8 Product Administration

The following topics are covered in this chapter:

Global Glossaries

The Global Glossaries define the keywords and order of those keywords in pick-lists available for selection throughout Product.

Simple keyword glossaries are maintained through a list of the single values, plus their translations. The more complex glossaries, that combine multiple fields, such as Nutrients, are maintained as individual records presented in a list view. If translations are provided for a glossary, pick-list options are presented to the user in the user's language. If no translation is present for that language, the options are shown in the portal's base language.

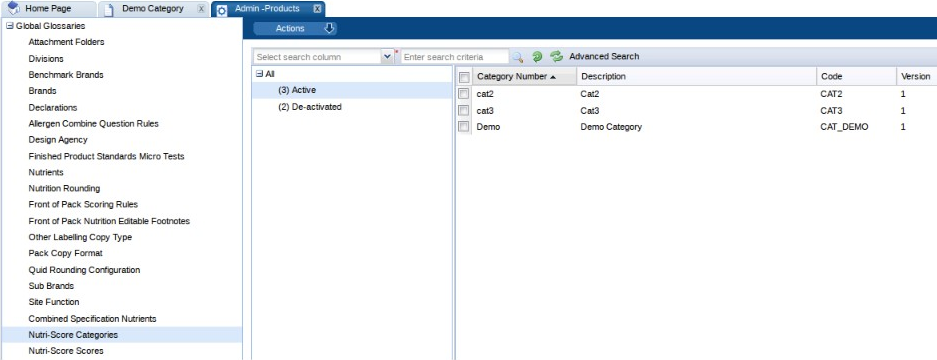

To access Global Glossaries, select Products from the Admin drop-down list. The Admin - Products tab opens. Figure 8-1 shows an example of the expanded Spec Glossaries in the left pane with the Declarations glossary open.

Figure 8-1 Global Glossaries Options

Nutri-Score Glossaries

Two glossaries are provided for Nutri-Score functionality:

Nutri-Score Categories Glossary

This glossary is used to configure the scoring rules for the Nutri-Score functionality. The glossary defines the Nutrients to be used for the Nutri-Score calculation, their incremental quantities, the points that each nutrient will contribute to the Nutri-Score calculation, and the Scores that will be derived from the calculated value.

The glossary allows separate scoring rules to be created for different product types. The scoring rules are configured by assigning sets of incremental bandings to specified baseline nutrients, based on per 100g/ml nutrient content, with points assigned to each banding. The points can be dynamically adjusted based on the content of other nutrients, by defining modifying nutrient rules.

When a product specification's Nutrition values are calculated, if the product has been assigned a Nutri-Score category, the configured values are used to calculate the total number of points based on the per 100g/ml nutrient values.

The points total is converted into a Nutri-Score score, which can be configured as a numeric score (such as 1 to 5), a grading (such as A to E), or a classification (such as Red, Amber Green).

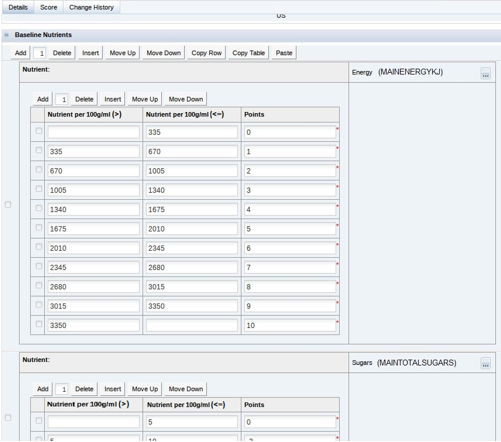

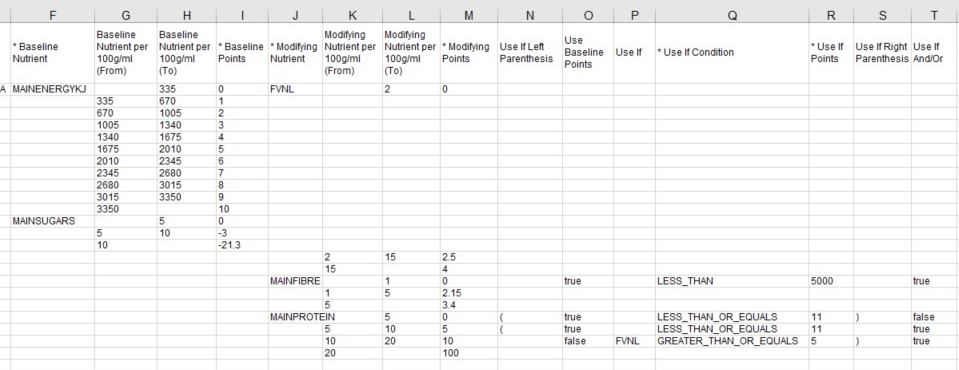

Baseline Nutrients

The Baseline nutrients table is built by adding the nutrients to be scored, and defining the points bandings for each. Any nutrient can be scored, however typically it would be Energy, Sugars, Saturated Fats, and Sodium.

The Nutrient per 100g/ml (>) and Nutrient per 100g/ml (<=) columns form the points banding ranges. The <= value must be greater than the > value. The Points value is mandatory. Any blank rows in the table are ignored.

Figure 8-2 Baseline Nutrients Table

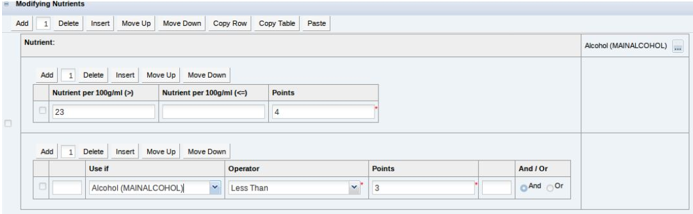

Modifying Nutrients

Modifying nutrients can optionally be defined, to adjust the baseline nutrient points calculation based on the presence of another nutrient. The maintenance of the table is similar to the Baseline Nutrients table.

Figure 8-3 Modifying Nutrients Table

The adjustments can optionally have conditions, to determine whether or not they are to be applied. The conditions are defined by building a structured statement in a table, similar to how clauses are constructed in the Advanced Search facility for list views.

The Used If column defines the condition type, which can be based on the number of points calculated for another nutrient (by selecting the nutrient), and/or the calculated total baseline nutrient points (by selecting the fixed Total Baseline Points entry).

Note:

If a nutrient row is removed from the Baseline Nutrients table, any corresponding nutrient row in the Modifying Nutrients table or Use If column is automatically removed.

