11 Assortment Administration Task

This chapter describes the functionality that allows you to review and maintain the assortment within IPOCS-Lifecycle Allocation and Replenishment.

In IPOCS-Lifecycle Allocation and Replenishment assortment information is used during the replenishment calculation. Replenishment should only be suggested for valid product and location combinations rather than for all product and location combinations. It is during this process where the assortment information is very important to allow IPOCS-Lifecycle Allocation and Replenishment to replenish only valid combinations, it also improves calculation performance by reducing the amount of product and location combinations.

Based on the assortment information IPOCS-Lifecycle Allocation and Replenishment identifies valid product and location combinations if the following conditions are met:

-

If the product and location combination is active when the system runs the replenishment calculations. In other words, if the system date (today’s date) is within the Assortment Start and Assortment End Dates for the product and location combination

-

There are historical sales for the product and location combination.

-

There is allocation information for the product and location combination.

-

If users have overridden the assortment information and have created an exception to force a particular product and location combination to be valid (assorted)

Assortment Administration Workspace, Steps, and Views

The following table lists the workspaces, steps, and views for the Assortment Administration task.

Table 11-1 Assortment Admin Workspace, Steps and Views

| Workspace | Step | Tab | Views |

|---|---|---|---|

|

Assortment Summary |

|||

|

Assortment Parameters |

|||

|

By Parent |

|||

|

By Item |

|||

|

Actual Data |

Assortment Admin Workspace

The Assortment Admin workspace allows you to access all the views listed in Assortment Administration Workspace, Steps, and Views. To build the Assortment Admin workspace, perform these steps:

-

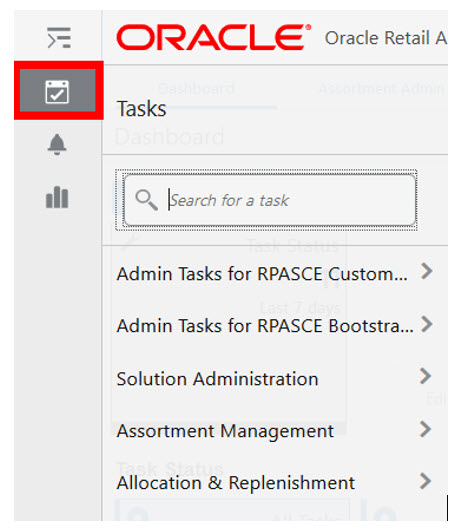

From the left sidebar menu, click the Task Module to view the available tasks.

Figure 11-1 Task Module

-

Click the Assortment Management activity to access the available workspaces.

-

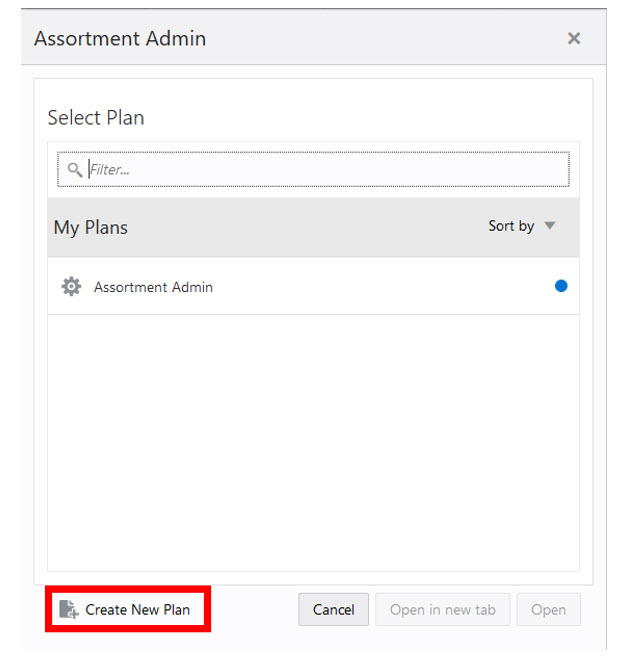

Click Assortment Admin. The Assortment Admin wizard opens. You can open an existing workspace, but to create a new workspace, click Create New Workspace.

Figure 11-2 Assortment Admin Wizard

-

Enter a name for your new workspace in the label text box and click OK.

Figure 11-3 Enter Workspace Label

-

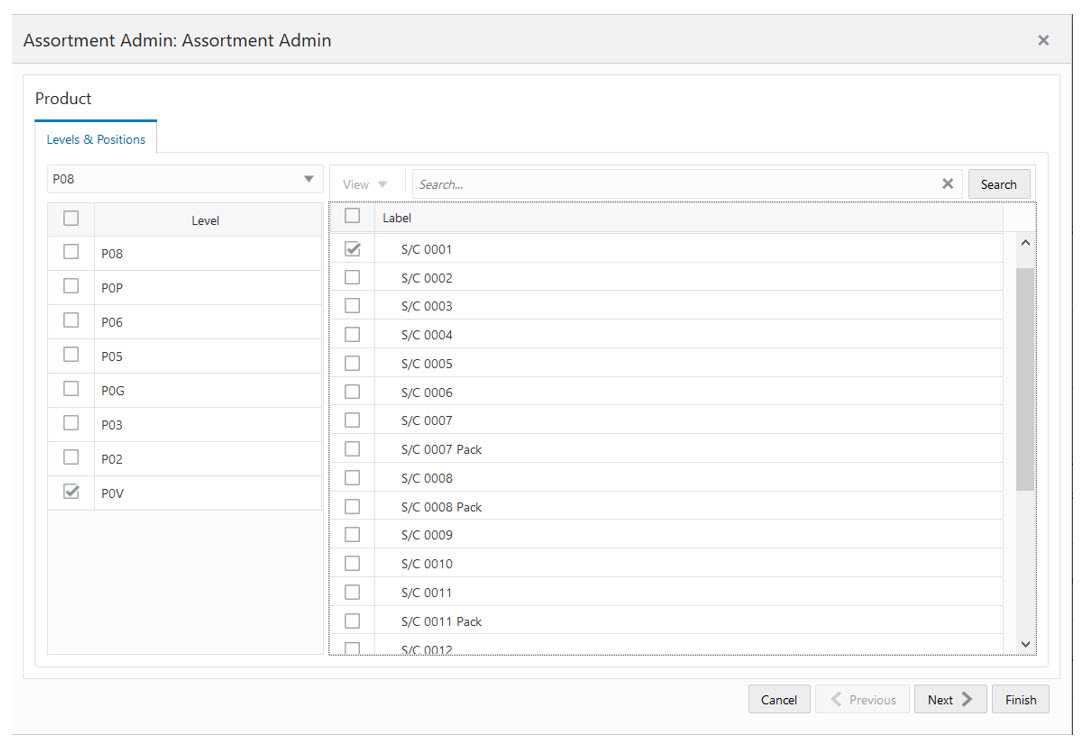

The Workspace wizard opens. Select the products you want to work with and click Next.

Figure 11-4 Workspace Wizard: Select Product

-

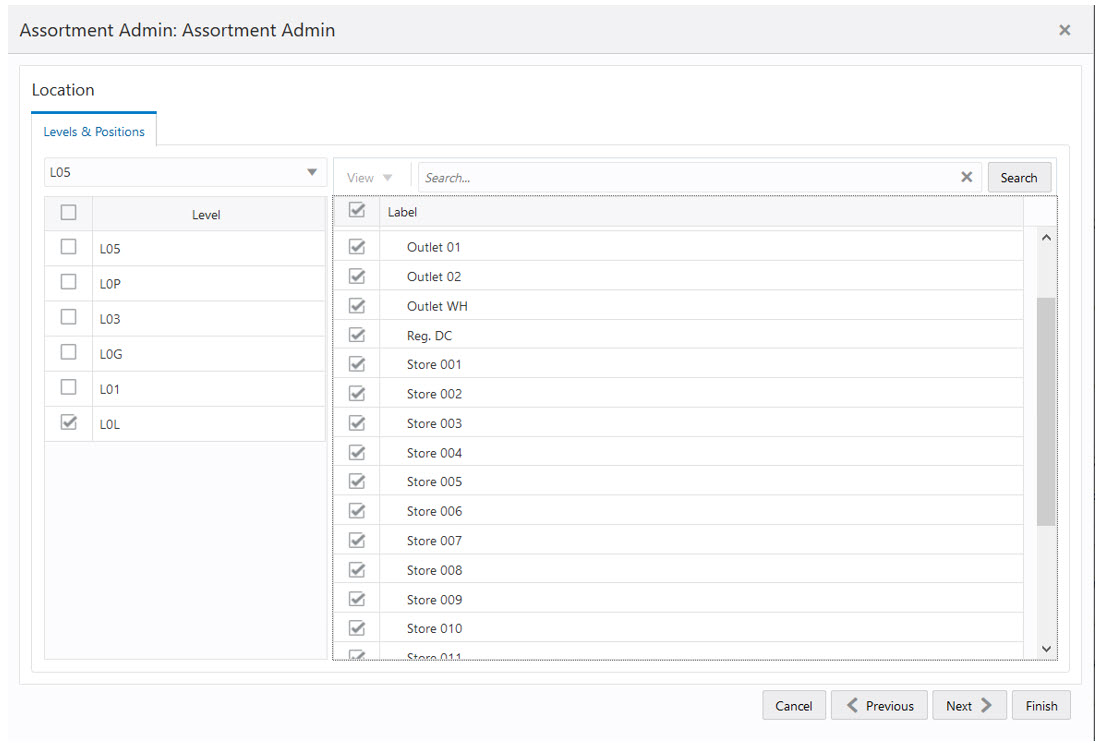

Select the locations you want to work with and click Next.

