Ship-for-Pickup Orders

Overview: You can use the ship-for-pickup option in the Order Orchestration Integration to send the merchandise for an order to a designated store, where the customer can pick it up. The Order Orchestration integration facilitates communication between Order Administration and the designated store location, so the store receives notification that the order is in transit, and sends notification back to Order Administration after the merchandise is received and when the customer picks up the order.

The items on the order do not need to be stocked in the store. In addition, the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value controls whether Order Administration fulfills the order or whether the order is sent to Order Orchestration for fulfillment assignment.

-

If this system control value is set to NEVER, Order Administration fulfills the order and sends the items on the order to the store selected for customer pick up. In this situation, if an item on the order is not in stock, the item is placed on backorder until it can be fulfilled by Order Administration. The order can include up to two locations for processing:

-

the originating, or placed, location that creates the order. For ship-for-pickup orders, the originating location is always an Order Administration warehouse.

-

the fulfilling, or sourcing, location that provides the inventory for the order. If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, this is always an Order Administration warehouse.

-

the pickup location where the customer picks up the items on the order. For ship-for-pickup orders, this is always the store location the customer selected for pickup.

-

-

If this system control value is set to ALWAYS, the system sends the order to Order Orchestration for fulfillment assignment. In this situation, Order Orchestration determines the best location to fulfill the order and the order can include up to three locations for processing:

-

the originating, or placed, location that creates the order. For ship-for-pickup orders, the originating location is always an Order Administration warehouse.

-

the fulfilling, or sourcing, location that provides the inventory for the order. If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, this is the location Order Orchestration selected for fulfillment of the order. This location can be a store location or an Order Administration warehouse.

-

the pickup location where the customer picks up the items on the order. For ship-for-pickup orders, this is always the store location the customer selected for pickup.

-

If Order Orchestration determines that Order Administration is the best location to fulfill the order, the system creates a new retail pickup order in Order Administration to fulfill the ship-for-pickup order; see Retail Pickup (including Ship-for-Pickup) or Delivery Orders

Important:

Regardless of when you send ship-for-pickup orders to Order Orchestration, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Orchestration. Once you enable ship for pickup, the Ship for Pickup Enabled Date displays on the Organization window and this option cannot be changed.Examples: Examples of ship-for-pickup include the following.

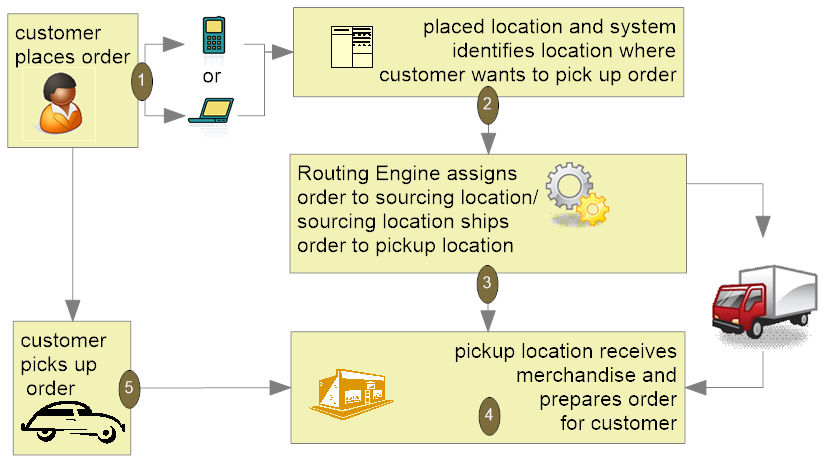

Example 1 (three different locations):

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Orchestration selects store location C as the fulfilling, or sourcing, location. Store location C ships the inventory to store location B, where the customer can pick it up.