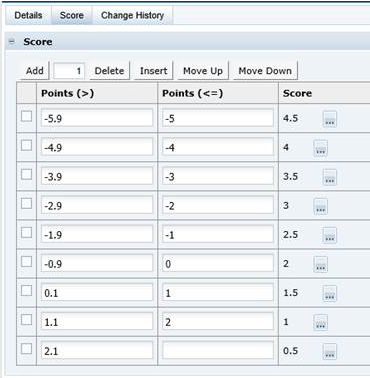

Scores

The conversion of the total calculated points to a score is achieved by defining ranges of points in the Scores table. The maintenance of the table is similar to the Baseline Nutrients and Modifying Nutrients tables.

Figure 8-4 Scores Table

The Points > and Points <= columns form the total points range. The > value must be greater than the <= value (unless the > value is left blank; for example, to specify if less than or equal to -1, the > value can be left blank and the <= value set to -1). The Score column is a selection from the Nutri-Score Scores glossary. Any blank rows in the table are ignored.

For more information on Nutri-Score calculations, see the Oracle Retail Brand Compliance Management Cloud Service Product User Guide.

Exporting the Glossary

The option to export the Nutri-Score Categories glossary is not available. Due to the complexity of the glossary, it is not suited to the import/export facility. The Export option has been removed from the Actions menu of the glossary's list view, and the option to bulk export glossaries now excludes this glossary. The Import option remains for the initial setup of the base glossary contents.

Figure 8-5 Example Of Exported Nutri-Score Category Glossary

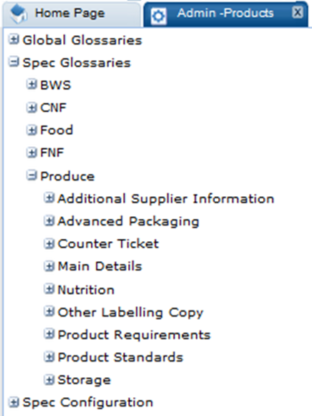

Spec Glossaries

The Spec Glossaries define the keywords and order of those keywords available for selection in pick-lists when working with specification records. A glossary folder is available for each section of a specification. The glossaries are grouped by specification type and are maintained either as a list of single values or a separate record per glossary entry for the more complex entries.

To access Spec Glossaries, select Products from the Admin drop-down list. The Admin - Products tab opens. Figure 8-6 shows an example of the expanded Spec Glossaries in the left pane.

Figure 8-6 Spec Glossaries Options

Spec Configuration

Spec Configuration is used to define the following for each stage of the Product workflow process:

-

Which specification fields become mandatory in order to progress to a certain status, that is, data must be entered for these fields.

-

The rules that determine when specification fields become locked due to a certain status being reached, that is, the data becomes read-only.

To access Spec Configuration, select Products from the Admin drop-down list. The Admin - Products tab opens.

The following options are available in the left pane for Spec Configuration:

-

Mandatory Field Rules

-

Specification Locking Rules

-

Manage Mandatory Field Rules

-

Manage Specification Locking Rules

There are other options, currently only available to Oracle Authorized User administrators, to set the specification types available for the portal and which sections are mandatory or optional within each specification type.

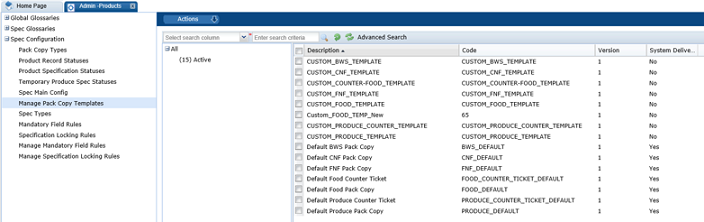

Pack Copy Templates

Each type of product specification has a Pack Copy or Counter Ticket file that contains the product's labelling information. A set of templates are provided for the system-delivered formats:

-

Food Pack Copy

-

Formulated (FNF) Pack Copy

-

Constructed Non Food (CNF) Pack Copy

-

Beers, Wines & Spirits (BWS) Pack Copy

-

Produce Pack Copy

-

Food Counter Ticket

-

Produce Counter Ticket

The Pack Copy and Counter Ticket files are generated by BI Publisher, using Rich Text Format (RTF) templates, which is the same concept behind the Reports module. Retailer administrator users can design a custom RTF file in a similar way to other reports. It is therefore possible to override the system-delivered layouts with custom formats, with alternative content and formatting.

The process for overriding a system-delivered Pack Copy or Counter Ticket file with a custom template is described below. The template is an RTF file, which could be created from scratch, but is recommended that an existing Pack Copy File (or other report template that uses the Specifications API data source) be copied and adapted as required.

To download an existing Pack Copy template:

-

Select the Manage Pack Copy Templates option in Products / Spec Configuration group in the Admin area.

Figure 8-7 Pack Copy Templates Page

-

Select the row that contains the template to be copied and then select the Edit action. For an example of this page, see Figure 8-8.

-

Select the Download Template action to save the RTF template file locally.

-

Select the Download Sample XML action to save the XML data file locally.

-

Open the RTF file in a suitable editing tool, such as Microsoft Word with the BI Publisher Template Builder plug-in installed. Import the XML file to provide the available data elements.

Note:

For details on building custom reports, see the Oracle Retail Brand Compliance Management Cloud Service Reports User Guide.

There is a known limitation in the output of bulleted and numbered lists in BI Publisher reports. This affects the rich text fields with CK Editor text formatting options, and results in the bullet point or number being omitted or replaced with a question mark. Typical rich text fields are in the Product Specification: Preparation, Serving and Recipe Suggestions, On Pack Ingredients, FPS Standards, Process Controls and Custom RTF fields. For list formatting in these fields, manually number the list, or use a character such as a hyphen as an alternative to a bullet point.

Some considerations when designing custom templates:

-

The Pack Copy XML data file is similar to that used by the Product Requirement reports (CR42 to CR46) in the Reports module, where the Specifications API is the data source. This allows for fields from any section of the specification to be included in the template.

-

The Pack Copy XML data file includes additional elements of data from the Product Record, Supplier and Site records that the specification is linked to, such as contact details, business categories, and surveillance classifications.

-

The default date format is dd-mmm-yyyy.

-

The XML includes an xxxFormatted element for all date fields, where xxx is the name of the associated element, for example, firstProductionDate will have a firstProductionDateFormatted element. The xxxFormatted element will contain the date, formatted appropriate to the locale of the specification's Pack Copy Language.

-

The format of the core templates is fixed, with tables showing empty cells where no data is present. If required, it is feasible to create a custom template that contains logic to hide rows or tables that have no data to output.

-

The system-delivered templates are effectively the master copies of the core templates. They cannot be updated or deleted.

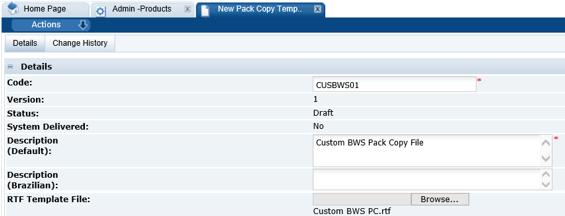

To upload a custom Pack Copy template:

-

Select the Manage Pack Copy Templates option in the Products / Spec Configuration group in the Admin area and then select the New action.