Figure 11-5 Workspace Wizard: Select Location

-

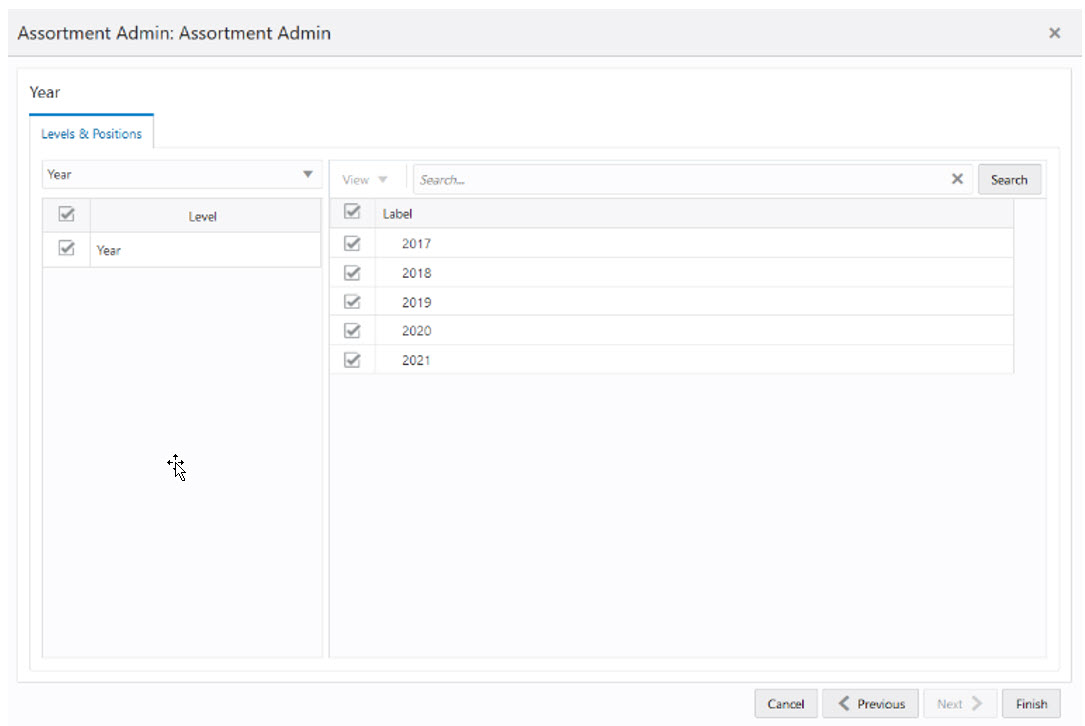

Select the calendar period you want to work with and click Finish.

Figure 11-6 Workspace Wizard: Select Calendar

-

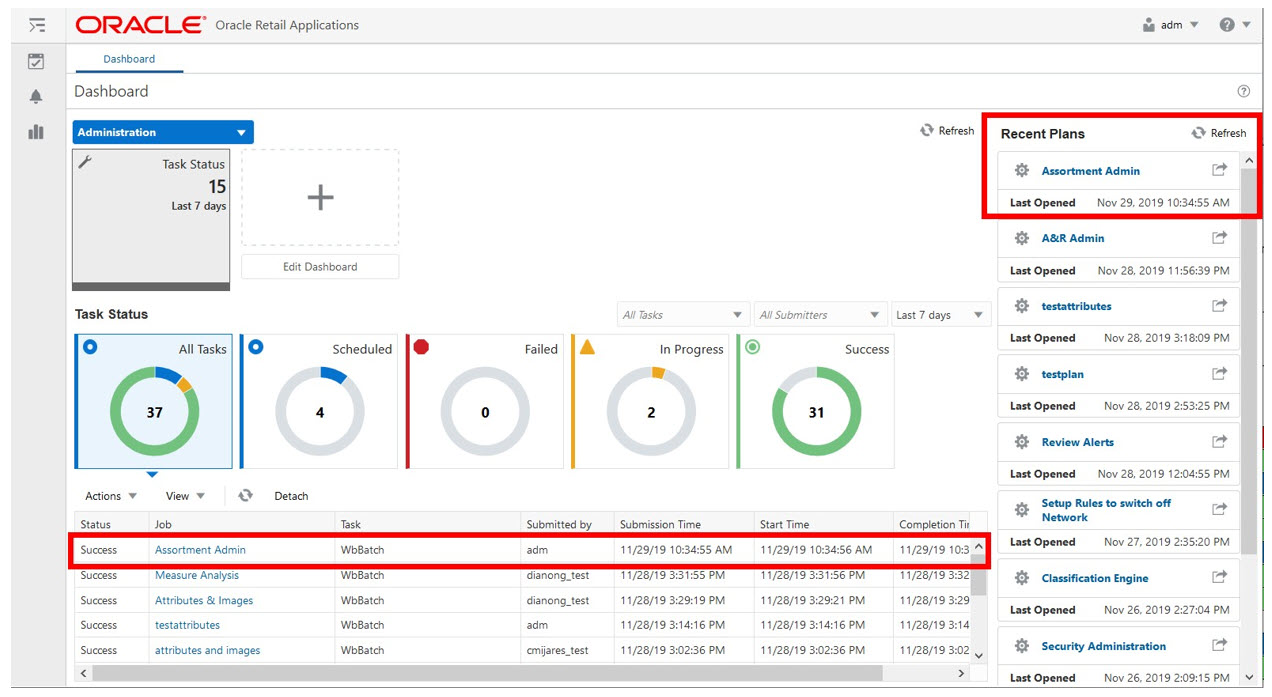

The wizard notifies you that your workspace is being prepared. Successful workspaces are available from the Dashboard.

Figure 11-7 Successful Workspace Build

Review Parameters Step

This step contains these views:

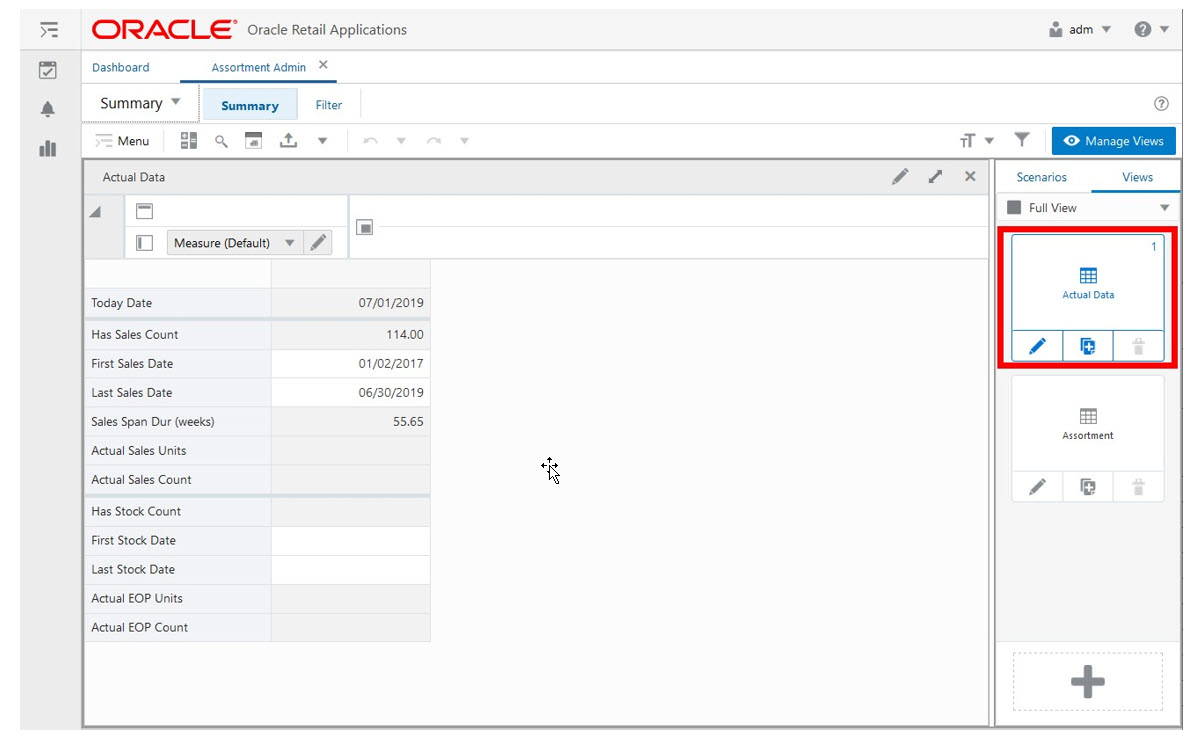

Actual Data View

The Actual Data View, under the Assortment Summary tab, allows you to review high-level actuals that are relevant for the assortment administration. For example, what is the date of the first sale within the workspace’s scope.

Figure 11-8 Actual Data View

Measures: Actual Data View

Note:

In this view, there are no hierarchies in the axis, all the measures in this view are shown aggregated based on all product and all location (and calendar where relevant). It is applicable to the scope loaded into the workspace.

Today Date

This is a loaded read-only measure to display the system date that is calculated by the IPOCS-Lifecycle Allocation and Replenishment batch.

Has Sales Count

This is a calculated measure used to indicate the total number of product and location combinations for which IPOCS-Lifecycle Allocation and Replenishment has sales data.