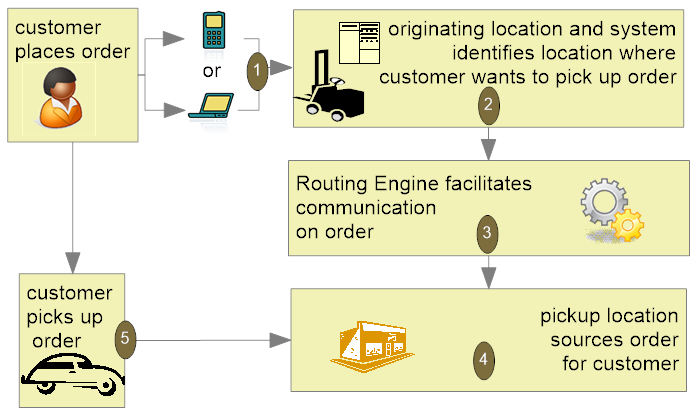

Example 2 (fulfilling location and pickup location are the same):

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Orchestration selects store location B as the fulfilling, or sourcing, location. Once the order is ready at store location B, the customer can pick it up.

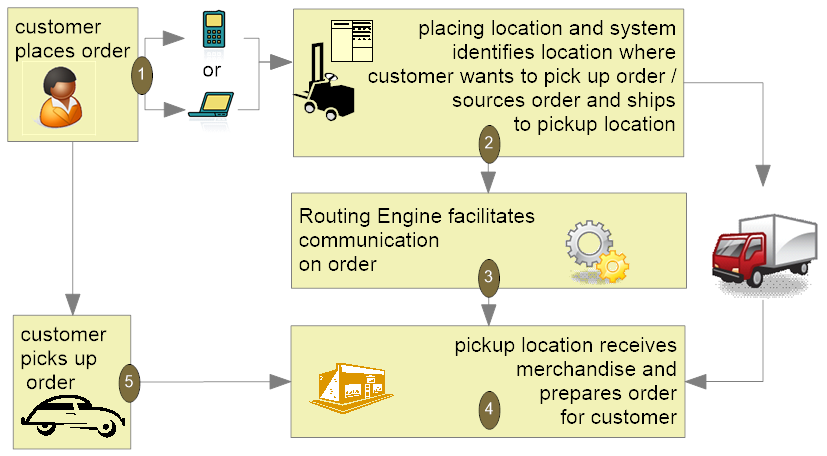

Example 3 (originating location and fulfilling location are the same):

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Orchestration selects warehouse location A, Order Administration, as the fulfilling, or sourcing, location. Order Administration ships the items on the order to store location B. Once the order is ready at store location B, the customer can pick it up.

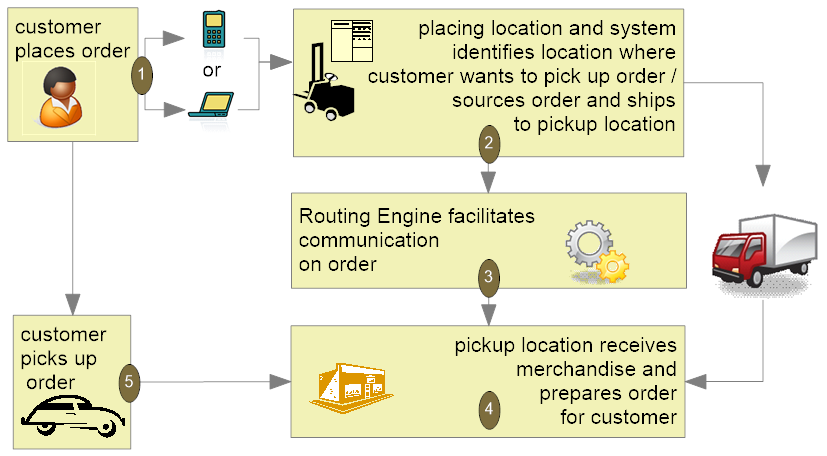

Example 4 (originating location and fulfillment location are the same; items on the order are shipped to the store during pick slip generation/drop ship processing):

The customer places an order on the web site (originating location A, Order Administration) and wants to pick the order up at store location B. Order Administration fulfills the items on the order and during pick slip generation, ships the items on the order to store location B. Order Orchestration manages communication between Order Administration and store location B. Once the order is ready at store location B, the customer can pick it up.

Version compatibility: Fulfillment assignment and ship-for-pickup functionality is available in release 16.0 or higher of Order Management System, or Order Administration, and release 16.0 or higher of Order Broker, or Order Orchestration. Also, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Orchestration. Once you enable ship for pickup, the Ship for Pickup Enabled Date displays on the Organization window and you cannot deselect this option.

An OROB_MESSAGE_VERSION of 16.0 or higher is required to use the Ship-for-Pickup Orders integration with Order Orchestration. Note that this property cannot be set higher than 19.9 for integration with Order Broker 19.x, or higher than 21.1 for integration with Order Orchestration 22.2.301.0 or higher.

In this topic:

Creating a Ship-for-Pickup Order in Order Administration

You can create a ship-for-pickup order through interactive order entry, or through the order API.

Note:

A ship-for-pickup order should have a single ship-to.Creating a Ship-for-Pickup Order in Order Entry

Ship-for-pickup orders originate in Order Administration, either through order entry or through the generic order API. The order creation process is similar to that of a regular order, except that a ship-for-pickup order includes a one-time ship-to address representing the store location.

To select the store location in order entry:

-

Select the One Time Ship To option.

-

At the Create One Time Ship To Address Screen, select Store.

-

Select a store at the Store Location Screen. This screen displays each store location set up through Work with Store Cross Reference (WSCR) whose Ship for Pickup flag is selected. The description and address set up for the Store Cross Reference default to the Create One Time Ship To Address screen.

-

Complete entry of the order.

-

If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, the system uses existing logic to reserve items in order to fulfill the ship-for-pickup order from an Order Administration warehouse. See Sending a Ship-for-Pickup Order to Order Orchestration during Pick Slip Generation and Drop Ship Order Processing.

-

If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS and the Send B/O to OROB (K08) system control value is selected, the system bypasses reservation and places all eligible items on backorder, even if the item is available in an Order Administration warehouse, in order to send all eligible items to Order Orchestration for fulfillment assignment; see Rules for Submitting Backorders to Order Orchestration. Order Orchestration will choose the best store location or Order Administration location to fulfill and ship the item to the store location selected by the customer for store pickup. See Brokered Backorders for processing details.

-

Note:

To avoid shipment problems, once you accept a ship-for-pickup order, the system does not allow you to change the store selected as the one-time ship-to address; in order to change the pickup store location, you must cancel the order and create a new ship-for-pickup order.Ship-alone items on ship-for-pickup orders: If an item is flagged as Ship alone, Order Administration does not let you enter an order line on a ship-for-pickup order with a quantity greater than one. If the customer wants more than one unit, enter a separate order line for each unit. This restriction applies even if the item is not flagged as OROB eligible.

Creating a Ship-for-Pickup Order through the Generic Order API

In the Inbound Order XML Message (CWORDERIN):

-

use the

store_codeattribute to specify the store location code. This needs to be a store location set up through Work with Store Cross Reference (WSCR), as described above for order entry. -

specify a

delivery_typeof S -

use the

ShipToelement in the Inbound Order XML Message (CWORDERIN) to specify the shipping address of the store, or leave the shipping name and address attributes blank in order to use the information set up in the Store Cross Reference record.For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1).

Name and address for ship-for-pickup order: If the ship-to name and address fields are passed for a ship-for-pickup order, these fields should indicate the shipping address of the store selected for pickup; otherwise, if no ship-to name and address is passed, the information defaults from the Store Cross Reference record.

Partial ship-to address? The name or address fields from the Store Cross Reference record default for any fields not passed in the message.

Example: If the CWOrderIn message indicates the ship-to customer’s first and last name, this information defaults to the order, in addition to the company name and address from the Store Cross Reference record.

Communicating with Order Orchestration about a Ship-for-Pickup Order

Submitting the order to Order Orchestration: The setting of the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value controls when the order is submitted to Order Orchestration.

