Transactions

This chapter covers the following topics:

- Overview of Inventory Transactions

- Receiving Transactions

- Using the Receiving Page

- Overview of Return to Vendor Transactions

- Transferring Between Subinventories

- Performing Miscellaneous Transactions

- Inter-organization Transfers

- Transferring Material Between Organizations

- Planning Transfer Transaction

- Transferring Consigned and VMI Material

- Shortage Alerts and Shortage Notifications

- Viewing Potential Shortages

- Overview of Movement Statistics

- Defining Movement Statistics Parameters

- Setting Up Movement Statistics

- Automatically Generating Movement Statistics

- Viewing and Maintaining Movement Statistics

- Viewing Material Transactions

- Viewing Message History

- Viewing Transaction Summaries

- Viewing Accounting Lines

- View Accounting Windows

- Drilling Down to Inventory from Oracle General Ledger

- Viewing Pending Transactions

- Pending Transactions Folder Window Available Fields

- Viewing and Updating Transaction Open Interface Activity

- Transaction Interface Folder Window Available Fields

- Purging Transaction History

- Transactions Reports

Overview of Inventory Transactions

Oracle Inventory, with Oracle Order Management, Oracle Purchasing, and Oracle Work in Process, provides you with a complete set of transactions and reports for maintaining inventory control. This allows you to control the flow of material from the time you receive items to the time you ship finished goods to the customer. You can:

-

Process miscellaneous issues and receipts. See: Performing Miscellaneous Transactions.

-

Transfer material between subinventories. See: Transferring Between Subinventories.

-

Move material from a shipping organization to a destination organization and move material to intransit inventory before it reaches its final destination. See: Transferring between Organizations.

-

Track lots and serial numbers for an item. See: Assigning Lot Numbers and Assigning Serial Numbers.

-

Generate shortage alerts and shortage notifications. See: Material Shortage Alerts and Shortage Notifications.

-

Enter and maintain movement statistics information. See: Entering Movement Statistics

-

View material transactions. See: Viewing Material Transactions.

-

View material transaction accounting distributions. See: Viewing Material Transaction Distributions, Oracle Cost Management User's Guide.

-

View summarized transactions for a range of dates. See: Viewing Transaction Summaries.

-

View pending transactions. See: Viewing Pending Transactions.

-

View pending transaction interface activity. See: Viewing and Updating Transaction Open Interface Activity.

-

Purge transaction history. See: Purging Transaction History.

-

View serial genealogy. See: Viewing Serial Genealogy.

Important: Inventory transactions and on hand balance supports decimal precision to 5 digits after the decimal point. Oracle Work in Process supports decimal precision to 6 digits. Other Oracle E-Business Suite applications support different decimal precision. As a result of the decimal precision mismatch, transactions another Oracle Application passes may be rounded when processed by Inventory. If the transaction quantity is rounded to zero, Inventory does not process the transaction. It is therefore suggested that the base unit of measure for an item is set up such that transaction quantities in the base unit of measure not require greater than 5 digits of decimal precision.

Related Topics

Receiving Transactions

You must perform the following setup steps before you can perform receiving transactions:

-

Define purchasing options for your organization, such as approval or control options, in the Purchasing Options window.

-

Define options that govern receipts in the Receiving Options window.

You can receive all or a partial list of open lines on any purchase order by using the Receipts window. You can also receive substitute items and goods or services you have not ordered. Oracle Inventory allows you to match goods you receive on the receiving dock to a purchase order they might be fulfilling. You can then record transfers and deliveries in the Receiving Transactions window, record inspections in the Inspections window, record Returns in the Returns window, and record adjustments and corrections in the Corrections window.

Using the Receiving Page

The Receiving page provides a tablet-optimized, centralized workspace where warehouse supervisors can manage inbound receipts against purchase orders, requisitions, advanced shipment notices (ASNs) and so on. Warehouse supervisors can identify exceptions and take quick receiving actions to:

-

Quickly receive materials while verifying quantities.

-

View the buyer/initiator to confirm who ordered the material.

-

Putaway and deliver receipts to appropriate subinventories/locators.

-

View all overdue expected receipts and manage receipt exceptions.

Using the simplified Receiving user interface you can receive packed material for specific distribution into separate LPNs for a multi-distribution PO. This enables you to track the transaction flow of items at the project level and the LPN level. This applies to the receipt routing options Standard and Inspection. You can put away these LPN receipts using the MSCA UI.

You can customize the WHERE conditions of the SQL query for the infotiles using the API RCV_CUSTOM_PUB. This procedure lets you increase or decrease the number of infotiles on the simplified Receiving UI up to 10. In addition, the procedure can modify the infotile name, color, and query the WHERE condition. For example, to customize the infotiles for the Deliver page, use RCV_CUSTOM_PUB.Get_Deliver_Infotile_Count.

In the Receiving page, click the task icon that corresponds to the action you desire:

| Task Icon | Description |

|---|---|

|

|

View and manage all the documents for current and expected receipt dates and for internal, external, and advance ship notices (ASNs). |

|

|

View and inspect receipts for WMS-enabled and non-WMS-enabled organizations. |

|

|

View and manage receipts for pending deliveries and for internal and external parties. |

|

|

View and manage receipts for defined time frames, and receipts for internal and external parties. |

|

|

View and manage all the receipts to perform returns. |

Prerequisites

- When you first navigate to the Receiving page, select an organization in the Context Settings page. The Organization field displays all the organizations available for your particular user/responsibility combination. Click Apply to save your selection.

To manage transactions on the Receive page

Use the Receive page to view and manage all the documents for current and expected receipt dates and for internal, external, and advance ship notices (ASNs).

-

Click the Receive icon to display the Receive page.

-

Click one of the following queries:

Query Name Description Expected Today Displays the documents that have an expected receipt date of the current day Overdue Displays the documents that have an expected receipt date in the past Internal Displays expected receipts for inter-org and internal requisition shipments External Displays the expected receipts for purchase orders (POs) and external requisitions ASNs Displays the expected receipts for advance ship notices (ASNs) -

The query displays the following information:

Field Name Description Document The document number Class The respective source for the document like PO, shipment, or RMA Type The type of document such as a standard PO, blanket PO, internal shipment, RMA Type, and so on Source Information about the party where the documented originated, such as the supplier, customer, or source organization Requester The name of the person who created the document Order Date The date when the document was created Progress The percentage of the document that has been processed. This is the average percentage of each PO line's receipt quantity over shipment quantity. -

Click Actions and then Directed to display the Directed Receipt page, on which you can enter details for each deliverable receipt line. You can enter details like Quantity, Supplier Lot, Destination, UOM, and so on. On the Directed Receipt page, you can confirm or cancel the individual lines.

-

Click Actions and then Quick to display the Quick Receipt page, where you can quickly receive purchase orders, shipments, and RMAs.

-

Click the + icon next to the Receipt Number field to generate a receipt number from an internal sequence. Alternatively, to add to an existing receipt, click the Find icon to search for an existing receipt then add to that receipt.

-

Optionally, enter Subinventory and Locator values at the header level to default these values to the rows in the table (if the subinventory or locator fields in the rows are blank). To change existing Subinventory or Locator values in a row, complete the following step.

-

In the Actions column, choose one of the following actions:

-

Click the Action icon to display the Receipt Details page. You can enter or update receipt details like the subinventory, locator, or destination. Then click Apply to save your changes.

-

Click the X icon to remove the selected line from the receipt.