First Sales Date

This is a calculated measure used to indicate the first sales date for the workbook scope based on the loaded product and location daily sales. The first sales date is the earliest date of all products sold in all locations.

Last Sales Date

This is a calculated measure used to indicate the last sales date for the location based on the loaded product and location daily sales. The last sales date is the later date of all products sold in all locations.

Sales Span Dur (Weeks)

This is a calculated measure to show the number of week’s sales across the calendar.

Actual Sales Units

This is a calculated measure used to indicate the total sales units considering the daily sales of the product and location combination.

Actual Sales Count

This is a calculated measure used to indicate the total number of product and location combinations with sales units (greater than 0 units).

Has Stock Count

This is a calculated measure used to indicate the total number of product and location combinations for which IPOCS-Lifecycle Allocation and Replenishment has stock data.

First Stock Date

This is a calculated measure used to indicate the first inventory date for the workbook scope based on the loaded product and location inventory. The first inventory date is the earliest date of all products and location inventories.

Last Stock Date

This is a calculated measure used to indicate the last inventory date for the workbook scope based on the loaded product and location inventory. The last inventory date is the later date of all products and location inventories.

Actual EOP Units

This is a calculated measure used to indicate the end-of-period inventory in units considering the actual inventory position for product and location combinations loaded into the workspace.

Actual EOP Count

This is a calculated measure used to indicate the total number of product and location combinations with end-of-period inventory (greater than 0 units).

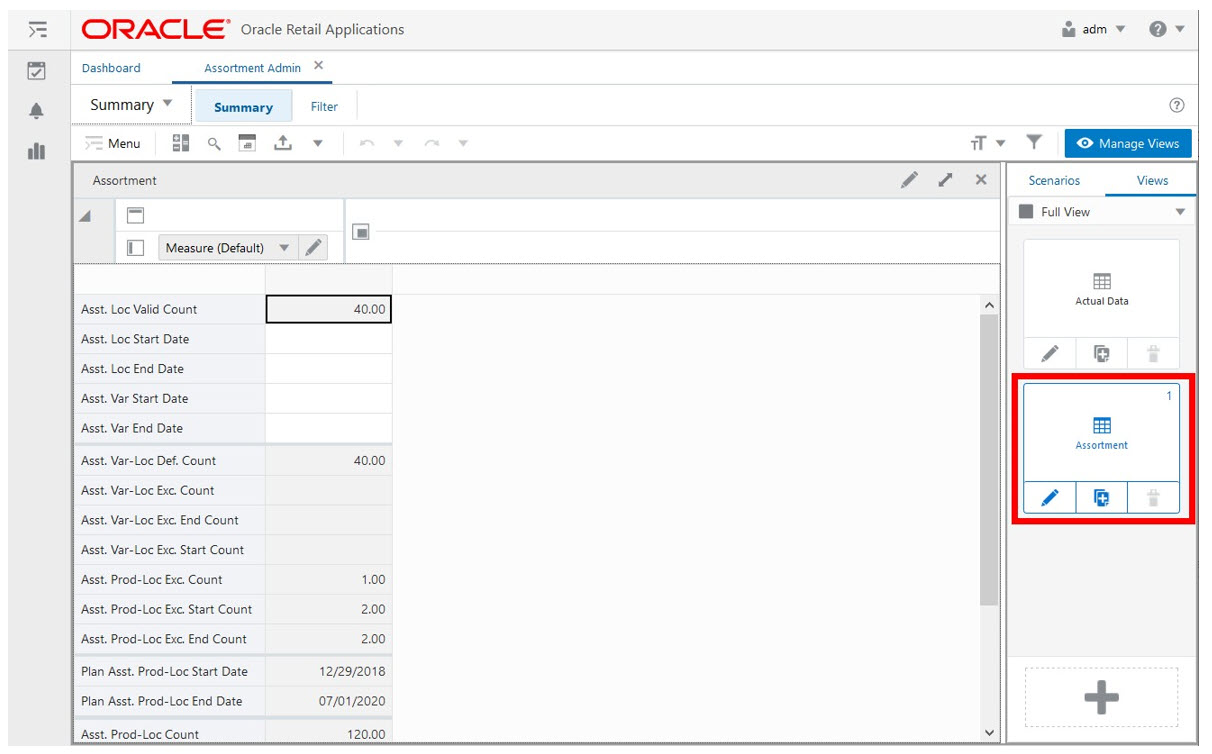

Assortment View

The Assortment View, under the Assortment Summary tab, allows you to see a high-level overview of the assortments.

Figure 11-9 Assortment View

Measures: Assortment View

The Assortment view contains the following measures.

Asst. Loc Valid Count

This is a calculated measure used to indicate the total number of locations with at least one valid product and location combination assorted. In this view, the measure contains the total number for the workspace scope.

Asst. Loc Start Date

This is a calculated measure used to indicate the earliest populated location start date within the [Validation] Location Step.

Asst. Loc End Date

This is a calculated measure used to indicate the last populated location end date within the [Validation] Location Step.

Asst. Var Start Date

This is a calculated measure used to indicate the earliest populated Variant start date within the [Validation] Variant Step.

Asst. Var End Date

This is a calculated measure used to indicate the last populated Variant end date within the [Validation] Variant Step.

Asst. Var-Loc Def. Count

This is a calculated measure used to indicate the total number of variance and location combinations assorted. In this view, the measure contains the total number for the workspace scope.

Asst. Var-Loc Exc. Count

This is a calculated measure used to indicate the number of exceptions that are being used at the Var-Loc level.

Asst. Var-Loc Exc. End Count

This is a calculated measure used to indicate the number of populated end date exceptions at the Variant Location level.

Asst. Var-Loc Exc. Start Count

This is a calculated measure used to indicate the number of populated start date exceptions at the Variant Location level.

Asst. Prod-Loc Exc. Count

This is a calculated measure used to indicate the number of exceptions that are being used at the Prod-Loc level.

Asst. Prod-Loc Exc. End Count

This is a calculated measure used to indicate the number of populated end date exceptions at the Product Location level.

Asst. Prod-Loc Exc. Start Count

This is a calculated measure used to indicate the number of populated start date exceptions at the Product Location level.

Plan Asst. Prod-Loc Start Date

This is a calculated measure used to indicate the earliest plan assortment start dates for all item / location.

Plan Asst. Prod-Loc End Date

This is a calculated measure used to indicate the last plan assortment end dates for all item / location.

Asst. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations assorted. In this view, the measure contains the total number for the workspace scope.

Asst. Prod-Loc Active Count

This is a calculated measure used to indicate the total number of product and location combinations assorted and still active. If the assortment end date has not been reached yet, then it is active. Otherwise, it is inactive meaning that the assortment has already stopped. In this view, the measure contains the total number for the workspace scope.

Asst. Var-Loc Count

This is a calculated measure used to indicate the total number of variance and location combinations assorted. In this view, the measure contains the total number for the workspace scope.

Asst. Var-Loc Active Count

This is a calculated measure used to indicate the total number of variance and location combinations assorted and still active. If the assortment end date has not been reached yet, for all products within the variance, then it is active. Otherwise, it is inactive meaning that the assortment has already stopped. In this view, the measure contains the total number for the workspace scope.

Lfc. Prod-Loc Def. Count

This is a calculated measure used to indicate the total number of product and location combinations with a default valid lifecycle. In this view, the measure contains the total number for the workspace scope.

Lfc. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations with a valid lifecycle considering the user-defined lifecycle exceptions. In this view, the measure contains the total number for the workspace scope.

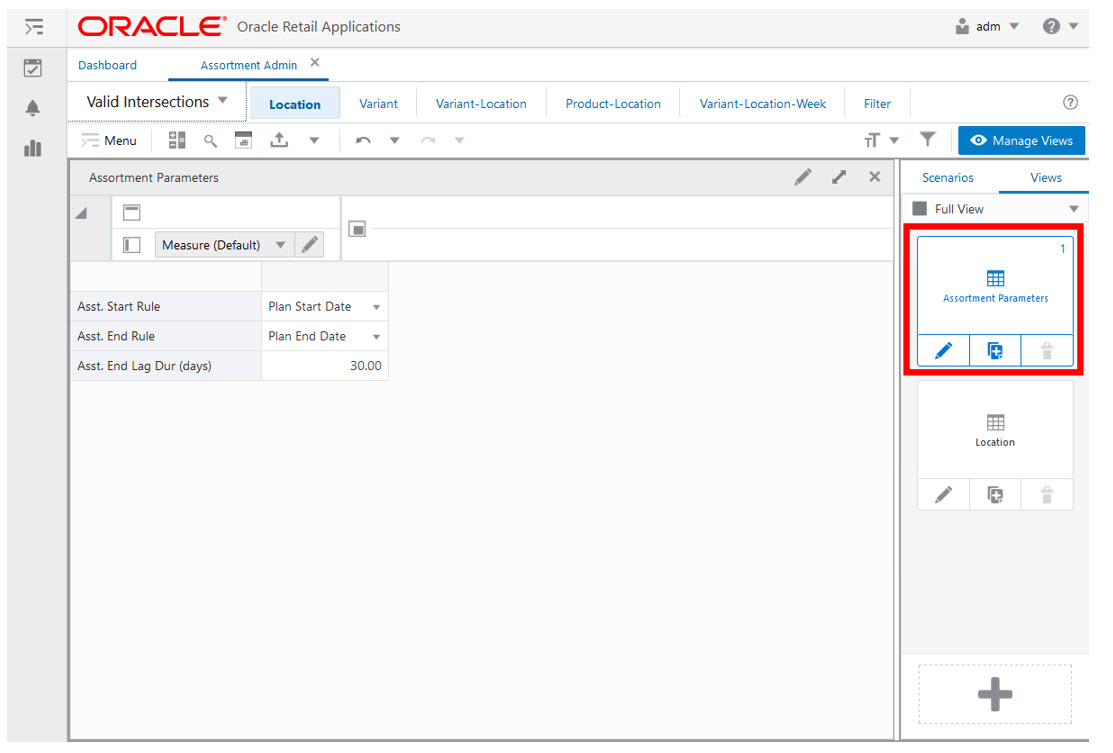

Assortment Parameters View

The Assortment Parameters View, under the Assortment Parameters tab, allows you to set up assortment rules to be considered by the IPOCS-Lifecycle Allocation and Replenishment assortment calculation functionality.

