Understanding Consigned Purchases in Inventory

Management

Understanding Consigned Purchases in Inventory

ManagementThis chapter provides an overview of consigned purchases in inventory management and discusses how to:

Set up the system for consigned purchases in inventory management.

Perform consignment transactions.

Report consigned inventory usage.

Understanding Consigned Purchases in Inventory

Management

Understanding Consigned Purchases in Inventory

ManagementPeopleSoft Inventory has two consigned goods features:

Consigned Purchases Inventory: To store vendor-owned stock in your organization's warehouse, distribution center, manufacturing facility, or other location.

Vendor Managed Inventory: To store your inventory stock in a customer's warehouse, distribution center, manufacturing facility, or other location.

This chapter discusses the consigned purchases inventory feature.

See Using Vendor Managed Inventory.

Consignment inventory is a supply chain management strategy in which you store goods in the business unit without paying the vendor until after the goods are consumed. Because the vendor owns consigned stock until you consume it, stocking your warehouse with items on consignment enables you to reduce the inventory carrying costs and defer payment for liabilities. You can implement this strategy across the enterprise, integrating functions in PeopleSoft Purchasing, Inventory, Manufacturing, Cost Management, and Payables.

When you define items, you designate them as owned, non-owned, or consigned. The following table illustrates the various ownership options.

|

Ownership Status |

Explanation |

|

Owned |

The business unit owns the item. The system costs all transactions for the item. |

|

Non-owned |

The business unit does not own the item, but neither is it consigned. The system does not cost transactions involving the item. |

|

Consigned |

The item is both non-owned and purchased on consignment. The system costs the item when you consume it and creates a voucher for payment. Note. Like other non-owned stock, consigned items are not counted as part of the total stock owned by the business unit. Provided that status and nettable rules are met, however, consigned items are included in the business unit's total quantity available and quantity on hand, and you can reserve and pick them to fulfill customer orders. |

After you define an item as owned, non-owned, or consigned, you can change that designation only under the following conditions:

From owned to non-owned or consigned.

The business unit does not contain any owned or on-hand quantity for the item, and the item does not exist in the putaway staging tables.

From non-owned or consigned to owned.

The quantity on hand equals the quantity owned for the business unit (all currently stocked material is owned), and the item does not exist in the putaway staging tables.

Note. You can always change the designation for an item that has not yet been approved.

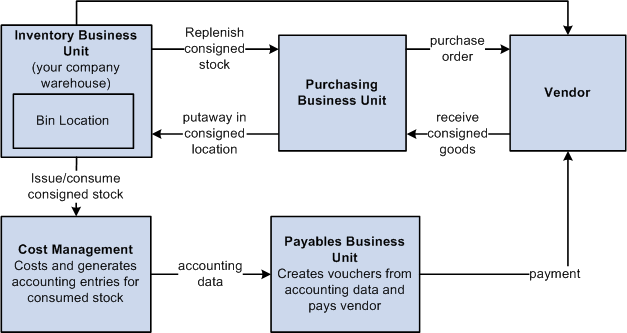

This diagram illustrates the business process flow of managing consigned inventory. A purchase order is dispatched to the vendor and then the vendor-owned items are received and putaway within your company warehouse. When the items are shipped (issued) from your inventory business unit, PeopleSoft Cost Management generates accounting entries for the consumed stock and PeopleSoft Payables creates vouchers to pay the vendor:

Managing consigned inventory process flow where vendor-owned stock is located in your company location

Setting up and implementing consigned purchases in PeopleSoft involves integrating the functions of several different PeopleSoft applications. After establishing consignment vendors in PeopleSoft Payables, you use PeopleSoft Inventory to designate items as consigned, determine which vendor supplies each item, and define rules governing the transferal of consigned items from non-owned to owned status while they are stocked in the business unit.

You create purchase orders (POs) for consigned goods using the Purchase Order component in PeopleSoft Purchasing. When the items arrive from the vendors, you receive them and put them away into PeopleSoft Inventory using the Receiving pages in PeopleSoft Purchasing.

