Order Orchestration Integration

Topics in this part: This part describes integration between Order Administration and Order Orchestration.

-

Order Orchestration Integration Overview describes the components of the integration between Order Orchestration and Order Administration, including the extract processes that occur automatically as well as the Order Orchestration and Merchandise Locator API’s, and describes required setup.

-

Order Orchestration Integration provides details on how the integration with Order Orchestration handles each order type.

-

Merchandise Locator API describes how to search for a store location where the customer can pick up an item.

Order Orchestration Integration

Order Orchestration: Integration with the Routing Engine module in Order Orchestration supports fulfilling orders across the enterprise.

Use the Order Orchestration integration for the following:

-

brokered backorders: Automatically send backordered lines to the Routing Engine module in Order Orchestration, so the orders can be assigned to locations for fulfillment.

-

If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system bypasses reservation in order to send all eligible items to Order Orchestration for fulfillment assignment, even if the item is available in the warehouse. In this situation, the fulfilling location may be a store location or an Order Administration warehouse.

-

If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the system bypasses reservation in order to send eligible items on a ship-for-pickup order to Order Orchestration for fulfillment assignment. In this situation, the fulfilling location may be a store location or an Order Administration warehouse.

-

-

receive retail pickup (including ship-for-pickup) or delivery orders from Order Orchestration: Receive and fulfill orders in Order Administration. If the order is a retail pickup order, Order Administration sends the merchandise to the customer’s selected store for pickup. If the order is a delivery order, Order Administration ships the merchandise to the customer’s ship-to address. Typically, retail pickup and delivery orders originated in an external retail location. In addition:

-

If the Use OROB for Fulfillment Assignment (M31) system control value is selected, Order Orchestration may send a delivery order to Order Administration that originated as a brokered backorder in Order Administration. In this situation, Order Orchestration determined that an Order Administration warehouse was the best location to fulfill the order.

-

If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, Order Orchestration may send a retail pickup order to Order Administration that originated as a ship-for-pickup order in Order Administration. In this situation, Order Orchestration determined that an Order Administration warehouse was the best location to fulfill the order.

-

-

send ship-for-pickup orders during pick slip generation/drop ship processing to Order Orchestration: If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, ship orders to an external retail location for customer pickup if the merchandise is not already available at that location.

-

send store pickup orders to Order Orchestration: Notify an external retail location that has inventory available that a customer will pick up an order.

Version compatibility: Fulfillment assignment and ship-for-pickup functionality is available in release 16.0 or higher of Order Management System, or Order Administration, and release 16.0 or higher of Order Broker, or Order Orchestration. Also, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Orchestration. Once you enable ship for pickup, the Organization window in Order Orchestration displays the Ship for Pickup Enabled Date, and you cannot deselect this option.

An OROB_MESSAGE_VERSION of 16.0 or higher is required to use the Ship-for-Pickup Orders integration with Order Orchestration.

For more information: See:

-

Order Orchestration Integration Overview for general background on integration between Order Orchestration and Order Administration.

-

Order Orchestration Configuration for required setup in Order Administration.

-

the Order Orchestration Operations Guide for details on each request and response message, as well as details on logging and troubleshooting in Order Orchestration.

-

the Order Orchestration online help for step-by-step instructions on populating the Order Orchestration database and on scheduling item and inventory imports.

For information on Order Orchestration processing in Order Administration, see:

Order Orchestration Integration Overview

Purpose: The integration between Order Orchestration and Order Administration enables you to share information on items’ availability and create orders across the enterprise, including:

-

providing periodic item and inventory import from Order Administration to Order Orchestration.

-

providing real-time, on-demand inventory availability information for specific items from the Order Administration warehouse to the point of sale or the web storefront, and vice versa.

-

using Order Orchestration’s routing engine to automatically assign backordered items to one or more locations for fulfillment. In addition:

-

If the Use OROB for Fulfillment Assignment (M31) system control value is selected, you can use the Order Orchestration routing engine to determine the fulfilling location for all eligible items.

-

If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS and the Send B/O to OROB (K08) system control value is selected, you can use the Order Orchestration routing engine to determine the fulfilling location for eligible items on a ship-for-pickup order.

-

-

searching for store locations that stock a requested item so that the customer can pick up the item at the store.

-

using Order Administration to fulfill ship-for-pickup, retail pickup, or delivery orders that originated in a retail store location or in Order Administration.

-

creating ship-for-pickup orders in Order Administration during pick slip generation/drop ship processing and shipping the merchandise to a retail store location for customer pickup.

-

creating store pickup orders so the customer can pick up the order at a retail store location where the merchandise is already in stock.

Integrated systems: Order Orchestration provides visibility into items and inventory across all integrated systems. Typically, you would integrate Order Orchestration with Order Administration and a POS system, such as Xstore.

Setting up the integration: See Order Orchestration Configuration.

Version compatibility: Fulfillment assignment and ship-for-pickup functionality is available in release 16.0 or higher of Order Management System, or Order Administration, and release 16.0 or higher of Order Broker, or Order Orchestration. Also, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Orchestration. Once you enable ship for pickup, the Ship for Pickup Enabled Date displays on the Organization window and this option cannot be changed.

Integration with releases of Order Broker earlier than 5.0 is not supported.

In this topic:

-

Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process

-

Retail Pickup (including Ship-for-Pickup) and Delivery Orders from Order Orchestration

Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process

Overview: The Order Orchestration product import process allows you to extract and import item and inventory information from Order Administration to Order Orchestration.

How does the import work? The following periodic functions allow you to generate output files to import into Order Orchestration.

-

The OBPROD OB Product Output File (program name PFR0127) periodic function allows you to generate a Product output file for import into Order Orchestration. This file contains product information for a specified company. See Order Orchestration Product Output File for details.

-

The OBPRLOC OB Product Location Output File (program name PFR0128) periodic function allows you to generate a Product Location output file for import into Order Orchestration. This file contains product location and availability information for a specified company. See Order Orchestration Product Location Output File for details.