Figure 11-10 Assortment Parameters View

Measures: Assortment Parameters View

The Assortment Parameters view contains the following measures.

Asst. Start Rule

-

Plan Start Date

The assortment start date loaded into IPOCS-Lifecycle Allocation and Replenishment is used. If there is an exception forced by you then the exception takes priority.

-

First Sales after Plan Start Date

If the first sale occurs after the planned start date, then the assortment start date is the first sales date. Otherwise, the assortment start date is the planned start date.

-

First Stock after Plan Start Date

If the first inventory has been received after the planned start date, then the assortment start date is the date that the first inventory was received. Otherwise, the assortment start date is the planned start date.

-

Min {Plan Start Date - First Sales}

The assortment start date is the oldest date between the first sale date and the planned assortment start date loaded into IPOCS-Lifecycle Allocation and Replenishment.

-

Min {Plan Start Date - First Stock}

The assortment start date is the oldest date between the first inventory date and the planned assortment start date loaded into IPOCS-Lifecycle Allocation and Replenishment.

-

Min {Plan Start Date - First Sales/Stock}

The assortment start date is the oldest date between the first inventory date, the first sales date and the planned assortment start date loaded into IPOCS-Lifecycle Allocation and Replenishment.

-

First Sales

The first sales date is used for the assortment start date.

-

First Stock

The first inventory date is used for the assortment start date.

-

First Stales/Stock

The assortment start date is the oldest date between the first inventory date and the first sales date.

Asst. End Rule

This is an editable measure to define how IPOCS-Lifecycle Allocation and Replenishment should calculate the assortment end date. Valid values are:

-

Plan End Date

The assortment end date loaded into IPOCS-Lifecycle Allocation and Replenishment. If there is an exception forced by you, then the exception takes priority.

-

Max {Plan End Date - Last Sales}

The assortment end date is the date that comes last between the last sale date and the planned assortment end date loaded into IPOCS-Lifecycle Allocation and Replenishment. Please note that when the loaded assortment end date is empty IPOCS-Lifecycle Allocation and Replenishment assumes the latest calendar day available as the assortment end date calculation.

-

Max {Plan End Date - Last Stock}

The assortment end date is the date that comes last between the last inventory date and the planned assortment end date loaded into IPOCS-Lifecycle Allocation and Replenishment. Please note that when the loaded assortment end date is empty IPOCS-Lifecycle Allocation and Replenishment assumes the latest calendar day available as the assortment end date calculation.

-

Max {Plan End Date - Last Sales/Stock}

The assortment end date is the date that comes last between the last sale date, the last inventory date and the planned assortment end date loaded into IPOCS-Lifecycle Allocation and Replenishment. Please note that when the loaded assortment end date is empty IPOCS-Lifecycle Allocation and Replenishment assumes the latest calendar day available as the assortment end date calculation.

-

Min {Plan End Date - Last Stock}

The assortment end date is the date that comes first between the last inventory date and the planned assortment end date loaded into IPOCS-Lifecycle Allocation and Replenishment. Please note that when the loaded assortment end date is empty IPOCS-Lifecycle Allocation and Replenishment assumes the latest calendar day available as the assortment end date calculation.

-

Min {Plan Start Date - Last Sales/Stock}

The assortment end date is the date that comes first between the last sale date, last inventory date and the planned assortment end date loaded into IPOCS-Lifecycle Allocation and Replenishment. Please note that when the loaded assortment end date is empty IPOCS-Lifecycle Allocation and Replenishment assumes the latest calendar day available as the assortment end date calculation.

-

Last Sales

The last sales date is used for the assortment end date.

-

Last Stock

The last inventory date is used for the assortment last date.

-

Last Stales/Stock

The assortment end date is date that comes last between the last inventory date and the last sales date.

Asst. End Lag Dur (days)

This is an editable measure to define the number of lag days that the system considers for the sales and inventory for the assortment calculations. When the assortment is calculated based on the sales or inventory data and if the data from today’s date is older than the lag days indicated then the product and location combination is not assorted. For example, if the product does not sell for more than 30 days in a particular location, then it is removed from the assortment of that location.

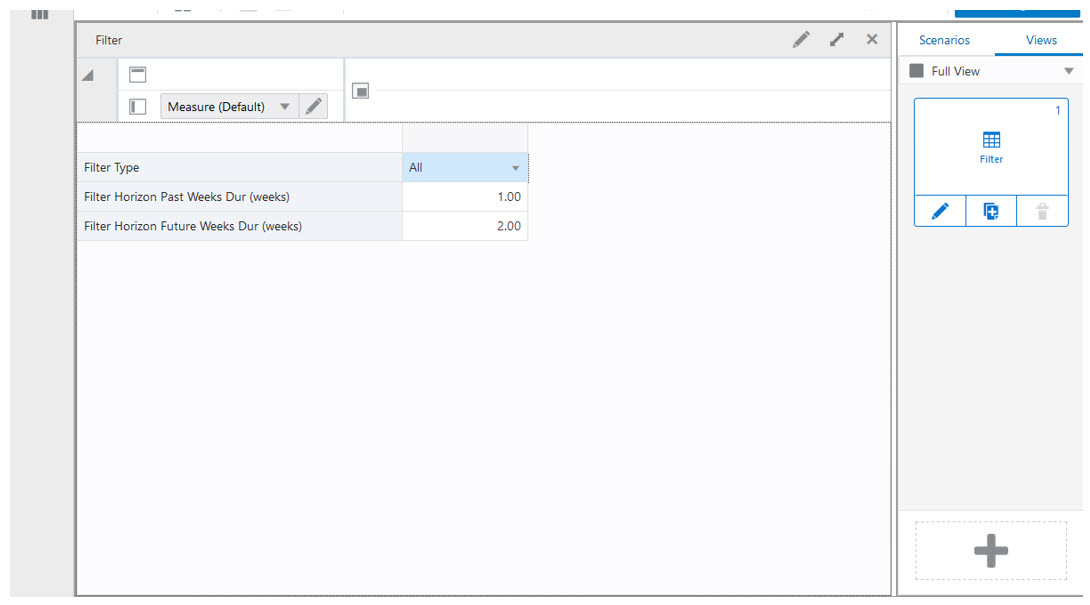

Filter View

The Filter View, under the Assortment Parameters tab, allows you to set up a filter to work the assortment. For example, you can use the filter to display product and location combinations where the assortment is valid.

Figure 11-11 Filter View

Measures: Filter View

The Filter view contains the following measures.

Filter Type

This is an editable measure to define what type of filter should be applied to the views within the Assortment Admin workspace. Valid values are:

-

All

No filter is applied. All information is displayed.

-

Default Asst

Only valid assortments, by default, are displayed. The product and location combinations are filter based on the value of the measure Asst. Var-Loc Def. If the measure is selected, then the combination is captured the filter. Otherwise, it is excluded by the filter.

-

Valid Asst

Only valid assortments are displayed. The product and location combinations are filtered based on the measure Asst. Var-Loc Def. value. If the measure is selected, then the combination is captured by the filter. Otherwise, it is excluded by the filter.

-

Asst Active

Only active assortments are displayed. The product and location combinations are filtered based on the measure Asst. Prod-Loc value. If the measure is selected, then the combination is captured by the filter. Otherwise, it is excluded by the filter.

-

Default Lfc

Only a valid lifecycle, by default, is displayed. The product and location combinations are filtered based on the measure Lfc. Prod-Loc Def. value. If the measure is selected, then the combination is captured by the filter. Otherwise, it is excluded by the filter.

-

Valid Lfc

Only the valid lifecycle is displayed. The product and location combinations are filtered based on the measure Lfc. Prod-Loc value. If the measure is selected, then the combination is captured by the filter. Otherwise, it is excluded by the filter.

Review Assortment Step

This step contains these views:

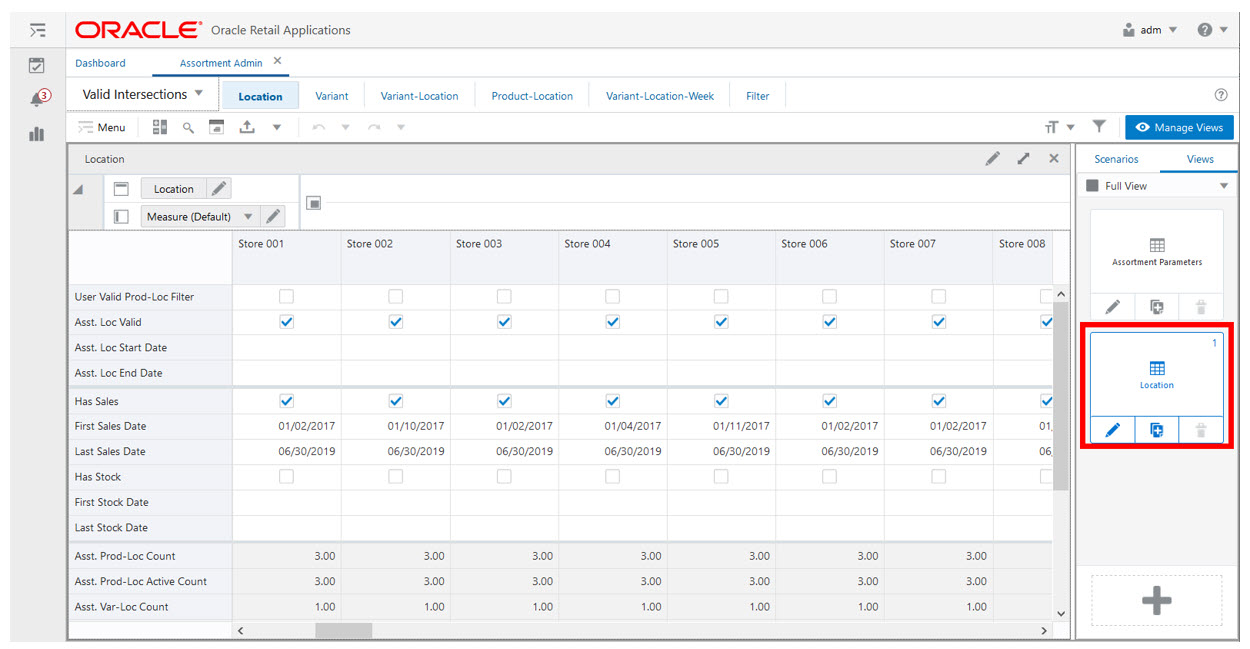

Location View

The Location View, under the Review Assortment tab and By Parent tabs, allows you to review and/or manage the assortment but at the location level only. The analysis is kept at location level without products.

Figure 11-12 Location View

Measures: Location View

The Location view contains the following measures.

Note:

The measures displayed in this view are supported by their counterparts defined at the product and location level. Therefore, the calculated measures in this view are the result of aggregating the ones at the product and location intersection.

User Valid Prod-Loc Filter

This is an editable measure to select locations to be filtered. The views display only the selected locations.

Asst. Loc Valid

This is a calculated measure to identify whether the location has a valid assortment or not. The location has a valid assortment when it contains a valid product assortment, or you have populated the location assortment start date or end date.

Asst. Loc Start Date

This is an editable measure to enter the location’s assortment start date.

Asst. Loc End Date

This is an editable measure to enter the location’s assortment end date.

Has Sales

This is a calculated measure used to indicate whether a location has sales data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected, at least one product within the location would have sales, otherwise, there are no sales in IPOCS-Lifecycle Allocation and Replenishment.

First Sales Date

This is a calculated measure used to indicate the first sales date for the location based on the loaded product and location daily sales. In this view the location first sales date is the earliest date of all products sold in the location.

Last Sales Date

This is a calculated measure used to indicate the last sales date for the location based on the loaded product and location daily sales. In this view, the location last sales date is the later date of all products sold in the location.

Has Stock

This is a calculated measure used to indicate whether a location has inventory data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected, then at least one product within the location would have sales, otherwise, there are no sales in IPOCS- Lifecycle Allocation and Replenishment.

First Stock Date

This is a calculated measure used to indicate the first inventory date for the location based on the loaded product and location inventory. The location first inventory date is the earliest date of all product inventory in the location.

Last Stock Date

This is a calculated measure used to indicate the last inventory date for the location based on the loaded product and location inventory. The location last inventory date is the later date of all product inventory in the location.

Asst. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations assorted. In this view, the measure displays the total number of products for the location.

Asst. Prod-Loc Active Count

This is a calculated measure used to indicate the total number of product and location combinations assorted and still active. If the assortment end date has not been reached yet, then it is active. Otherwise, it is inactive, meaning that the assortment has already stopped. In this view, the measure displays the total number of products for the location.

Asst. Var-Loc Count

This is a calculated measure used to indicate the total number of variance and location combinations assorted. In this view, the measure displays the total number of variants for the location.

Asst. Var-Loc Active Count

This is a calculated measure used to indicate the total number of variance and location combinations assorted and still active. If the assortment end date has not been reached yet, for all products within the variance, then it is active. Otherwise, it is inactive, meaning that the assortment has already stopped. In this view, the measure displays the total number of variants for the location.

Asst. Var-Loc Start Date

This is a calculated measure used to indicate the assortment start date for the assorted variance and location combinations. In this view, the measure displays the earliest date from all the variances assorted for the location.

Asst. Var-Loc End Date

This is a calculated measure used to indicate the assortment end date for the assorted variance and location combinations. In this view, the measure displays the later date from all the variances assorted for the location.

Asst. Var-Loc From Start Dur (weeks)

This is a calculated measure used to indicate the number of elapsed weeks since the assortment started date indicated in the measure Asst. Var-Loc Start Date. The number of weeks is calculated until the IPOCS-Lifecycle Allocation and Replenishment today’s week.

Lfc. Loc Valid

This is a calculated measure to identify whether the location has valid lifecycle products or not. The location has a valid lifecycle when it contains at least one valid lifecycle product.

Lfc. Prod-Loc Exc.

This is an editable measure to set a lifecycle exception for all products within the location. Valid values are:

-

Default

This value ignores the lifecycle exception and keeps the default lifecycle result.

-

On

This value enables the exception and uses the exception dates for the lifecycle calculation.

-

Off

This value enables the exception and disables all of the products in the location for the lifecycle calculation.

Lfc. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations with a valid lifecycle. In this view, the measure displays the total number of valid lifecycles for all the products in the location.

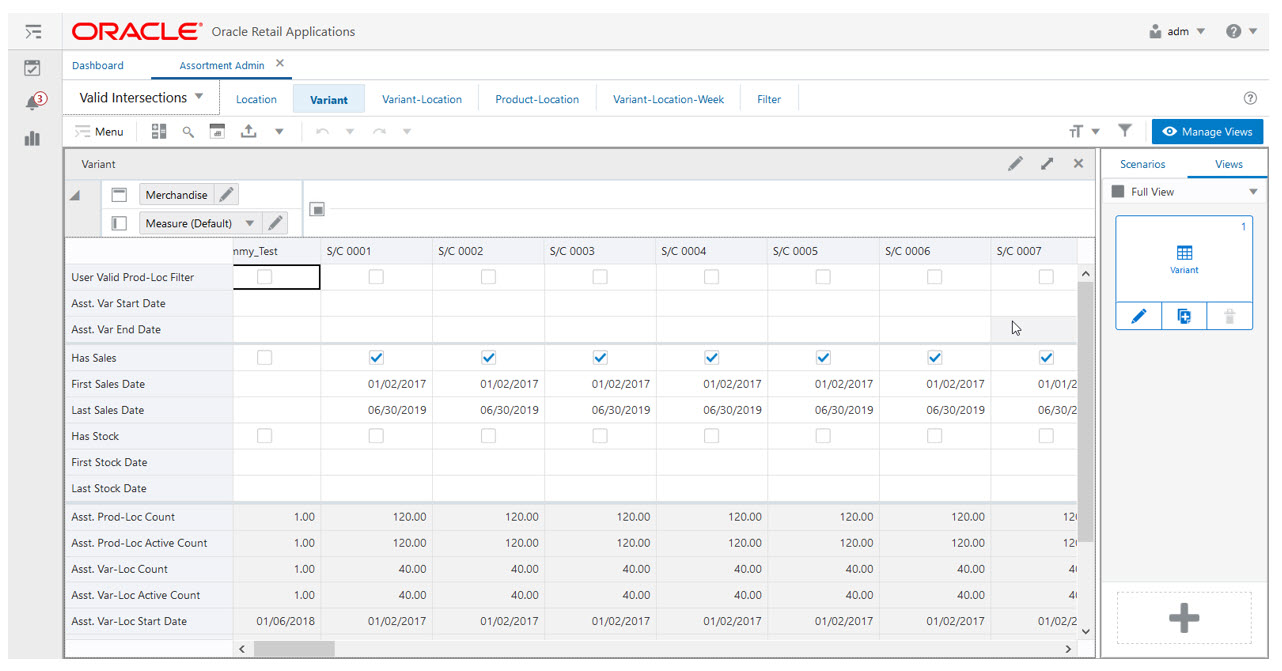

Variant View

The Variant View, under the Review Assortment tab, and By Parent tab, allows you to review and manage the assortment but at the variant level only. The analysis is kept at variant level without locations.

Figure 11-13 Variant View

Measures: Variant View

The Variant view contains the following measures.

Note:

The measures displayed in this view are supported by their counterparts defined at the product and location level. Therefore, the calculated measures in this view are the result of aggregating the ones at the product and location intersection.

User Valid Prod-Loc Filter

This is an editable measure to select a variant to be filtered. The views display only the selected variants.

Asst. Var Start Date

This is an editable measure to enter the variant’s assortment start date.

Asst. Var End Date

This is an editable measure to enter the variant’s assortment end date.

Has Sales

This is a calculated measure used to indicate whether a variant has sales data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected, then at least one product within the variant would have sales, otherwise, there are no sales in IPOCS- Lifecycle Allocation and Replenishment for the variant.