-

-

After you have completed your entries, click Receive to complete the receipt into the specified subinventory and locator.

To manage transactions on the Inspect page

Use the Inspection Details section of the Transaction Details page to inspect items and review detailed information about your receiving transactions.

You can reinspect receipts where the entire quantity of a receipt has already been inspected. Search for such receipts on the Inspection Search page and then perform the inspection. In the Receiving Transactions window, if you search for receipts that have to be inspected, the UI displays receipts that have been inspected, can be reinspected and delivered. However, in the Receiving HTML UI, the inspected receipts are not displayed on the info tiles page. For example, if four receipts require inspection and all four have been inspected then, the inspect tiles number is displayed as 4 in the Receiving Transactions window and as 0 in the Receiving HTML UI.

-

Click the Inspect icon.

-

Click one of the following queries:

Name Description Pending Inspection Lists all receipts that require inspection Internal Lists internal receipts that require inspection External Lists external receipts that require inspection ASNs Lists Advance Shipment Notice (ASN) receipts that require inspection -

The Inspect page displays the following data about the documents:

Name Description Receipt The receipt number LPN The license plate number Class The source for the document, such as purchase order (PO), shipment, or RMA Type The type of document, such as standard PO, blanket PO, internal shipment, RMA Type, and so on Source The party where the document originated, such as supplier or customer Received By The name of the receiver Receipt Date The date when the document was received -

Click a Receipt link to display the Receiving Transactions: Receipt page. This page displays the receipt lines that can be inspected.

-

In the Actions column, click the icon to display the Transaction Details page where you can enter inspection details.

-

The Transaction Details page contains the Inspection Details section, which displays various details about the receipts, such as Status, Quantity, UOM, Inspection Date, and so on.

-

Select a status and enter values in the other fields to complete the inspection process.

-

Click OK to return to the Receiving Transactions: Receipt page where the Inspected column indicates whether the item has been inspected.

Prioritize Inspections of Receipts Using Machine Learning

You can use Machine Learning to prioritize inspection of receipts. Machine learning calculates an inspection failure probability for each inbound line using past inspection results and returns transaction history for items, receipt sources, and carriers. This process helps in understanding rejection probability of items in the receiving area.

For more information about machine learning, see Oracle Machine Learning for SQL User's Guide.

Steps to generate the Rejection Probability of Items in the Receiving Area:

-

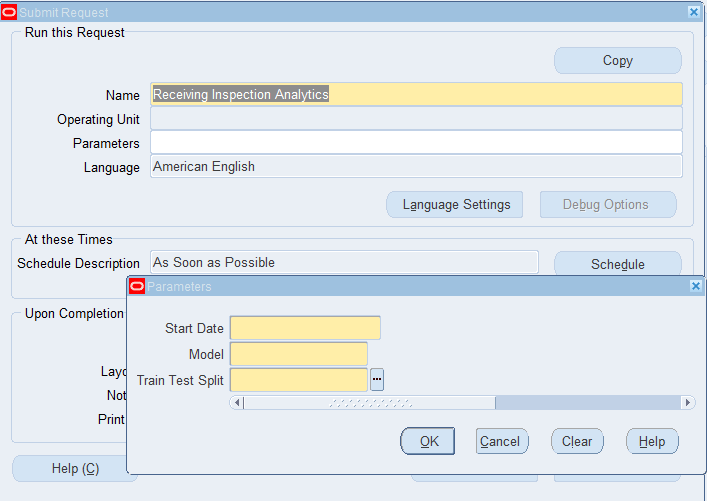

Run the concurrent program Receiving Inspection Analytics. This concurrent program:

-

Prepares the training data in the required format from the transaction history.

-

Builds and trains the machine learning model.

Ensure that this program completes successfully.

Receiving Inspection Analytics Concurrent Program

Parameters:

-

Start Date: The date from which the transactions will be used to train the Machine Learning Model.

-

Model: The regression algorithm that is used to build the model.

Model Window

-

Train Test Split: The data split percentage or ratio that will be used to train and to test the model.

Train Test Split Window

-

-

Run the concurrent program Receiving Inspection Recommendations. You can schedule this program to run periodically.

This concurrent program:

-

Identifies the items present in the Receiving area.

-

Generates rejection probabilities for such items using the trained model.

Ensure that this program completes successfully.

Receiving Inspection Recommendations Concurrent Program

Parameter:

Organization Code: The organization code for which the concurrent program must be run.

-

-

To view the predictions, navigate to the Inspect page and view the column Rejection Probability. The receipts are sorted in the order of decreasing rejection probability percentage.

Inspect Page - Rejection Probability Column

Click the links in the Receipt column to drill down to the rejection probability percentage of the items in that receipt.

Receipt Page - Rejection Probability Column

To manage transactions on the Deliver page

Use the Deliver page to view information about receipts pending delivery, and expected receipts for internal, external, and advance shipping notices (ASNs).

-

Click the Deliver icon to display the Deliver page.

-

Click one of the following queries:

Query Name Description Pending Deliver Displays expected deliveries Internal Displays expected receipts for inter-org and internal requisition shipments External Displays the expected receipts for purchase orders (POs) and external requisitions ASNs Displays the expected receipts for advance ship notices (ASNs) -

The query displays the following data about the documents:

Field Name Description Receipt The receipt document number Class The respective source for the document like purchase order (PO), shipment, or RMA Type The type of document such as a standard PO, blanket PO, internal shipment, RMA Type, and so on Source Information about the party where the documented originated, such as the supplier, customer, or source organization Received By The name of the person who received the document Order Date The date when the document was created Progress The percentage of the document that has been processed. This is the average percentage of each purchase order line's receipt quantity over shipment quantity. -

Click Actions and then Directed to display the Directed Deliver page, on which you can enter details for each deliverable receipt line. You can enter details like Quantity, Supplier Lot, Destination, Transaction Date, UOM, and so on. On the Directed Deliver page, you can go to the next item, skip, confirm, or cancel the individual lines.

-

Click Actions and then Quick to display the Quick Deliver page. This page uses pre-filled data to provide a quick way to receive purchase orders, shipments, and RMAs.

-

Optionally, enter Subinventory and Locator values at the header level to default these values to the applicable rows in the table (those rows with blank subinventory and locator values). To change existing subinventory/locator values for a row, complete the following step.

-

In the Actions column, choose one of the following actions:

-

Click the Action icon to enter or update receipt details like subinventory, locator, or destination.

Click Apply to save your changes.

-

Click the X icon to remove the selected line from the receipt.

-

-

Click Deliver to complete the deliver process.

To manage transactions on the Return page

Use the Return page to view receipt lines available for items and to view receipt lines available for items. The simplified Return user interface enables you to return material from an organization that is different from the receiving organization even though Oracle Shipping is not interfaced with Oracle Inventory.

-

Click the Return icon to display the Return page.

-

Click one of the following queries:

Name Description Rejected Lists all the documents that have failed inspection Returned to Receiving Lists receipts with return to receiving transactions and transaction type as Receive and Accept Today's Receipts Lists all the receipts for today's date -

The Return page displays the following data about the documents:

Field Name Description Receipt The receipt number Class The source for the document, such as purchase order (PO), shipment, or RMA Type The type of document, such as standard PO, blanket PO, RMA Type, and so on Source The party where the document originated, such as supplier or customer Received By The name of the first receiver Receipt Date The date when the document was received -

Click a receipt to display the Receiving Returns page. Receipt lines that can be returned are displayed on this page.