The consumption of consigned items, which occurs when you perform various transactions in PeopleSoft Inventory or Manufacturing, transfers ownership of the items from the vendors to your business. You then run the Transaction Costing and Accounting Line Creation processes in PeopleSoft Cost Management.

Once items have been costed and accounting lines created, you can generate the Consigned Inventory report. This report tracks the consumption of the consigned items, including total quantity received and total quantity consumed, and furnishes the requisite information for creating vouchers manually.

The costing and accounting processes make consignment information available to PeopleSoft Payables for the creation of vouchers. Depending upon how you set up the system, the Voucher Build process (AP_VCHRBLD) either creates vouchers automatically or stages the information for later voucher creation.

The last step in managing the consigned inventory is replenishing stock. You can use the business unit to manage the replenishment process using the same ad hoc and reorder point methods used for owned stock. You can also have the vendor replenish the stock through the Inventory Balance Notification integration point transaction, which enables the vendor to monitor stock quantity levels and replenish items.

See Also

Performing Consignment Transactions

Processing Enterprise Integration Points (EIPs)

Setting up the System for Consigned Purchases

in Inventory Management

Setting up the System for Consigned Purchases

in Inventory Management

Setting up the system for consignment is a multistep process that you perform in both PeopleSoft Payables and Inventory.

To set up consignment inventory:

Establish consignment vendors and locations in PeopleSoft Payables.

Use the Vendor Information - Location - Procurement Options page to indicate which vendors supply the business with consigned items. For each consignment vendor, determine whether to create vouchers automatically, stage them as pending transactions, or create them manually when consigned items are consumed.

Establish default consignment parameters for items in the setID.

On the Define Item - General: Common page, designate the item as consigned (and, by definition, non-owned). The selection that you make here is for default purposes only; you can override it for individual business units on the Define Business Unit Item - General: Common page.

Establish consignment parameters for items in the business unit.

On the Inventory Definition - Business Unit Definition page, select an accounts payable (AP) business unit for use when the AP information is not available on a PeopleSoft Purchasing receipt. PeopleSoft uses this business unit to retrieve the correct setID for the vendor location when you designate an item as consigned on the Define Business Unit Item - General page.

On the Define Business Unit Item - General page, designate the item as consigned in the business unit and assign a vendor and vendor location to supply the item. Only one vendor-location combination can supply the item for this business unit; once you have made the vendor assignment, you cannot change it if stock exists in a non-owned storage location or if the item has been staged for putaway.

Establish material movement rules for consigned items in the business unit.

On the Inventory Definition - Business Unit Definition page, indicate whether the business unit allows the transfer of consigned items from non-owned to owned storage locations. This option enables you to give the item an owned status while it is still stocked in your warehouse.

Note. Transferring a consigned item to an owned storage location qualifies as a consumption transaction. At this point, the item becomes an owned item.

Establish storage locations for consigned items.

Define the storage locations in which you plan to stock consigned items as non-owned locations. Default putaway locations set up for non-owned items are eligible for storing consigned stock.

Pages Used to Set Up Consigned Purchases in Inventory

Pages Used to Set Up Consigned Purchases in Inventory|

Page Name |

Definition Name |

Navigation |

Usage |

|

Vendor Information - Procurement Options page |

VNDR_PROC_OPT_SEC |

Vendors, Vendor Information, Add/Update, Vendor, Location Click the Procurement link on the Vendor Information - Location page. |

Use to indicate which vendors supply the business with consigned items |

|

Define Item - General: Common page |

INV_ITEMS_DEFIN1 |

Items, Review Item Information, Items, General Items, Define Items and Attributes, Define Item, General |

Designate items as consigned. |

|

Inventory Definition - Business Unit Definition |

BUS_UNIT_INV1 |

Set Up Financials/Supply Chain, Business Unit Related, Inventory, Inventory Definition, Business Unit Definition |

