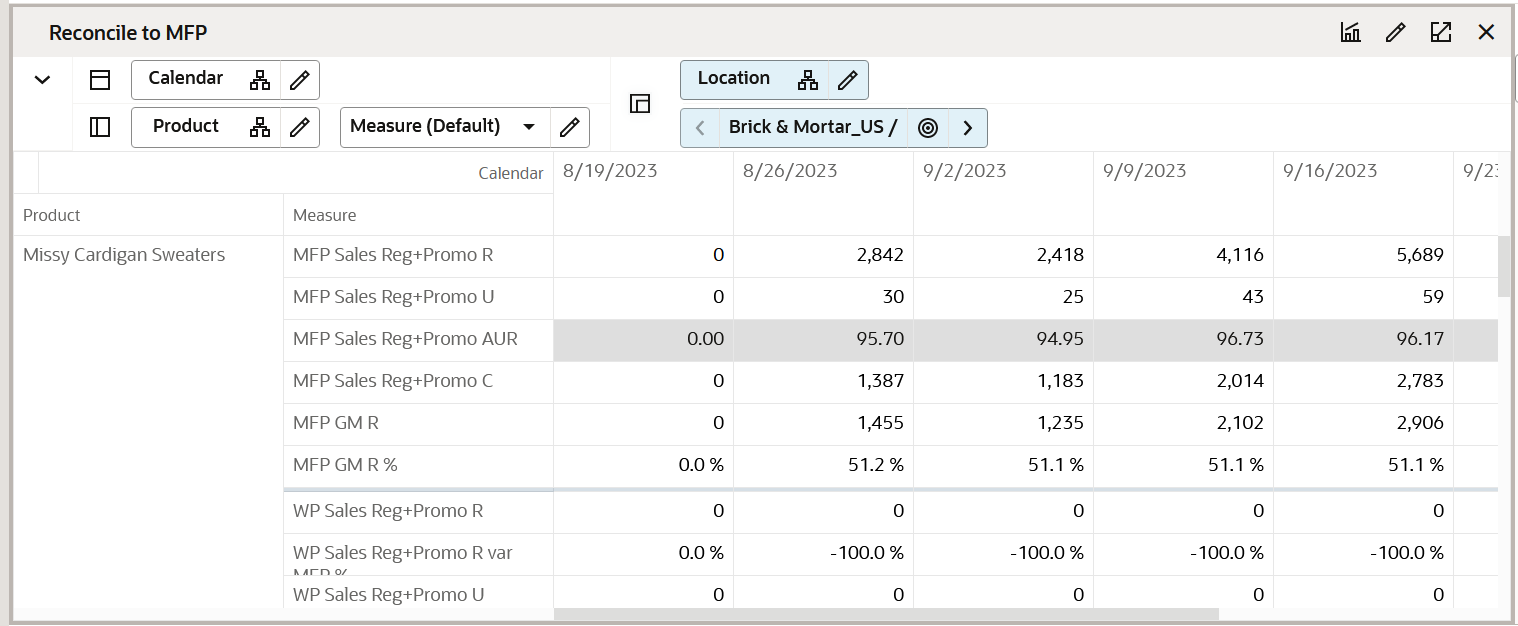

Reconcile to MFP View

The Reconcile to MFP view is used to compare the working plan of the item plan to the approved MFP Current Plan (MFP Tgt) for each subclass and cluster.

The steps to complete this process:

-

Review WP Sales var MFP Tgt % measures to identify variances that are outside of acceptable parameters.

-

Review Sales R, Sales U, Sales C, and GM variances to ensure that all of the financials meet targets.

-

Make adjustments to the sales and the receipt plans to be within an acceptable variance.

Repeat this process for each subclass and cluster in the assortment.

Note:

If a Location Plan is not available, the MFP CP view displays the MFP Current Plan by subclass spread to Location using last year's location sales' proportionality. If a Location Plan is available, the MFP CP view displays the MFP Current Plan by subclass spread to Location using the Location Plan CP sales' proportionality.

