3.2 Prepare to Install an Exalogic Machine

This section contains the following topics:

3.2.1 Before You Begin

Before installing the Exalogic machine, or installing any server or equipment into the rack, read the Important Safety Information for Sun Hardware Systems (816-7190) document included with the rack.

Observe all safety notices printed on the packaging and listed in the Sun Rack II Safety and Compliance Guide (820-4762) and the Sun Rack II Power Distribution Units Users Guide (820-4760). Go to http://download.oracle.com/docs/cd/E19657-01/index.html to download these guides.

Exalogic machine cabinets can enclose a variety of rack-mountable Sun servers, storage products, and other third-party equipment.

3.2.2 Exalogic Installation Safety Guidelines

Before the Exalogic machine arrives, the following safety precautions should be reviewed to ensure the site is safe, as well as ready for delivery. Failing to observe these precautions can result in injury, equipment damage, or malfunction.

-

Do not block ventilation openings.

-

Do not install the Exalogic machine in a location that is exposed to direct sunlight or near a device that may become hot.

-

Do not install the Exalogic machine in a location that is exposed to excessive dust, corrosive gases, or air with high salt concentrations.

-

Do not install the Exalogic machine in a location that is exposed to frequent vibrations. Install the Exalogic machine on a flat, level surface.

-

Use a power outlet that uses proper grounding. When using shared grounding, the grounding resistance must not be greater than 10 ohms. Ensure that your facility administrator or a qualified electrical engineer verifies the grounding method for the building, and performs the grounding work.

-

Be sure that each grounding wire used for the Exalogic machine is used exclusively for the Exalogic machine. Also be sure to observe the precautions, warnings, and notes about handling that appear on labels on the equipment.

-

Do not place cables under the equipment or stretch the cables too tightly.

-

Do not disconnect power cords from the equipment while its power is on.

-

If you cannot reach the connector lock when disconnecting LAN cables, then press the connector lock with a flathead screwdriver to disconnect the cable. You could damage the system board if you force your fingers into the gap rather than using a flathead screwdriver.

-

Do not place anything on top of the Exalogic machine or perform any work directly above it.

-

Do not let the room temperature rise sharply, especially in winter. Sudden temperature changes can cause condensation to form inside the Exalogic machine. Allow for a sufficient warm-up period prior to server operation.

-

Do not install the Exalogic machine near a photocopy machine, air conditioner, welding machine, or any other equipment that generates loud, electronic noises.

-

Avoid static electricity at the installation location. Static electricity transferred to the Exalogic machine can cause malfunctions. Static electricity is often generated on carpets.

-

Confirm that the supply voltage and frequency match the electrical ratings indicated on the Exalogic machine.

-

Do not insert anything into any Exalogic machine opening, unless doing so is part of a documented procedure. The Exalogic machine contains high-voltage parts. If a metal object or other electrically-conductive object enters an opening in the Exalogic machine, then it could cause a short circuit. This could result in personal injury, fire, electric shock, and equipment damage.

See Also:

-

Important Safety Information for Sun Hardware Systems (816-7190) document that is included with the rack

-

All safety notices printed on the packaging and listed in Sun Rack II Safety and Compliance Guide (820-4762), and Sun Rack II Power Distribution Units Users Guide (820-4760)

3.2.3 Unpack the Exalogic Machine Rack

Refer to the unpacking instructions included with the packaging when unpacking the rack from the shipping carton. After unpacking the rack, follow local laws and guidelines to recycle the packaging properly.

Caution:

Carefully unpack the rack from the packaging and shipping pallet. Rocking or tilting the rack can cause it to fall over and cause serious injury or death. You should always use professional movers when unpacking and installing this rack.

Note:

After unpacking the rack from the packaging, save the mounting brackets used to secure the rack to the shipping pallet. You can use these mounting brackets to secure the rack permanently to the installation site floor. Do not dispose of these brackets, as you will not be able to order replacement brackets.