Select an accounts payable (AP) business unit for use when the payables information is not available on a PeopleSoft Purchasing receipt. PeopleSoft uses this business unit to retrieve the correct SetID for the vendor location when you designate an item as consigned on the Define Business Unit Item - General page Indicate whether the business unit allows the transfer of consigned items from non-owned to owned storage locations. This option enables you to give the item an owned status while it is still stocked in your warehouse. |

|

Material Storage Locations |

STOR_LOCATIONS_INV |

Inventory, Maintain Storage Locations, Material Storage Locations |

Define non-owned storage locations for consigned items. |

Performing Consignment Transactions

Performing Consignment TransactionsAfter you set up the PeopleSoft system for consignment inventory management, you can perform business transactions involving the consigned stock.

This section discusses how to:

Purchase consigned stock.

Receive consigned stock.

Put away consigned stock.

Consume consigned stock.

Cost consigned stock transactions.

Generate vouchers for consigned stock.

Replenish consigned stock.

Pages Used to Perform Consignment Transactions

Pages Used to Perform Consignment Transactions|

Page Name |

Definition Name |

Navigation |

Usage |

|

Purchase Order - Form |

PO_LINE |

Purchasing, Purchase Orders, Add/Update POs, Maintain Purchase Order - Purchase Order |

Purchase consigned stock from vendors. |

|

Receiving |

RECV_WPO |

Purchasing, Receipts, Add/Update Receipts, Maintain Receipts - Receiving |

Receive consigned items. See Receiving Shipments |

|

Process Receipts |

RUN_PO_RECEIPT |

Purchasing, Receipts, Process Receipts |

Run this process to load consigned items received into PeopleSoft Purchasing into PeopleSoft Inventory's putaway processes. |

|

Load Staged Items |

STAGED_REQ_INV |

Inventory, Putaway Stock, Load Staged Items |

Load receipts into the PeopleSoft Inventory to be putaway. |

Purchasing Consigned Stock

Purchasing Consigned Stock

You purchase consigned stock from vendors using the Purchase Order - Form page. When creating a PO for a requisition, the Create Purchase Orders process uses the consignment options that you defined on the Define Business Unit Item - General: Common page to determine whether to mark the item as consigned.

See Defining PeopleSoft Inventory Business Unit Attributes.

The purchase order's consignment indicator on the Distribution Details page determines whether you can purchase the item as a consigned item. Use the following rules for setting and changing this option:

If the item is consigned in the business unit and the vendor location on the PO is the assigned consignment vendor, the item is by default purchased as consigned.

You can override this option and purchase the item as an owned item. You cannot purchase the item as non-owned.

If the item is consigned in the business unit, but the vendor location on the PO is not the assigned consignment vendor, you can purchase the item only as owned.

If the item is not consigned in the business unit, you cannot purchase it as a consigned item.

You can purchase the item as either owned or non-owned, depending on its designation at the business-unit level.

To help vendors ascertain which stock you are purchasing as owned and which you're purchasing as consigned, items marked as consigned on the PO are identified as such on the Purchase Orders Print report.

See Also

Creating Purchase Orders Online

Receiving Consigned Stock

Receiving Consigned Stock

When consigned stock arrives at your warehouse, you receive it using the Receiving pages in PeopleSoft Purchasing. You can receive items with or without associated POs on the Receiving page. If you do not implement a separate inspection process, enter putaway information on the Inventory Putaway Information page. If you do inspections separately, record putaway information on the Inspection & Putaway Information page.

Note. The Receiving component is the only place in which you can receive consigned stock. You cannot use Inventory's InterUnit and RMA Receiving, Express Putaway, or Manual Staging pages.

The consignment option that appears on the Inventory Putaway Information and Inspection Putaway Information pages indicates whether the item being received is consigned. If the receipt is associated with a PO, the default value comes from the distribution line and is for informational purposes only. If the receipt is not associated with a PO, you can use the Receipt Distributions page to override the setting before sending the transaction to PeopleSoft Inventory. The rules governing how this option is set and whether you can override it are the same as those described for the PO.