-

Enter values in the Quantity, UOM, and Return To fields. Add attachments, if required.

-

In the Actions column, do one of the following:

-

Click the Action icon to enter return details such as RMA Number, Supplier Lot, and so on. Then click Apply to save your changes.

-

Click the X icon to remove the selected line from the receipt.

-

Click the +L/S button to enter the Lot/Serial details. This button is enabled for lot or serial controlled items.

-

-

Click Return to complete the return process.

Set the profile option RCV: Track Shipments for Return To Vendors value to Yes to display the Missing Receipt button on the Return page. Click Missing Receipt to open the Receiving Returns: Missing Receipt Transactions page. On this page you enter details and return the items that do not have receipts.

To manage transactions on the Receipts page

Use the Receipts page to view receipt details such as receiver or receipt dates of the receiving transactions.

-

Click the Receipts icon to display the Receipts page.

-

Click one of the following queries:

Name Description Today's Receipts Lists all the receipts for today's date Weekly Late Lists all the receipts that were delayed last week Weekly Early Lists all the receipts that were early last week Weekly External Lists all the receipts that came from external parties (supplier and customer) last week Weekly Internal Lists all the receipts that came from internal parties (other warehouses) last week -

The query displays the following data about the documents:

Field Name Description Receipt The receipt document number Received By The first receiver if there are multiple receivers Receipt Date The date when the document was received Class Source for the documents such as purchase order (PO), shipment, or RMA Type The type of document such as standard PO, blanket PO, internal shipment, RMA Type, and so on Source The party where the document originated such as supplier, customer, or source organization Actions The action you can perform is receipt corrections. -

Click a receipt to display the Receiving Transactions page.

-

Click the arrow in the Transaction column to view the transactions for the receiving record, such as accept, reject, return to receiving, return to supplier, and deliver.

-

Click Done.

Overview of Return to Vendor Transactions

The return to vendor process enables you to create unique return orders and to ship the return order back to the vendor (supplier). After the return order is created and the material has been picked, you can create deliveries and check for export compliance, and then ship the return order with any required shipping documents.

Important: The return to vendor feature can be accessed from the Return window and from the simplified Return user interface.

You can return items that were received through a purchase order or an internal sales order shipment.

The return to vendor (RTV) process begins with a requirement to return an item to a vendor, and consists of the following steps to complete the return:

Additional Information: For items under lot, serial, or revision control you must specify the lots, serial, and revision as appropriate. If the material resides in a locator-controlled subinventory, you must also specify the locator. (If Oracle Quality module is installed, you can enter information about quality.)

-

The initial step involves requesting a returns material authorization (RMA) from the vendor, then creating a return order in the system.

-

A return order confirmation is sent to the vendor.

-

The return delivery is sent to the shipping department where the item(s) are picked and shipped back along with a delivery note.

Note: During ship-confirm, the inventory is decremented from the system which changes the available on-hand quantity.

-

A debit memo is sent to the vendor for the return.

The returns to vendor process also provides the ability to:

-

Return material to a vendor which differs from the receipt organization.

The return to vendor process enables you to return material from an organization which differs from the receipt organization.

-

Create returns without referencing a purchase order or receipt.

In some situations, you may need to return a specific component to a supplier but you do not have a backing document for the receipt of the item [such as a tracking purchase order (PO) number]. This situation may arise, for example, if the:

-

PO was cancelled.

-

The item received was a final assembly but you only need to return a component and not the entire assembly.

In the preceding situations, you can create a new return shipment without a reference document.

The following example describes a situation where a return may be required without referencing a purchase order or receipt:

-

SmartBuy (a fictitious company) purchases a server from a supplier and ships it to Customer B.

-

Customer B finds that the item is faulty, and returns it to SmartBuy.

-

SmartBuy investigates the issue and finds that only one component is faulty.

Note: In this scenario, there is no purchase order or receipt to return against. You do not have a purchase order because you are returning only a component and not the entire server; however, there would be a purchase order for the original server.

-

SmartBuy issues the material to send to the vendor using the RTV transaction type.

-

-

Track the status of the return orders, print shipping documents, enforce export compliance, and ship returns to vendors.

Oracle returns are integrated with shipping so you can query return orders in shipping, and create deliveries, check compliance, and ship materials.

-

Return Order Reservations: When the return order is created, the inventory is reserved so that it cannot be picked by any other demand.

-

Pending returns displayed in the Transaction Status window cannot be deleted.

Process Flow for Returns

You can perform a return by identifying the receipt shipment, creating the return order, selecting the document printing options (and export compliance documents, if required) then shipping the return order. In this example, returns are completed from the same organization as the receipt organization. The following steps outline the return to vendor process:

-

Identify the receipt shipment.

-

Create the return order shipment.

Note: This process is performed in Oracle Purchasing.

-

Print documents, export compliance, and shipping.

Note: This process is performed in Oracle Shipping Execution.

You can also perform a return from a different organization to the receipt organization using the simplified Return user interface.

Return of Items Received Through an Internal Sales Order Shipment

Use the Return on Internal Sales Order Shipment feature to return an internal shipment. You can return the internal shipment to the source organization or to a different organization that belongs to the same operating unit as the source organization.

The following section provides an overview of the process flow in the following applications: Oracle Inventory, Oracle Order Management, Oracle Purchasing, Oracle Shipping Execution, and Oracle Warehouse Management.

-

Ship material from one organization to another organization using an internal sales order (ISO). The destination organization receives this material through an ISO shipment.

-

To return items received through an ISO shipment, create a return order by searching for the internal requisition on the Returns page.

-

The return order creates delivery details in Oracle Shipping Execution.

-

The return order populates the Order Management interface tables to create an internal RMA. The Order Import concurrent program creates this internal RMA.

-

Oracle Shipping Execution logs shipping exceptions for the return order lines to prevent the lines from being shipped prematurely or in error.

-

If the internal RMA uses the Order Header approval workflow, then Oracle Order Management removes the shipping exceptions after the internal RMA is approved. If the internal RMA does not use the Order Header approval workflow, then the application removes the shipping exceptions when the internal RMA is created.

-

After you ship and interface the delivery details, Oracle Inventory creates a return ASN for the internal RMA.

-

The source organization receives the material using this return ASN shipment number.

-

You can perform corrections to the return ASNs.

-

You can return the material to a different destination organization in the same operating unit as the source organization.

Prerequisite

For the organization that receives the material through return ASN, set the value of the profile option RCV: Return Order Type for Internal RMA. Set the profile option at the source operating unit level for Oracle Order Management (OM) to use the profile value as the return order type of the internal RMA.

To return an internal shipment, complete the following steps:

-

Navigate to Inventory, Inbound, and then Receiving.

-

Select the organization from which you want to return the material.

-

On the Receiving Returns page of your receipt:

-

Select the quantity that you want to return.

-

In the Return To field, the organization value is automatically displayed. Select a value for the Organization, if required.

For items that are lot controlled, serial controlled, or plain, you can perform the following actions:

-

Return

-

Receive

-

Corrections for positive and negative values

-

-

Select the items that you want to return and click Return. The application generates and displays a return order number.

-

In Oracle Shipping Execution, navigate to the Shipping Transactions Form window. In the Search for region of Query Manager, select Lines. In the Source System field, select Returns. This creates the delivery details with an exception that you must resolve before you ship the delivery.