-

The OBINCIN OB Incremental Inventory Output File (program name PFR0129) periodic function allows you to generate an Incremental Inventory output file for import into Order Orchestration. This file contains inventory updates for a specified company. See Oracle Retail Order Orchestration Incremental Inventory Output File for details.

Only items and SKU’s whose OROB eligible flags are selected are eligible for extract. This flag is selected by default.

Required setup: See Order Orchestration Configuration.

For more information: See the Order Orchestration online help and the Order Orchestration Operations Guide.

Location of files: The OROB_DIRECTORY_PATH in Working with Admin Properties (CPRP) defines the location where the system creates the output files.

Import process: When running an Order Orchestration import, the system

-

deletes any matching import file in the OROB-Imports location in Order Orchestration.

-

creates a zip file for the import text file in the OROB_DIRECTORY_PATH and then deletes the text file in the OROB_DIRECTORY_PATH.

-

calls the OACS Import RESTful web service using the setting in the OROB_IMPORTS_URL and the authentication defined for the OACS Imports web service, to automatically upload the import file to the OROB-Imports location in Order Orchestration.

-

deletes the zip file in the OROB_DIRECTORY_PATH.

Application log: The system writes any messages related to the Order Orchestration import process to the application log.

Scheduling the import or running it on demand:

-

In Order Administration, you can use the job scheduler to schedule when a periodic process runs. See Scheduling Jobs for instructions.

-

In Order Orchestration, you use the Schedule Import Process screen in Order Orchestration to set up a schedule for importing item and inventory information from Order Administration. You can also run the import on demand from this screen.

Before you can run the import, you need to complete the required setup in Order Orchestration as well as the Order Orchestration Configuration.

Mapping the Order Administration item and SKU code to the Order Orchestration product or system product code:

-

The Order Administration item and SKU maps to the Order Orchestration system product code. The system maps the full 12 positions for the item and the full 14 positions for the SKU; for example:

SKU YELW SML WMNS. -

The setting of the OROB Product Code ID (K66) system control value defines which field in Order Administration is used as the product code in Order Orchestration. You can map the item and SKU, reference number, or UPC code to the product code.

Order Orchestration Product Output File

Use the OBPROD OB Product Output File (program name PFR0127) periodic function to generate the Order Orchestration Product Output file. This file contains product information for a specified company to import into Order Orchestration. See Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process for processing details.

Location of file: The OROB_DIRECTORY_PATH in Working with Admin Properties (CPRP) defines the location where the system creates the output file. See Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process for processing details.

Name of file: The system names the file PRODUCT_SYS.TXT, where SYS is the

company code where you submitted the periodic function.

Sample file:

system_cd|department|class|sub_class|system_product|product_cd|product_description|master_style

7|7777 LONG SKU DEPARTMENT|7777 LONG SKU CLASS|777 LONG

SKU DIVISION|SKU YELW

SML WMNS|SKU YELW

SML WMNS|SKU ITEM DESCRIPTION|SKU

The system includes empty pipes in the file for data that is not included.

| Field | Description |

|---|---|

|

system_cd |

The company code where the periodic function was submitted. Maps to the Order Orchestration system code. |

|

department |

The code and description of the long SKU department assigned to the item. Maps to the Order Orchestration Department field if the Order Administration company is the default system. |

|

class |

The code and description of the long SKU class assigned to the item. Maps to the Order Orchestration Class field if the Order Administration company is the default system. |

|

subclass |

Depending on the setting of the OROB Item Category Value (M54) system control value:

Maps to the Order Orchestration Category field if the Order Administration company is the default system. |

|

system_product |

The item

and SKU. The system includes the full 12 positions for the item and

the full 14 positions for the SKU; for example: |

|

product_cd |

The item’s product code in Order Orchestration. The setting of the OROB Product Code ID (K66) system control value defines which field in Order Administration is used as the product code in Order Orchestration. Note: When mapping the item and SKU, the system includes the full 12 positions for the item and the full 14 positions for the SKU; for example:SKU YELW

SML WMNS.

|

|

product_description |

A description of the item. Maps to the product description if the Order Administration company is the default system. |

|

master_style |

The item code if the item contains SKUs. Maps to the Order Orchestration master style code if the item has SKU’s. |

Order Orchestration Product Location Output File

Use the OBPRLOC OB Product Location Output File (program name PFR0128) periodic function to generate the Order Orchestration Product Location Output file. This file contains product location, attribute, and availability information for a specified company to import into Order Orchestration. See Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process for processing details.

Location of file: The OROB_DIRECTORY_PATH in Working with Admin Properties (CPRP) defines the location where the system creates the output file. See Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process for processing details.

Name of file: The system names the file PRODUCT_LOCATION_SYS.TXT, where SYS is

the company code where you submitted the periodic function.

Note:

It is important to use Purchase Order Layering to update the PO Layering table before running the import; otherwise, the Next PO date and Next PO quantity sent to Order Orchestration will not be up to date.Send inventory by warehouse? You can either map inventory information for individual item warehouses to the related locations in Order Orchestration, or aggregate item warehouse totals across all allocatable warehouses for an item or SKU into a default location representing your distribution center.

If the Send Inventory by Warehouse to OROB (L06) system control value is:

-

selected: the import process includes each Item Warehouse record for items flagged OROB eligible if the warehouse has an OROB location specified and the warehouse is flagged as Allocatable. Any purchase order information is related to that warehouse only.

-

unselected: the import process sends the total available quantity for the item in all allocatable warehouses, regardless of whether the warehouse has an OROB location specified, and updates the product location in Order Orchestration using the OROB Default Location (K51). Any purchase order information is the earliest eligible purchase order across all allocatable warehouses.

