2 Site Requirements for Recovery Appliance

This chapter describes the site requirements for Recovery Appliance. It contains these sections:

2.1 General Environmental Requirements

The environmental requirements for Recovery Appliance depend on the type and size of the system. The following tables provide an overview of the rack and disk requirements. Measurements are approximate.

Table 2-1 identifies the general environmental requirements for a Recovery Appliance X6 rack.

Table 2-1 Environmental Requirements for Recovery Appliance X6 Racks

| Environmental Component | Full Rack | Minimum Configuration(1) |

|---|---|---|

|

Weight See Also: "Flooring Requirements" |

875.7 kg (1930.5 lbs) |

381.2 kg (840.5 lbs) |

|

Power See Also: "Electrical Power Requirements" |

Maximum: 13.1 kVA (12.8 kW) Typical: 9.2 kVA (9.0 kW) |

Maximum: 4.1 kVA (4.0 kW) Typical: 2.9 kVA (2.8 kW) |

|

Cooling See Also: "Temperature and Humidity Requirements", and "Ventilation and Cooling Requirements" |

Maximum: 43,774 BTU/hour (46,182 kJ/hour) Typical: 30,642 BTU/hour (32,327 kJ/hour) |

Maximum: 13,679 BTU/hour (14,432 kJ/hour) Typical: 9,575 BTU/hour (10,102 kJ/hour) |

|

Air flow front-to-back (subject to actual data center environment) See Also: "Temperature and Humidity Requirements", and "Ventilation and Cooling Requirements" |

Maximum: 2,027 CFM Typical: 1,419 CFM |

Maximum: 633 CFM Typical: 443 CFM |

|

Acoustic levels |

8.5 Bel |

8.3 Bel |

|

See Also: "Factory IP Address Settings" |

69 for Ethernet network (single cluster) 36 maximum for InfiniBand network |

22 for Ethernet network (single cluster) 8 maximum for InfiniBand network |

|

Network drops See Also: "Overview of Network Requirements" |

11 network drops minimum |

5 network drops minimum |

|

Fiber san drops (optional) See Also: "Overview of Network Requirements" |

4 x OM3 fiber cables |

4 x OM3 fiber cables |

|

External connectivity See Also: "Network Connection Requirements for Recovery Appliance" |

6 x 1 Gbps Ethernet ports 4 x 10 Gbps Ethernet ports 12 or more InfiniBand ports 4 x 16 Gb fiber channel SAN connections (optional) |

6 x 1 Gbps Ethernet ports 4 x 10 Gbps Ethernet ports 12 or more InfiniBand ports 4 x 16 Gb fiber channel SAN connections (optional) |

Footnote 1 Recovery Appliance rack with the minimum number (3) of storage servers

Table 2-2 identifies the general environmental requirements for a Recovery Appliance X5 rack.

Table 2-2 Environmental Requirements for Recovery Appliance X5 Racks

| Environmental Component | Full Rack | Minimum Configuration(2) |

|---|---|---|

|

Weight See Also: "Flooring Requirements" |

875.7 kg (1930.5 lbs) |

381.2 kg (840.5 lbs) |

|

Power See Also: "Electrical Power Requirements" |

Maximum: 12.0 kW Typical: 8.4 kW |

Maximum: 4.0 kW Typical: 2.8 kW |

|

Cooling See Also: "Temperature and Humidity Requirements", and "Ventilation and Cooling Requirements" |

Maximum: 40,942 BTU/hour (43,194 kJ/hour) Typical: 28,660 BTU/hour (30,236 kJ/hour) |

Maximum: 13,560 BTU/hour (14,306 kJ/hour) Typical: 9,492 BTU/hour (10,014 kJ/hour) |

|

Air flow front-to-back (subject to actual data center environment) See Also: "Temperature and Humidity Requirements", and "Ventilation and Cooling Requirements" |

Maximum: 1,895 CFM Typical: 1,327 CFM |

Maximum: 628 CFM Typical: 439 CFM |

|

Acoustic levels |

8.5 Bel |

8.3 Bel |

|

See Also: "Factory IP Address Settings" |

69 for Ethernet network (single cluster) 36 maximum for InfiniBand network |

22 for Ethernet network (single cluster) 8 maximum for InfiniBand network |

|

Network drops See Also: "Overview of Network Requirements" |

11 network drops minimum |

5 network drops minimum |

|

Fiber san drops (optional) See Also: "Overview of Network Requirements" |

4 x OM3 fiber cables |

4 x OM3 fiber cables |

|

External connectivity See Also: "Network Connection Requirements for Recovery Appliance" |

6 x 1 Gbps Ethernet ports 4 x 10 Gbps Ethernet ports 12 or more InfiniBand ports 4 x 16 Gb fiber channel SAN connections (optional) |

6 x 1 Gbps Ethernet ports 4 x 10 Gbps Ethernet ports 12 or more InfiniBand ports 4 x 16 Gb fiber channel SAN connections (optional) |

Footnote 2 Recovery Appliance rack with the minimum number (3) of storage servers

Table 2-3 identifies the general environmental requirements for a Recovery Appliance X4 rack.