-

Run the concurrent program Order Import to create an internal RMA. Enter the following parameter values:

-

Order Source: Internal Return

-

Order Reference: Return order number

-

-

The organization that is receiving the RMA must approve it before the organization that is returning the RMA ships it. If the RMA is approved, the Oracle Order Management workflow removes the exception and the RMA is created.

-

Navigate to the Shipping Transactions window, Actions list, select Auto-create Deliveries, and click Go.

-

Click Ship Confirm and run the concurrent program Interface Trip Stop, which triggers the concurrent program Receiving Transaction Processor. This step in turn creates the return ASN that is the same as the delivery name.

-

To receive this shipment, navigate to the Receive infotile of Oracle Purchasing. The number in the Document column is the delivery name or the return ASN number.

-

In the Actions column, select the mode of receipt as Quick, Directed, or Item. If you select Directed, the Directed Receipt: Return ASN page appears.

-

Select the quantity that you want to receive.

-

Click Confirm.

-

Click Receive. The application generates and displays a receipt number.

-

On the Deliver infotile, enter the required details and click Deliver.

To receive the receipts:

-

Navigate to Inventory, Transactions, Receiving, and then Receipts.

The Find Expected Receipts window appears.

-

On the Customer tab, in the Return ASN field select a value from the list, and then click Find.

The Receipts window appears.

-

Enter Quantity. In the Receiving Transactions window, you can deliver the required quantity.

-

Run the concurrent program Receiving Transaction Processor.

From the Receiving Corrections window, you can perform corrections only to the lines that are received but not yet delivered.

The return flow generates two transactions:

-

A Return to organization transaction in the buying organization that is initiating the return and an Internal RMA receipt transaction in the organization that will receive back the returned goods.

-

Oracle Cost Management ensures that the accounting generated in the forward flow against the Intercompany accrual, Intercompany COGS, Profit in Inventory, and Inventory valuation accounts is reversed using the same rate at which the shipment and receipt in the forward flow were costed.

Note: The return flow for internal order shipments is not supported for intercompany transfers involving:

-

Process manufacturing organizations

-

Global procurement and drop shipment

-

Expense items

-

Expense subinventories

-

Expense destination

-

Periodic costing organizations

-

Project manufacturing organizations

-

Encumbrance accounting

Canceling an ISO Shipment

You can cancel an ISO shipment and shipment lines from the Manage Shipments window.

Prerequisites

-

The shipment must be in transit or partially received at the destination organization.

-

Use the Application Developer responsibility to set the parameter ALLOW_CANCEL to Y for the Manage Shipments window (Function Name is RCV_RCVSHESH ).

-

The shipment must not have any Receiving Transactions Interfaces (RTIs).

To cancel an ISO shipment, complete the following steps:

-

In the destination organization, navigate to the Manage Shipments window.

The Find In-Transit Shipments window appears.

-

In the Supplier and Internal tab’s Shipment field, enter the shipment number that you want to cancel.

-

Click Find.

-

Place your cursor in the shipment header or line.

-

From the Tools menu, select Cancel.

If you cancel a shipment at the header level, then all the individual lines are automatically canceled. You can cancel shipment lines with the status Expected or Partially Received. To cancel a shipment line that is partially received, deliver the received quantity before initiating cancellation.

In WMS-enabled organizations, if you cancel a shipment line, then the application unpacks the line quantity from the corresponding LPN.

-

Click OK.

A confirmation message appears with the cancel order reference number.

-

Click OK.

This action initiates the Order Import concurrent program to import the internal RMA. After the concurrent program completes successfully, search for the same shipment to view the internal RMA number at the line level. When you cancel a shipment line, a new internal RMA number is generated for the same.

-

From the Tools menu, select Generate Return ASN.

A confirmation message appears with the return ASN number.

If you generate a return ASN at the header level, then all the lines will display the same return ASN number. To generate separate return ASN numbers, repeat the step at the line level.

In WMS-enabled organizations:

-

At the header level, if you cancel a shipment and generate a return ASN, then the application updates the status of the corresponding LPNs from Intransit to In transit for Return ASN.

-

At the line level, if you generate a return ASN, then the application unpacks the line quantity from the corresponding LPN.

-

-

Click OK.

This action initiates the Receiving Transaction Processor concurrent program to import the return ASN. After the concurrent program completes successfully, search for the same shipment to view the return ASN number at the line level.

Important: Internal RMA and Return ASN are folder fields. With the cursor in the shipment lines region, you can show or hide them from the Folder menu.

-

Verify that the Status column displays Canceled or Partially Canceled.

To search for the internal RMAs that are created when an ISO shipment is canceled:

-

Navigate to the Order Organizer window.

The Find Orders/Quotes window appears.

-

In the Quote/Order Information tab, enter the following values:

-

Order Source: Internal In-Transit Return

-

Order Reference: Cancel order reference number

-

-

Click Find.

Canceling an Inter-Organization Transfer Shipment

You can cancel an inter-organization transfer (IOT) shipment and shipment lines from the Manage Shipments window.

Prerequisites

-

The shipment must be in transit or partially received at the destination organization.

-

Use the Application Developer responsibility to set the parameter ALLOW_CANCEL to Y for the Manage Shipments window (Function Name is RCV_RCVSHESH ).

-

The shipment must not have any Receiving Transactions Interfaces (RTIs).

To cancel an IOT shipment, complete the following steps:

-

In the destination organization, navigate to the Manage Shipments window. The Find In-Transit Shipments window appears.

-

In the Supplier and Internal tab’s Shipment field, enter the shipment number that you want to cancel.

-

Click Find.

-

Place your cursor in the shipment header or line.

-

From the Tools menu, select Cancel. If you cancel a shipment at the header level, then all the individual lines are automatically canceled.

In WMS-enabled organizations, if you cancel a shipment line, then the application unpacks the line quantity from the corresponding LPN.

-

Click OK.

A confirmation message appears.

-

Click OK.

-

From the Tools menu, select Generate Return ASN.

A confirmation message appears with the return ASN number.

In WMS-enabled organizations:

-

At the header level, if you cancel a shipment and generate a return ASN, then the application updates the status of the corresponding LPNs from Intransit to In transit for Return ASN.

-

At the line level, if you generate a return ASN, then the application unpacks the line quantity from the corresponding LPN.

-

-

Click OK.

Search for the same shipment to view the return ASN number at the line level.

Additional Information: Return ASN is a folder field. With the cursor in the shipment lines region, you can show or hide it from the Folder menu.

-

Verify that the Status column displays Canceled or Partially Canceled.

Cancel ISO or IOT Shipment That is Lost During Transit

If a shipment is lost during transit, then the source or the destination organizations cannot receive the material, however the order can be canceled. Because the lost shipment cannot be accounted for, a write off of the material is required.

To do this, you must set up a nonquantity tracked expense subinventory and then cancel the lost shipment.

To define the expense subinventory and locator, complete the following set up steps:

In the Subinventories window, Main tab do the following:

-

Deselect these two parameters: Quantity Tracked and Asset Subinventory

-

Set up the locator control as required.

-

Ensure that the subinventory Status is set to Active: Not Available for Netting, ATP and Reservations.

-

Verify that the following parameters Status Attributes are disabled: Include in ATP, Allow Reservation, and Nettable.

To set up the expense subinventory or locator for receiving the lost material, navigate to the Organization Parameters window, Inter-Org Information tab, and then Lost In-Transit Shipment Processing Controls region.