Example:

Item AB100 is stocked in:

-

Warehouse 1 (allocatable, OROB location = DC1)

-

Available quantity = 100

-

Next purchase order date = 6/30

-

Next purchase order quantity = 15

-

-

Warehouse 2 (allocatable, OROB location = S2)

-

Available quantity = -10

-

No open purchase orders

-

-

Warehouse 3 (allocatable, no OROB location)

-

Available quantity = 5

-

Next purchase order date = 6/28

-

Next purchase order quantity = 50

-

OROB Default Location (K51) is set to DC.

Results when sending by warehouse:

If Send Inventory by Warehouse to OROB (L06) is selected, update:

OROB location DC1:

-

Available quantity = 100

-

Next purchase order date = 6/30

-

Next purchase order quantity = 15

OROB location S2:

-

Available quantity = -10

-

No purchase order information is included

Warehouse 3 is not included because there is no OROB location.

Results when sending sum:

If Send Inventory by Warehouse to OROB (L06) is unselected, update:

OROB location DC:

-

Available quantity = 95 (warehouse 1 + warehouse 2 + warehouse 3)

-

Next purchase order date = 6/28

-

Next purchase order quantity = 50

Availability for Drop Ship and Non-Inventory Items, including Main Set Items

-

Drop ship items: If an item is flagged as Drop ship, the available quantity passed to Order Orchestration is 9999, unless you actually have an available quantity of the drop ship item in the warehouse; in this case, the available quantity sent to Order Orchestration is based on the standard availability calculation described above. Also, in this case, if there are any open purchase orders for the drop ship item tracked in the Purchase Order Layering table, then the next PO date and quantity from the first Purchase Order Layering record is also passed to Order Orchestration. (Purchase orders for drop ship items are in the Purchase Order Layering table only if they are not generated through customer orders, but are requesting shipment to the warehouse.)

Example:

12 units in warehouse 2 (OROB location = 2)

0 units in warehouse 3 (OROB location = DC; this is the OROB Default Location (K51))

If the Send Inventory by Warehouse to OROB (L06) system control value is:

-

selected: the available quantity reported for each OROB location:

-

2 = 12

-

DC = 9999

-

-

unselected: the available quantity reported for OROB location DC = 12

Note:

If there is a quantity on-hand in the warehouse, but it is not currently available (for example, because it is reserved against an order), then the available quantity reported is 9999.-

Main set items and other non-inventory items: The available quantity reported for the main set item is typically 0; however, if you actually have an available quantity of the item in the warehouse, this quantity is used. To determine the true availability of a set, check the set components and the set quantity of each component required to make up a set, or look up the main set item in Entering Set Information (WSET).

Sample file:

system_cd|location_cd|product_cd|available_qty|next_po_qty|next_po_date|daily_sell_through_qty|sell_qty_multiple|minimum_sell_qty|shrink_rate|sales_velocity

7|1|SKU YELW

SML WMNS|1000|200|2015-12-07||1|||

The system includes empty pipes in the file for data that is not included.

| Field | Description |

|---|---|

|

system_cd |

The company code where the periodic function was submitted. Maps to the Order Orchestration system code. |

|

location_cd |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is from the OROB Default Location (K51), even if the item is not stored in this warehouse, but is stored in another allocatable warehouse; otherwise, this is the OROB location specified for the warehouse. If the Send Inventory by Warehouse to OROB (L06) is selected and the warehouse does not have a OROB location, the information is not sent to Order Orchestration. Maps to a Order Orchestration location. |

|

product_cd |

The item

and SKU. The system includes the full 12 positions for the item and

the full 14 positions for the SKU; for example: |

|

available_qty |

If the Send

Inventory by Warehouse to OROB (L06) system control value is

unselected, this is the total quantity available across all allocatable

warehouses; otherwise, this is the total quantity available for the

warehouse. Calculated as: |

|

next_po_qty |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is the quantity expected on the next open purchase order that might be able to fulfill a new backorder; otherwise, this is the quantity expected on the next eligible open purchase order for that warehouse only. From the Purchase Order Layering table. |

|

next_po_date |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is the date of the next open purchase order that might be able to fulfill a new backorder; otherwise, this is the date of the next eligible open purchase order for that warehouse only. From the Purchase Order Layering table. |

|

daily_sell_through_qty |

This value is not populated. |

|

sell_qty_multiple |

The Sell Quantity defined for the item. |

|

minimum_sell_qty |

This value is not populated. |

|

shrink_rate |

This value is not populated. |

|

sales_velocity |

This value is not populated. |

Item Availability Updates

The Order Orchestration item availability update process allows Order Orchestration to obtain up-to-date inventory information from Order Administration.

How does the update work?

-

The OBINCIN OB Incremental Inventory Output File (program name PFR0129) periodic function allows you to generate an Incremental Inventory output file for import into Order Orchestration. This file contains inventory updates for a specified company since the last time the periodic function was run. See Oracle Retail Order Orchestration Incremental Inventory Output File for details.

-

The Order Orchestration Product Inventory Availability API returns location availability information for a specific product, based on a request from Order Orchestration.

Oracle Retail Order Orchestration Incremental Inventory Output File

Use the OBINCIN OB Incremental Inventory Output File (program name PFR0129) periodic function to generate an Incremental Inventory output file to send to Order Orchestration. This file contains inventory updates for a specified company to send to Order Orchestration.

Include only items with changed availability: When you run this periodic function, the system calculates

the quantity currently available and updates the Virtual current

available field in the Item Warehouse table. If the Send Inventory

by Warehouse to OROB (L06) system control value is unselected,

this is the total quantity available across all allocatable warehouses;

otherwise, this is the total quantity available for the warehouse.

Calculated as: On hand - Protected - Reserved - Reserve Transfer

- Backordered = Quantity available. See Availability for Drop Ship and Non-Inventory Items, including Main

Set Items for a discussion on drop ship and non-inventory

items, such as main set items.

The system compares the quantity in the Virtual current available to the quantity in the Last available sent field in the Item Warehouse table. If the quantities do not match, the system:

-

includes the item in the incremental inventory output file, updating the available_qty in the file with the Virtual current available quantity.