-

Enter a unique code, and a suitable description.

Figure 8-8 Pack Copy Template Details Page

-

Click Browse to search for the RTF template file.

-

Select the Save action and then select the Activate action.

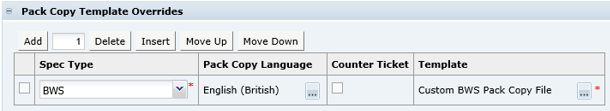

To apply a custom Pack Copy template override:

-

Select the Spec Types option in the Spec Configuration group in the Products Admin area.

-

Select the row for the appropriate type of specification and then select the Edit Specification Type action.

-

Scroll down to the Pack Copy Template Overrides field set and click Add to add a row to the table.

Figure 8-9 Spec Type Details Page

-

Select the Spec Type and Pack Copy Language. This allows for alternative templates per language.

-

Check the Counter Ticket box if the override is for a Counter Ticket.

-

Select the Pack Copy Template that contains the custom RTF file.

-

Select Save & Exit.

Note:

To revert back to the system-delivered template, remove the appropriate rows from the Pack Copy Template Overrides using the Delete button.

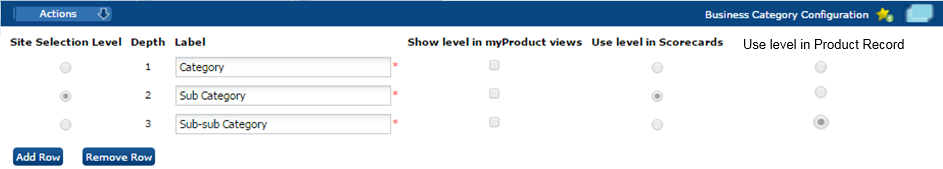

Business Category Configuration

This configuration controls the number of levels that can be maintained within the actual glossary of Business Categories. The glossary is maintained under the Suppliers & Sites Admin option. For more information on that option, see Business Categories.

To configure the Business Categories used within Product, select the System Control option and then select Business Category Configuration in the left panel. The Business Category Configuration page opens.

Figure 8-10 Business Category Configuration Page

To change the configuration, select the Edit action. The page is changed to edit mode. The labels and the number of rows can be changed. To select a category level to be shown in the Product views, check the box for that level. The maximum number of levels is five.

The Use level in Product Record radio button controls the number of levels of business category used within the Product Record.

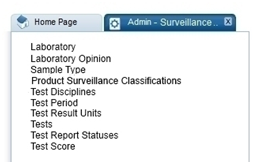

Surveillance

The configuration of the Product Surveillance module is administered within its own section in the Admin section of Product. It is only accessible to those users with Product Surveillance Administrator authority profile.

Select Product Surveillance to open the Product Surveillance Admin tab.

Figure 8-11 Admin - Surveillance Options

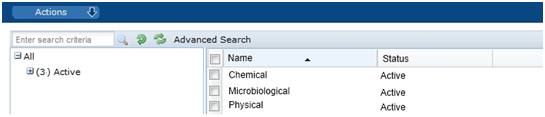

Test Disciplines

The Test Disciplines within Product Surveillance are the categories of testing carried out on products.

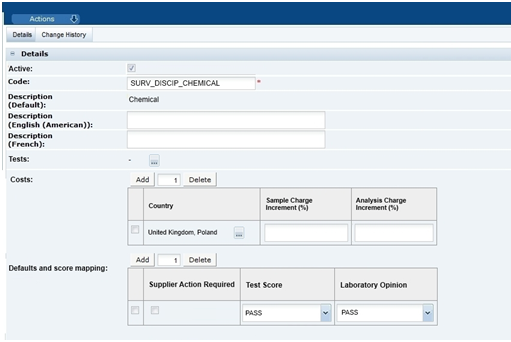

Figure 8-12 Surveillance Test Disciplines

Each individual discipline record contains the configuration of the tests which can be applied, the associated costs, and the mapping for laboratory opinion and score. By default, there are three entries, disciplines can be added or deleted but only by the Oracle Brand Compliance Management Cloud Service administrator.

Figure 8-13 Surveillance Discipline Record

The tests table defines what tests can be used for any classification under the Discipline. The tests available are held in the Tests glossary.

The Costs table determines the incremental percentage to be added to the laboratory supplied charges associated with any sample testing. Charges can be configured on a Country or multi-Country level. The country to be used for the calculation is selected on import. If there is no configuration for the country selected, no costs are calculated and the costs tab is hidden from the test report record. There is a validation check when saving the record to check that the same country does not appear in two or more rows in the table. If the check fails, the record cannot be saved.

The Default and Score Mapping table defines the default for the Test Score and Supplier Action Required fields in the Results Summary when a result is imported into the system. The available values are held in the respective Laboratory Opinion and Test Score glossaries. There is a validation check when saving the record to check that the same value does not appear in two or more rows in the table. If the check fails, the record cannot be saved.

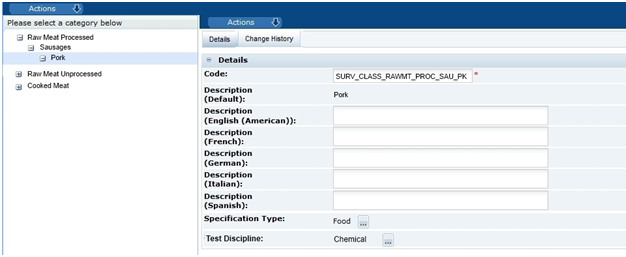

Product Surveillance Classifications

Under each Test Discipline, the Product Surveillance Classifications categorize products that require the same Product Surveillance testing. In core, by default, there is a 3-tier classification hierarchy. Classifications can be assigned to one or more specification types.

The following figure shows an example product surveillance classification hierarchy for Raw Meat under the product surveillance discipline of Microbiological.

Figure 8-14 Product Surveillance Classification Example

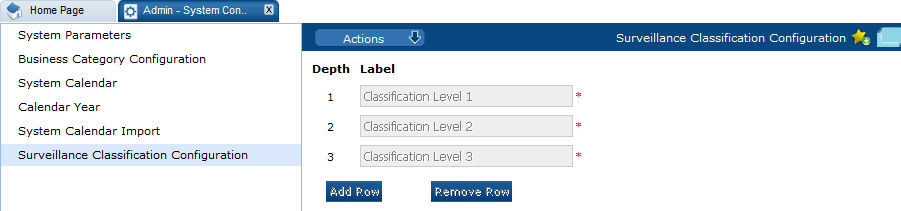

Each classification record can be assigned to one of more specification type. By default, the number of Product Surveillance classification levels is set to three. However, this can be configured for individual client needs, as with the Business Categories, within the System Control administration section.