To cancel a lost shipment which is in transit, complete the following steps:

-

In the destination organization, navigate to the Manage Shipments window.

The Find In-Transit Shipments window appears.

-

In the Supplier and Internal tab’s Shipment field, enter the shipment number that you want to cancel.

-

Click Find.

-

Place your cursor in the shipment header or line.

-

From the Tools menu, select Cancel Lost Shipment.

This action automatically initiates the concurrent request Process Cancellation of Lost Shipment. This request marks the lost items as canceled and their receipt will be registered in the expense subinventory or locator.

Important: You cannot cancel a lost shipment line if the item is shipped as consigned.

Receiving and Delivering Material in Inventory MSCA

When receiving or delivering material, verify the source to distinguish the return ASN of the shipment type; for IOT shipments the return ASN source is Inventory and for ISO shipments the return ASN source is Customer.

To receive material in Inventory MSCA:

-

Navigate to the Materials & Mfg responsibility, Receiving, and then Receipts.

The Receipts page appears.

-

Select Return ASN.

-

Select the organization where you want to receive the material.

-

Enter or select values for the fields Return ASN and Item.

-

Enter or select values in the other required fields.

-

Click Next Item or Done to receive the material.

To deliver material in Inventory MSCA:

-

Navigate to the Materials & Mfg responsibility, Receiving, and then Deliver.

The Deliver page appears.

-

Select Return ASN.

-

Select the organization where you want to deliver the material.

-

Enter or select values for the fields Return ASN and Item.

-

Enter or select values in the other required fields.

-

Click Next Item or Done to deliver the material.

Canceling a Return Order

To cancel a return order

-

Navigate to the Transactions Status Summary window.

The Find Transaction Statuses window appears.

-

In the Supplier and Internal tab, enter the number in the Return Order field.

-

Click Find.

The Transaction Statuses window appears.

-

In the Transactions tab, select the lines that you want to return.

-

From the Tools menu, select Cancel Return Shipment Lines.

Reversing an ISO Shipment Cancellation

To reverse the ISO shipment cancellation, cancel the internal RMA using the Order Manager responsibility.

To reverse the ISO shipment cancellation:

-

Navigate to the Order Organizer window.

-

Search for the internal RMA to reverse the cancellation.

-

From the Tools menu, select Cancel. To reverse the ISO shipment or line level cancellation, cancel the internal RMA at the header or line level. Complete this task to receive the shipment line at the destination organization.

For more information, see Creating an RMA Against Internal Sales Order, Oracle Order Management Implementation Manual.

Reversing an IOT Shipment Cancellation

To reverse the IOT shipment cancellation, cancel the return ASN.

To reverse the IOT shipment cancellation:

-

Navigate to the Find In-Transit Shipments window in the source organization.

-

In the Supplier and Internal tab’s Shipment field, search for the return ASN for which you want to reverse the cancellation.

-

From the Tools menu, select Cancel. To reverse the IOT shipment or line level cancellation, cancel the return ASN at the header or line level. Complete this task to receive the shipment line at the destination organization.

-

Search for the same return ASN.

-

Verify that the Status column displays Canceled.

Related Topics

For information about the return to vendor process in Oracle Purchasing, see Oracle Purchasing User's Guide, Returns chapter.

For information about the return to vendor process in Oracle Shipping Execution, see Oracle Shipping Execution User's Guide, Miscellaneous Shipments.

Transferring Between Subinventories

You can transfer material within your current organization between subinventories, or between two locators within the same subinventory. You can transfer from asset to expense subinventories, as well as from tracked to non-tracked subinventories. If an item has a restricted list of subinventories, you can only transfer material from and to subinventories in that list. Oracle Inventory allows you to use user-defined transaction types when performing a subinventory transfer.

To enter a subinventory transfer

-

Navigate to the Subinventory Transfer window.

-

Enter the date and time of entry for the transaction.

The date you can enter is controlled by the INV: Transaction Date Validation profile option. See: Oracle Inventory Profile Options.

-

Enter a transaction type for the subinventory transfer. This can either be a predefined system type or one you defined. See: Defining Transaction Types.

-

Optionally, enter the source of the transaction type. See: Defining and Updating Transaction Source Types.

-

Optionally, indicate if inventory information should be defaulted from the serial number.

To enter the item to transfer

-

Choose Transaction Lines in the Subinventory Transfer window. The Transaction Lines Detail folder window appears.

-

Enter an inventory item to transfer. If you choose to default inventory information from the serial number, enter a serial number.

-

Optionally, enter the revision for the item. You must enter a value here if the item is under revision control.

-

Enter the subinventories from and to which to transfer material. Enter the same subinventory in the Sub and To Sub fields to transfer material between locators.

-

Optionally, enter the locators from and to which to transfer the item. You must enter a value here if you established locator control.

You can enter a new value in the To Locator field only if you defined locator control as dynamic entry.

-

Optionally, enter a lot number for the item. If you want to enter multiple lot numbers, complete the remaining steps, then choose the Lot/Serial button to display the Lot Entry window.

-

Enter a unit of measure. This can be the primary unit of measure (the default) or any valid alternate unit of measure.

If you enter an alternate unit of measure, Oracle Inventory issues the quantity you specify in this unit of measure. Oracle Inventory also converts the quantity to the primary unit of measure so that it can correctly update the on-hand quantity.

-

Enter the quantity of the inventory item to transfer, based on the unit of measure you specified. If the item is under dual unit of measure control, the secondary unit of measure and the secondary quantity populate automatically in the Secondary UOM and Secondary Quantity fields

-

Optionally, enter a reason code for the transaction. For example, you can use reason codes to allow you to mark exceptional charges to support a quality data collection and reporting system. See: Defining Transaction Reasons.

-

Optionally, enter up to 240 characters of free text that describes the transaction.

To enter lot or serial number information.

Click the Lot/Serial button. See: Assigning Lot Numbers and Assigning Serial Numbers.

To view quantity available and quantity on hand values

-

Review the following fields:

Available: Displays the quantity available to transfer, based on the unit of measure you specified. The available quantity is the quantity on hand less all reservations for the item. This amount could include the amount you have reserved if you enter a transaction source that has reservations against it. The available quantity includes reservations against current transaction source. The available quantity is specific to the revision level, lot number, From subinventory, and From locator you specify for the transfer.

Secondary Available: Displays the quantity available to transfer in the secondary unit of measure if the item is under dual unit of measure control.

On hand: Displays the current on-hand quantity for the item, based on the unit of measure you specified. The on-hand quantity is specific to the revision, lot number, From subinventory, and From locator you specify for the transfer. On-hand includes quantities for pending transactions in the MTL-MATERIAL-TRANSACTIONS table.

Secondary On hand: Displays the current on-hand quantity of the item in the secondary unit of measure if the item is under dual unit of measure control.

To process the transaction

-

Save your work.

Related Topics

Customizing the Presentation of Data, Oracle E-Business Suite User's Guide

Performing Miscellaneous Transactions

With a miscellaneous transaction you can issue material to or receive material from general ledger accounts in your current organization. This allows you to issue material to groups that are not inventory, receiving, or work in process such as a research and development group or an accounting department. You can also make manual adjustments to the general ledger by receiving material from one account to inventory, and then issuing that material from inventory to another account.

You can use your user-defined transaction types and sources to further classify and name your transactions. You can use this feature to issue items to individuals, departments, or projects; or to issue damaged items to expense accounts such as scrap. You can perform the receipts for items that were acquired by means other than a purchase order from a supplier. You can also use this feature to load all item on-hand quantities when you start implementing Oracle Inventory.