Table 2-3 Environmental Requirements for Recovery Appliance X4 Racks

| Environmental Component | Full Rack | Minimum Configuration(3) |

|---|---|---|

|

Weight See Also: "Flooring Requirements" |

724.9 kg (1598 lb) |

393.3 kg (867 lb) |

|

Power See Also: "Electrical Power Requirements" |

Maximum: 8.1 kVA (8.0 kW) Typical: 5.7 kVAFoot 4 (5.6 kW) |

Maximum: 3.2 kVA (3.1 kW) Typical: 2.3 kVAFootref 4 (2.2 kW) |

|

Cooling See Also: "Temperature and Humidity Requirements", and "Ventilation and Cooling Requirements" |

Maximum: 27,200 BTU/hour (28,700 kJ/hour) Typical: 19,000 BTU/hour (20,100 kJ/hour) |

Maximum: 10,600 BTU/hour (11,200 kJ/hour) Typical: 7,500 BTU/hour (7,900 kJ/hour) |

|

Air flow front-to-back (subject to actual data center environment) See Also: "Temperature and Humidity Requirements", and "Ventilation and Cooling Requirements" |

Maximum: 1,260 CFM Typical: 880 CFM |

Maximum: 490 CFM Typical: 350 CFM |

|

Acoustic levels |

9.1 Bel |

8.5 Bel |

|

See Also: "Factory IP Address Settings" |

69 for Ethernet network (single cluster) 36 maximum for InfiniBand network |

22 for Ethernet network (single cluster) 8 maximum for InfiniBand network |

|

Network drops See Also: "Overview of Network Requirements" |

11 network drops minimum |

5 network drops minimum |

|

Fiber san drops (optional) See Also: "Overview of Network Requirements" |

4 x OM3 fiber cables |

4 x OM3 fiber cables |

|

External connectivity See Also: "Network Connection Requirements for Recovery Appliance" |

6 x 1 Gbps Ethernet ports 4 x 10 Gbps Ethernet ports 12 or more InfiniBand ports 4 x 16 Gb fiber channel SAN connections (optional) |

6 x 1 Gbps Ethernet ports 4 x 10 Gbps Ethernet ports 12 or more InfiniBand ports 4 x 16 Gb fiber channel SAN connections (optional) |

Footnote 3 Recovery Appliance rack with the minimum number (3) of storage servers

Footnote 4

Varies based on application load

2.2 Space Requirements

All Recovery Appliance hardware configurations use the same rack and have the same space requirements. The space requirements are as follows:

-

Height: 1998 mm (78.66 inches)

-

Width: 600 mm with side panels (23.62 inches)

-

Depth: 1200 mm (47.24 inches)

The minimum ceiling height for the cabinet is 2300 mm (90 inches), measured from the true floor or raised floor, whichever is higher. An additional 914 mm (36 inches) is required above the rack height in the front and rear aisle space for maintenance access. The space surrounding the cabinet must not restrict the movement of cool air between the air conditioner and the front of the systems within the cabinet, or the movement of hot air coming out of the rear of the cabinet.

2.2.1 Receiving and Unpacking Requirements

Before Recovery Appliance arrives, ensure that the receiving area is large enough for the package.

Table 2-4 lists the dimensions and weight of the shipment.

Table 2-4 Shipping Measurements

| Measurement | Full Rack | Minimum Configuration |

|---|---|---|

|

Height |

2159 mm (85 inches) |

2159 mm (85 inches) |

|

Width |

1219 mm (48 inches) |

1219 mm (48 inches) |

|

Depth |

1575 mm (62 inches) |

1575 mm (62 inches) |

|

X6 and X5 Weight |

875.7 kg (1930.5 lbs) |

381.2 kg (840.5 lbs) |

|

X4 Weight |

866 kg (1909 lb) |

469 kg (1034 lb) |

If your loading dock meets the height and ramp requirements for a standard freight carrier truck, then you can use a pallet jack to unload the rack. If the loading dock does not meet the requirements, then you must provide a standard forklift or other means to unload the rack. You can also request that the rack be shipped in a truck with a lift gate.