Figure 12-2 Reconcile to MFP View

Measure Table

Table 12-5 Reconcile to MFP View Measures

| Label | Definition |

|---|---|

|

MFP Sales R, U, AUR, C, AUC, GM R, GMR% |

MFP Sales Retail, Units, Average Unit Retail, Cost, Average Unit Cost, Gross Margin value, Gross Margin percent. |

|

WP Sales Reg+Promo R, U, AUR |

IP Working Plan Full Price Retail, Units, Average Unit Retail. |

Define Product Rollup Tab

This tab is used to select item attributes to view in an alternate hierarchy.

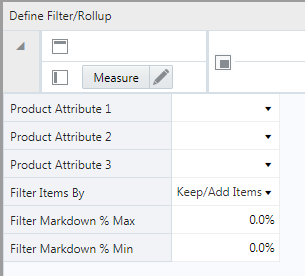

Define Filter/Rollup View

The Define Filter/Rollup view is used to select item attributes to view in an alternate hierarchy. This is available in views that display the item level. For example, if you select Color as a product attribute, in the Create and Review Assortment steps, you can click the Product Hierarchy tile to select the attribute as an alternate hierarchy, and view the proposed assortment by Black, Red, Navy, and so on. This allows you to rollup your items by different attributes to analyze and review the proposed assortment based on important attributes. You may select one attribute at a time from the alternate hierarchy.

The steps to complete this process:

-

Select up to three dynamic product attributes from the drop-down list.

-

Run the Refresh Attributes Rollup Application Action.

-

To set a filter:

-

In the Filter Items By measure drop-down list, select the real-time alert to filter by.

-

Click Calculate.

-

Go to a view that shows the item level and has the Filter function available. Click Filter.

-

Measure Table

Table 12-6 Define Filter/Rollup View Measures

| Label | Definition |

|---|---|

|

Product Attribute 1, 2, 3 |

Drop-down list to present product attributes for a dynamic product hierarchy rollup. |

|

Filter Items By |

Drop-down list used to select a real-time alert to filter items. |

Measure Profile

Default Profile

The Default profile is used to select dynamic product attributes and filter items.

Application Action

Refresh Product Rollup

The Refresh Product Rollup Application Action creates dynamically updated alternate hierarchies based on user-defined attribute selections. After running the Application Action, you may select the alternate product hierarchy to see rollups based on the attribute selections.

Step 3: Receipts and Inventory

The next step in the In-season Planning process is Receipts and Inventory. Use his step to define parameters for use in Real Time Alerts, replan receipts based on the updated sales plan, validate open-to-buy, and review and resolve Real Time Alerts. Note that Net Sales are used for the sales plan.

The steps to complete this process:

-

Review and update inventory parameters for use in inventory-driven Real Time Alerts, if necessary.

-

Adjust receipts and inventory based on the updated sales plan, in the context of the plan and/or open to buy.

-

Review and resolve Real Time Alerts.

-

Reconcile the plan to MFP.

Tabs and Views in this Step:

Application Actions

Round Receipts

The Round Receipts Application Action uses the inputs of WP Pack Size U and WP Min Order Quantity to round receipts up to match these parameters.

Refresh Product Rollup

The Refresh Product Rollup Application Action creates dynamically updated alternate hierarchies based on user-defined attribute selections. After running the Application Action, you may select the alternate product hierarchy to see rollups based on the attribute selections.

Receipts and Inventory Tab

Use the Receipts and Inventory tab for receipts and inventory.

Inventory Parameters View

The Inventory Parameters view is used to update and assign inventory and receipt parameters if they have changed from the Item Pre-season settings, or for new items for each location cluster.

The steps to complete this process:

-

Wp Reforecast Receipts allows you to qualify style-colors to generate the receipts forecast again for the un-elapsed period. Select the checkbox with True to qualify the measures for re-forecasting and run the custom menu, Re-forecast Receipts.