You will receive a material shortage alert while performing a miscellaneous transaction if you have enabled shortage alerts for the miscellaneous transaction type being performed. Also, a miscellaneous transaction can trigger a shortage notification to be sent to various pre-defined individuals. See: Material Shortage Alerts and Shortage Notifications.

To enter a miscellaneous transaction

-

Navigate to the Miscellaneous Transaction window.

-

Enter the date and time of entry for the transaction.

The date you can enter is controlled by the INV: Transaction Date Validation profile option. See: Oracle Inventory Profile Options.

-

Enter a miscellaneous transaction type for the transfer. This can either be a predefined system type or one you defined. See: Defining Transaction Types.

-

Optionally, enter the source of the transaction type. See: Defining and Updating Transaction Source Types.

-

Optionally, enter the general ledger account against which the material is issued or received.

-

Optionally, indicate if inventory information should be defaulted from the serial number.

To enter the item to transfer

-

Choose Transaction Lines in the Miscellaneous Transaction window. The Transaction Lines Detail folder window appears.

-

Enter an inventory item to issue or receive. If you choose to default inventory information from the serial number, enter a serial number.

-

Enter the revision for the item to issue or receive. You must enter a value in this field if the item is under revision control.

-

Enter a subinventory. For an issue transaction, you cannot enter a subinventory that does not have Quantity Tracking turned on.

-

Enter a locator. You must enter a value here if you established locator control for the item.

-

Optionally, enter a lot number for the item. If you want to enter multiple lot numbers, complete the remaining steps, then choose the Lot/Serial button to display the Lot Entry window.

-

Optionally enter a transfer location for the item.

Note: If you enabled the Location Required parameter for this transaction type on the Transaction Types window, this field is mandatory.

-

Enter a unit of measure. This can be the primary unit of measure (the default) or any valid alternate unit of measure.

If you enter an alternate unit of measure, Oracle Inventory issues the quantity you specify in this unit of measure. Oracle Inventory also converts the quantity to the primary unit of measure so that it can correctly update the on-hand quantity.

-

Enter the quantity of the inventory item to issue or receive, based on the unit of measure you specified. If the item is under dual unit of measure control, the secondary unit of measure and the secondary quantity populate automatically in the Secondary UOM and Secondary Quantity fields.

-

If using average costing, enter the unit cost of the item to receive or issue. Leave this field blank to use the system average cost at the time of the transaction.

-

Optionally, enter a reason code for the transaction. For example, you can use reason codes to allow you to mark exceptional charges to support quality data collection.

-

Optionally, enter up to 240 characters of free text that describe the transaction.

-

Enter a general ledger account for the item to use in the transaction. You can change this account only for miscellaneous issue/receipt or user-defined transaction types.

-

Optionally, enter the owning party if the owner controls the item.

-

Optionally, enter the planning party if a vendor has planning authority for the item.

Note: You can view fields that do not appear on the default miscellaneous transaction window. You can also hide unused fields. See Customizing the Presentation of Data, Oracle E-Business Suite User's Guide.

To enter lot or serial number information

Choose the Lot/Serial button. See: Assigning Lot Numbers and Assigning Serial Numbers.

To view quantity available and quantity on hand values

-

Review the following fields:

Available: Displays the quantity available to transfer, based on the unit of measure you specified. The available quantity is the quantity on hand less all reservations for the item. This amount could include the amount you have reserved if you enter a transaction source that has reservations against it. The available quantity includes reservations against current transaction source. The available quantity is specific to the revision level, lot number, From subinventory, and From locator you specify for the transfer.

Secondary Available: Displays the quantity available to transfer in the secondary unit of measure if the item is under dual unit of measure control.

On hand: Displays the current on-hand quantity for the item, based on the unit of measure you specified. The on-hand quantity is specific to the revision, lot number, From subinventory, and From locator you specify for the transfer. On-hand includes quantities for pending transactions in the MTL-MATERIAL-TRANSACTIONS table.

Secondary On hand: Displays the current on-hand quantity of the item in the secondary unit of measure if the item is under dual unit of measure control.

-

Save your work to process the transaction.

Related Topics

Customizing the Presentation of Data, Oracle E-Business Suite User's Guide

Inter-organization Transfers

You can define multiple inventories, warehouses, and manufacturing facilities as distinct organizations. With Oracle Inventory you can perform inter-organization transfers as direct or intransit shipments.

You can transfer one or more items in a single transaction. You can also transfer partial quantities of the same item to different subinventories and locators in a single transaction. The items you transfer must exist in both organizations. You can also transfer expense and asset items from one organization to another using intransit inventory.

Direct Inter-organization Transfers

You can use a direct inter-organization transfer to move inventory directly from a shipping organization to a destination organization.

The validity of a transfer transaction depends on the controls you have defined in both the shipping and destination organizations for the items you want to transfer. For example, you can transfer item A from organization X to organization Y, even though item A is under lot control only in organization X (you can specify the lot numbers for item A in organization X during the transfer transaction). However, you cannot transfer item B from organization X to organization Y if item B is under lot control only in organization Y (you cannot specify lot numbers for item B in the destination organization because you are performing a direct transfer).

The following tables present direct, inter-organization transfers.

Dual Unit of Measure Control

| Shipped Item | Destination Item | Allowed |

|---|---|---|

| None | None | OK |

| None | Fixed | OK |

| None | Default | OK |

| None | No Default | OK*** |

| Fixed | None | OK |

| Fixed | Fixed | OK |

| Fixed | Default | OK |

| Fixed | No Default | OK*** |

| Default | None | OK |

| Default | Fixed | OK |

| Default | Default | OK |

| Default | No Default | OK*** |

| No Default | None | OK |

| No Default | Fixed | OK |

| No Default | Default | OK |

| No Default | No Default | OK*** |

*** Apply default UOM conversion from destination organization.

Revision Control

| REVISION CONTROL | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK | OK |

| On (Destination Organization) | - | OK |

Lot Control

| LOT CONTROL | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK | OK |

| On (Destination Organization) | - | OK |

Grade Control

| Grade Control | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK** | OK |

| On (Destination Organization) | OK | OK* |

* The Shipped lot grade does not override the destination lot grade

** Grade Defaults from item master

Process Manufacturing Lot Attributes

| OPM Lot Attributes | Not Used (Shipping Organization) | Used (Shipping Organization |

|---|---|---|

| Not Used (Destination Organization | OK | OK |

| Used (Destination Organization) | OK** | OK* |

* The Shipped lot grade does not override the destination lot grade

**Lot attributes default from the item master for new lots.

Serial Number Control

| SERIAL NUMBER CONTROL | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK | OK |

| On (Destination Organization) | - | OK |

Asset Expense Subinventory

| Destination Org Shipping Org | Expense sub and/or Expense item | Asset sub and Asset item |

|---|---|---|

| Expense sub and/or Expense item | OK | - |

| Asset sub and Asset item | OK | OK |

Unit of Measure Conversions

When you transfer items under dual UOM control between organization, the system honors the UOM conversion of the destination organization. Consequently, the system could potentially recalculate the secondary quantity for the item if the conversions differ between the shipping organization and the destination organization. The system always processes transaction quantities in the primary UOM.

You must apply UOM conversions in both the shipping and destination organization before the system can process the transaction.

Inter-Organization Transfers via Intransit Inventory

You usually transfer material to intransit inventory when transportation time is significant. When you perform the transfer transaction, you do not need to specify the delivery location. You only need to enter the subinventory you are shipping from, a shipment number, the freight information, and, depending on the inter-organization transfer charge that applies between the organizations, a percentage of the transaction value or a discrete amount that Oracle Inventory uses to compute transfer charges.

If the FOB point is set to Receipt in the Shipping Networks window, the destination organization owns the shipment when they receive it. If it is set to Shipment, the destination organization owns the shipment when the shipping organization ships it, and while it is intransit.

While your shipment is intransit, you can update shipping information such as the freight carrier or arrival date in the Maintain Shipments window. See: Managing Shipments, Oracle Purchasing User's Guide.

At the time of shipment, you must define your receiving parameters for the destination organization. You can receive and deliver your shipment in a single transaction or you can receive and store your shipment at the receiving dock. See: Receipts, Oracle Purchasing User's Guide.

The validity of a transfer transaction depends on the controls you have defined in both the shipping and destination organizations for the items you want to transfer. For example, you can transfer item A from organization X to organization Y, even though item A is under lot control only in organization X (you can specify the lot numbers for item A in organization X during the transfer transaction). You can also transfer item B from organization X to organization Y if item B is under lot control only in organization Y (you can specify lot numbers for item B in the destination organization when you perform the receiving transaction).

The following tables present inter-organization transfers via intransit inventory.

Dual Unit of Measure Control

| Shipped Item | Destination Item | Allowed Intransit |

|---|---|---|

| None | None | OK |

| None | Fixed | OK |

| None | Default | OK |

| None | No Default | OK |

| Fixed | None | OK |

| Fixed | Fixed | OK |

| Fixed | Default | OK |

| Fixed | No Default | OK |

| Default | None | OK |

| Default | Fixed | OK |

| Default | Default | OK |

| Default | No Default | OK |

| No Default | None | OK |

| No Default | Fixed | OK |

| No Default | Default | OK |

| No Default | No Default | OK |

Revision Control

| REVISION CONTROL | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK | OK |

| On (Destination Organization) | Receive any revision | Receive only the revision you ship |

Lot Control

| LOT CONTROL | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK | OK |

| On (Destination Organization) | OK | OK |

Grade Control

| Grade Control | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK** | OK |

| On (Destination Organization) | OK | OK* |

* The Shipped lot grade does not override the destination lot grade

** Grade Defaults from item master

Process Manufacturing Lot Attributes

| OPM Lot Attributes | Not Used (Shipping Organization) | Used (Shipping Organization |

|---|---|---|

| Not Used (Destination Organization | OK | OK |

| Used (Destination Organization) | OK** | OK* |

* The Shipped lot grade does not override the destination lot grade

**Lot attributes default from the item master for new lots.

Serial Number Control

| SERIAL NUMBER CONTROL | Off (Shipping Organization) | On (Shipping Organization) |

|---|---|---|

| Off (Destination Organization) | OK | OK |

| On (Destination Organization) | OK | OK |

Asset Expense Subinventory Item

| Item Type | Asset Subinventory | Expense Subinventory |

|---|---|---|

| Asset item | OK | - |

| Expense Item | OK | OK |

Unit of Measure Conversions

When you transfer items under dual UOM control between organization, the system honors the UOM conversion of the destination organization. Consequently, the system could potentially recalculate the secondary quantity for the item if the conversions differ between the shipping organization and the destination organization. The system always processes transaction quantities in the primary UOM.

You must UOM conversions in both the shipping and destination organization before the system can process the transaction.

Related Topics

Transferring Between Organizations

Transferring Material Between Organizations

You can transfer material from your current organization to another organization, or from your current organization to intransit inventory.

Material in intransit inventory belongs to the organization identified by the FOB point. See: Defining Inter-Organization Shipping Networks.

Prerequisites

- Define an inventory item that is common to both organizations. See: Defining Items and Assigning Items to Organizations.

- Define at least two organizations, one of which is valid to receive material from the other. See: Creating an Organization, Oracle HRMS Enterprise and Workforce Management Guide and Defining Organization Parameters.

- Set up inter-organization relationships and their corresponding accounts. See: Defining Inter-Organization Shipping Networks.

- For direct transfers, if the item to transfer is under serial number control, the item must have the same unit of measure in each organization. See: Defining Items.

To enter the information to perform a transfer between organizations

-

Navigate to the Inter-organization Transfer window.

-

Enter the date of entry for the transaction.

The date you can enter is controlled by the INV: Transaction Date Validation profile option. See: Oracle Inventory Profile Options.

-

Enter an organization to which to transfer the material. You must first define this organization as valid to receive material from your current organization. See: Defining Inter-Organization Shipping Networks.

In addition, if this organization uses intransit inventory, Oracle Inventory stores the material as intransit inventory when you transfer any material to this organization. You must then move the material from intransit inventory to this organization with an intransit inventory receipt.

-

Enter a transaction type. This can be either a predefined system type or one you defined. See: Defining and Updating Transaction Types.

Optionally, you can enter the source of the transaction type. See: Defining and Updating Transaction Source Types.

-

Indicate if inventory information should be defaulted from the serial number.

-

Enter any optional Shipment information.

Optionally, you can enter the following Shipment information:

-

A shipment number to uniquely identify an item or group of items to transfer. When the To Org uses intransit inventory, you must enter a value here.

The freight carrier for the transfer.

A waybill or airbill number for the transfer.

The number of containers in which the material is stored for the transfer.

The date you expect to receive the material at the destination organization. You must enter a date equal to or later than the current date. Oracle Inventory uses this date for reporting purposes only.

To enter the items to transfer

-

Choose Transaction Lines from the Inter-organization Transfer window.

-

Enter an inventory item to transfer.

You can transfer the same item more than once. For example, you can specify an item more than once to transfer partial quantities to different subinventories or stock locators.

-

For a direct transfer, if the item is under revision control in either organization, enter a revision that is common to the item in both organizations.

-

Enter a subinventory from which to transfer the material.

-

Optionally, enter the subinventory to which to transfer the material. You must enter a value in this field for direct inter-organization transfers.

-

If you established locator control for the item, enter from and to locators.

-

Enter a lot number for the item. If you want to enter multiple lot numbers, complete the remaining steps, then choose the Lot/Serial button to display the Lot Entry window.

For receipt transactions, if you enter a lot number, enter the date the lot expires. You can enter a value here only if the Lot Expiration (Shelf Life) Control attribute is set to User-defined Expiration Date.

-

Enter a unit of measure. This can be the primary unit of measure (the default) or any valid alternate unit of measure.

If you enter an alternate unit of measure, Oracle Inventory issues the quantity you specify in this unit of measure. Oracle Inventory also converts the quantity to the primary unit of measure so that it can correctly update the on-hand quantity.

-

Enter the quantity of the item to transfer. If the item is under dual unit of measure control, the secondary unit of measure and the secondary quantity populate automatically in the Secondary UOM and Secondary Quantity fields.

-

Optionally enter a reason code for the transaction. For example, you can use reason codes to allow you to mark exceptional charges to support a quality data collection and reporting system.

You can also enter up to 240 characters of free text in the Reference field that describe the transaction.

To enter internal transfer charges to assign to the To organization

-

Enter a value in the Added Value field that represents the transfer charge. You can enter a value here only if you entered Requested value in the Inter-Organization Transfer Charge field in the Organization Parameters window.