First Sales Date

This is a calculated measure used to indicate the date of the first sale for the variant based on the loaded product and location daily sales. In this view, the variant’s first sales date is the earliest date of all products, within the variant, sold in all the locations.

Last Sales Date

This is a calculated measure used to indicate the last sales date for the variant based on the loaded product and location daily sales. In this view, the variant’s last sales date is the later date of all products, within the variant, sold in all the locations.

Has Stock

This is a calculated measure used to indicate whether a variant has inventory data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected, then at least one product within the variant would have inventory in one location, otherwise, there is no inventory in IPOCS- Lifecycle Allocation and Replenishment for the variant.

First Stock Date

This is a calculated measure used to indicate the first inventory date for the variant based on the loaded product and location inventory. In this view, the variant’s first inventory date is the earliest date of all the variant’s products from all location inventories.

Last Stock Date

This is a calculated measure used to indicate the last inventory date for the location based on the loaded product and location inventory. In this view, the variant’s last inventory date is the later date of all the variant’s products from all location inventories.

Asst. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations assorted. In this view, the measure displays the total number of locations assorted for all the products within the variant.

Asst. Prod-Loc Active Count

This is a calculated measure used to indicate the total number of product and location combinations assorted and still active. If the assortment end date has not been reached yet, then it is active. Otherwise, it is inactive, meaning that the assortment has already stopped. In this view, the measure displays the total number of locations assorted for all the products within the variant.

Asst. Var-Loc Count

This is a calculated measure used to indicate the total number of variant and location combinations assorted. In this view, the measure displays the total number of locations for the variant.

Asst. Var-Loc Active Count

This is a calculated measure used to indicate the total number of variant and location combinations assorted and still active. If the assortment end date has not been reached yet, for all products within the variance, then it is active. Otherwise, it is inactive meaning, that the assortment has already stopped. In this view, the measure displays the total number of locations for the variant.

Asst. Var-Loc Start Date

This is a calculated measure used to indicate the assortment start date for the assorted variance and location combinations. In this view, the measure displays the earliest date from all the locations assorted for the variance.

Asst. Var-Loc End Date

This is a calculated measure used to indicate the assortment end date for the assorted variance and location combinations. In this view, the measure displays the earliest date from all the locations assorted for the variance.

Asst. Var-Loc from Start Dur (weeks)

This is a calculated measure used to indicate the number of elapsed weeks since the assortment start date indicated in the measure Asst. Var-Loc Start Date. The number of weeks is calculated until the IPOCS-Lifecycle Allocation and Replenishment today’s week.

Lfc. Prod-Loc Exc.

This is an editable measure to set a lifecycle exception for the variant (all products within) in all locations. Valid values are:

-

Default

This value ignores the lifecycle exception and keeps the default lifecycle result.

-

On

This value enables the exception and uses the exception dates for the lifecycle calculation.

-

Off

This value enables the exception and disables the variant for all products in all locations for the lifecycle calculation.

Lfc. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations with a valid lifecycle. In this view, the measure displays the total number of valid lifecycles for all the products, within the variant, in all locations.

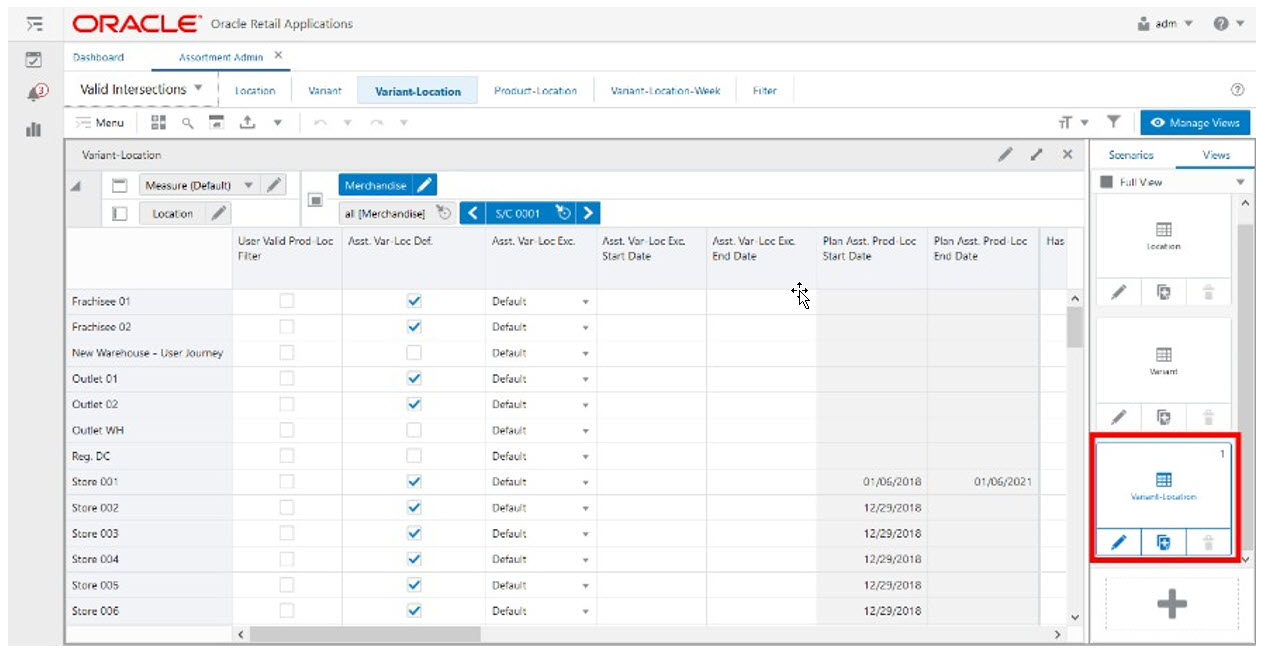

Variant-Location View

The Variant-Location View, under the Review Assortment tab, and By Parent tab, allows you to review and manage the assortment but at the variant and location level only. The analysis is kept at variant level without the products within.

Figure 11-14 Variant-Location View

Measures: Variant-Location View

The Variant-Location view contains the following measures.

Note:

The measures displayed in this view are supported by their counterparts defined at the product and location level. Therefore, the calculated measures in this view are the result of aggregating the ones at the product and location intersection.

User Valid Prod-Loc Filter

This is an editable measure to select variant and location combinations to be filtered. The views display only the selected variant and location combinations.

Asst. Var-Loc Def

This is a calculated measure used to indicate if the variant and location combinations are valid by default.

Asst. Var-Loc Exc.

This is an editable measure to set an assortment exception for the variant and location combinations. Valid values are:

-

Default

This value ignores the assortment exception and keeps the default assortment result.

-

On

This value enables the exception and uses the exception dates for the assortment calculation.

-

Off

This value enables the exception and disables the variant and location combination for the assortment calculation.

Asst. Var-Loc Exc. Start Date

This is an editable measure to enter the assortment start date for the variant and location combination exception. When the exception is set to Default or On, this is the date used by the assortment calculation.

Asst. Var-Loc Exc. End Date

This is an editable measure to enter the assortment end date for the variant and location combination exception. When the exception is set to Default or On, this is the date used by the assortment calculation.

Plan Asst. Prod-Loc Start Date

This is a calculated measure used to indicate the planned assortment start date for the product and location combination. When there is an assortment start date exception the planned assortment start date is the exception. Otherwise, it is the assortment start date loaded from the external system. In this view, the measure displays the earliest date of all the products within the variant for the location.

Plan Asst. Prod-Loc End Date

This is a calculated measure used to indicate the planned assortment end date for the product and location combination. When there is an assortment end date exception the planned assortment end date is the exception. Otherwise, it is the assortment end date loaded from the external system. In this view, the measure displays the later date of all the products within the variant for the location.

Has Sales

This is a calculated measure used to indicate whether a variant and location combination has sales data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected then at least one product, within the variant, has sales for the location. Otherwise, there are no sales in IPOCS-Lifecycle Allocation and Replenishment for the variant and location combination.

First Sales Date

This is a calculated measure used to indicate the first sales date for the variant and location combination based on the loaded product and location daily sales. In this view, the variant and location combination’s first sales date is the earliest date of all products within the variant sold in the location.

Last Sales Date

This is a calculated measure used to indicate the last sales date for the variant and location combination based on the loaded product and location daily sales. In this view, the variant and location combination’s last sales date is the later date of all products within the variant sold in the location.

Has Stock

This is a calculated measure used to indicate whether a variant and location combination has inventory data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected then at least one product, within the variant, has inventory in the location. Otherwise, there is no inventory in IPOCS-Lifecycle Allocation and Replenishment for the variant and location combination.

First Stock Date

This is a calculated measure used to indicate the first inventory date for the variant and location combination based on the loaded product and location inventory. In this view, the variant and location combination’s first inventory date is the earliest date of all products within the variant with inventory in the location.

Last Stock Date

This is a calculated measure used to indicate the last inventory date for the variant and location combination based on the loaded product and location inventory. In this view, the variant and location combination’s last inventory date is the later date of all products within the variant with inventory in the location.

Asst. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations assorted. In this view, the measure displays the total number of assorted products, within the variant, for the location.

Asst. Prod-Loc Active Count

This is a calculated measure used to indicate the total number of product and location combinations assorted and still active. If the assortment end date has not been reached yet then it is active. Otherwise, it is inactive, meaning that the assortment has already stopped. In this view, the measure displays the total number of active assorted products, within the variant, for the location.