-

In the WP Lead Time (Days) measure, enter the number of days it takes for the product to arrive from your vendor/supplier to the warehouse or store.

This measure is used to generate the Immediate Need Real Time Alert, letting you know that your EOP is less than your Safety Stock.

-

In the TGT Sell Thru % measure, enter the targeted Sell Thru %.

This measure is used to generate the Sell Thru Warning Real Time Alert, letting you know that your Sell Thru is higher or lower than your targeted Sell Thru.

-

In the TGT WOS measure, enter the targeted Weeks of Supply.

-

This measure is used to generate the Overage Real Time Alert, letting you know that your WOS is higher than your targeted WOS.

-

In the WP Presentation Min U measure, enter the minimum amount of inventory on the sales floor per store.

-

In the Safety Stock (Weeks) measure, enter the number of weeks of sales that the safety stock should cover.

Use this measure to use future weeks of sales to generate a dynamic safety stock recommendation. It is recommended to use Safety Stock (Weeks) to generate a recommended initial buy to be used in Real Time Alerts.

-

In the WP Pack Size U measure, enter how many items come in a pack.

This measure is used in conjunction with the Round Receipt Application Action to round receipts up to the pack size entered.

For example, if your pack size is 10 and your receipts are 88, it will round up to 90 to meet the pack size.

-

In the WP Min Order Quantity measure, enter a minimum order quantity.

This measure is used in conjunction with the Round Receipt Application Action to round receipts up to the minimum order quantity entered.

For example, if your minimum order quantity is 100 and your receipts are 88, it will round up to 100.

-

Click Calculate.

-

Run the Round Receipts Application Action to round receipts using the Pack Size and/or Min Order Quantity measure inputs.

Review your WP EOP, WP WOS and WP Sell Thru % after running the Round Receipts Application Action to ensure that you are not over-inventoried due to rounding up.

Figure 12-3 Inventory Parameters View

Measure Table

Table 12-7 Inventory Parameters View Measures

| Label | Definition |

|---|---|

|

Wp Reforecast Receipts |

Boolean measure to qualify the style-colors for generating receipts forecast for the un-elapsed period in the season. |

|

WP Lead Time (Days) |

The number of days it takes for product to arrive from your vendor/supplier to the warehouse or store, used in the Immediate Need Real Time Alert. |

|

TGT Sell Thru % |

The planner entered targeted Sell Thru % by item/cluster, used in the Sell Thru Warning Real Time Alert. |

|

TGT WOS |

The planner entered targeted WOS by item/cluster, used in the Overage Real Time Alert. |

|

WP Presentation Min U |

The minimum amount of inventory on the sales floor per store, used in the Inventory Threshold Real Time Alert. |

|

WP Safety Stock (Weeks) |

The number of future weeks of sales that additional units should be maintained to mitigate the risk of stockouts, based on future sales weeks. It is used for the initial buy as well as for subsequent receipt drops as well as used in the Inventory Threshold, and Immediate Need. |

|

WP Pack Size U |

The number of units that come in a pack, used to round up receipts. |

|

WP Min Order Quantity |

The minimum order quantity, used to round up receipts. |

Measure Profile

Default Profile

The Default profile is used to update receipt parameters.

Application Action

Round Receipts

The Round Receipts Application Action uses the inputs of WP Pack Size U and WP Min Order Quantity to round receipts up to match these parameters.

Plan Receipts and Inventory View

The Plan Receipts and Inventory view is used to readjust the receipt plan to meet sales trends based on business knowledge or constraints.

The steps to complete this process:

-

Review the WP Receipts U, generate receipts forecast for the style-colors if required to adjust quantities or delivery weeks based on business knowledge, forecast generated and the updated sales plan.

-

Review the WP EOP U to ensure there are no over or under-stock issues.

If the receipt plan does not support the sales plan, a Real Time Alert will be activated to alert you that action is needed.

-

Review the WP WOS to view the calculated Weeks of Supply based on the sales and receipt plan.

The WP WOS metric represents the number of future calendar positions that the current stock will cover. For example, If your calendar is aggregated to month, then WP WOS represents the future number of months that the stock will cover, if the calendar is aggregated to quarter, then it represents the number of quarters that the stock will cover.

The WP WOS Weeks metric represents the inventory available to cover the future weeks at week level irrespective of the calendar level selected.

For each week, WOS is calculated as the number of future weeks of sales covered by the current period's EOP U.

-

Review the WP Sell Thru % as a reference value to see how fast inventory is projected to sell through.

For each week, Sell Thru % is calculated as Net Sales Units / (BOP U + Receipts U).

-

Review the Cost measures.

-

Repeat this process for each item and cluster in the assortment.

-

Once all item/clusters have been planned, utilize the measure profiles to compare to LY, OP, and CP, as well as to reconcile to MFP.

Note that you can use Product Attributes to rollup your items by attributes. For example, this can be used to view inventory levels by attributes that are important to the category, to make sure that receipts are invested for important attributes.

Measure Table

Table 12-8 Plan Receipts and Inventory View Measures

| Label | Definition |

|---|---|

|

WP BOP U, C, AUC |

The calculated Beginning of Period Units, Cost, and Average Unit Cost. |

|

WP Net Sales U, C, AUC |

Net Sales = Sales - Customer Returns Working Plan Net Sales Units, Cost, and Average Unit Cost. |

|

WP Receipts U, C, AUC |

Working Plan Receipts Units, Cost, and Average Unit Cost. |

|

WP EOP U, C, AUC |

The Working Plan calculated End of Period Units, Cost and Average Unit. |

|

WP WOS |

The number of future weeks of sales that will be covered by the current week's EOP U for the calendar level selected. |

|

WP WOS Weeks |

The number of future weeks of sales that will be covered by the current week's EOP U at the week level |

|

WP Sell Thru % |

The Working Plan percent of inventory that will be sold during a period, calculated as Net Sales Units / (BOP U + Receipts U). |

|

On Order U, C, AUC |

On Order Units, Cost, and Average Unit Cost. |

|

WP OTB U |

Open to Buy Units, calculated as: CP EOP U - WP EOPU + WP Receipts U - WP Net On Order U. Elapsed periods are always 0. |

|

On Order U |

On Order Units. |

|

WP On Order Adj U |

User-entered measure to plan updates to future weeks where Open To Buy needs to be updated to achieve the inventory plan, either due to high or low planned/ projected EOP. |

|

WP Net On Order U |

Read-only measure, calculated as WP On Order U + WP On Order Adj U. |

Real Time Alerts

Inventory Threshold

The alert activates when the current week EOP units is less than the Pres Min and Safety Stock (Weeks) measures. This alert is used in the Item Planning and In-season Planning segments.

Immediate Need

The alert activates when the current week EOP units is less than the Lead Time Days for an item/cluster/week. Note that Lead Time Days are converted to week. This alert is used in the In-season Planning segment.

Overage

The alert activates when the WP WOS between the current week and the current week + WP Lead Time Days is greater than the TGT WOS and there are non-zero values in Receipt U or On Order U from the current week + WP Lead Time Days for an item/cluster/ week. This alert is used in the In-season Planning segment..

On Order Reconciliation

The alert will activate when WP On Order U is greater than zero and does not match WP Receipt U for an item/cluster/week. This alert is used in the In-season Planning segment.

Sell Thru Warning

The alert activates to green when the WP Sell Thru % is higher than you entered TGT Sell Thru % and activates to yellow when the WP Sell Thru % is lower than the TGT Sell Thru % for an item/cluster/week. This alert is used in the In-season Planning segment.

Measure Profiles

Default Profile

The Default profile is used to plan weekly receipts to cover the sales plan based on the updated sales plan EOP inventory objectives.

Last Year Profile

The Last Year profile is used to compare the WP weekly receipts and inventory levels to last year values.

Original Plan Profile

The Original Plan profile is used to compare the WP weekly receipts and inventory levels to an approved Original Plan.

Current Plan Profile

The Current Plan profile is used to compare the WP weekly receipts and inventory levels to an approved Current Plan.

Application Action

Refresh Product Rollup

The Refresh Product Rollup Application Action creates dynamically updated alternate hierarchies based on user-defined attribute selections. After running the Application Action, you may select the alternate product hierarchy to see rollups based on the attribute selections.

Define Product Rollup Tab

This tab is used to select item attributes to view in an alternate hierarchy.

Define Filter/Rollup View

The Define Filter/Rollup view is used to select item attributes to view in an alternate hierarchy. This is available in views that display the item level. For example, if you select Color as a product attribute, in the Create and Review Assortment steps, you can click the Product Hierarchy tile to select the attribute as an alternate hierarchy, and view the proposed assortment by Black, Red, Navy, and so on. This allows you to rollup your items by different attributes to analyze and review the proposed assortment based on important attributes. You may select one attribute at a time from the alternate hierarchy.

The Filter Items By drop-down list allows you to select one of the Real-Time Alerts and use it to filter the items on each view. One filter may be used at a time in the segment.

The steps to complete this process:

-

Select up to three dynamic product attributes from the drop-down list.

-

Run the Refresh Attributes Rollup Application Action.

-

To view the product attribute:

-

In a view that displays the item level, click the Product Hierarchy tile.

-

Select the attribute that you want to view in the alternate hierarchy.

-

Click OK.

Figure 12-4 Define Filter/Rollup View

-

-

To set a filter:

-

In the Filter Items By measure drop-down list, select the real-time alert to filter by.

-

Click Calculate.

-

Measure Table

Table 12-9 Define Filter/Rollup View Measures

| Label | Definition |

|---|---|

|

Product Attribute 1, 2, 3 |

Drop-down list to present product attributes for a dynamic product hierarchy rollup. |

|

Filter Items By: |

Drop-down list used to select a real-time alert to filter items. |

Measure Profile

Default Profile

The Default profile is used to select dynamic product attributes and filter items.

Application Action

Refresh Product Rollup

The Refresh Product Rollup Application Action creates dynamically updated alternate hierarchies based on user-defined attribute selections. After running the Application Action, you may select the alternate product hierarchy to see rollups based on the attribute selections.

Step 4: Approve Plan

The final step in the In-season Planning process is the Approve Plan. This step approves the item plans that you have created, analyzed, and reviewed for accuracy. The output of this step is an approved Item Plan Current Plan.

The step to complete this process:

-

Approve the item plan.

Tab and View in this Step:

Application Actions

Approve Plan

The Approve Plan Application Action copies data from the Working Plan (WP) to the Current Plan (CP).

Approve Plan Tab

This tab is used to approve the plan.

Approve Plan View

The steps to complete this process:

-

In the WP Approve to OP/CP measure, select the Boolean flag for the subcategories and clusters that should be approved.

If all subcategories and clusters should be approved at once, rollup to All Product and All Location and select the Approve to OP measure at that level.

-

In the WP Comment measure, enter approval comments.

The WP Approval Comments will be copied to the OP Approval Comments and concatenated with the approver's ID, for future reference in this view.

-

Run the Approve Application Action.

Note:

The Approve Application Action creates the OP and CP versions of the plan.

Measure Table

Table 12-10 Approve Plan View Measures

| Label | Definition |

|---|---|

|

WP Approve to CP |

Boolean flag measure that when selected approves the Working Plan Item Plan to the Current Plan. |

|

WP Comments |

Comments entered here will be copied to the CP Approval Comments and concatenated with the approver's ID, for future reference in this view. |

|

CP Comments |

Current Plan comments used as a reference. |

Measure Profile

Default Profile

The Default profile is used to approve the Item Plan to the CP version.

Application Action

Approve Plan

The Approve Plan Application Action copies data from the Working Plan (WP) to the Current Plan (CP).