The system submits a ship-for-pickup order to Order Orchestration for fulfillment assignment when the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS and the Send B/O to OROB (K08) system control value is selected, and:

-

You create an order that contains an eligible item in interactive order entry or through the generic order interface (Order API).

-

You run the BROKER Periodic Function to find eligible items to send to Order Orchestration.

See Brokered Backorders for processing details.

The system submits a ship-for-pickup order to Order Orchestration during pick slip generation or drop ship purchase order processing in the following scenarios.

-

When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER or blank, or

-

When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS but the Send B/O to OROB (K08) system control value is unselected.

See Sending a Ship-for-Pickup Order to Order Orchestration during Pick Slip Generation and Drop Ship Order Processing for processing details.

Sending a Ship-for-Pickup Order to Order Orchestration during Pick Slip Generation and Drop Ship Order Processing

Submitting the order to Order Orchestration: The system submits a ship-for-pickup order to Order Orchestration when you generate the pick slip or drop ship purchase order in the following scenarios.

-

When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER or blank.

-

When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS but the Send B/O to OROB (K08) system control value is unselected.

At this time, the system also creates the Order Orchestration record displayed at the Work with the Order Orchestration Screen.

Which items are included in the Submit Order message? Only items that are flagged as OROB eligible are included in the message to Order Orchestration. However, all items that print on the pick slip or purchase order can be included in the shipment to the store location.

Note:

It is important to confirm that including additional items on the pick slip or purchase order and in the shipment will not present a problem to the store receiving the ship-for-pickup order.No items OROB eligible? If you create a ship-for-pickup that does not include any OROB eligible items, Order Administration does not submit the order to Order Orchestration or create an Order Orchestration record; however, you can still generate the pick slip or drop ship purchase order and ship the order to the store location for customer pickup. It is important to note that, in this case, the selected store does not receive advance notification of the order.

For more information on the contents of the message, see theOrder Administration Web Services Guide on My Oracle Support (ID 2953017.1).

Submit separate orders for each order line? If the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected, Order Administration generates a separate pick slip or drop ship purchase order for each item, and as a result, submits each order line as a separate order to Order Orchestration. Creating separate orders in Order Orchestration can prevent confusion about order status if, for example, a single order line is canceled or fulfilled. See the Create Separate Picks for Ship for Pickup Orders (L89) system control value for more information.

What if Order Orchestration is unavailable? If Order Orchestration does not respond to the submit

order request during pick slip or drop ship purchase order generation,

Order Administration does not print the pick slip or purchase

order. Instead, it writes an order transaction history message: Submit Order Failed - OROB Unavailable. The order is eligible

for selection the next time you generate pick slips or drop ship purchase

orders.

Creating the Order Orchestration record: When the job generates the Submit Order request, it initially creates the Order Orchestration record in In Process status.

Message response: The Submit Order response message indicates whether Order Orchestration was able to create the order:

-

Order rejected? If Order Orchestration returns an error in the response message, Order Administration puts the order on hold using the Hold Reason for Errored Ship for Pickup Orders (L10). Order Orchestration might return an error if, for example, the order includes an item that does not exist in Order Orchestration or in the point-of-sale system associated with the store location. In this case, the Order Orchestration record in Order Administration is deleted and Order Transaction History indicates:

Submit Order Rejected/Order HeldRsn:PRODUCT NOT STOCKED IN REQUESTED LOCATION. -

Order accepted? If Order Orchestration accepts the order, the generation process sends a status update indicating a status of Picked. The process finishes and the Order Orchestration record remains in Picking status until you confirm shipment of the pick slip or purchase order.

Note:

The designated store location cannot reject a ship-for-pickup order.Sample message: See Order Administration Web Services Guide on My Oracle Support (ID 2953017.1) for a sample message and more information.

Fulfilling location in Order Administration vs. Order Orchestration:

-

When order submitted to Order Orchestration:

-

originating / placed location = the OACS warehouse shipping the merchandise to the store location.

-

fulfilling / sourced location = the OACS warehouse shipping the merchandise to the store location.