-

updates the Last available sent field with the quantity defined in the Virtual current available field.

Note:

If the quantities in the Virtual current available and Last available sent match, the system does not include the item in the incremental inventory output file.Send inventory by warehouse? You can either map inventory information for individual item warehouses to the related locations in Order Orchestration, or aggregate item warehouse totals across all allocatable warehouses for an item or SKU into a default location representing your distribution center.

If the Send Inventory by Warehouse to OROB (L06) system control value is:

-

selected: the import process includes availability for items flagged OROB eligible if the warehouse has an OROB location specified and the warehouse is flagged as Allocatable. Any purchase order information is related to that warehouse only. Only warehouses whose available quantity has changed are included.

-

unselected: the import process sends the total available quantity for the item in all allocatable warehouses, regardless of whether the warehouse has an OROB location specified, and updates the product location in Order Orchestration using the OROB Default Location (K51). Any purchase order information is the earliest eligible purchase order across all allocatable warehouses.

Example:

Item AB100 is stocked in:

-

Warehouse 1 (allocatable, OROB location = DC1)

-

Available quantity = 100

-

Next purchase order date = 6/30

-

Next purchase order quantity = 15

-

-

Warehouse 2 (allocatable, OROB location = S2)

-

Available quantity = -10

-

No open purchase orders

-

-

Warehouse 3 (allocatable, no OROB location)

-

Available quantity = 5

-

Next purchase order date = 6/28

-

Next purchase order quantity = 50

-

OROB Default Location (K51) is set to DC.

Results when sending by warehouse:

If Send Inventory by Warehouse to OROB (L06) is selected, update:

OROB location DC1:

-

Available quantity = 100

-

Next purchase order date = 6/30

-

Next purchase order quantity = 15

OROB location S2:

-

Available quantity = -10

-

No purchase order information is included

Warehouse 3 is not included because there is no OROB location.

Results when sending sum:

If Send Inventory by Warehouse to OROB (L06) is unselected, update:

OROB location DC:

-

Available quantity = 95 (warehouse 1 + warehouse 2 + warehouse 3)

-

Next purchase order date = 6/28

-

Next purchase order quantity = 50

See Availability for Drop Ship and Non-Inventory Items, including Main Set Items for more information on how the system determines the available quantity for drop ship items, non-inventory items, and main set items.

Location of file: The OROB_DIRECTORY_PATH in Working with Admin Properties (CPRP) defines the location where the system downloads the Incremental Inventory output file. See Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process for processing details.

Name of file: The system names the file

INCREMENTAL_INVENTORY_999_YYMMDDHHMMSS.TXT, where 999 is the company code where you submitted the periodic function

and YYMMDDHHMMSS is the date and time when the

download occurred. The file has a .tmp suffix while it is being generated.

Application log: The system writes any messages related to the download to the application log.

Sample file:

system_cd|location_cd|product_cd|available_qty|next_po_qty|next_po_date

9|1|2006 PINK

S REG|10|20|2015-10-31

The system includes empty pipes in the file for data that is not included.

| Field | Description |

|---|---|

|

system_cd |

The company code where the periodic function was submitted. Maps to the Order Orchestration system code. |

|

location_cd |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is from the OROB Default Location (K51), even if the item is not stored in this warehouse, but is stored in another allocatable warehouse; otherwise, this is the OROB location specified for the warehouse. If the Send Inventory by Warehouse to OROB (L06) is selected and the warehouse does not have a OROB location, the information is not sent to Order Orchestration. Maps to a Order Orchestration location. |

|

product_cd |

The item

and SKU. The system includes the full 12 positions for the item and

the full 14 positions for the SKU; for example: |

|

available_qty |

If the Send

Inventory by Warehouse to OROB (L06) system control value is

unselected, this is the total quantity available across all allocatable

warehouses; otherwise, this is the total quantity available for the

warehouse. Calculated as: |

|

next_po_qty |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is the quantity expected on the next open purchase order that might be able to fulfill a new backorder; otherwise, this is the quantity expected on the next eligible open purchase order for that warehouse only. From the Purchase Order Layering table. |

|

next_po_date |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is the date of the next open purchase order that might be able to fulfill a new backorder; otherwise, this is the date of the next eligible open purchase order for that warehouse only. From the Purchase Order Layering table. |

Order Orchestration Product Inventory Availability API

Use the Order Orchestration Product Inventory Availability API to return location availability information for a specific product, based on a request from Order Orchestration.

Process overview: When a remote system requests inventory information, Order Orchestration checks for current inventory information from Order Administration if:

-

the system representing Order Administration is configured in Order Orchestration as an online system, and

-

there is a product location record in Order Orchestration indicating that the item is stocked in a Order Administration warehouse. This record is normally created automatically through Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process.

If the above conditions are true, Order Orchestration automatically checks the item’s inventory information in Order Administration, and updates the product location record for the product in the OROB Default Location (K51) if the Send Inventory by Warehouse to OROB (L06) system control value is unselected; otherwise, it updates the location matching the warehouse’s OROB location. The rules used to update the product location’s Available quantity, Next PO quantity, and Next PO date are the same as those used for Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process.

Setup:

-

Complete all the setup required for Order Orchestration’s Product, Product Location, and Incremental Inventory Import Process.

-

Flag the Order Administration system in Order Orchestration as Online.

-

Complete the setup required for the Order Orchestration Availability API.

Order Orchestration Availability API setup: The CWServiceIn Web Service allows an external system to post the Order Orchestration Product Inventory Availability Request directly to Order Administration.

Web service authentication? Use the Work with Web Service Authentication (WWSA) menu option to define a valid user and password for basic web service authentication, or client ID and client secret if using OAuth.