If you have defined storage locations on Purchasing Receiving pages, the locations offered as putaway options on the Inventory Putaway Information page, the Inspection Putaway Information page, and the Storage Location Search page vary depending on the item's ownership status:

If the item is owned, only owned storage locations appear.

If the item is consigned and the receipt is from the consigned vendor of the item, only non-owned storage locations appear.

If the item is consigned and the receipts if from a vendor and vendor location that is not the consigned vendor of the item, only owned storage locations appear.

If the item is non-owned and not consigned, both types of storage locations appear.

To complete the receiving procedure, transfer receipt information into the Inventory staging interface table (STAGED_INF_INV) by running the Receiver Interface Push process.

Note. Be sure to deselect the Hold Inventory check box on the Header Details page of the receipt ID before running this process. Clearing this check box enables the system to pass inventory items contained in the PeopleSoft Purchasing receipt ID to PeopleSoft Inventory for putaway processing.

See Also

Using the Receiver Interface Push Application Engine Process (PO_RECVPUSH)

Putting Away Consigned Stock

Putting Away Consigned Stock

The setting of the consignment option on the PO (or on the receipt, if there is no PO) determines whether the Receiver Interface Push process inserts an item into the Inventory staging table as an owned, non-owned, or consigned item. If the item is consigned on the PO, it is staged for putaway as a consigned item. If the item is not consigned on the PO, it is staged for putaway as an owned item, unless it is designated as non-owned in the business unit where it is staged as a non-owned item.

After consigned items are staged for putaway, run the PeopleSoft Inventory putaway processes, including the Load Staged Items process (INPSSTGE), the Putaway Plan report, and the Complete Putaway process (INPPPTWY), to update the item and storage location quantities.

See the documentation for tables accessed and tables updated by PeopleSoft Inventory processes and reports on My Oracle Support.

Note. The Complete Putaway process does not calculate the perpetual average cost of consigned items. The only time the system calculates the cost is when the item is transferred from a non-owned to an owned storage location. However, Complete Putaway updates the average cost at the business unit-item level (BU_ITEMS_INV) for informational purposes, regardless of the item's cost method or ownership status.

For items to retain their consigned status, you must put them away into non-owned storage locations. Default putaway locations that have been set up for non-owned items can contain consigned stock.

You cannot put consigned items away using any of the PeopleSoft Inventory putaway pages; if you do, you must put the items into owned storage locations, in which case they are no longer designated as consigned. Consigned items that you put away using interunit transfers (including intercompany transfers) are considered consumed at the time of shipment and are classified as owned when received at the destination business unit. Returned materials (RMAs) are defined as owned or non-owned upon putaway, because their consumption was recorded during the original issue.

If you selected the Allow Transfers to Owned Loc (allow transfers to owned locations) option on the Inventory Definition - Business Unit Options page, you can move consigned items from non-owned to owned storage locations after putaway, where they are considered to be consumed and owned.

See Defining PeopleSoft Inventory Business Unit Attributes.

After items have been put away, the storage locations in which they reside determine whether they are still designated as consigned. Items in owned storage locations are always considered owned, no matter how they are defined at the business unit level. Items in non-owned locations are considered consigned if they are consigned in the business unit; otherwise, they are considered non-owned.

See Also

Using the Receiver Interface Push Application Engine Process (PO_RECVPUSH)

Understanding Receiving and Putaway Processing

Page Used to Generate the Putaway Plan Report

Costing Transactions and Creating Accounting Entries

Associating an Item with Putaway and Picking Zones

Consuming Consigned Stock

Consuming Consigned Stock

Consuming consigned items transfers ownership from the vendor to the business unit. When you conduct any of the consumption transactions in PeopleSoft Inventory or Manufacturing, the system recognizes the items as owned by the business unit and makes the consumption information available for costing and accounting.

Consumption transactions in PeopleSoft Inventory include:

Transfers of consigned stock from non-owned to owned storage locations.