Leave Recovery Appliance in its shipping container until it arrives at the installation site. Ensure sufficient clearance and clear pathways for moving it from the unpacking location to the installation location. The entire access route to the installation site should be free of raised-pattern flooring that can cause vibration.

Use a conditioned space when removing the packaging material, to reduce particles before entering the data center. Allow enough space for unpacking Recovery Appliance from its shipping cartons. Table 2-5 lists the access route requirements.

Table 2-5 Access Route Requirements

| Access Route Item | With Shipping Pallet | Without Shipping Pallet |

|---|---|---|

|

Minimum door height |

218.4 cm (86 inches) |

204 cm (80.5 inches) |

|

Minimum door width |

127 cm (50 inches) |

64 cm (25.19 inches) |

|

Minimum elevator depth |

162.6 cm (64 inches) |

124 cm (49 inches) |

|

Maximum incline |

6 degrees |

6 degrees |

|

Minimum elevator, pallet jack, and floor loading capacity |

1134 kg (2500 lb) |

1134 kg (2500 lb) |

2.2.2 Maintenance Access Requirements

The maintenance area must be large enough for Recovery Appliance and have the required access space. For example, the required space to remove the side panels is 67.6 cm (26.6 inches). Table 2-6 lists the maintenance access requirements.

Table 2-6 Maintenance Access Requirements for Recovery Appliance

| Location | Maintenance Access Requirement |

|---|---|

|

Rear maintenance |

91.4 cm (36 inches) |

|

Front maintenance |

123 cm (48.5 inches) |

|

Top maintenance |

91.4 cm (36 inches) |

Note:

-

Open tiles are required for electrical access.

-

The Recovery Appliance racks can be placed side-by-side when interconnecting them.

2.3 Flooring Requirements

Oracle recommends that the Recovery Appliance racks be installed on raised flooring. The site floor and the raised flooring must be able to support the total weight of the rack.

Table 2-7 lists the floor load requirements.

Table 2-7 Floor Load Requirements for Recovery Appliance

| Description | Requirement |

|---|---|

|

Maximum allowable weight of installed rack equipment |

952.5 kg (2100 lb) |

|

Maximum allowable weight of installed power distribution units |

52 kg (115 lb) |

|

Maximum dynamic load (maximum allowable weight of installed equipment including PDUs) |

1005 kg (2215 lb) |

2.4 Electrical Power Requirements

Recovery Appliance can operate effectively over a wide range of voltages and frequencies. However, they must have a reliable power source. Damage may occur if the ranges are exceeded. Electrical disturbances such as the following might damage Recovery Appliance:

-

Fluctuations caused by brownouts

-

Wide and rapid variations in input voltage levels or in input power frequency

-

Electrical storms

-

Faults in the distribution system, such as defective wiring

To protect Recovery Appliance from such disturbances, you should have a dedicated power distribution system, power-conditioning equipment, and either lightning arresters or power cables to protect from electrical storms.

Each rack has two preinstalled power distribution units (PDUs). The PDUs accept different power sources. You must specify the type of PDU that is correct for your rack and data center.

2.4.1 PDUs for Recovery Appliance

The type of PDUs depends on the geographic location of the data center. The following tables lists the requirements for Recovery Appliance:

2.4.1.1 Single-Phase PDUs for North America, South America, Japan, and Taiwan

Table 2-8 lists the requirements for a low-voltage single-phase PDU for North America, South America, Japan, and Taiwan. There are two PDUs per rack.

Table 2-8 Low-Voltage 15 kVA Single-Phase PDUs

| Option | Requirement per PDU |

|---|---|

|

Voltage |

200 to 240 VAC |

|

Frequency |

50/60 Hz |

|

Current |

24A maximum per input |

|

Power rating |

15 kVA |

|

Output current |

72A (3 x 24A) |

|

Outlets |

42 x C13; 6 x C19 |

|

Outlet groups |

6 |

|

Group protectionFoot 5 |

20A |

|

Data center receptacle |

15 kVA, with three 30A/250V 2-pole/3-wire NEMA L6-30P plugs |

Footnote 5

UL489 2-pole circuit breaker

You need the following items to connect Recovery Appliance to a low-voltage single-phase power source:

-

6 power cords for two PDUs, 30A at 200 to 240 VAC

-

6 receptacles to connect the PDUs to 6 NEMA L6-30 data center receptacles

Figure 2-1 shows the low-voltage, single-phase PDU power connector for North America, South America, Japan and Taiwan.