Figure 8-15 Surveillance Classification Configuration Page

To change the configuration, select the Edit action. The page is changed to edit mode. The labels and the number of rows can be changed.

System Parameters

Note:

Before using Surveillance, ensure that the parameters listed in this section have been set up.

To maintain the parameters used to support Product, select the System Control option and then System Parameters.

Table 8-1 shows the specific system parameters, by subtab on the System Parameters page, used to support Product.

Table 8-1 System Parameters to Support Product

| Subtab | Parameter | Description |

|---|---|---|

|

Products |

Notify Supplier on Product Creation |

If Yes, generate an email for the supplier when a product is created. Default is Yes. |

|

Products |

Notify Retailer on Product Creation |

If Yes, generate an email for the retailer when a product is created. Default is Yes. |

|

Products |

Retain D&A Answers When Copying a Specification tab within Spec |

If set to Yes, the answers to D&A questions are carried across when a new version of a Specification is created. If set to No, the answers are cleared. Default is Yes. |

|

Products |

Retain D&A Answers When Creating a New Version of a Spec |

If set to Yes, the answers to D&A questions are carried across when a Specification is copied. If set to No, the answers are cleared. Default is Yes. |

|

Products |

Pack Copy Format |

Data file format used for a Produce specification's pack copy file. |

|

Products |

Show Specification Section Attachments table by Default |

If set to Yes, attachments are not listed within the Attachments field-set within each section of a Specification, but instead are controlled through the use of the Show Attachments button. Default is No. |

|

Products |

Show Codes in Product Record |

If set to Yes, the EAN/Barcode and Shipping Case code fields are present in the Product Record. If set to No, they are hidden. Default is No. |

|

Products |

Enable Recipe & Formulation Import/Export |

If set to Yes, the Import Recipe and Export Recipe buttons appear in the Food Specification's Recipe and Raw Materials section and the Import Formulation and Export Formulation buttons appear in the FNF Specification's Formulation and Raw Materials section. If set to No, the buttons are not shown. Default is No. |

|

Products |

Allow Creation of multiple Products |

Allows multiple products to be associated to a single Product Record. Default is off (single product per Product Record). This is locked once the first Product Record or Specification is created. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Capture Declarations |

Controls whether a reason for not declaring a table appears in the Specification. Default is on (the table appears). Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Set Pack Copy Language |

Control whether Pack Copy files can be created in alternative languages. Default is off (Pack Copy files are solely created in the system's business language). Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

System Uses Single Legislation |

If set, the system uses a single legislation. Default is off (the required legislation can be selected). Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Legislation |

If the System Uses Single Legislation parameter is set on, this field must be set to one of the legislations available for the portal. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Product Record Controls Countries Field |

Allows the Countries Where Sold to be specified in the Product Record and automatically cascaded to the associated Specifications. Default is off (the Countries Where Sold field is hidden in the Product Record and is editable in the Specification). Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Show Lead Business Category in Product Record |

If set on, the system will show a Lead Business category field in the Product Record and Specification, and relabel the Business Category field to Other Business Category in both records. This approach is also taken in the Site record. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Are Nutrient Targets Used? |

Controls whether Nutrient Targets (such as Salt Targets) are enabled within the Specification's Nutrition section. Default is off. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

FoP Nutrition Labelling Used? |

Controls whether Front of Pack Nutrition (such as Traffic Lights) is enabled within the Specification's Nutrition section. Default is off. If set on, the relevant glossaries become visible, the FoP table is present in the Specification for the data entry and calculations to take place, and the FoP data is included in the Pack Copy file. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Legislations Supporting Nutrition Targets |

The legislations used in the calculation of Nutrition Targets. Must be set to one or more if Nutrition Targets are used. Default is EU. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Enable Sustainability |

If a specification type is selected, the ability to capture sustainability-related information is enabled for that type of product specification (additional columns and pages appear in the Recipe/Formulation sections). Only Food and/or Formulated Non Food specification types may be selected. The initial default for new implementations is Food; otherwise none are selected. If a specification type is deselected, after previously being enabled, any Sustainability data that has already been entered will no longer be shown on screen, but will remain accessible through reports. |

|

Products |

Barcode Regular Expression Validation |

Validation rule for Barcodes. The default is:

Validation is applied to ensure the entered value is a valid regular expression. If a value is present, validation is applied to Barcodes in the Product Record and Specification. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

OLC Shipping Case Code Regular Expression Validation |

Validation rule for Shipping Case code. The

default is: Validation is applied to ensure the entered value is a valid regular expression. If a value is present, validation is applied to Barcodes in the Product Record and Specification. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Validate Bar Code Check Digit |

A checkbox which defaults to checked, that is, On. |

|

Products |

Validate Shipping Case Code Check Digit |

A checkbox which defaults to checked, that is, On. |

|

Products |

Validate for Cutter Guide Attachment? |

If switched on, when a non-Produce Specification is validated to move from Collaborative Draft to Pack Copy Sent, a check is made to ensure a Cutter Guide attachment is present, resulting in an error if not present. Default is off (the Cutter Guide is optional). For Produce Specifications, if switched on, the validation is applied when the Specification is progressed from Draft to Draft - Pack Copy Sent status, or from Draft to Approved status (if the Specification has an OLC section). Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Exclude FPS As Sold Page from Spec Types |

Select specification types to have the page hidden in the Finished Product Standards section for that specification type. The selection is specification type (such as Food or BWS), not specification format (such as Pre-packed Food or Counter Ticket). |

|

Products |

Exclude FPS As Consumed Page from Spec Types |

|

|

Products |

Exclude FPS Benchmarks Page from Spec Types |

|

|

Products |

Supplier Can Edit Benchmark |

If No, only Retailer users can edit the Benchmark fields on Product Records. If Yes, both Retailer and Supplier users can edit the Benchmark fields on Product Records. Note: This does not apply to Produce Product Records. Default is No. |

|

Products |

Allergen Override Approval fields not Mandatory at Status |

Use this to control at which statuses the approval of allergen overrides (that is, completion of the Allergen Override Approval and Comments fields) becomes mandatory in the D&A specification section. Any prior statuses must be specified, for example, for the status Collaborative Draft, statuses Supplier Draft and Retailer Draft must also be included. Default is Supplier Draft, Retailer Draft, Collaborative Draft. |

|

Products |

Product Number read only in Product Record at Status |

Use this to enable the ability to make the Retailer Product Number in the Product Record read-only to Supplier users when it is linked to a product specification of a certain status. This prevents the Supplier changing the product number beyond a certain stage in the workflow. Select one or more specification statuses; none are selected by default. If none are selected, the feature is not enabled. |

|

Products |

Show Alt. Product No. in Product Record and Specification |

If set to Yes, the Alt. Product No. field will be enabled within the Product Record and the Product Specification, which is typically used to hold an alternative product identifier such as a GTIN code. Default is No. If enabled and subsequently disabled, any values previously saved in the fields are retained; if then re-enabled, the values will then reappear. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Show Division in Product Record and Specification |