You can make such transfers only if you selected the Allow Transfers to Owned Loc (allow transfers to owned locations) option on the Inventory Definition - Business Unit Options page.

Shipping or express issues.

You must run the Deplete On Hand Qty (Depletion) process (IN_FUL_DPL) after recording a shipment or express issue for the system to consider the stock consumed.

Decrease or scrap transactions performed during ad hoc quantity adjustments.

Stock quantity decreases performed for cycle counts or physical counts during the Stock Quantity Update process (INPOPOST).

Consumption transactions in PeopleSoft Manufacturing include:

Issues or returns of kit components.

Record completions and scrap transactions.

Work order issues (transaction group 230).

Working with Consigned Items in a Manufacturing Environment

In PeopleSoft Manufacturing, you can work with consigned items in a variety of ways. In addition to performing the previously defined consumption transactions, you can:

Maintain bills of material (BOMs) and routings for consigned items.

Include consigned items in production assemblies.

Issue consigned items to production and include them on production picking plans.

Include consigned items in the completions process.

See Also

Processing Kit Issues and Returns

Completing Operations and Recording Scrap

Issuing Material to Production

Costing Consigned Stock Transactions

Costing Consigned Stock Transactions

When you use consigned items, PeopleSoft makes the consumption information available to be costed and accounted for in PeopleSoft Cost Management. The Cost Accounting Creation process update the CM_DEPLETE and CM_ACTUAL_COST tables, providing the requisite data for creating the Consigned Inventory report and for building vouchers.

See Also

Setting Up PeopleSoft Payables Business Units

Reporting Consigned Inventory Usage

Generating Vouchers for Consigned Stock

Generating Vouchers for Consigned Stock

After you consume, cost, and generate accounting lines for consigned items, you create vouchers using the Voucher Build process (AP_VCHRBLD). The Consigned Voucher option that you select on the Procurement Options page determines whether vouchers are created automatically, staged as pending transactions, or created manually. If you specified manual creation, Voucher Build process does not create vouchers. In this case, you can send the Consigned Inventory Usage report to the vendor.

See Also

Understanding Voucher Build Processing

Replenishing Consigned Stock

Replenishing Consigned Stock

The business unit or the vendors can drive the replenishment of consigned stock. If you choose business unit-managed replenishment, use the same ad hoc and reorder-point replenishment methods that you use for owned stock.

If you choose vendor-managed replenishment, you need to communicate the business unit's current inventory levels to each vendor on a regular basis. You can send these periodic stock inquiries using the Inventory Balance Notification integration point. This transaction extracts stock quantities (including quantity available, quantity reserved, quantity on hand, and quantity owned) from the BU_ITEMS_INV record for specified items in the business unit and relays this information to the vendor. The vendor then determines appropriate replenishment quantities.

To receive automatically replenished stock without creating a new PO for each receipt, you can:

Use online receiving in PeopleSoft Purchasing without the POs option.

Set up a PO that has been dispatched for the entire quantity of the contract.

See Also

Processing Enterprise Integration Points (EIPs)

Providing Inventory Balances to Third-Party Systems

Reporting Consigned Inventory Usage

Reporting Consigned Inventory Usage

You can track the movement of the consigned stock by periodically generating the Consigned Inventory report, which lists items that were consumed within a given time period. You establish selection criteria for the report, including which items and vendors should be included and the time frame to be considered, on the Consigned Inventory report page.

Because the Consigned Inventory report extracts data from the Depletion table (CM_DEPLETE) in PeopleSoft Cost Management, items are eligible for inclusion only after their consumption transactions have been costed.

Page Used to Report Consigned Inventory

Usage

Page Used to Report Consigned Inventory

Usage

|

Page Name |

Definition Name |

Navigation |

Usage |

|

Consigned Inventory |

RUN_INS5350 |

Inventory, Manage Inventory, Reports, Consigned Inventory |

Generate a list of consigned stock that was consumed within a given time period. |