Figure 2-1 Low-Voltage Single Phase Power Connector

Description of "Figure 2-1 Low-Voltage Single Phase Power Connector"

2.4.1.2 Three-Phase PDUs for North America, South America, Japan, and Taiwan

Table 2-9 lists the requirements for a low-voltage three-phase PDU for North America, South America, Japan, and Taiwan. There are two PDUs per rack.

Table 2-9 Low-Voltage 15 kVA Three-Phase PDUs

| Option | Requirement per PDU |

|---|---|

|

Voltage |

190 to 220 VAC |

|

Frequency |

50/60 Hz |

|

Current |

40A maximum per phase |

|

Power rating |

14.4 kVA |

|

Output current |

69.3A (3 x 23.1A) |

|

Outlets |

42 x C13; 6 x C19 |

|

Outlet groups |

6 |

|

Group protectionFoot 6 |

20A |

|

Data center receptacle |

15 kVA IEC 60309 60A 4-pin 250 VAC three-phase IP67 |

Footnote 6

UL489 2-pole circuit breaker

You need the following items to connect Recovery Appliance to a low-voltage three-phase power source:

-

2 power cords for two PDUs, 60A at 190 to 220 VAC three-phase voltage

-

2 receptacles to connect the PDUs to 2 IEC 60309 60A 4-pin 250VAC 3ph IP67 data center receptacles

Figure 2-2 shows the low-voltage three-phase PDU power connector for North America, South America, Japan and Taiwan.

Figure 2-2 Low-Voltage Three-Phase Power Connector

Description of "Figure 2-2 Low-Voltage Three-Phase Power Connector"

2.4.1.3 Single-Phase PDUs for Europe, the Middle East, Africa, and Asia Pacific

Table 2-10 lists the requirements for a high-voltage single-phase PDU for Europe, the Middle East, Africa, and Asia Pacific, except Japan and Taiwan. There are two PDUs per rack.

Table 2-10 High-Voltage 15 kVA Single Phase PDUs

| Option | Requirement per PDU |

|---|---|

|

Voltage |

220 to 240 VAC |

|

Frequency |

50/60 Hz |

|

Current |

25A maximum per input |

|

Power rating |

15 kVA |

|

Output current |

72A (3 x 24A) |

|

Outlets |

42 x C13; 6 x C19 |

|

Outlet groups |

6 |

|

Group protectionFoot 7 |

20A |

|

Data center receptacle |

15 kVA, with three blue 32A/240V splash-proof 2-pole/3-wire IEC 60309 plugs |

Footnote 7

UL489 1-pole circuit breaker

You need the following items to connect Recovery Appliance to a high-voltage single-phase power source:

-

6 power cords for two PDUs, 25A at 220/380 to 240/415 VAC 1-phase voltage

-

6 receptacles to connect the PDUs to 2 IEC 60309 32A 3-pin 250 VAC IP44 data center receptacles, and that require 22 kVA, 1-phase

Figure 2-3 shows the high-voltage single-phase PDU power connector for EMEA, and APAC, except for Japan and Taiwan.

Figure 2-3 High-Voltage Single Phase Power Connector

Description of "Figure 2-3 High-Voltage Single Phase Power Connector"

2.4.1.4 Three-Phase PDUs for Europe, the Middle East, Africa, and Asia Pacific

Table 2-11 lists the requirements for a high-voltage, three-phase PDU for Europe, the Middle East, Africa, and Asia Pacific, except Japan and Taiwan. There are two PDUs per rack.

Table 2-11 High-Voltage 15 kVA Three-Phase PDUs

| Option | Requirement per PDU |

|---|---|

|

Voltage |

220/380 to 240/415 VAC 3-phase |

|

Frequency |

50/60 Hz |

|

Current |

25A maximum per phase |

|

Power rating |

14.4 kVA |

|

Output current |

62.7A (3 x 20.9A) |

|

Outlets |

42 x C13; 6 x C19 |

|

Outlet groups |

6 |

|

Group protectionFoot 8 |

20A |

|

Data center receptacle |

15 kVA, three-phase, 5-pin, IEC 60309 32A, 5-pin 230/400V, three-phase IP44 |

Footnote 8

UL489 1-pole circuit breaker

You need the following items to connect Recovery Appliance to a high-voltage three-phase power source:

-

2 power cords for two PDUs, 25A at 220/380 to 240/415 VAC three-phase

-

2 receptacles to connect the PDUs to 2 IEC 60309 32A 5-pin 230/400 VAC 3-phase IP44 data center receptacles

Figure 2-4 shows the high-voltage three-phase PDU power connector for EMEA and APAC, except Japan and Taiwan.