-

Enter the percent of the transaction value that represents the transfer charge. You can enter a value here only if you entered Requested percent in the Inter-Organization Transfer Charge field in the Organization Parameters window. Defining Inter-Organization Information.

To enter freight information costs to assign to the From (current) organization:

-

Enter the transportation cost to physically transfer the material; that is, the freight carrier charges.

-

Enter the general ledger account to which to charge the value you entered in the Transportation Cost field. Oracle Inventory displays the account you defined for the freight carrier as the default. See: Defining Freight Carriers, Oracle Order Management Implementation Guide.

To enter a unit number

If Oracle Project Manufacturing is installed and if you have enabled its end item model/unit effectivity feature, you can enter a unit number for the item. See: Model/Unit Effectivity, Oracle Project Manufacturing Implementation Manual.

Note: The Unit Number field is visible only if you have installed Project Manufacturing.

To enter lot or serial number information.

Click the Lot/Serial button. See: Assigning Lot Numbers and Assigning Serial Numbers.

To view quantity available and quantity on hand values:

Review the following fields:

| Field | Description |

|---|---|

| Available | Displays the quantity available to transfer, based on the unit of measure you specified. The available quantity is the quantity on hand less all reservations for the item. This amount could include the amount you have reserved if you enter a transaction source that has reservations against it. The available quantity includes reservations against current transaction source. The available quantity is specific to the revision level, lot number, From subinventory, and From locator you specify for the transfer. |

| Secondary Available | Displays the quantity available to transfer in the secondary unit of measure if the item is under dual unit of measure control. |

| On hand | Displays the current on-hand quantity for the item, based on the unit of measure you specified. The on-hand quantity is specific to the revision, lot number, From subinventory, and From locator you specify for the transfer. On-hand includes quantities for pending transactions in the MTL-MATERIAL-TRANSACTIONS table. |

| Secondary On hand | Displays the current on-hand quantity of the item in the secondary unit of measure if the item is under dual unit of measure control. |

To process the transaction

Save your work.

To record movement statistics:

Use either of the following methods to record and maintain information associated with the movement of goods:

-

Navigate to the Movement Statistics window and record information manually. See: Entering Movement Statistics.

-

Automate the collection of this information by setting up parameters in the Movement Statistics Parameters and Economic Zones windows. See: Defining Movement Statistics Parameters and Defining Economic Zones.

Planning Transfer Transaction

Vendor Managed Inventory is a procurement and planning practice in which you delegate key inventory management functions to one or more suppliers. Under this arrangement, the supplier determines the items, quantities, and delivery schedules on your behalf based on information the supplier receives from your inventory and procurement systems.

Planning transfers enables you to assume the planning responsibility from the supplier. This transaction does not move goods, it changes the planning organization from the supplier site to the internal organization that holds the goods. After you perform a planning transfer and run collection, your supplier can no longer see the transferred quantity in the on hand quantity column.

To enter a planning transfer transaction

-

Navigate to the Planning Transfer window.

-

Enter the date and time of entry for the transaction.

The date you can enter is controlled by the INV: Transaction Date Validation profile option. See: Oracle Inventory Profile Options.

-

Select Transaction Lines.

-

Enter an inventory item to issue or receive. If you choose to default inventory information from the serial number, enter a serial number.

-

Enter the revision for the item to issue or receive. You must enter a value in this field if the item is under revision control.

-

Enter the Subinventory. This is the subinventory where the vendor managed inventory resides.

-

Enter the Supplier. This is the supplier from which you receive the consigned inventory.

-

Enter the Supplier Site. This is the location from which you receive the consigned inventory.

-

Enter a unit of measure. This can be the primary unit of measure (the default) or any valid alternate unit of measure.

If you enter an alternate unit of measure, Oracle Inventory issues the quantity you specify in this unit of measure. Oracle Inventory also converts the quantity to the primary unit of measure so that it can correctly update the on-hand quantity.

-

Enter the quantity of the inventory item to issue or receive, based on the unit of measure you specified. If the item is under dual unit of measure control, the secondary unit of measure and the secondary quantity populate automatically in the Secondary UOM and Secondary Quantity fields.

-

Optionally, enter a reason code for the transaction. For example, you can use reason codes to allow you to mark exceptional charges to support quality data collection.

-

Optionally, enter up to 240 characters of free text that describe the transaction.

To enter lot or serial number information.

-

Choose the Lot/Serial button. See: Assigning Lot Numbers and Assigning Serial Numbers.

To view quantity available and quantity on hand values

-

Review the following fields:

Available: Displays the quantity available to transfer, based on the unit of measure you specified. The available quantity is the quantity on hand less all reservations for the item. This amount could include the amount you have reserved if you enter a transaction source that has reservations against it. The available quantity includes reservations against current transaction source. The available quantity is specific to the revision level, lot number, From subinventory, and From locator you specify for the transfer.

Secondary Available: Displays the quantity available to transfer in the secondary unit of measure if the item is under dual unit of measure control

On hand: Displays the current on-hand quantity for the item, based on the unit of measure you specified. The on-hand quantity is specific to the revision, lot number, From subinventory, and From locator you specify for the transfer. On-hand includes quantities for pending transactions in the MTL-MATERIAL-TRANSACTIONS table.

Secondary On hand: Displays the current on-hand quantity of the item in the secondary unit of measure if the item is under dual unit of measure control.

To process the transaction

-

Save your work.

See: How do I set up Collaborative Planning with Oracle Advanced Supply Chain Planning or another Oracle ERP system? Oracle Collaborative Planning Online Help.

Transferring Consigned and VMI Material

Use the Consigned Transaction window to transfer ownership of consigned inventory. You can transfer ownership of consigned material to or from a supplier. Material can also be returned to the consigned status after the material is consumed and the consumption advice and/or invoice is generated.

Additional Information: Serial and lot transaction information (if applicable) is also tracked during Transfer to Regular and Transfer to Consigned transactions. If you transfer the ownership of the material back to supplier from inventory using the Transfer to Consigned procedure, then the lot and serial controlled information is also transferred.

To create a transfer transaction:

-

Navigate to the Consigned Transactions window.

-

Choose a transaction type that defines the type of material transfer:

-

Transfer to Regular: Transfers ownership of the material from the supplier.

-

Transfer to Consigned: Transfers ownership of the material to the supplier.

-

-

Optionally, enter the transaction Source.

-

Select the Serial-Triggered check box if the part number is serialized.

-

Click Transaction Lines to open the detail window.

-

Select an item from the list of values.

-

Enter the revision number if necessary.

-

Select the Subinventory where the inventory resides from the list of values.

-

Enter locator information if necessary.

-

Enter the Lot and Serial information if necessary.

-

Select the Owning Party form the list of values.

-

Select the Consumption Transaction ID of the material for which the consumption advice was generated.

Note: If the material is consumed and the consumption advice is created, the Consumption Transaction field displays the eligible records that fall within the dates defined in the form function parameter

CONS_INV_RTN_DAYS. For example, if the parameter value is 30, then the system displays only those records from the last 30 days. However, if the consumption advice is not created, all the records for that material appear regardless of the form function parameter setting. -

Change the default UOM if necessary.

-

Enter the Item Quantity. If the item is under dual unit of measure control, the secondary unit of measure and the secondary quantity populate automatically in the Secondary UOM and Secondary Quantity fields.

-

Optionally, select the appropriate transaction reason.