-

pickup location = the store location the customer selected for store pickup.

-

-

When store receives the merchandise or customer picks up the order: Once Order Administration receives a status inquiry response indicating that the store location has received the merchandise on the order, or that the customer has picked the order up, the store location is identified as the fulfilling location.

-

originating / placed location = the OACS warehouse shipping the merchandise to the store location.

-

fulfilling / sourced location = the OACS warehouse shipping the merchandise to the store location.

-

pickup location = the store location the customer selected for store pickup.

-

Excluded from brokered backorder processing: If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, backordered items on ship-for-pickup orders are not eligible for processing through the brokered backorder integration with Order Orchestration.

Creating ship-for-pickup orders for drop ship items: When you create a ship-for-pickup order for a drop ship item, Order Administration submits the order to Order Orchestration when you use Selecting Vendors for Drop Ship Processing (MDSP).

Note:

There is no warehouse associated with a drop ship item, so in this case Order Administration designates the OROB Default Location (K51) as the requesting location. If you are generating ship-for-pickup orders for drop ship items, you need to specify a valid Order Orchestration location in this system control value; otherwise, Order Orchestration returns an error indicating that the requesting location is invalid.Documents for store receiving: In order to support store receiving, you can generate the Pick Message from Order Administration (CWPickOut) or the PO Download XML Message (CWPurchaseOrderOut). Each of these messages includes details on the order submitted to Order Orchestration, including the Order Orchestration request ID, the order number in the originating system, and the delivery type. See the Generic Pick Out API and the Generic Outbound Purchase Order API in the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1) for more information.

Special Ship-for-Pickup Orders

In order to support processing special ship-for-pickup orders that originated in a retail location and then sent to Order Administration through the order API:

-

If the order type matches the Order Type for Special Orders (L15), the Submit Order message specifies the e-commerce order number, rather than the Order Administration order number, as the

order_id, so that the originating location can more easily identify and track the order. -

If the pay type matches the Pay Type for Special Orders (L16), the

balance_duespecified in the Submit Order message is the order total, indicating that the customer needs to pay for the order when picking it up. Otherwise, if the pay type on the order does not match this system control value, the Submit Order message does not specify a balance due, even if the order type matches the Order Type for Special Orders (L15).

See the Order Type for Special Orders (L15) and Pay Type for Special Orders (L16) system control values for more information.

If you use the Generic Pick In API (Shipments, Voids, and Backorders) to void a pick slip for a special ship-for-pickup order and the Cancel Reason (Pick In) (L86) system control value specifies a cancel reason code, or a backorder cancel reason is specified in the CWPickIn XML Message, Order Administration cancels the order using the specified cancel reason and sends a status update to Order Orchestration canceling the order.

Important:

To prevent inconsistent updates to Order Orchestration for special ship-for-pickup orders, do not process partial backorders for these orders through the Generic Pick In API (Shipments, Voids, and Backorders); confirm or void the entire pick slip.For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1).

Collect Payment for a Ship-for-Pickup Order at the Store?

You can use the Payment at POS for Ship for Pickup Orders (L60) system control value to indicate that the customer pays for a ship-for-pickup order when picking up the order at the store, rather than billing the order when you ship it to the store from the warehouse. In this case:

-

The order must include only credit card payment methods; also, each pay type’s Card type must be set to Credit. No other card types, such as stored value cards, can be included.

-

The payment method’s Suppress deposit and Suppress refund flags are set to Y.

-

The payment method is authorized for $1.00 only during online authorization.

-

Authorization is suppressed during pick slip generation.

-

Order Administration sends the order total to Order Orchestration as the

balance_duein the Submit Order message.

Note:

The above restrictions do not apply to ship-for-pickup orders whose order type matches the Order Type for Special Orders (L15).Returns suppressed: Selecting the Payment at POS for Ship for Pickup Orders (L60) system control value suppresses most options for creating a return authorization, processing a return, and creating a refund. See that system control value for details.