Figure 2-4 High-Voltage Three-Phase Power Connector

Description of "Figure 2-4 High-Voltage Three-Phase Power Connector"

2.4.2 Facility Power Requirements

Electrical work and installations must obey applicable local, state, and national electrical codes. Contact your facilities manager or a qualified electrician to determine what type of power is supplied to the building.

To prevent catastrophic failures, design the input power sources to ensure adequate power is provided to the PDUs. Use dedicated AC breaker panels for all power circuits that supply power to the PDU. When planning for power distribution requirements, balance the power load between available AC supply branch circuits. In the United States and Canada, ensure that the overall system AC input current load does not exceed 80 percent of the branch circuit AC current rating.

PDU power cords are 4 meters (13.12 feet) long, and 1 to 1.5 meters (3.3 to 4.9 feet) of the cord is routed within the rack cabinet. The installation site AC power receptacle must be within 2 meters (6.6 feet) of the rack.

2.4.3 Circuit Breaker Requirements

To prevent catastrophic failures, the design of your power system must ensure that adequate power is provided to the servers. Use dedicated AC breaker panels for all power circuits that supply power to the server. Electrical work and installations must obey applicable local, state, and national electrical codes. Servers require that electrical circuits be grounded to the earth.

In addition to the circuit breakers, you must provide a stable power source, such as an uninterruptible power supply (UPS) to reduce the possibility of component failures. If computer equipment is subjected to repeated power interruptions and fluctuations, then it is susceptible to a higher rate of component failure.

Note:

The owner supplies the circuit breakers. Each power cord requires a circuit breaker.

2.4.4 Grounding Guidelines

The Recovery Appliance cabinets are shipped with grounding-type power cords. Always connect the cords to grounded power outlets. Because different grounding methods are used depending on location, check the grounding type and refer to documentation, such as IEC documents, for the correct grounding method. Ensure that the facility administrator or a qualified electrical engineer verifies the grounding method for the building and performs the grounding work.

2.5 Temperature and Humidity Requirements

Airflow through the Recovery Appliance rack is from front to back. Refer to Table 2-3 for information on cooling and airflow.

Note:

Studies show that temperature increases of 10 degrees Celsius (15 degrees Fahrenheit) above 20 degrees Celsius (70 degrees Fahrenheit) reduce long-term electronics reliability by 50 percent.

Excessive internal temperatures may result in a full or partial shut down of Recovery Appliance.

Table 2-12 lists the temperature, humidity, and altitude requirements for operating and nonoperating Recovery Appliances in the data center.

Table 2-12 Temperature, Humidity and Altitude Requirements

| Condition | Operating Requirement | Nonoperating Requirement | Optimum |

|---|---|---|---|

|

Temperature |

5 to 32 degrees Celsius (41 to 89.6 degrees Fahrenheit) |

-40 to 70 degrees Celsius (-40 to 158 degrees Fahrenheit) |

21 to 23 degrees Celsius (70 to 74 degrees Fahrenheit) |

|

Relative humidity |

10 to 90 percent relative humidity, noncondensing |

Up to 93 percent relative humidity |

45 to 50 percent, noncondensing |

|

Altitude |

3,048 meters (10,000 feet) maximum |

12000 meters (40,000 feet). |

Ambient temperature is reduced by 1 degree Celsius for each 300 meters above 900 meters altitude above sea level |

Set conditions to the optimal temperature and humidity ranges to minimize the chance of downtime because of component failure. Operating Recovery Appliance for extended periods at or near the operating range limits, or installing it in an environment where it remains at or near nonoperating range limits, can significantly increase hardware component failure.

The ambient temperature range of 21 to 23 degrees Celsius (70 to 74 degrees Fahrenheit) is optimal for server reliability and operator comfort. Most computer equipment can operate in a wide temperature range, but near 22 degrees Celsius (72 degrees Fahrenheit) is desirable, because it is easier to maintain safe humidity levels. Operating in this temperature range provides a safety buffer if the air conditioning system fails.

The ambient relative humidity range of 45 to 50 percent is suitable for safe data processing operations. Most computer equipment can operate in a wide range (20 to 80 percent), but the range of 45 to 50 percent is recommended for the following reasons:

-

Helps protect computer systems from corrosion problems associated with high humidity levels.