Web service type? You can use the CWServiceIn RESTful web service for the Order Orchestration Product Inventory Availability API. You POST the Order Orchestration Product Inventory Availability Request to the web service’s URL, or endpoint, of the RESTful service. The web service routes the messages sent to the endpoint and dispatches them to the Item Availability Update process. When the Item Availability Update process generates an Order Orchestration Product Inventory Availability Response, the CWServiceIn web service routes the response.

Determine the endpoint: The individual

URL for the CWServiceIn RESTful service used for the Order Orchestration

Product Inventory Availability API uses the following format: http://server/oms/sxrs/Inventory, where server identifies the application server where the

RESTful service is located.

Errors: If the Order Orchestration Product Inventory Availability Request fails, the response returns with an error message. Possible errors are:

| Error Message | Reason |

|---|---|

|

Message is Invalid |

The message is not in the correct JSON format. |

|

Product Code in Invalid |

The product code must be a valid item in Order Administration. |

|

System Code in Invalid |

The system code must be a valid company code in Order Administration. |

Order Orchestration Product Inventory Availability Request

See Order Orchestration Product Inventory Availability: Sample Messages for sample messages.

| Name | Type | Length | Comments |

|---|---|---|---|

|

urlString |

Identifies

the URL for the Order Administration web service. The individual

URL for the CWServiceIn RESTful service uses the following format: |

||

|

productCd |

alpha |

12 |

The Order Administration item number and SKU. |

|

systemCd |

numeric |

3 |

The Order Administration company code. |

|

Response |

Not used. |

||

|

systemId |

Not used. |

||

|

timeOut |

Not used. |

Order Orchestration Product Inventory Availability Response

See Order Orchestration Product Inventory Availability: Sample Messages for sample messages.

| Name | Type | Length | Comments |

|---|---|---|---|

|

ProductCode |

alpha |

12 |

The item

and SKU. The system includes the full 12 positions for the item and

the full 14 positions for the SKU; for example: |

|

LocationCode |

numeric |

3 |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is from the OROB Default Location (K51), even if the item is not stored in this warehouse, but is stored in another allocatable warehouse; otherwise, this is the OROB location specified for the warehouse. If the Send Inventory by Warehouse to OROB (L06) is selected and the warehouse does not have a OROB location, the information is not sent to Order Orchestration. Maps to a Order Orchestration location. |

|

AvailableQuantity |

If the Send

Inventory by Warehouse to OROB (L06) system control value is

unselected, this is the total quantity available across all allocatable

warehouses; otherwise, this is the total quantity available for the

warehouse. Calculated as: A negative quantity indicates the item in on backorder. See Availability for Drop Ship and Non-Inventory Items, including Main Set Items for a discussion on drop ship and non-inventory items, such as main set items. |

||

|

NextPOQuantity |

If the Send Inventory by Warehouse to OROB (L06)system control value is unselected, this is the quantity expected on the next open purchase order that might be able to fulfill a new backorder; otherwise, this is the quantity expected on the next eligible open purchase order for that warehouse only. From the Purchase Order Layering table. |

||

|

NextPODate |

If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this is the date and time, in YYYY-MM-DD HH:MM:SS format, of the next open purchase order that might be able to fulfill a new backorder; otherwise, this is the date of the next eligible open purchase order for that warehouse only. From the Purchase Order Layering table. |

Order Orchestration Product Inventory Availability: Sample Messages

Samples of the Order Orchestration Availability messages are presented below.

Successful Order Orchestration Availability Request:

{"urlString":"https://wbooms55app2/oms/sxrs/Inventory","productCd":"LOCATE","systemCd":"7","response":"-1","systemId":425430,"timeOut":30000}

Order Orchestration Availability Response:

[

{

"ProductCode": "LOCATE",

"LocationCode": "S2",

"AvailableQuantity": -10,

"NextPOQuantity": 0,

"NextPODate": ""

},

{

"ProductCode": "LOCATE",

"LocationCode": "1",

"AvailableQuantity": 100,

"NextPOQuantity": 15,

"NextPODate": "2016-01-30

12:00:00 AM"

}

]

Unsuccessful Order Orchestration Availability Request:

{"urlString":"https://wbooms55app2/oms/sxrs/Inventory","productCd":"ITM","systemCd":"7","response":"-1","systemId":425430,"timeOut":30000}

Order Orchestration Availability Response:

{"error": "Product Code is Invalid"}

Brokered Backorder Integration with Order Broker

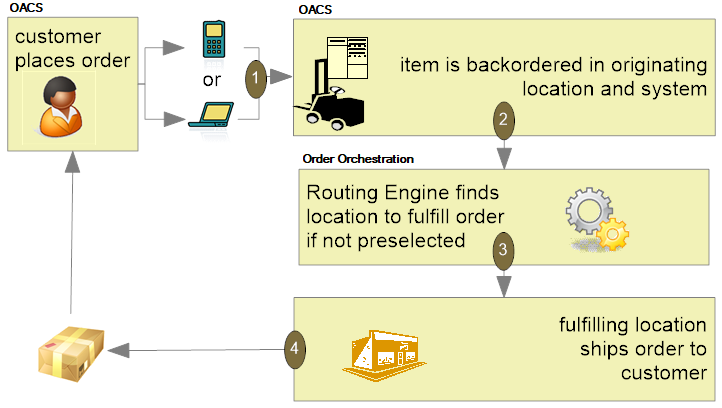

Brokered backorder: Use the brokered backorder integration with Order Orchestration to automatically send backordered lines to the Order Broker module in Order Orchestration for fulfillment.

-

If the Use OROB for Fulfillment Assignment (M31) system control value is unselected, the system sends eligible backordered items to the Order Broker for fulfillment. The Order Broker will choose the best store location to fulfill and ship the item to the customer. Items that are in stock follow normal reservation and fulfillment processing.

-

If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system bypasses reservation and places all eligible items on backorder, even if the item is available in an Order Administration warehouse. The Order Broker will choose the best store location or Order Administration location to fulfill and ship the item to the customer.