If checked, the Division field will be enabled within the Product Record and the Product Specification, which is typically used to provide an additional categorization of the product by selecting from a glossary of Division. Default is No. If enabled and subsequently disabled, any values previously saved in the fields are retained; if then re-enabled, the values will then reappear. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Cascade Product Number from Non-Produce Product Record to Specification |

If Yes, the Retailer Product Number is updated in a Specification if it is changed in the associated Product Record. Validation prevents this being set if the show Alt. Product Number and Show Division parameters are not checked. Default is No. This would typically be used where the Retailer Product Number holds the product's identifier from an external system, such as an Article Number. If this updating is enabled, when a Product Record is saved, any rows in associated Specifications that have the same Alt. Product Number/GTIN and Division values have the Retailer Product Number/Article Number replaced with the corresponding value from the Product Record. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Cascade Product Number from Produce Specification to Product Record |

If Yes, the Retailer Product Number is updated in a Produce Product Record if it is changed in the associated Specification. Validation prevents this being set if the show Alt. Product Number and Show Division parameters are not checked. Default is No. This would typically be used where the Retailer Product Number holds the product's identifier from an external system, such as an Article Number. If this updating is enabled, when a Product Specification is saved, any rows in associated Product Records that have the same Alt. Product Number/GTIN and Division values have the Retailer Product Number/Article Number replaced with the corresponding value from the Product Record. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Enable Combined Specification |

Use this to enable or disable the Combined Specifications facility. Options are Yes or No. Default is Yes (enabled). If set to Yes, the following is enabled for users who have the requisite access rights:

If set to No, the above options are hidden. For further details, see Combined Specifications. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Use Advanced Packaging Recycling Advice |

A multi-select pick list of the specification types will provide control as to which specification types the Recycling Advice table will appear on, under the Advanced Packaging section for a specification. |

|

Products |

Enable Advanced Packaging Component Detail Import/Export |

Use this control to enable or disable the Import and Export functionality for the Advanced Packaging section of a specification. When set to Yes, the Import Packaging Component and Export Packaging Component buttons will appear in the Advanced Packaging section of a specification. If set to No, the buttons are not shown. Default is No. |

|

Products |

Advanced Packaging Component Attribute Table Column Limit |

Use this control to manage the maximum number of columns on the read-only pivot table for the Packaging Attributes. This is located in a specification's Advanced Packaging section under the Packaging Attributes tab. |

|

Products |

Nutri-Score Spec Types |

If a specification type is selected, the Nutri-Score functionality is enabled for that specification type. When creating a new specification, a Nutri-Score field-set is included in the Nutrition section. Only the Food and Produce specification types may be selected. Default is no specification type is selected. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Default Use Nutri-Score on Pack |

This checkbox sets the default for the Nutri-Score Use on Pack option in the specification's Nutrition section. If checked, the Nutri-Score data will be carried through to the selected specification's Pack Copy File when Nutri-Score functionality is enabled for the specification. Default is not checked. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Use Material Transparency |

If a specification type is selected, the ability to capture Material Supplier Connections within the Recipe / Formulation Raw Materials table is enabled for that type of product specification (all formats). The available options are Food and Formulated Non Food (FNF). The initial default for new implementations is for none to be selected. If a specification type is deselected, after previously being enabled, any material supplier connections data that has already been entered will no longer be shown on the screen, but will remain accessible through reports and data exports. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Products |

Material Transparency Mandatory Status |

Used in conjunction with the Use Material Transparency parameter, to set the status at which the Material Supplier Connections data in the Recipe / Formulation Raw Materials table becomes mandatory. The available options are derived from the Product Specification Statuses glossary. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Global |

Show Business Language Fields |

If set to Yes, the system does the following:

Default is No. |

|

Global |

Background Polling Interval (ms) |

This is the time in milliseconds which the system will use to poll to the server to check for updates. May be set to greater than 500, however the default of 500 is the recommended setting. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Global |

Portal Code |

The portal's identifier. If the allocation of Supplier and Site account codes is configured to include a prefix, the portal code is used as the prefix. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Global |

Use Alternative Code for Product SOAP API |

Use this to enable a facility that provides a means of cross-referencing supplier codes when creating or updating Product Records using the Product Inbound SOAP API. This feature is of use where the external system does not hold the ORBC supplier codes. Options are Yes and No. Default is Yes (enabled). If enabled, it allows alternative supplier codes to be added to the Invoicing Information table in the Supplier record; when transactions are submitted to the API, if the Supplier record cannot be located using the ORBC supplier code, a secondary lookup is performed to locate the Supplier record using the alternative codes. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Global |

Allow Duplicate Product Codes for Product SOAP API |

Use this to control whether multiple Product Records can have the same product identifier when submitted using the Product Inbound SOAP API. Options are Yes and No. Default is Yes (enabled). If enabled, when Product Records are created using the API, the same Retailer Product Number may be present on multiple Product Records (as long as the supplier is different); otherwise the API will validate that the Retailer Product Number is unique across all suppliers. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

|

Surveillance |

Task App External Contact Roles |

Allows administrators to select which Contact Roles for external users should be able to see the number of reports relevant to them, that is, the number for their Supplier or their Site depending on the role in the Task App. This is a multi-select selector that shows the Contact Roles set up on the system. If the global parameter Use Site Code is False, any Site Contacts selected will be ignored. |

|

Surveillance |

Use Site Codes |

This is set when the portal is implemented. The options are Yes and No. Default is No. When set to Yes, the import of Surveillance test results will validate the site code to ensure it is associated to the respective Product Record, resulting in an error if not. If this parameter is set to No, the site code is ignored during the import, and the site code and site name will be blank in the imported test report. Note: This parameter can only be seen and maintained by a user with the Oracle Authorized Administrator authority profile. |

Retailer users with the Oracle Authorized Administrator authority profile will see a Settings parameters tab. This tab displays core parameters, what their purpose is, which area of the system they are used in, and what value they are set to.

Note:

These parameters are read-only; they cannot be edited.