Figure 3-1 Unpacking Exalogic Machine Rack

Description of "Figure 3-1 Unpacking Exalogic Machine Rack"

3.2.4 Tools for Installation

The following tools are required for installation:

-

Screwdriver handle (magnetic)

-

T-30 Torx wrench key

-

T-25 Torx wrench key

-

6-mm hexagon Allen wrench key

-

SW 12-mm single-headed wrench

-

Side panel removal tool

-

Keys to the front door, rear door, and side panel locks

-

Cage nut mounting tool

-

32 M6 cage nuts

-

32 M6 screws

-

Straight tip

3.2.5 Prepare the Installation Site

The following procedure describes how to prepare the site prior to unpacking and situating the Exalogic machine:

3.2.6 Place the Exalogic Machine in Its Allocated Space

This section contains the following topics:

3.2.6.1 Move the Exalogic Machine

The following procedure describes how to move an Exalogic machine:

WARNING:

-

Never attempt to move the Exalogic machine by pushing on the side panels. Pushing on the side panels can tip the rack over. This action can cause serious personal injury or death as well as damage to the equipment.

-

Never tip or rock the Exalogic machine because the rack can fall over.

3.2.6.2 Stabilize the Exalogic Machine

After moving the Exalogic machine to the installation site, stabilize the rack to ensure that it does not move or tip over. You can stabilize the rack permanently by extending the rack leveling feet, using mounting brackets, or both. After installation, use feet and the brackets to stabilize the Exalogic machine.

3.2.6.3 Stabilize the Exalogic Machine with Leveling Feet

The rack contains four leveling feet that can be lowered to stabilize the rack. The leveling feet can be used even when the rack is permanently secured to the floor. To adjust the leveling feet, do the following:

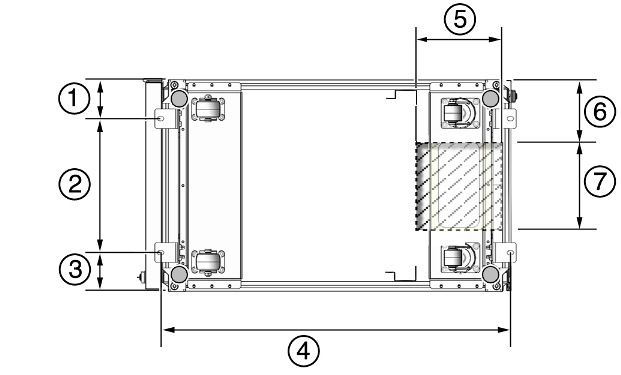

Figure 3-3 Securing Exalogic Machine Using the Leveling Feet

Description of "Figure 3-3 Securing Exalogic Machine Using the Leveling Feet"

3.2.6.4 Stabilize the Exalogic Machine with Mounting Brackets

The rack can be permanently mounted to the installation site floor using the same mounting brackets that secured the rack to the shipping pallet. The rack is secured to the pallet with four mounting brackets. Use the front and rear brackets to stabilize the rack to the installation floor. Prepare the installation site by drilling four holes into the floor. Before permanently stabilizing the Exalogic machine with the mounting brackets, pre-drill the mounting holes. Figure 3-4 shows the location and dimensions of the mounting brackets.

Figure 3-4 Location of Mounting Brackets on Rack

Description of "Figure 3-4 Location of Mounting Brackets on Rack"

3.2.6.5 Attach a Ground Cable (Optional)

The Exalogic machine power distribution units (PDUs) achieve earth ground through their power cords. Final chassis ground is achieved by way of the ground prong when you connect the power cord to a socket. For additional grounding, attach a chassis earth ground cable to the Exalogic machine. The additional ground point enables electrical current leakage to dissipate more efficiently.

WARNING:

The PDU power input lead cords and the ground cable must reference a common earth ground. If they do not, then a difference in ground potential can be introduced. If you are unsure of your facility's PDU receptacle grounding, then do not install a ground cable until you confirm that there is a proper PDU receptacle grounding. If a difference in ground potential is apparent, then you must take corrective action.

Note:

A grounding cable is not shipped with the system.