Asst. Var-Loc

This is a calculated measure used to indicate whether the variant and location combinations are assorted or not. A variant and location combination is assorted if at least one product, within the variant, is assorted in the location.

Asst. Var-Loc Active

This is a calculated measure used to indicate whether the variant and location combinations are assorted and still active or not. If the assortment end date has not been reached yet, then it is active. A variant and location combination is assorted and active if at least one product, within the variant, is assorted and active in the location.

Asst. Var-Loc Start Date

This is a calculated measure used to indicate the assortment start date for the assorted variance and location combinations. In this view, the measure displays the earliest assortment start date of all assorted products, within the variant, for the location.

Asst. Var-Loc End Date

This is a calculated measure used to indicate the assortment end date for the assorted variance and location combinations. In this view, the measure displays the later assortment end date of all assorted products, within the variant, for the location.

Asst. Var-Loc from Start Dur (weeks)

This is a calculated measure used to indicate the number of elapsed weeks since the assortment started date indicated in the measure Asst. Var-Loc Start Date. The number the weeks are calculated until the IPOCS-Lifecycle Allocation and Replenishment today’s week.

Lfc. Prod-Loc Exc.

This is an editable measure to set a lifecycle exception for the variant (all products within) and location combination. Valid values are:

-

Default

This value ignores the lifecycle exception and keeps the default lifecycle result.

-

On

This value enables the exception and uses the exception dates for the lifecycle calculation.

-

Off

This value enables the exception and disables the variant (all products within) and location combination for the lifecycle calculation.

Lfc. Prod-Loc Count

This is a calculated measure used to indicate the total number of product and location combinations with a valid lifecycle. In this view, the measure displays the total number of valid lifecycles for all the products, within the variant, in the location.

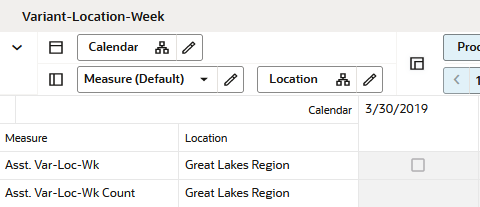

Variant-Location-Week View

The Variant-Location-Week View, under the By Parent tab, allows you to review the assortment week by week at the variant and location level.

Figure 11-15 Variant-Location-Week View

Measures: Variant-Location-Week View

The Variant-Location-Week view contains the following measures.

Asst. Var-Loc-Week

This is a calculated measure used to indicate for each week whether the variant and location combinations are assorted or not. A variant and location combination is assorted, for a particular week, if at least one product within the variant is assorted in the location for that same week.

Asst. Var-Loc-Week Count

This is a calculated measure used to indicate the total number of variant and location combinations assorted for each week.

Asst. Var-Loc-Week

This is a calculated measure, not visible but available in the view for selection, to display the variant image and help you by having a visual assortment.

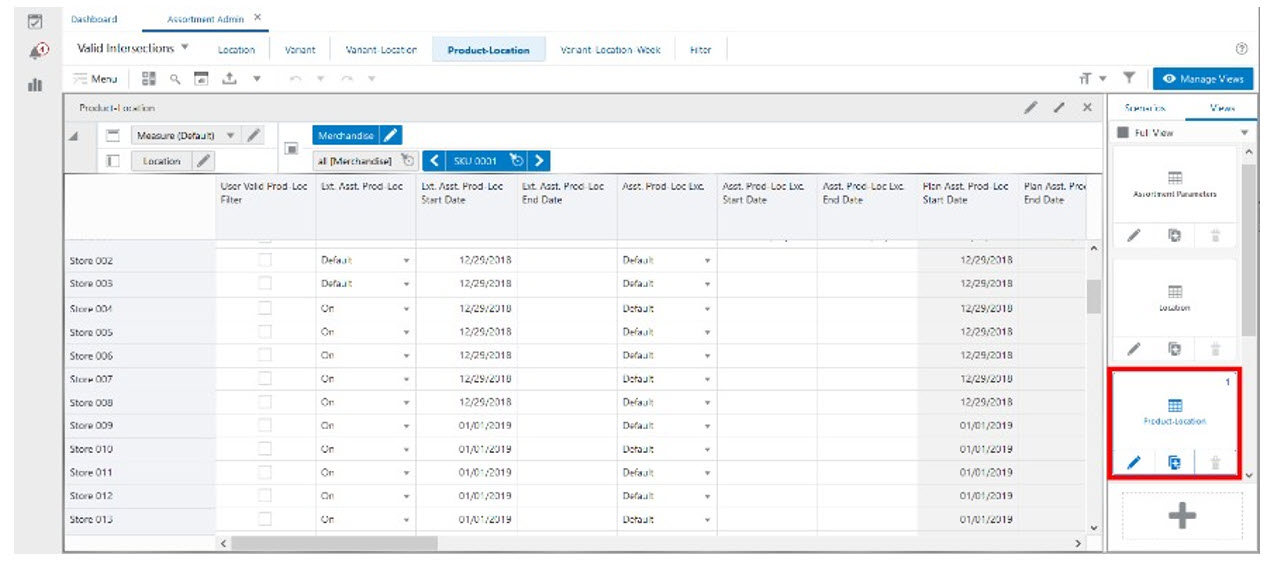

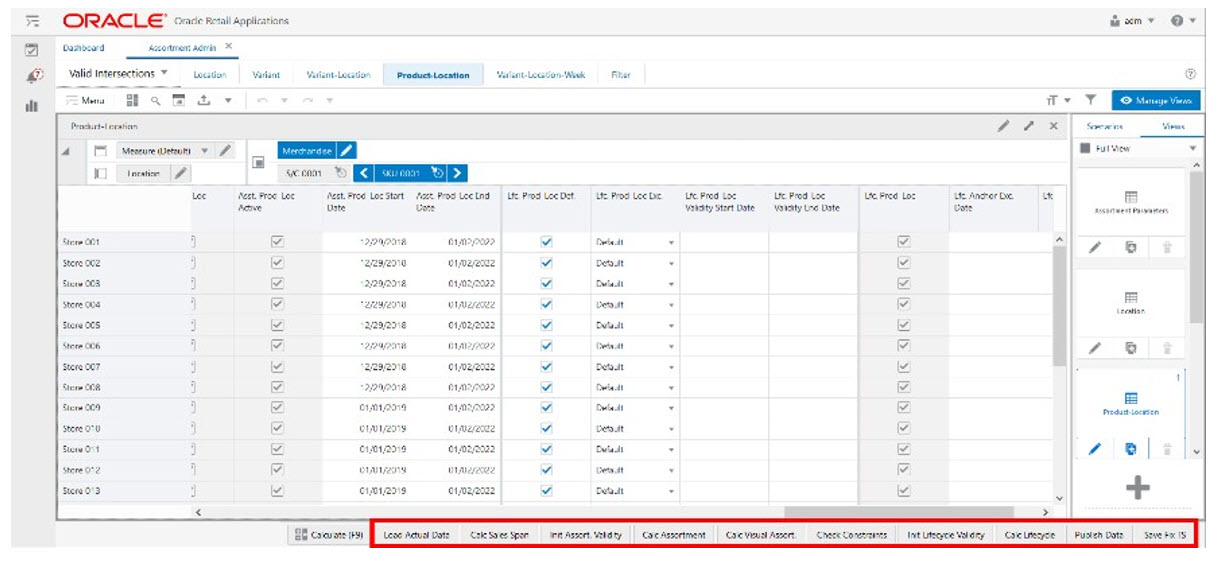

Product-Location View

The Product-Location View, under the By Item tab, allows you to review and manage the assortment at the lowest level - product and location level.

Figure 11-16 Product-Location View

Measures: Product-Location View

The Product-Location view contains the following measures.

User Valid Prod-Loc Filter

This is an editable measure to select product and location combinations to be filtered. The views display only the selected product and location combinations.

Ext Asst. Prod-Loc

This is a measure loaded into IPOCS-Lifecycle Allocation and Replenishment to indicate whether a product and location combination is assorted or not. Valid values are:

-

Default

If the assortment dates are empty, but IPOCS-Lifecycle Allocation and Replenishment has sales or inventory data for the product and location combination, then IPOCS-Lifecycle Allocation and Replenishment assumes the product and location combination as assorted.

-

On

This value assumes the product and location combination as assorted and use the loaded assortment dates to assign the assortment start and end dates.

-

Off

This value assumes the product and location combination as not assorted even if there are assortment dates loaded.

Ext Asst. Prod-Loc Start Date

This is a measure loaded into IPOCS-Lifecycle Allocation and Replenishment to indicate the assortment start date for the product and location combination.

Ext Asst. Prod-Loc End Date

This is a measure loaded into IPOCS-Lifecycle Allocation and Replenishment to indicate the assortment end date for the product and location combination.

Asst. Var-Loc Exc.

This is an editable measure to override the loaded assortment for the product and location combinations. Valid values are:

-

Default

This value ignores the assortment exception and keeps the loaded assortment.

-

On

This value overrides the loaded value. It forces the product and location combination to be assorted and uses the assortment exception dates to assign the assortment start and end dates. If no exception dates are entered by you and a loaded date exists, then IPOCS-Lifecycle Allocation and Replenishment uses the loaded assortment dates to assign the assortment start and end dates.

-

Off

This value overrides the loaded value. It forces the product and location combination to be not assorted.