Table 8-2 Settings Parameters

| Subtab | Parameter | Description |

|---|---|---|

|

Products |

Specification Draft Statuses |

The statuses at which a Specification is considered to be a draft specification. These states influence field locking and snapshotting as well as validation. Default is Supplier Draft, Retailer Draft, Collaborative Draft, Produce Draft. |

|

Products |

Specification Private Draft Statuses / Allergen Override Non Approval Statuses |

These are the specification statuses at which an allergen override does not have to be approved in order to reach this status. The default setting is: Supplier Draft, Retailer Draft. |

|

Products |

Specification Public Draft Statuses |

The specification states that are considered to be draft, but visible to both parties. Default is Collaborative Draft, Gate Step. |

|

Products |

Specification Statuses where Nutrition Sections are editable |

The specification statuses at which the Nutrition section is editable. Defaults is: Supplier Draft, Retailer Draft, Collaborative Draft, Produce Draft, Part Pack Copy Sent. |

|

Products |

Business Categories Mandatory Status (Non-Produce) |

Controls at which status the business category becomes mandatory within a Specification (all specification types other than Produce). The default setting is that it becomes mandatory at and beyond Gate Step. |

|

Products |

Business Categories Mandatory Status (Produce) |

Controls at which status the business category becomes mandatory within a Produce Specification. The default setting is that it becomes mandatory at Produce Pack Copy status. |

|

Products |

CNF Component Decimal Precision |

Sets the number of decimal places shown in the Components table of a CNF Specification. Default is 2. |

|

Products |

FPS Product Attribute Columns |

This is used to control which of the three columns (red, amber, and green) are used within the Finished Product Standards section, and in which order they are shown. Default is Red, Amber, Green. |

|

Products |

Require Active Ingredient Statuses |

The statuses of the Specification where ingredients must be active for the Specification to reach that status. Default is Supplier Draft, Retailer Draft, Collaborative Draft, Gate Step. |

|

Products |

Report Missing Benchmark Message as a Warning? |

If this is switched on, the system will report a missing Benchmark within a Product Record as a warning, not an error. Default is off. |

|

Products |

OLC Quantities Mandatory Status (Non-Produce) |

Missing mandatory fields from the Quantities page in Specifications are raised as a warning before this status and as errors at or after this status. This parameter is for all specification types other than Produce. Default is Gate Step. |

|

Products |

OLC Quantities Mandatory Status (Produce) |

Missing mandatory fields from the Quantities page in Specifications are raised as a warning before this status and as errors at or after this status. This parameter is for Produce specifications. Default is Produce Pack Copy. |

|

Products |

Pack Copy Generation Statuses |

The specification states that can generate a Pack Copy file. Default is Pack Copy Sent, Part Pack Copy Sent, Produce Pack Copy, Produce Approved. |

|

Products |

Product Record Other User Roles |

Enables additional user roles to be used within a Product Record. Default is Buyer, Product Development Manager. |

|

Products |

Product Record Technologist List Config |

The List Configs used to show the names in the Product Technologist selector. |

|

Products |

Product Record Technologist Role Code |

The code used within a Product Record that is considered to be the Product Technologist. The Product Technologist user role plays an important role within the system. As the description may be changed to suit a portal owner's terminology, this code provides the system with a static identifier. Default is: PRODUCT TECHNOLOGIST. |

|

Products |

Show Ingredient Separator After Forced Addition? |

Modifies the formatting of the Ingredient Declaration. Default is off. If switched on, a comma is added after a forced addition group finishes and there are further ingredient in the generated output. Example with the ingredient separator: Water, Colourings: Apricot, Magenta;, Sugar Example without the ingredient separator: Water, Colourings: Apricot, Magenta; Sugar |

|

Products |

Suppress Forced Addition Closing Character If Last In Group |

Modifies the formatting of the Ingredient Declaration. Default is off. If switched on, a closing character is applied when the forced addition group is the last member of the ingredient list or of a compound. Example with the closing character present: Water, Filling (Meat, Colourings: Apricot, Magenta;), Sugar Example without the closing character present: Water, Filling (Meat, Colourings: Apricot, Magenta), Sugar |

|

Supplier |

Supplier Linking Enabled |

If switched on, a Supplier Linking page will be shown in the Supplier record. Default is off. |

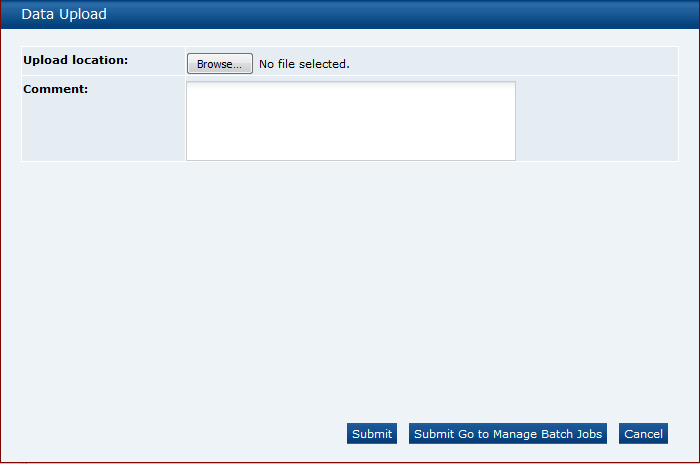

Upload Product Record Data

Retailer users with the Upload Administrator authority profile have access to the Upload Data option within the Admin menu for the upload of products.

To upload new Product Records:

-

Select the Import option in the left hand pane. The Data Upload dialog box opens.

Figure 8-16 Data Upload Dialog Box

-

Click Browse to search for the upload file.

-

Enter any comments to describe the reason for the upload.

-

To upload the file, select either the Submit or Submit Go to Manage Batch Jobs action. At this point the system will create a background job to process the spreadsheet. The spreadsheet used to upload the data will be stored within the Attachments tab of the batch job.

Note:

An email will be sent to the job submitter if the data within the upload file fails validation.

Download Product Record Upload Spreadsheet

Retailer users with the Upload Administrator authority profile also have access to the option to download a blank spreadsheet.

To download the latest version of the upload spreadsheet:

-

Select the Download Blank Spreadsheet action from the Product Records View actions menu. An operating system specific dialog box opens with the option to either open or save the file.

-

Select the save option to download the ZIP file to your desktop.

Note:

The ZIP file contains a spreadsheet workbook with the first tab used to upload the data. The second tab contains guidance notes and the remaining tabs contain the valid glossary values.

The column heading text shown on the first tab is in the user's language. If translations are not present for the user's language, the system the portal's default language is substituted. An asterisk (*) is shown in a column heading if an entry is mandatory.

Combined Specifications

The Combined Specifications facility is administered using the following configurations:

System Parameter

The use of the Combined Specifications feature is enabled or disabled for the portal using the Enable Combined Specification system parameter - see System Parameters. The parameter is accessible to users with the Oracle Authorized Administrator authority profile.

To maintain the system parameter, select the System Control option and then System Parameters.

The following scenarios show the effect the Combined Specifications feature being enabled, disabled, and re-enabled:

Table 8-3 Combined Specification Scenarios

| Scenario | Handling |

|---|---|

|

The Combined Specifications feature is enabled. |

|

|

The Combined Specifications feature is disabled. |

|

|

The Combined Specifications feature is enabled, and subsequently disabled. |

|

Declaration Glossary

The Default Priority for Combined Specs field in the Declaration Glossary is used to assign a priority to the declarations (May Contain, Does Not Contain, and so on), so that when D&A/Additional Product Info sections are combined into a specification, if there are numerous label declarations, the priority determines which is to be used.

If no priority has been set, no default will be set, so it will be necessary to manually unlock the specification and assign a label declaration before it can be progressed (the usual specification validation will trap this error).

To set the default priority value:

-

Open the Declaration Glossary record for editing (found in Products/Global Glossaries).

-

Set the Default Priority for Combined Specs field to a numeric value to represent the priority. 1 represents the highest priority.

-

Save the record.

When saving the record, the system will check if another Declaration glossary record has the same priority value, and if so, will issue a warning message.

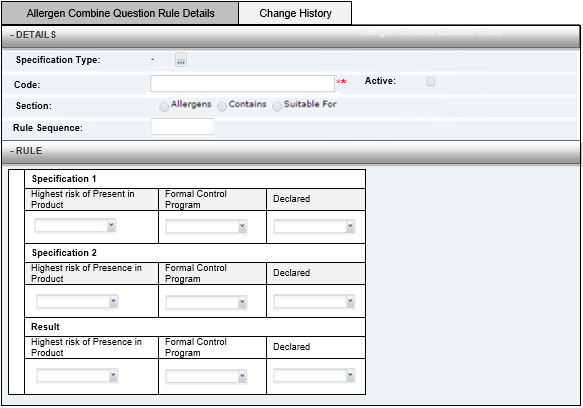

Allergen Combine Question Rules Glossary

The Allergen Combine Question Rules glossary is used to define the rules for determining how the Allergy & Dietary Advice section in a Food specification, and the Additional Product Information section in a non-Food specification is to be populated when using the Combined Specifications facility.

The approach for applying the rules is based on determining a worst case answer for each question by comparing the answers for that question across all specifications being combined.

If for example there are five specifications to be combined, the system will process the specifications, comparing the same question in each of the specifications as follows:

-

Specification 1 question compared to Specification 2 and a result is derived.

-

The derived result is compared with Specification 3 and a result is derived.

-

The derived result is compared with Specification 4 and a result is derived.

-

The derived result is compared with Specification 5 and a result is derived.

-

The derived value is used in the target specification (as specified by the result part of the rule).

The rules are applied in the order of source specification percentage breakdown (highest first), however the rules are not applied to the first source specification, as that is the starting point of the combined specification. For example, applying the core default rules specified in Table 8-5:

-

If Specification 1 has a breakdown of 75%, the combined specification starts as Present in Product = Yes and Declared = Yes. The first rule (10) does not match as Specification 1 is not present in product. The second rule (20) also does not match as it is required both to be set to Not Present in Product. The result is the combined specification is Present in Product = Yes and Declared = No.

-

When reversed, Specification 2 is the starting point for the combined specification, rule 10 matches as Specification 1 is Present in Product = Yes and Declared = Yes, as the declared rule is Prefer Yes.

The Declared result is used if the rule wins.

To maintain the rules:

-

Open the glossary from within the Products/Global Glossaries group in the Admin area. The option is available to users with the Product Administrator authority profile.

Note:

The glossary will be pre-populated in new installations and upgrades from release 18.1 onwards with the core default rules.

-

Select an existing entry in the list view, or select New to create a new record.

Opening the record presents as follows:

Table 8-4 Information Needed to Create an Allergen Combine Question Rule

Field Description Specification Type

Select one or more specification types. This field is mandatory.

Code

Enter a unique identifier for this rule in uppercase. This field is mandatory.

Active

Check the box if this rule is set active when created.

Section

Select the section this rule applies to. The options are Allergens, Contains, and Suitable For. This field is mandatory.

Sequence

Enter a numeric value to signify the order in which this rule is to be applied. The value must be unique for the specification type/section combination. This field is mandatory.

Specification 1 - Question from Specification 1

Highest risk of Present in Product

Select the answer for comparison 1. The options are Present in Product, Not Present in Product, Possibly Present in Product, Present on the Production Line, Present in Factory, and Any.

Formal Control Program/Declared

Select the answer for comparison 1. The options are Yes, No, and Any.

Specification 2 - Question from Specification 2

Highest risk of Present in Product

Select the answer for comparison 2. The options are Present in Product, Not Present in Product, Possibly Present in Product, Present on the Production Line, Present in Factory, and Any.

Formal Control Program/Declared

Select the answer for comparison 2. The options are Yes, No, and Any.

Result - see below for further details

Highest risk of Present in Product

Select the answer for the result of the comparison. The options are Present in Product, Not Present in Product, Possibly Present in Product, Present on the Production Line, Present in Factory, and Any.

Other options include:

As per Specification 1 (the field will be set to the same value as the question from Specification 1);

As per Specification 2 (the field will be set to the same value as the question from the Specification 2);

Prefer Yes (if either of the questions is set to Yes; the result will be set to Yes; otherwise it is set to No);

Prefer No (if either of the questions is set to No, the result is set to No, otherwise it is set to Yes).

Formal Control Program/Declared

Select the answer for the result of the comparison. The options are Yes, No, and Any.

Note:

A spreadsheet containing the core default rules (for EU legislation) can be downloaded from the System Control /Core Glossary Download admin area by users with the Oracle Authorized Administrator authority profile.

Below are examples of how the core default rules will be configured. It is not recommended that these be changed without consulting Oracle.

Allergen Rules

The table below shows how these four rules are configured:

Rules 1 and 2 - If any specification is Present in Product, the combined result is Present in Product.

Rule 3 - If all specifications are Not Present in Product, the combined result is Not Present in Product.

Rule 4 - Otherwise, the combined result is Possibly Present in Ingredients.

Table 8-5 Allergen Rules for Food and BWS Specifications

| Field | Rule 1 | Rule 2 | Rule 3 | Rule 4 | |

|---|---|---|---|---|---|

|

Specification Type |

Food BWS |

Food BWS |

Food BWS |

Food BWS |

|

|

Code |

FOOD_PRESENT_IN_PRODUCT1 BWS_PRESENT_IN_PRODUCT1 |

FOOD_PRESENT_IN_PRODUCT2 BWS_PRESENT_IN_PRODUCT2 |

FOOD_NOT_PRESENT_IN_PRODUCT BWS_NOT_PRESENT_IN_PRODUCT |

FOOD_POSSIBLY_PRESENT BWS_POSSIBLY_PRESENT |

|

|

Section |

Allergens |

Allergens |

Allergens |

Allergens |

|

|

Rule Sequence |

10 |

20 |

30 |

40 |

|

|

Spec 1 |

Highest Risk of Present in Product |

Present in Product |

Any |

Not Present in Product |

Any |

|

Formal Control Program |

Any |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

Any |

|

|

Spec 2 |

Highest Risk of Present in Product |

Any |

Present in Product |

Not Present in Product |

Any |

|

Formal Control Program |

Any |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

Any |

|

|

Result |

Highest Risk of Present in Product |

Present in Product |

Present in Product |

Not Present in Product |

Possibly Present in Product |

|

Formal Control Program |

No |

Any |

No |

No |

|

|

Declared |

Prefer Yes |

Any |

No |

Prefer Yes |

|

Contains Rules

The table below shows how these three rules are configured:

Rule 1 and 2 - If any specification is Present in Product = Yes, the combined result is Yes.

Rule 3 - If all specifications are Present in Product = No, the combined result is No.

Table 8-6 Contains Rules for Food and BWS Specifications

| Field | Rule 1 | Rule 2 | Rule 3 | |

|---|---|---|---|---|

|

Specification Type |

Food BWS |

Food BWS |

Food BWS |

|

|

Code |

FOOD_CONTAINS1 BWS_CONTAINS1 |

FOOD_CONTAINS2 BWS_CONTAINS2 |

FOOD_DOES_NOT_CONTAIN BWS_DOES_NOT_CONTAIN |

|

|

Section |

Contains |

Contains |

Contains |

|

|

Rule Sequence |

10 |

20 |

30 |

|

|

Spec 1 |

Highest Risk of Present in Product |

Present in Product |

Any |

Not Present in Product |

|

Formal Control Program |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

|

|

Spec 2 |

Highest Risk of Present in Product |

Any |

Present in Product |

Present in Product |

|

Formal Control Program |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

|

|

Result |

Highest Risk of Present in Product |

Present in Product |

Present in Product |

Not Present in Product |

|

Formal Control Program |

No |

Any |

No |

|

|

Declared |

Prefer Yes |

Prefer Yes |

No |

|

Table 8-7 Contains Rules for FNF and CNF Specifications

| Field | Rule 1 | Rule 2 | Rule 3 | |

|---|---|---|---|---|

|

Specification Type |

FNF CNF |

FNF CNF |

FNF CNF |

|

|

Code |

FNF_CONTAINS1 CNF_CONTAINS1 |

FNF_CONTAINS2 CNF_CONTAINS2 |

FNF_DOES_NOT_CONTAIN CNF_DOES_NOT_CONTAIN |

|

|

Section |

Contains |

Contains |

Contains |

|

|

Rule Sequence |

10 |

20 |

30 |

|

|

Spec 1 |

Highest Risk of Present in Product |

Present in Product |

Any |

Not Present in Product |

|

Formal Control Program |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

|

|

Spec 2 |

Highest Risk of Present in Product |

Any |

Present in Product |

Not Present in Product |

|

Formal Control Program |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

|

|

Result |

Highest Risk of Present in Product |

Present in Product |

Present in Product |

Not Present in Product |

|

Formal Control Program |

No |

Any |

No |

|

|

Declared |

Prefer Yes |

Prefer Yes |

No |

|

Suitable For Rules

The table below shows how these three rules are configured:

Rules 1 and 2 - If any source specification is Suitable For = No, the combined result is No.

Rule 3 - If all source specifications are Suitable For = Yes, the combined result is Yes.

When applying the Suitable For questions, Present in Product = Yes equates to Suitable For = Yes.

Table 8-8 Suitable for Rules for Food and BWS Specifications

| Field | Rule 1 | Rule 2 | Rule 3 | |

|---|---|---|---|---|

|

Specification Type |

Food BWS |

Food BWS |

Food BWS |

|

|

Code |

FOOD_NOT_SUITABLE_FOR1 BWS_NOT_SUITABLE_FOR1 |

FOOD_NOT_SUITABLE_FOR2 BWS_NOT_SUITABLE_FOR2 |

FOOD_SUITABLE_FOR BWS_SUITABLE_FOR |

|

|

Section |

Suitable For |

Suitable For |

Suitable For |

|

|

Rule Sequence |

10 |

20 |

30 |

|

|

Spec 1 |

Highest Risk of Present in Product |

Not Present in Product |

Any |

Present in Product |

|

Formal Control Program |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

|

|

Spec 2 |

Highest Risk of Present in Product |

Any |

Present in Product |

Present in Product |

|

Formal Control Program |

Any |

Any |

Any |

|

|

Declared |

Any |

Any |

Any |

|

|

Result |

Highest Risk of Present in Product |

Not Present in Product |

Not Present in Product |

Present in Product |

|

Formal Control Program |

No |

No |

No |

|

|

Declared |

No |

No |

Prefer Yes |

|

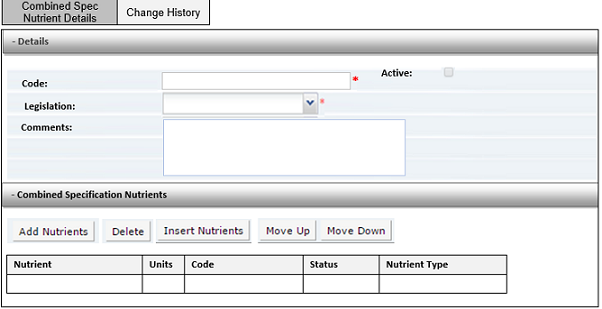

Combined Specification Nutrient Glossary

The Combined Specification Nutrition glossary is used to define a set of core default nutrients used to populate the Nutrition section of Food specification when using the Combined Specifications facility.

-

Open the glossary from the Products/Global Glossaries group in the Admin area. The option is available to users with the Product Administrator authority profile.

-

Select an existing entry in the list view, or select New to create a new record.

-

The record presents as follows:

Table 8-9 Information Needed to Create a Combined Specification Nutrient

Field Description Code

Enter a unique identifier for this rule in uppercase. This field is mandatory.

Active

Check the box if this rule is set active when created.

Legislation

Select the legislation that this set of nutrients applies to. This is a mandatory field, which must be unique, so that there is only one record per legislation.

Comments

Optionally enter any comments to explain the purpose of this record.

The Combined Specification Nutrients table specifies the nutrients that are considered to be the core set.

The table shows the selected nutrients' name, code, unit of measure, and status from the main Nutrients glossary.

The nutrients to be assigned to a Combined Specification Nutrient record would typically be the mandatory nutrients for a specific legislation.

The following validation checks are also applied:

-

If saving as active, there cannot already be an active record for the same legislation.

-

At least one nutrient must be selected.

-

All selected nutrients must be active.

Note:

A spreadsheet containing the core default rules (for EU legislation) can be downloaded from the System Control /Core Glossary Download admin area by users with the Oracle Authorized Administrator authority profile.