Updates to a Ship-for-Pickup Order in Order Administration

Add an item? If you add an item to a ship-for-pickup order, or are able to ship a backordered item once you have generated the pick slip and created the ship-for-pickup order in Order Orchestration, the new item is not added to the original Order Orchestration record or to the order in Order Orchestration. Printing the pick slip for the new order line creates a new Order Orchestration record and a new order in Order Orchestration.

Voiding or reprinting a pick slip: Order Administration sends a status update to Order Orchestration if you void a pick slip for an order line on an existing ship-for-pickup order:

-

Special ship-for-pickup orders: If the Cancel Reason (Pick In) (L86) system control value specifies a cancel reason or if a backorder cancellation reason code is specified in the CWPickIn XML Message, and you void the pick slip for a special ship-for-pickup order through the generic pick in API, Order Administration cancels the order or line and sends a cancellation to Order Orchestration, including the cancel reason from the system control value. For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). Also see Special Ship-for-Pickup Orders for background on these orders.

-

Regular ship-for-pickup orders: If the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected and you void the pick slip for a regular (not special) ship-for-pickup order, Order Administration does not cancel the order or line, but it does send a cancellation to Order Orchestration. No cancel reason is included in this case. This status update occurs regardless of whether you use the generic pick in API to void the pick slip, or void it at an Order Administration screen.

If you then reprint the pick slip for a regular ship-for-pickup order in this situation, Order Administration submits a new order to Order Orchestration; however, if you cancel the order after voiding the pick slip, no update is sent to Order Orchestration.

Aside from the two scenarios described above, Order Administration does not send a status update to Order Orchestration when you void or reprint a pick slip.

Canceling a ship-for-pickup order: Aside from the two scenarios, described above, which generate status updates for voided pick slips, Order Administration sends a status update to Order Orchestration when you cancel the order or item. In most cases, this status update includes the cancel reason you enter:

-

Cancel after voiding pick slip: If you cancel an item or the entire ship-for-pickup order in order maintenance after voiding the pick slip, and Order Administration has not already sent a status update when the pick slip was voided, it sends a status update that includes the cancel reason you enter. This situation can occur if, for example, you void a ship-for-pickup order through the Void/Reprint Picks menu option, or if you void a regular ship-for-pickup order with the Create Separate Picks for Ship for Pickup Orders (L89) system control value unselected.

-

Cancel drop ship purchase order in purchase order maintenance: If you cancel a drop ship purchase order in purchase order maintenance, Order Administration sends a status update that includes the Auto Soldout Cancel Reason (C20), since you do not have an opportunity to enter a cancel reason in this case.

-

Cancel drop ship purchase order sent to vendor through drop ship integration: To cancel items fulfilled through the drop ship integration, you need to use the Display P/O Drop Ship Screen in order inquiry. If you cancel a drop ship purchase order at this screen, and the purchase order is successfully canceled through the drop ship integration, it sends a status update that includes the cancel reason you enter.

Note:

-

Canceling single item cancels entire order in Order Orchestration: If you do not split orders and the pick slip creating the order in Order Orchestration included multiple items, canceling a single item in Order Administration results in canceling the entire order in Order Orchestration. This situation might occur if the Create Separate Picks for Ship for Pickup Orders (L89) system control value is not selected.

-

Canceling before order created in Order Orchestration: If you cancel the order before pick slip generation or drop ship purchase order generation, there is no need to notify Order Orchestration, since the order was never sent.

-

Cancel after shipment confirmation? Once you have confirmed shipment, it is not possible to cancel the ship-for-pickup order in Order Orchestration.

Ship-for-Pickup Order Processing on or after Shipment

Confirm shipment: When you confirm shipment of the pick slip, Order Administration changes the status of the Order Orchestration record and sends a status update to Order Orchestration with a status of Intransit, indicating that the order is on its way.

Additional processing:

-

When the assigned location sends a fulfillments request message to Order Orchestration to poll for newly assigned orders, it receives notification of the ship-for-pickup order.