Asst. Var-Loc Exc. Start Date

This is an editable measure to enter the assortment start date exception for the product and location combination. When the exception is set to Default or On, this is the date used by the assortment calculation.

Asst. Var-Loc Exc. End Date

This is an editable measure to enter the assortment end date exception for the product and location combination. When the exception is set to Default or On, this is the date used by the assortment calculation.

Plan Asst. Prod-Loc Start Date

This is a calculated measure used to indicate the planned assortment start date for the product and location combination. When there is an assortment start date exception the planned assortment start date is the exception. Otherwise, it is the assortment start date loaded from the external system.

Plan Asst. Prod-Loc End Date

This is a calculated measure used to indicate the planned assortment end date for the product and location combination. When there is an assortment end date exception the planned assortment end date is the exception. Otherwise, it is the assortment end date loaded from the external system.

Has Sales

This is a calculated measure used to indicate whether a product and location combination has sales data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected then there are sales. Otherwise, there are no sales in IPOCS-Lifecycle Allocation and Replenishment for the product and location combination.

First Sales Date

This is a calculated measure used to indicate the first sales date for the product and location combination based on the loaded product and location daily sales. The product and location combination's first sales date is the earliest date from the product and location combination sales.

Last Sales Date

This is a calculated measure used to indicate the last sales date for the product and location combination based on the loaded product and location daily sales. The product and location combination's last sales date is the later date from the product and location combination sales.

Has Stock

This is a calculated measure used to indicate whether a product and location combination has inventory data within IPOCS-Lifecycle Allocation and Replenishment or not. When selected then there is inventory. Otherwise, there is no inventory in IPOCS-Lifecycle Allocation and Replenishment for the product and location combination.

First Stock Date

This is a calculated measure used to indicate the first inventory date for the product and location combination based on the loaded product and location inventory. The product and location combination's first inventory date is the earliest date from the product and location combination inventory.

Last Stock Date

This is a calculated measure used to indicate the last inventory date for the product and location combination based on the loaded product and location inventory. The product and location combination's last inventory date is the later date from the product and location combination inventory.

Fixed TS Units 1

This is a measure loaded into IPOCS-Lifecycle Allocation and Replenishment to indicate the initial allocation, in units, for the product and location combination.

Fixed TS Units 2

This is an editable measure used to indicate a manual allocation for the product and location combination.

Fixed TS Units 3

This is an editable/loadable measure that is a placeholder to indicate other allocations for the product and location combination. It can be loaded from another source system.

Asst. Prod-Loc

This is a calculated measure used to indicate whether the product and location combinations are assorted or not.

Asst. Prod-Loc Active

This is a calculated measure used to indicate whether the product and location combinations are assorted and still active or not. If the assortment end date has not been reached yet, then it is active. Otherwise, the product and location combination is assorted, but not active.

Asst. Prod-Loc Start Date

This is a calculated measure used to indicate the assortment start date for the assorted product and location combinations. The date is calculated based on the option selected in the Assortment Parameters view.

Asst. Prod-Loc End Date

This is a calculated measure used to indicate the assortment end date for the assorted product and location combinations. The date is calculated based on the option selected in the Assortment Parameters view.

Lfc. Prod-Loc Def.

This is a calculated measure to identify whether the product and location combination has a valid lifecycle by default or not.

Lfc. Prod-Loc Exc.

This is an editable measure to set a lifecycle exception for the product and location combination. Valid values are:

-

Default

This value ignores the lifecycle exception and keeps the default lifecycle result.

-

On

This value enables the exception and uses the lifecycle exception dates for the lifecycle calculation.

-

Off

This value enables the exception and disables the product and location combination for the lifecycle calculation.

Lfc. Prod-Loc Validity Start Date

This is an editable measure to enter the lifecycle start date exception for the product and location combination. This date overrides the lifecycle start date calculated in the Allocation & Replenishment Setup Rules workspace.

Lfc. Prod-Loc Validity End Date

This is an editable measure to enter the lifecycle end date exception for the product and location combination. This date overrides the lifecycle end date calculated in the Allocation & Replenishment Setup Rules workspace.

Lfc. Prod-Loc

This is a calculated measure to identify whether the product and location combination has a valid lifecycle or not. This measure takes into consideration the lifecycle exceptions. The exception takes priority over the Lfc. Prod-Loc Def.

Lfc. Anchor Exc. Date

This is an editable measure to enter the lifecycle anchor date exception for the product and location combination. This date overrides the lifecycle anchor date calculated in the Allocation & Replenishment Setup Rules workspace.

Lfc. End Exc. Date

This is an editable measure to enter the lifecycle’s exception end date for the product and location combination. This date overrides the lifecycle anchor date calculated in the Allocation & Replenishment Setup Rules workspace.

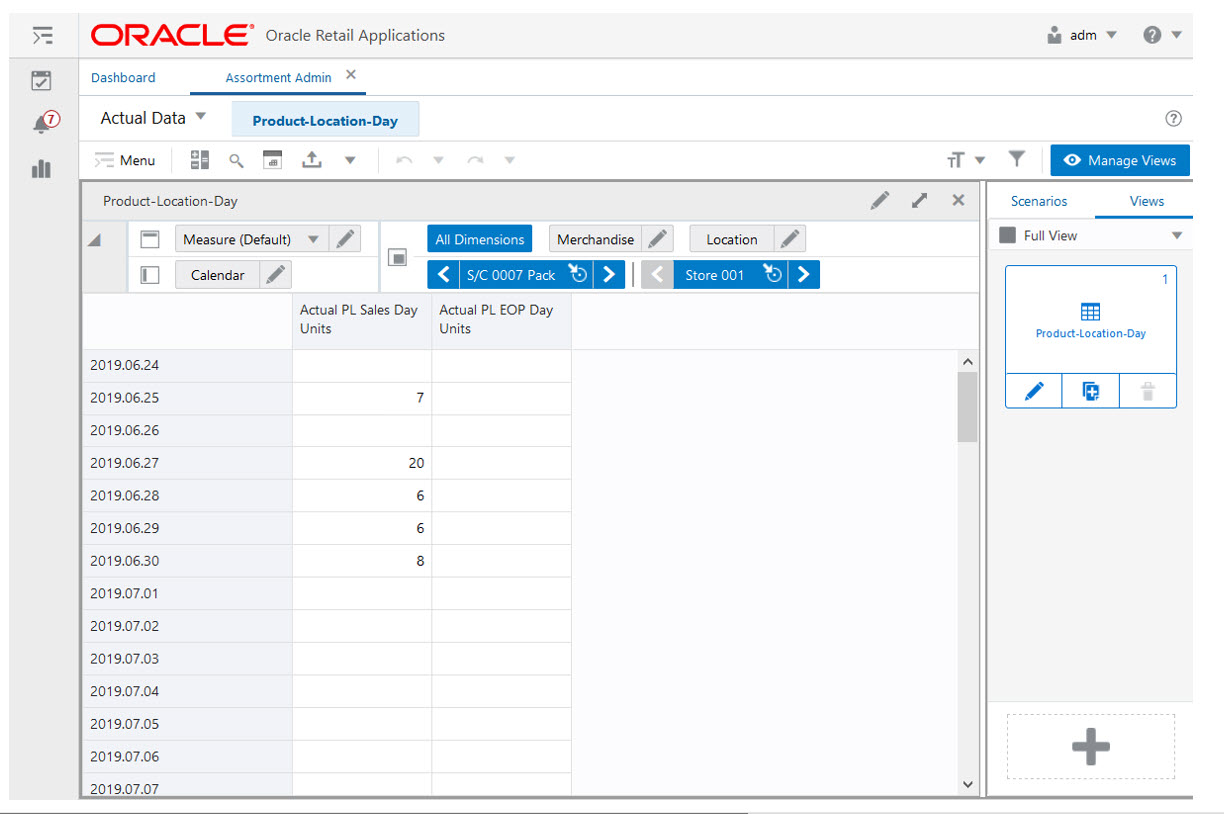

Product-Location-Week View

The Product-Location-Week View, under the Actual Data tab, allows you to review the sales and inventory actual data at the product, location, and week level.

Figure 11-17 Product-Location-Week View

Measures: Product-Location-Week View

The Product-Location-Day view contains the following measures.

Actual Loc. Sales Units

This is a loaded measure used to indicate the total sales units for the day, product, and location combination.

Loc. On Hand EOP Day

This is a loaded measure used to indicate the closing inventory units for the day, product and location combination.

Assortment Admin Action Buttons

The Assortment Admin workspace has the following action buttons available:

-

Load Actual Data

-

Calc Sales Span

-

Calc Assortment

-

Calc Lifecycle

-

Publish Data

Figure 11-18 Assortment Admin Action Buttons

Load Actual Data

This action button is responsible for loading the actual sales and actual inventory data. It populates the measures available in the Product-Location-Day view.

Calc Sales Span

This action button is responsible for the calculation of the first and last selling dates of the item/location. The assortment calculation can use this information to get the start and end dates of the assortment.

Calc Assortment

This action button is responsible for the assortment calculation. This action calculates the assortment start and end dates, using the rule selected by you in the view Assortment Parameters, and if the product and location combination is assorted or not.

Calc Lifecycle

This action button is responsible for the lifecycle calculation. The measure Lfc. Prod-Loc, in the Product-Location view, is calculated and populated by this action button.

Publish Data

This action button is responsible for committing all the measures managed within this workspace to be used by other IPOCS-Lifecycle Allocation and Replenishment processes and workspaces.