-

If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the system bypasses reservation in order to send eligible items on a ship-for-pickup order to the Order Broker for fulfillment assignment. In this situation, the fulfilling location may be a store location or an Order Administration warehouse and the merchandise is shipped to the customer’s selected store for pickup.

When using Order Orchestration for fulfillment assignment, the fulfilling location can be a store location or an OACS warehouse location. In addition, for ship-for-pickup orders, the fulfilling location ships the order to the customer’s selected store for pickup.

Unlike the merchandise locator API, the brokered backorder integration with Order Orchestration enables you to fulfill these orders automatically “behind the scenes” using business rules you have configured in Order Orchestration and Order Administration, without the need to select a fulfilling location; the Order Broker selects the location for you.

For more information: See Order Orchestration Configuration and Brokered Backorders.

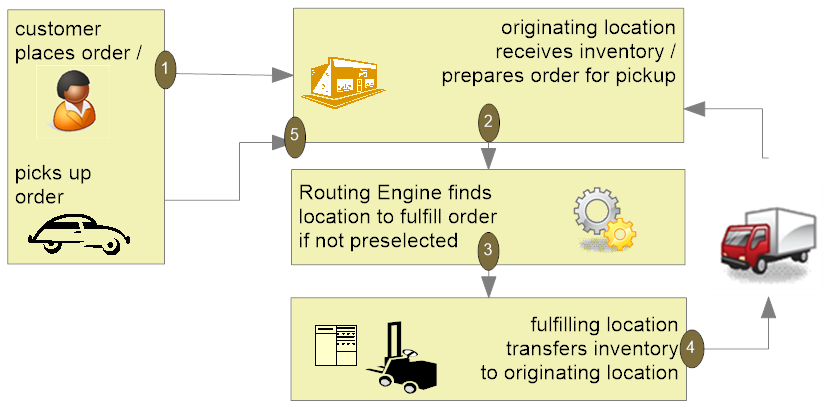

Ship-for-Pickup Orders

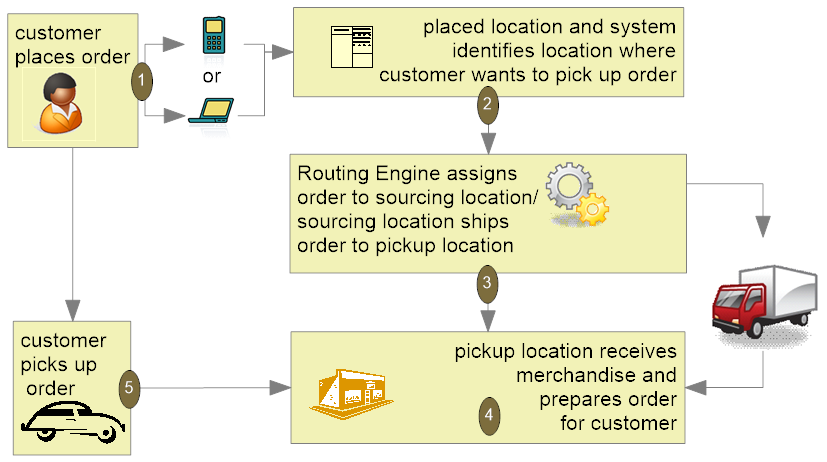

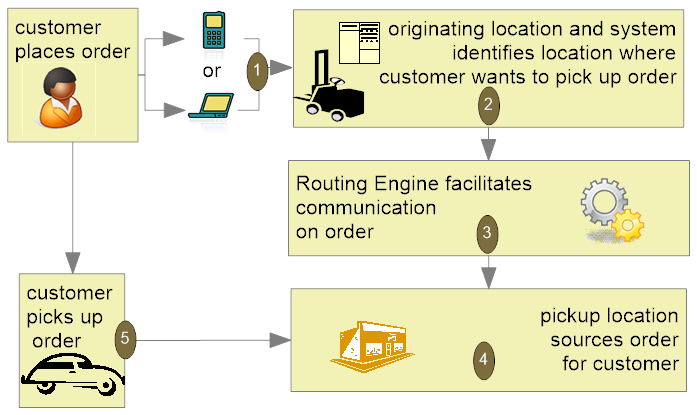

Ship-for-pickup order: Use the ship-for-pickup integration with Order Orchestration to send the merchandise for an order to a designated store, where the customer can pick it up. The Order Orchestration integration facilitates communication between Order Administration and the designated store location, so the store receives notification that the order is in transit, and sends notification back to Order Administration after the merchandise is received and when the customer picks up the order.

The items on the order do not need to be stocked in the store. In addition, the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value controls whether Order Administration fulfills the order or whether the order is sent to Order Orchestration for fulfillment assignment.

-

If this system control value is set to NEVER, Order Administration fulfills the order and sends the items on the order to the store selected for customer pick up during pick slip generation and/or drop ship processing. In this situation, if an item on the order is not in stock, the item is placed on backorder until it can be fulfilled by Order Administration. The order can include up to two locations for processing:

-

the originating, or placed, location that creates the order. For ship-for-pickup orders, the originating location is always an Order Administration warehouse.

-

the fulfilling, or sourcing, location that provides the inventory for the order. If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, this is always an Order Administration warehouse.

-

the pickup location where the customer picks up the items on the order. For ship-for-pickup orders, this is always the store location the customer selected for pickup.

-

-

If this system control value is set to ALWAYS, the system sends the order to Order Orchestration for fulfillment assignment after the order is created. In this situation, Order Orchestration determines the best location to fulfill the order and the order can include up to three locations for processing:

-

the originating, or placed, location that creates the order. For ship-for-pickup orders, the originating location is always an Order Administration warehouse.

-

the fulfilling, or sourcing, location that provides the inventory for the order. If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, this is the location the Order Broker selected for fulfillment of the order. This location can be a store location or an Order Administration warehouse.

-

the pickup location where the customer picks up the items on the order. For ship-for-pickup orders, this is always the store location the customer selected for pickup.

-

If Order Orchestration determines that Order Administration is the best location to fulfill the order, the system creates a new retail pickup order in Order Administration to fulfill the ship-for-pickup order.

Important:

Regardless of when you send ship-for-pickup orders to Order Orchestration, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Orchestration. Once you enable ship for pickup, the Ship for Pickup Enabled Date displays on the Organization window and cannot be changed.Examples: Examples of ship-for-pickup include the following.

Example 1 (three different locations; Order Orchestration determines fulfilling location):

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Orchestration selects store location C as the fulfilling, or sourcing, location. Store location C ships the inventory to store location B, where the customer can pick it up.

Example 2 (fulfillment location and pickup location are the same; Order Orchestration determines fulfilling location):

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Orchestration selects store location B as the fulfilling, or sourcing, location. Once the order is ready at store location B, the customer can pick it up.

Example 3 (originating location and fulfillment location are the same); Order Orchestration determines fulfilling location:

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Orchestration selects warehouse location A, Order Administration, as the fulfilling, or sourcing, location. Order Administration ships the items on the order to store location B. Once the order is ready at store location B, the customer can pick it up.

Example 4 (originating location and fulfillment location are the same; items on the order are shipped to the store during pick slip generation/drop ship processing):

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Administration fulfills the items on the order and during pick slip generation, ships the items on the order to store location B. Order Orchestration manages communication between Order Administration and store location B. Once the order is ready at store location B, the customer can pick it up.

For more information: See Order Orchestration Configuration and Ship-for-Pickup Orders.

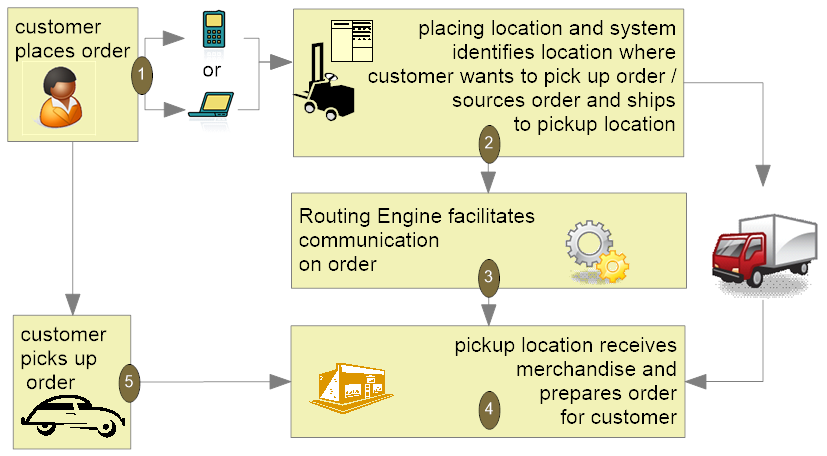

Retail Pickup (including Ship-for-Pickup) and Delivery Orders from Order Orchestration

Purpose: Use the retail pickup and delivery order integration with Order Orchestration to fulfill orders received from Order Orchestration. The originating location may be a store location or an Order Administration order.

Retail pickup or ship-for-pickup order: The Order Broker sends a retail pickup order or ship-for-pickup order to Order Administration for fulfillment when the customer would like to pick up the order at a retail location. The ship-to address on the order sent to Order Administration for fulfilment is the name and address of the pickup store location. If Order Orchestration sends a ship-for-pickup order to Order Administration for fulfillment, the system treats the ship-for-pickup order the same as a retail pickup order.

Delivery order: The Order Broker sends a delivery order to Order Administration for fulfillment when the customer would like the order shipped to his or her address. The ship-to address on a delivery order is the name and address of the customer.

For more information: See Order Orchestration Configuration and Retail Pickup (including Ship-for-Pickup) or Delivery Orders.

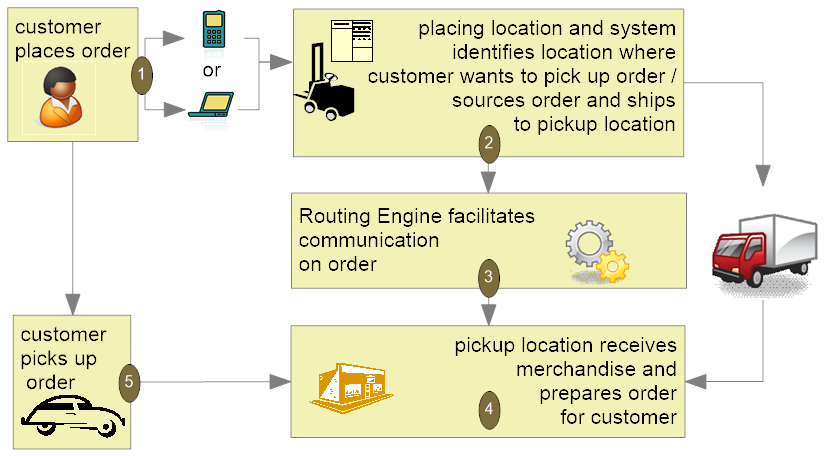

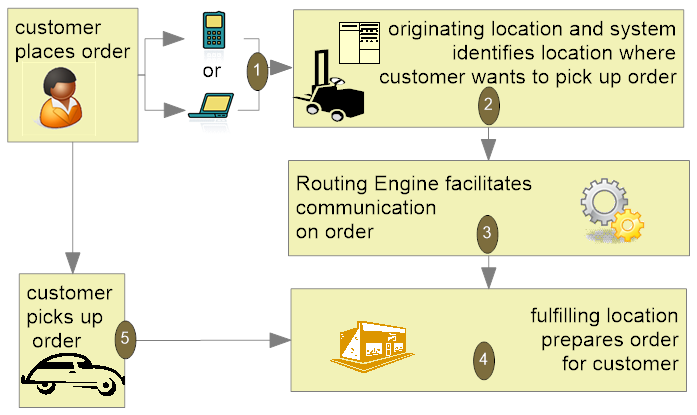

Store Pickup Orders

Store pickup order: Use the store pickup integration with Order Orchestration to send orders to an external retail location where the merchandise is already available for pickup. Unlike a ship-for-pickup order, a store pickup order does not require Order Administration to transfer the inventory to the store. The ship-to address on a store pickup order sent from Order Administration to the Order Broker is the name and address of the originating store location.

For more information: See Order Orchestration Configuration and Store Pickup Orders.

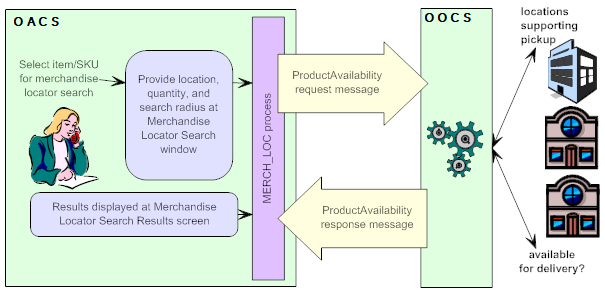

Merchandise Locator Searching

Merchandise locator searching: This integration with Order Orchestration provides a way to search for a location across the enterprise where the customer can pick up an item. This option is available in item availability, order entry, and order maintenance. The results are informational only.

For more information: See Order Orchestration Configuration, and the Merchandise Locator API.

Store Connect

Overview: Store Connect is a module of Order Orchestration that provides store associates with a suite of screens to process delivery orders (brokered backorders from Order Administration) or store pickup orders. Store Connect is represented in Order Orchestration as a separate integrated system, and stores using Store Connect identified as locations; however, the Order Broker assigns and tracks orders assigned to Store Connect locations as it does for any other orders.

Types of orders: When using Order Administration, only delivery orders (brokered backorders) and store pickup orders can be fulfilled through Store Connect:

-

Brokered backorders (delivery orders): When Order Orchestration receives a brokered backorder from Order Administration, it assigns the order to a fulfilling location using standard Order Orchestration rules. If the selected location is part of the Store Connect system, the associates use Store Connect to accept, print, pick, and ship the order, and Order Administration tracks the activity as with any other brokered backorder.

-

Store pickup orders: Selecting a fulfilling location for a store pickup order uses standard Order Orchestration rules; however, since Store Connect is represented in Order Orchestration as a separate system, you need to associate Store Connect store locations with that system code, either through the Store Cross Reference record or through a default specified in a system control value. The store associate uses Store Connect to accept, print, and pick the order, and to confirm customer pickup.

For more information: See:

-

the Order Orchestration Operations Guide and online help

Summary of Order Types for the Order Orchestration Integration

The different types of orders that Order Administration sends to or receives from Order Orchestration are summarized below. This summary is from the Order Administration perspective.

| Brokered Backorder | Delivery | Store Pickup | Retail Pickup | Ship-for-Pickup | |

|---|---|---|---|---|---|

|

used to: |

Create an

order in Order Administration and send backordered items to the

Order Broker so that the items can be assigned to locations for fulfillment.

Additional settings allow you to send all items to Order Broker to

determine the fulfilling location even if the item is in stock in

the warehouse.

Note: A brokered backorder order type does not exist in Order Orchestration. |

Receive and fulfill an order from Order Orchestration and ship the order to the customer’s ship to address. |

Create an order in Order Administration and send the order to Order Orchestration to notify a store location that already has the inventory available that a customer will pick up the order. |

Receive and fulfill an order from Order Orchestration and ship the order to the customer’s selected store for pickup. Ship-for-pickup orders that originate in a store come into Order Administration as retail pickup orders. |

Create an order in Order Administration and ship the order to a store location for customer pickup if the inventory is not already available at that store location. A system control value setting defines whether ship-for-pickup orders are immediately sent to Order Orchestration to determine the fulfilling location, similar to a brokered backoder, or are fulfilled by an Order Administration warehouse and then sent to Order Orchestration to complete the process. |

|

originating location is where the order is placed: |

This is an Order Administration warehouse. |

This is a store location but can be an Order Administration warehouse if the order originated in Order Administration and Order Orchestration assigned an Order Administration warehouse as the fulfilling location. |

This is an Order Administration warehouse. |

This is a store location. |

This is an Order Administration warehouse. |

|

fulfilling location is where the order is fulfilled: |

This can be a store location or an Order Administration warehouse. |

This is an Order Administration warehouse. |

This is a store location. |

This is an Order Administration warehouse. |

This can be an Order Administration warehouse or a store location. |

|

pickup location is where the order is picked up by the customer: |

Not applicable if the order is shipped to the customer. |

Not applicable; the order is shipped to the customer. |

This is a store location. |

This is a store location. |

This is a store location. |

|

order shipped to: |

Customer. |

Customer. |

Not applicable; the fulfilling location and pickup location are always the same. |

Store location; this is typically the originating store location. |

Pickup store location. |

Note:

-

When Order Administration is the originating location of a delivery order, the order is identified as a brokered backorder in Order Administration. To Order Orchestration it is considered a delivery order.

-

When Order Administration is fulfilling a delivery order, the order is identified as a delivery order in Order Administration.

-

When Order Administration is the originating location of a ship-for-pickup order, the order is identified as a ship-for-pickup order. A system control value setting defines whether ship-for-pickup orders are immediately sent to Order Orchestration to determine the fulfilling location, similar to a brokered backorder, or are fulfilled by an Order Administration warehouse and then sent to Order Orchestration to complete the process.

-

When Order Administration is the fulfilling location of a ship-for-pickup order, the order is identified as a retail pickup order in Order Administration.

-

Order Administration can only be the fulfilling location of a retail pickup order.

-

Order Administration can only be the originating location of a store pickup order.