Note:

The location assigned to a ship-for-pickup order cannot reject the order. -

The assigned store location sends the following additional status updates:

-

Received when the merchandise arrives at the store

-

Fulfilled (Order Administration status = Completed) when the customer picks up the order, or Partially fulfilled if the customer does not initially pick up the entire order

Note:

When Order Administration receives a status list inquiry response from Order Orchestration indicating that the merchandise was received at the store or that the customer has picked up the order, the fulfilling location on the Order Orchestration record in Order Administration changes from the warehouse shipping the order to the store location where the customer picks up the order. -

How Order Administration checks for additional status updates: Once you confirm shipment of the ship-for-pickup order to the store location, Order Administration includes the order in a status list inquiry request message once a day to Order Orchestration to check on whether the order has been received or picked up. See Setting the Daily Status Inquiry Time Window (all versions) for more information.

Returning a ship-for-pickup order: Selecting the Payment at POS for Ship for Pickup Orders (L60) system control value suppresses most options for creating a return authorization, processing a return, and creating a refund. See that system control value for details.

Reviewing a Ship-for-Pickup Order in Order Inquiry

In addition to reviewing information through the Working with Order Broker (WOBR) menu option, you can also use order inquiry. Your options include:

-

Identifying the Order Orchestration type: The Broker delivery type at the Display Order Properties Screen and the Display Order Broker Details Screen identifies a Ship for Pickup order.

-

Broker detail and history: Use the Display Order Broker Details Screen to review Order Orchestration Detail and Order Orchestration History.

-

Designated store: The Display Alternate Address Screen displays the store shipping address. You can advance to this screen by selecting the Ship To option from the header screen in order inquiry.

-

Order history: The Display Order History Screen displays activity related to sending status updates to and from Order Orchestration, such as:

-

Ln#: 1 Selected for Fulfillment:Written for each line on a ship-for-pickup order printed on a pick slip and sent to Order Orchestration in the Submit Order Message. -

Ln#: 1 In Transit shipment:Written for each printed line when you confirm shipment. -

Ln#: 1 Accepted by Broker:Written when you receive the status inquiry request indicating that the location where the customer is picking up the ship-for-pickup order has been notified. -

Ln#: 1 Cancel Acknowledged by Broker:Written when you receive the status update response message following the cancellation of a ship-for-pickup order. This situation occurs if you void the pick slip after initially notifying Order Orchestration about the order. -

Ln#: 1 Store Received:Written when you receive the status inquiry response message indicating that the order merchandise has been received at the store where the customer will pick up the order. At this point, the fulfilling location on the Order Orchestration record in Order Administration changes from the warehouse shipping the merchandise to the store location where the customer picks up the order. -

Ln#: 1 Customer Partial Pick Up:Written when you receive the status inquiry response message indicating that the customer has picked up some, but not all, of the merchandise on the order. -

Ln#: 1 Shipped by Broker order:Written when you receive a status inquiry response message indicating that the customer has picked up the order in full.

-

If Order Orchestration returns an error: If Order Orchestration returns an error during pick slip generation, Order Administration writes Order Transaction History messages such as:

Submit Order Rejected/Order Held

Rsn:INVALID ITEM (SYSTEM PRODUCT), ITEM

(PEN BLUE ) DOES NO

T EXIST. PRODUCT NOT STOCKED IN REQU

If the error occurs as a result of Selecting Vendors for Drop Ship Processing (MDSP), the messages might also indicate that the pick slip or purchase order was created, for example:

DROP SHIP PO# 1234567 CREATED.

However, in this situation the process does not produce the pick slip or purchase order.

If you submit a drop ship order and the OROB Default Location (K51) system control value does not specify a valid location in Order Orchestration, Order Orchestration returns an error during drop ship processing. In this case, Order Administration writes Order Transaction History messages such as:

Submit Order Rejected/Order Held

Rsn:INVALID OR MISSING REQUESTING LOCATI

ON LOCATION CODE, (STORE_LOCATION.LO

CATION_CD) IS REQUIRED.