-

Provides the greatest operating time buffer if the air conditioner control fails

-

Helps prevent failures or temporary malfunctions caused by intermittent interference from static discharges, which may occur when the relative humidity is too low.

Note:

Electrostatic discharge (ESD) is easily generated, and hard to dissipate in areas of low relative humidity, such as below 35 percent. ESD becomes critical when humidity drops below 30 percent. Maintaining humidity in a data center is not difficult, because a high-efficiency vapor barrier and a low rate of air changes are normally present.

2.6 Ventilation and Cooling Requirements

Always provide adequate space in front and behind the rack to allow for proper ventilation. Do not obstruct the front or rear of the rack with equipment or objects that might prevent air from flowing through the rack. Rack-mountable servers and equipment typically draw cool air in through the front of the rack and let out warm air through the rear of the rack. There is no air flow requirement for the left and right sides because of front-to-back cooling.

If the rack is not completely filled with components, then cover the empty sections with filler panels. Gaps between components can adversely affect air flow and cooling within the rack.

Relative humidity is the percentage of the total water vapor that can exist in the air without condensing, and it is inversely proportional to the air temperature. Humidity goes down when the temperature rises, and it goes up when the temperature drops. For example, air with a relative humidity of 45 percent at a temperature of 24 degrees Celsius (75 degrees Fahrenheit) has a relative humidity of 65 percent at a temperature of 18 degrees Celsius (64 degrees Fahrenheit). As the temperature drops, the relative humidity rises to more than 65 percent, and water droplets form.

Air conditioning facilities usually do not precisely monitor or control temperature and humidity throughout an entire computer room. Generally, you should monitor individual points corresponding to multiple exhaust vents in the main unit and other units in the room, because the distribution of temperature and humidity is uneven across the room. Pay special attention to humidity when using underfloor ventilation.

The Recovery Appliance racks are designed to function while mounted in a natural convection air flow. Follow these requirements to meet the environmental specification:

-

Ensure that the rack has adequate air flow

-

Ensure that the rack has front-to-back cooling. The air inlet is at the front of the servers, and the air is let out the rear.

-

Allow a minimum clearance of 152.5 cm (60 inches) at the front of the rack and 91.4 cm (36 inches) at the rear for ventilation.

Use perforated tiles, rated for 400 cubic feet per minute (CFM) per tile air flow, in front of the rack for cold air intake. The tiles can be arranged in any order in front of the rack, if cold air from the tiles can flow into the rack. Inadequate cold air flow could result in a higher inlet temperature in the servers due to exhaust air recirculation. Oracle recommends four perforated floor tiles for a full Recovery Appliance rack, and one tile for a minimum configuration.

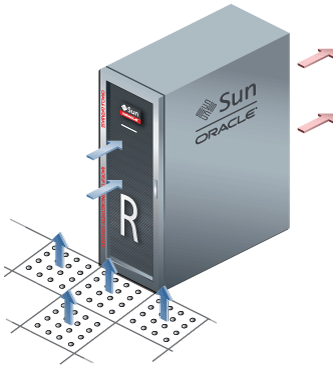

Figure 2-5 shows a typical installation of the floor tiles for a full rack.

Figure 2-5 Typical Data Center Configuration for Perforated Floor Tiles

Description of "Figure 2-5 Typical Data Center Configuration for Perforated Floor Tiles"

2.7 Network Connection Requirements for Recovery Appliance

Before installation, network cables must be run from your existing network infrastructure to the installation site. When you run Oracle Exadata Deployment Assistant, it calculates the number of network connections that you need, based on your rack configuration and other information you provide. Use this information when preparing your site for the installation.

2.8 Ensuring That the Site Is Ready

Before Recovery Appliance is delivered to the site, ensure that it is ready by completing these tasks:

2.8.1 Generate the Configuration Files

Run the Oracle Exadata Deployment Assistant and generate the configuration files.

See Also:

Using the Deployment Assistant for information about the configuration utility

2.8.2 Configure the Network

Configure the network using the information generated by Oracle Exadata Deployment Assistant. Configuration includes the following tasks:

-

Registering the networks in the Domain Name System (DNS)

-

Assigning IP addresses

-

Configuring data center switches and firewalls

2.8.3 Prepare the Site

Review the site requirements in this chapter and the Zero Data Loss Recovery Appliance Site Checklists when preparing the site for installation.

Before the Recovery Appliance rack arrives at your site: