4 Installing the System into a Rack

This chapter includes the following sections:

-

Inserting Oracle Database Appliance X3-2/X4-2/X5-2 into a Rack

Inserting Oracle Database Appliance (Original Version) into a Rack

Task Overview

Follow the appropriate procedures to rack your system.

Note:

These procedures describe how to insert the system into a rack. For cabling instructions, refer to the Getting Started Guide and setup poster.| ODA (Original Version) | ODA X3-2/X4-2 | ODA X5-2 |

|---|---|---|

|

|

|

Optional Component Installation

Standard system components are installed at the factory. Optional components that you purchased independent of the standard configuration are shipped separately, and in most cases should be installed before you install the server in a rack.

The following optional components can be ordered separately:

-

DIMM memory kits

For the Oracle Database Appliance X5-2, you have the option of ordering memory expansion to 512 GB or 768 GB. Memory kits come in sets of 8 x 32 GB DIMMs, which means you need two kits (one for each server node) for 512 GB, and four kits (two for each server node) for 768 GB. Both server nodes must have the same amount of memory. Refer to the Service Manual for instructions on installing memory.

-

Storage drives

-

For the Oracle Database Appliance X5-2, you have the option of ordering two Sun Dual 10GbE SFP+ PCIe 2.0 Low Profile Adapters to replace the two standard InfiniBand adapters (one in each server node) to support an Ethernet fiber connection to the data center or public network (it cannot be used for the appliance private node-to-node connection).

To replace the standard InfiniBand adapter, refer to the Service Manual for instructions on replacing a PCIe card in Slot 1. After the card is replaced, refer to the Getting Started Guide for instructions on cabling and software configuration.

Safety Precautions When Rackmounting

This section describes safety precautions you must follow when installing the server into a rack.

Caution:

Personal injury or equipment damage. Prevent the rack from tipping over. 1) Deploy the anti-tilt bar or legs on the equipment rack before beginning an installation. 2) Always load equipment into a rack from the bottom up so that the rack will not become top-heavy and tip over. 3) Mount equipment in the rack such that it does not create uneven or dangerous mechanical loading. 4) Do not use slide-rail mounted equipment as a shelf or workspace.Caution:

Equipment damage caused by elevated temperature. 1) If you install the equipment in a closed or multi-unit rack assembly, ensure that the operating ambient temperature inside the rack does not exceed the maximum ambient temperature specified for the server. For server environmental requirements, see Environmental Specifications. 2) Install the equipment in the rack such that airflow is not restricted or impeded.Caution:

Supply circuit damage and data loss. The AC circuits used to supply power to the system must be rated for the maximum amount of power that the system requires. See Electrical Specifications for input power requirements.Caution:

Equipment damage. Maintain reliable earthing. Pay particular attention to supply connections other than direct connections to the branch circuit (for example, use of power strips).ESD Precautions

Caution:

Equipment damage. To prevent damage from electrostatic discharge, use the following precautions when installing or servicing components.-

Place components on an antistatic surface, such as an antistatic discharge mat, an antistatic bag, or a disposable antistatic mat.

-

Wear an antistatic grounding strap connected to a metal surface on the chassis when you work on system components.

Rack Compatibility Requirements

The rack-mounting hardware can be used only in specialized racks that meet the requirements in the following table.

| Feature | ODA (Original Version) | ODA X3-2/X4-2 | ODA X5-2 |

|---|---|---|---|

|

Rack structure |

Four-post rack (mounting at both front and rear). Two-post racks are not compatible. |

4RU without optional storage expansion shelf. 6RU with optional storage expansion shelf. |

6RU without optional storage expansion shelf. 10RU with optional storage expansion shelf. |

|

Space available |

Must have 4 rack units (4RUs) of space available. |

Four-post rack (mounting at both front and rear). Two-post racks are not compatible. |

Four-post rack (mounting at both front and rear). Two-post racks are not compatible. |

|

Rack horizontal opening and unit vertical pitch |

Conforms to ANSI/EIA 310-D-1992 or IEC 60927 standards. |

Conforms to ANSI/EIA 310-D-1992 or IEC 60927 standards. |

Conforms to ANSI/EIA 310-D-1992 or IEC 60927 standards. |

|

Distance between front and rear mounting planes |

Minimum 660.4 mm and maximum 876.3 mm (26 in to 34.5 in). |

Minimum 610 mm and maximum 915 mm (24 in to 36 in). |

Minimum 610 mm and maximum 915 mm (24 in to 36 in). |

|

Clearance depth in front of front mounting plane |

Distance to front cabinet door is at least 25.4 mm (1 in). |

Distance to front cabinet door is at least 25.4 mm (1 in). |

Distance to front cabinet door is at least 25.4 mm (1 in). |

|

Clearance depth behind front mounting plane |

Distance to rear cabinet door is at least 700 mm (27.5 in). |

Distance to rear cabinet door is at least 900 mm (35.43 in) with the cable management arm, or 800 mm (31.5 in) without the cable management arm. |

Distance to rear cabinet door is at least 900 mm (35.43 in) with the cable management arm, or 800 mm (31.5 in) without the cable management arm. |

|

Clearance width between front and rear mounting planes |

Distance between structural supports and cable troughs is at least 456 mm (18 in). |

Distance between structural supports and cable troughs is at least 456 mm (18 in). |

Distance between structural supports and cable troughs is at least 456 mm (18 in). |

|

Minimum clearance for service access |

|

|

|

|

Server node dimensions |

Height: 175.1 mm (6.9 in). Width (without mounting ears): 437 mm (17.2 in). Width (with mounting ears): 482.6 mm (19 in). Depth: 762 mm (30 in). |

Height: 42.6 mm (1.7 in). Width: 436.5 mm (17.2 in). Depth: 737 mm (29 in). |

Height: 42.6 mm (1.7 in). Width: 436.5 mm (17.2 in). Depth: 737 mm (29 in). |

|

Storage shelf dimensions |

N/A |

Height: 87.9 mm (3.5 in) Width: 483 mm (19 in) Depth: 630 mm (24.8 in) |

Height: 175 mm (6.9 in) Width: 483 mm (19 in) Depth: 630 mm (24.8 in) |

Caution:

Personal injury or equipment damage. Always load equipment into a rack from the bottom up so that it will not become top-heavy and tip over. Deploy your rack’s anti-tilt bar to prevent the rack from tilting during equipment installation. This caution is not applicable if an earthquake kit has been installed on the rack and it is bolted to the floor.Inserting Oracle Database Appliance X3-2/X4-2/X5-2 into a Rack

This section describes how to install the server nodes and storage shelves of Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, or Oracle Database Appliance X5-2 into a rack. If you are installing Oracle Database Appliance (original version), see Inserting Oracle Database Appliance (Original Version) into a Rack.

This section includes the following subsections:

Caution:

Personal injury or equipment damage. Always install equipment in a rack from the bottom up. See Installation Sequence.Caution:

System Failure. Oracle Database Appliance is shipped with matched sets of components that must be installed together. Mixing components from different systems might cause the system to fail.Contents of the Shipping Pallet

Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, and Oracle Database Appliance X5-2 are shipped with the entire system on a single pallet. It includes all server nodes, storage shelves, mounting hardware, cables, and labels.

Caution:

System failure. All items in a shipment are designed to be used together as a single system. Do not mix components from different shipments; this could cause the system to fail. For details, see Verify Component Compatibility.The items in this shipment include:

Server node 0 and server node 1

Rackmounting hardware, cables, and labels for server nodes 0 and 1

One storage shelf

Rackmounting hardware for the storage shelf

If you ordered a storage expansion shelf, it is shipped separately.

Installation Sequence

Always install equipment in a rack starting at the bottom and working upwards. For Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, or Oracle Database Appliance X5-2, install the equipment in the following order:

-

Storage expansion shelf, if equipped.

-

Storage shelf.

-

Server node 0.

-

Server node 1.

Verify Component Compatibility

For Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, or Oracle Database Appliance X5-2, all appliance components that are bundled at the factory have a Top Level Identifier (TLI) number that is matched for the system. Both server nodes, the storage shelf, and the (optional) storage expansion shelf (if included in the initial appliance configuration from the factory), must have the same TLI.

Note:

If you add a storage expansion shelf to the system after the initial installation (that is, the storage expansion shelf was not part of the initial configuration order for the appliance), its TLI will be different from the rest of the system. In this scenario, an add-on component having a different TLI from the main appliance TLI is appropriate.- Locate the TLI for both server nodes, the storage shelf, and (if

present) the storage expansion shelf.

The TLI label is on top of the component, on the left-hand side, near the front.

- Check to ensure that all components have the same TLI numbers (a TLI part number and TLI serial number).

Tools and Equipment Needed

Obtain the following tools and equipment before beginning the installation of Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, or Oracle Database Appliance X5-2.

Phillips head No. 2 screwdriver that is a minimum of 4 inches long.

T20 Torx driver if using a threaded rack.

A mechanical lift is highly recommended.

Caution:

Personal injury or equipment damage. The storage shelf weighs approximately 51 lbs (23 kg). If no mechanical lift is available, use three people to place it in the rack.

Stabilize the Rack for Installation

Caution:

Personal injury or equipment damage. To reduce the risk of personal injury, stabilize the rack cabinet, and extend all anti-tilt devices before installing the server.See your rack documentation for detailed instructions for the following steps.

- Open and remove the front and rear doors from the rack

cabinet.

Note:

The front and rear doors need to be removed only if they interfere with the installation. - To prevent the rack cabinet from tipping during the installation, fully extend the rack cabinet's anti-tilt legs or anti-tilt bar, which are located at the bottom front of the rack cabinet.

- If there are leveling feet beneath the rack cabinet to prevent it from rolling, extend these leveling feet fully downward to the floor.

Applying Labels

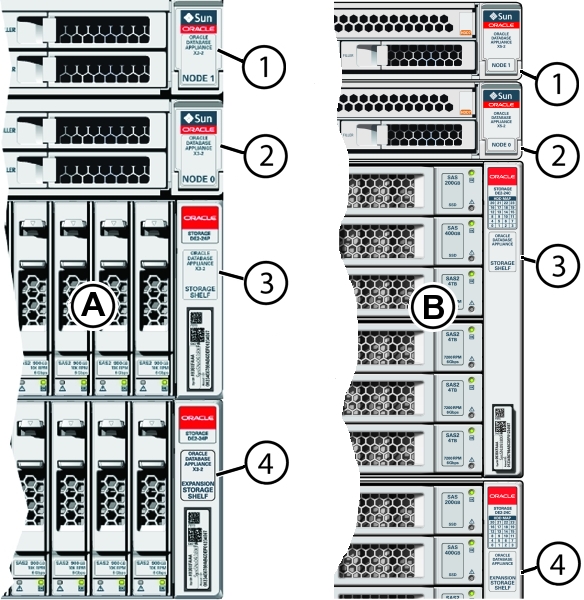

Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, and Oracle Database Appliance X5-2 are shipped with a label kit that provides four labels, to be applied to the front of each server node and storage shelf.

To Apply Labels to Server Nodes and Storage Shelves

- Find the labels.

Depending on your model, the shipping kit might include server node labels and a sheet with storage shelve labels.

-

Oracle Database Appliance X3-2 and Oracle Database Appliance X4-2 systems include both server node and storage shelf labels that you need to attach.

-

Oracle Database Appliance X5-2 systems only include server node labels to attach. The storage shelf labels are attached at the factory.

-

- Verify that the locations where the labels need to go are clean, and free of grease and dirt.

- Apply the labels where needed:

For labels that you attach, peel off the backing sheet and apply the label to the corresponding spot on the right-hand side of the appliance front panel.

-

Server Node 1: Apply this label to the top server node [1].

-

Server Node 0: Apply this label to the lower server node [2].

-

Storage shelf: Apply this label to the storage shelf directly beneath server node 0 [3].

-

Storage expansion shelf (optional): Apply this label to the bottom storage shelf, if one is present [4].

Callout Description A

ODA X3-2 and ODA X4-2

B

ODA X5-2

1

Server node 1

2

Server node 0

3

Storage shelf

4

Optional storage expansion shelf

-

Installing the Storage Shelves in the Rack

This section includes instructions for installing the storage shelf into a rack.

Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, and Oracle Database Appliance X5-2 require one storage shelf and might include a second storage shelf, called the storage expansion shelf. Both are installed in the same way, with the following caveats:

-

If you have a storage expansion shelf, install it first. Follow the procedure for your system:

-

If you are adding a storage expansion shelf to an existing system, see Add a Storage Expansion Shelf in an Existing System for additional details.

Install the ODA X5-2 DE2-24C Storage Shelf in a Rack

The Oracle Storage Drive Enclosure DE2-24C requires four standard mounting units (4RU) of vertical space in the cabinet. Starting at the bottom of the cabinet, locate the appropriate rack unit (RU) height. Install disk shelves below controllers to prevent the rack from tipping.

Before You Begin

This task provides instructions for both threaded and unthreaded racks.

-

Ensure that your site meets the requirements in Oracle Database Appliance Specifications

-

Ensure that the rack meets the requirements in Rack Compatibility Requirements

-

Observe all precautions in Safety Precautions When Rackmounting

- If using an unthreaded universal 19-inch or Sun Rack II cabinet, snap one supplied cage nut

into the 8th rack hole, counting upward, in each front rail of the 4RU space.

- Prepare the screws in each rail end:

-

Square-hole unthreaded cabinet: No preparation.

-

Round-hole unthreaded cabinet: Remove the screws from each rail end and discard. Locate the screws for round-hole cabinets and place aside.

-

Threaded cabinet: Remove screws and replace them in the opposite direction (from the inside of the rail flange) so they act as location pins. Also remove the clip nut from each front rail end and discard.

-

- Position the front of the rails inside the cabinet, with the rail flange inside of the cabinet

flange, and the rail label facing the inside of the cabinet.

-

Square-hole unthreaded cabinet: The screw heads fit inside the rack holes.

-

Round-hole unthreaded cabinet: Install two screws through the rack and into the front of each rail. Do not install into the cage nut in the rack, or the clip nut on the rail.

-

Threaded cabinet: The location pins fit inside the rack holes.

-

- Adjust the rail lengths to fit.

- Install one screw through the rack and into the rear of each rail.

- Tighten the two locking screws in the rails.

- Using a mechanical lift or two people, one at each side of the disk shelf, carefully lift and

rest the shelf on the bottom ledge of the left and right rails. Do not lift using the power supply

handles.

- Carefully slide the shelf into the cabinet. Ensure that the shelf is fully seated within the rails. If removing the shelf to reseat it, support it at all times.

- Remove the front side caps, install two screws into each front side, and replace the caps.

- Install one long patchlock screw per rail to secure the rear of the shelf to the rear of the

rack.

- Repeat these steps if you have an additional storage shelf to install.

Install the ODA X3-2/X4-2 DE2-24P Storage Shelf in a Rack

The Oracle Storage Drive Enclosure DE2-24P requires two standard mounting units (2RU) of vertical space in the cabinet.. The storage shelf rack-mount kit contains two rack rails, long and short M6 screws, and a 10mm wrench.

Before You Begin

This task provides instructions for both threaded and unthreaded racks.

Ensure that your site meets the requirements in Oracle Database Appliance Specifications

Ensure that the rack meets the requirements in Rack Compatibility Requirements

Observe all precautions in Safety Precautions When Rackmounting

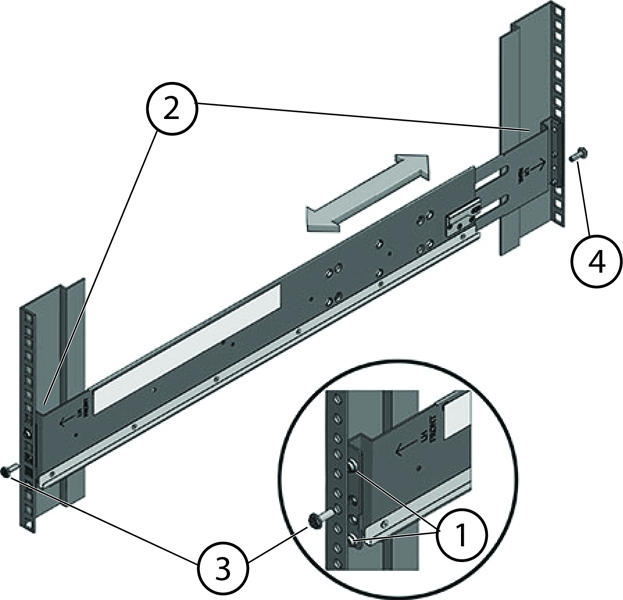

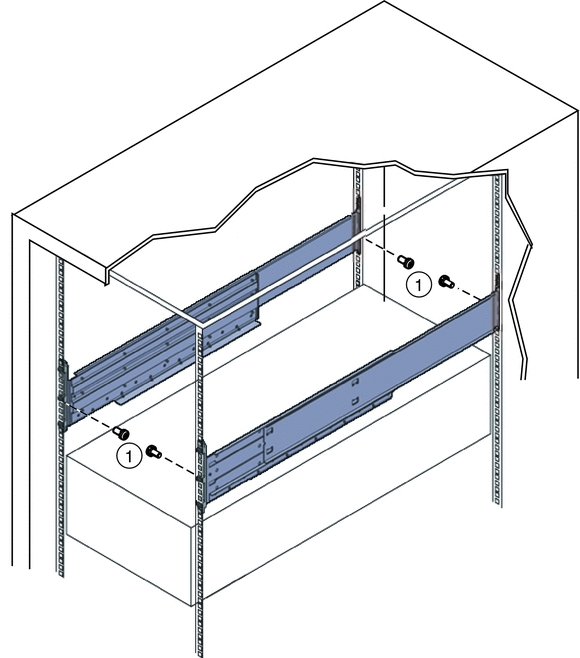

- Install the rails in the rack.

- If you have an unthreaded rack:

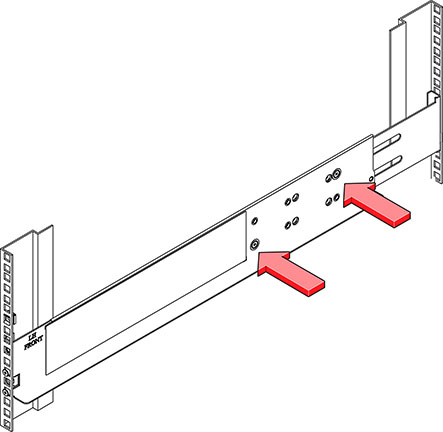

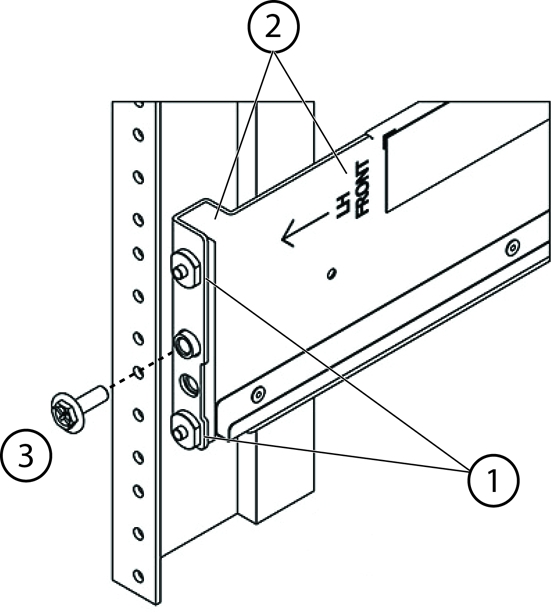

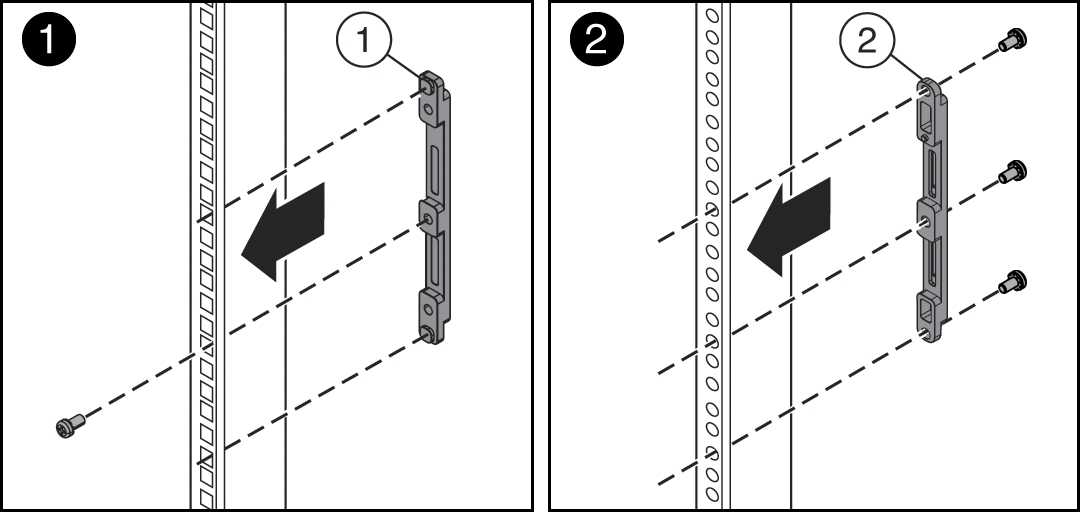

- Position the front rail location pegs [1] fully inside the appropriate

holes in the front of the rack.

The rail flange [2] must be inside of the cabinet flange, and the rail label facing the inside of the cabinet.

- Insert and loosely tighten one screw through the front of the rack and into the top hole in the rails [3].

- Insert and loosely tighten one screw through the back of the rack

and into the back of the rails [4].

Callout Description 1

Location pegs

2

Rail flange and label

3

Front mounting screw

4

Rear mounting screw

- Position the front rail location pegs [1] fully inside the appropriate

holes in the front of the rack.

- If you have a threaded rack:

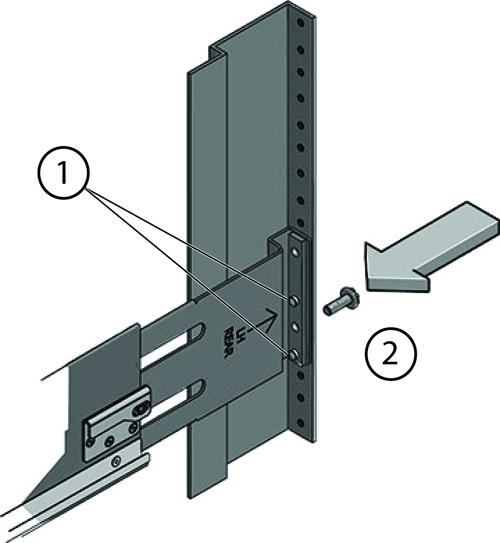

- Use the T20 Torx driver to remove the rail location pegs from the front and rear of the rails [1].

- Use a 10mm wrench (supplied) to insert the pins into the ends of the rails where you removed the location pegs [1].

- Position the front of the rails inside the cabinet, with the rail

flange inside of the cabinet flange, and the rail label facing the inside

of the cabinet [2].

The pins should be fully located within the rack holes.

- Insert and loosely tighten one screw through the front of the

rack and into the top hole in the rails [3].

The screws for threaded racks have an unthreaded area near the top of the shaft. Before threading these screws into the rails, thread them through the rack until the threads clear the rack and the screws turn freely.

Caution:

Mechanical failure. When installing a storage shelf in a threaded rack, be sure to use the screws with the partially unthreaded shaft. Before threading them into the rails, be sure to thread them through the rack until the threads clear the rack and the screws turn freely.

Callout Description 1

Pins (these replaced the location pegs)

2

Rail flange and label

3

Front mounting screw

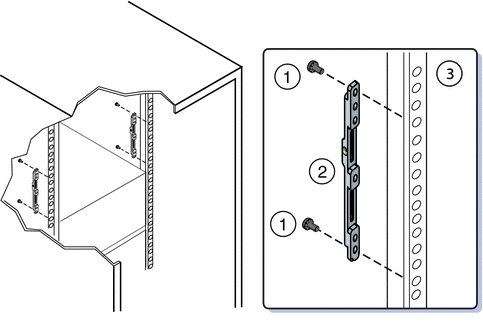

- Adjust the rail lengths to fit, and locate the rear pins inside the corresponding rear rack holes [1].

- Insert and loosely tighten one screw through the back of the rack

and into the back of the rails [2].

Number Description 1

Pins (replace location pegs)

2

Rear mounting screw

- If you have an unthreaded rack:

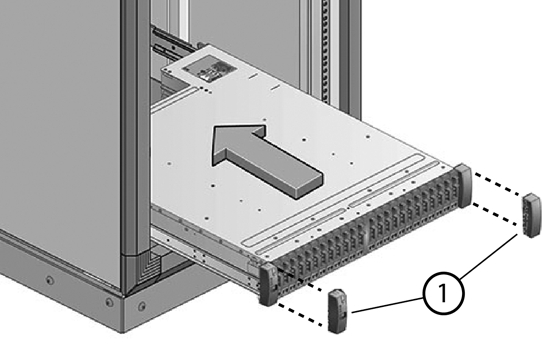

- Carefully slide the storage shelf onto the shelf rails until it

is fully seated in the rack.

Caution:

Equipment damage. Do not lift the storage shelf using the handles on the power supply/fan module.Caution:

Personal injury or equipment damage. Use a mechanical lift, or three persons. If you are using three persons, use two to lift the storage shelf into place, and a third to check that it is resting securely on the rails before releasing it. - Pull the storage shelf partway out of the rack until it is approximately 7.8 inches (200 mm) out of the rack.

- Tighten the four screws that fasten the rails to the rack (two in front, two in back).

- Slide the storage shelf back into the rack and check to ensure

that it is resting securely on the rails.

- Remove the front end caps that cover the ears on the front of the storage shelf [1]. They snap off.

- Use one short screw on each side to fasten the front of the storage shelf to the rack.

- Snap the end caps back onto the storage shelf.

- Use one short screw per rail to secure the rear of the storage

shelf to threaded hole on the rail.

- Repeat these steps if you have an additional storage shelf to install.

Add a Storage Expansion Shelf in an Existing System

Before You Begin

This task assumes that you are adding a storage expansion shelf to an already running Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, or Oracle Database Appliance X5-2.

It is not necessary to shut down your system to complete this task.

Please note the following exceptional conditions:

The storage expansion shelf normally sits at the bottom of Oracle Database Appliance, beneath the storage shelf. However, since racks should always be provisioned from the bottom up, that space might be unavailable. In these cases, to avoid re-rackmounting the entire system, it can be placed above the server nodes, or even in a different rack.

The Top Level Identifier (TLI) on the storage expansion shelf will not match the rest of the system as described in Verify Component Compatibility. However, adding a storage expansion shelf after your initial purchase and setup of the appliance is a supported configuration.

- Apply the label, if needed.

The expansion storage shelf shipment includes a label that says "EXPANSION STORAGE SHELF". If the label is not already applied to the front of the shelf, apply it now as described in Applying Labels.

- Install the expansion storage shelf as described in Installing the Storage Shelves in the Rack.

- Cable, power-on, and verify that the new storage is added.

Refer to the Getting Started Guide.

Installing the Server Nodes in the Rack

Use the instructions in this section to install server nodes in the rack.

Note:

The links in the following table take you to instructions outside of the Oracle Database Appliance library to the Sun Server X3-2, Sun Server X4-2, and Oracle Server X5-2 documentation libraries. Use your browser's Back button to return to the Oracle Database Appliance library.| ODA X3-2 | ODA X4-2 | ODA X5-2 |

|---|---|---|

|

|

Inserting Oracle Database Appliance (Original Version) into a Rack

This section describes inserting Oracle Database Appliance (original version) into a rack. If you are installing an Oracle Database Appliance X3-2, Oracle Database Appliance X4-2, or Oracle Database Appliance X5-2, see Inserting Oracle Database Appliance X3-2/X4-2/X5-2 into a Rack:

This section includes the following subsections:

Note:

If you are going to use a mechanical lift, you do not need to perform this procedure.Note:

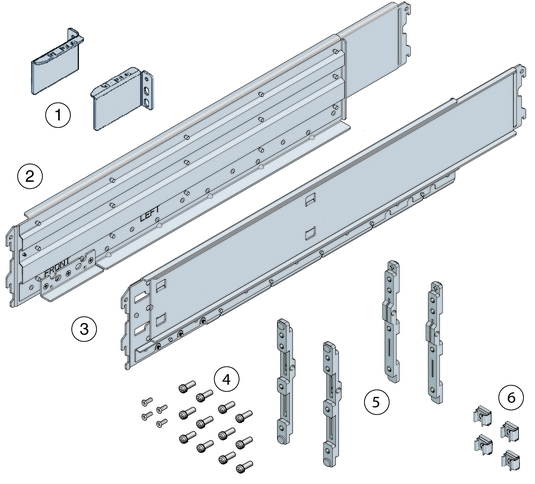

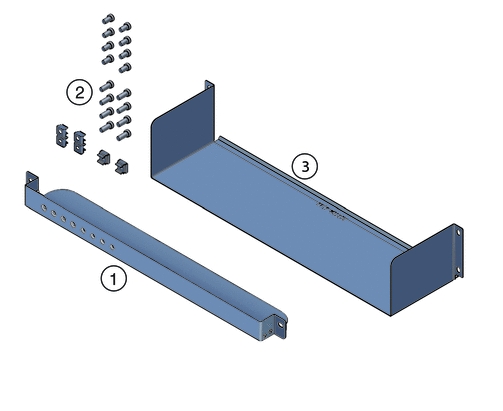

The system chassis is fixed in the rack by the rack-mounting kit hardware. The rack-mounting kit does not include slide rails. After the system chassis is installed in the rack, it does not slide in or out of the rack. The server nodes (also called system controllers) can be removed from the chassis while the chassis is installed in the rack.Rackmounting Kit Contents

The Rackmount Kit contains the hardware required to install Oracle Database Appliance (original version) into a supported rack. The Rackmount Guide and Alignment Template is shipped with the system in the accessory kit. Use this template when you are installing the system into the rack.

Note:

The rack-mounting kit does not include slide rails. After the system is installed, it does not slide in or out of the rack. See the Rackmount Guide and Alignment Template for additional instructions on how to install your system into a four-post rack.The following figure shows the hardware that comes with the rack-mounting kit.

| Callout | Description |

|---|---|

|

1 |

Top rear braces that attach to the posts at the upper rear of the system. |

|

2 |

Left shelf rail. |

|

3 |

Right shelf rail. |

|

4 |

An assortment of M6 and 10-32 screws, including twelve M6 x 16 screws, twelve M6 x 12 screws, four M6 x 4 flathead screws, ten 10–32 screws, and twelve 10–32 shoulder screws. |

|

5 |

Two sets of four adapter brackets, one set for round-hole racks, and one set for square-hole racks. |

|

6 |

Four M6 cage nuts. Note - The cage

nuts are not used. You can recycle them.

|

Staff, Tools, and Equipment Required to Rackmount the System

Caution:

Personal injury or equipment damage. Use a mechanical lift to install the system or follow the precautions in Removing Components to Reduce System Weight.Before starting the installation, gather the staff, tools, and equipment required to rackmount the system.

| Staff, Tools, and Equipment | Notes |

|---|---|

|

Four trained staff |

Four people are needed to lift or transport the system.

Note - If a mechanical lift is available or components have been removed from the system, it is safe for two people to lift or transport the system. |

|

No. 2 10-inch Phillips screwdriver |

A magnetic tip is recommended. |

|

Mechanical lift |

Strongly recommended. If not available, reduce the weight of the system. See Removing Components to Reduce System Weight.

|

|

Compatible four-post rack |

|

|

Rackmounting kit |

|

|

Transportation kit |

|

|

Antistatic wrist strap and antistatic mat |

Required only if you remove system components. |

Removing Components to Reduce System Weight

Before installing Oracle Database Appliance (original version) into a rack, you can remove components to reduce the weight of the system so that two persons can lift the system into the rack. Removing system components reduces the weight to approximately 96 pounds (43.5 kg).

Remove the following components to reduce the system weight:

Server nodes

Power supplies

Note:

Because of their light weight, you do not need to remove filler panels from the system.For instructions on removing components from the system and associated safety information, see the Oracle Database Appliance Service Manual.

Install Rack-Mounting Hardware into a Rack

Oracle Database Appliance (original version) rack-mounting hardware consists of shelf rails, front and rear adapter brackets, rear braces, and screws.

Caution:

Personal injury or equipment damage. Use a mechanical lift to install the system, or follow the precautions in Removing Components to Reduce System Weight. Removing components reduces the weight from 160 pounds (72.6 kg) when fully loaded with components to approximately 96 pounds (43.5 kg).Caution:

Tip hazard. Always load equipment into a rack from the bottom up so that it does not become top-heavy and tip over. Deploy your rack’s anti-tilt bar to prevent the rack from tipping during installation.Caution:

Elevated operating ambient temperature. Install this equipment in an environment that does not exceed the maximum ambient temperature (Tma) specified in Environmental Specifications. If the system is installed in a closed or multi-unit rack assembly, then the operating ambient temperature of the rack environment might be greater than room ambient temperature.Caution:

Thermal damage. Install the equipment in a rack so that the air flow is not restricted.Caution:

Circuit overloading. Consider the connection of the equipment to the supply circuit and the effect that overloading of the circuits might have on overcurrent protection and supply wiring. Be aware of equipment nameplate power ratings when addressing this concern.Caution:

Equipment damage. Maintain reliable grounding of rack-mounted equipment. Pay attention to supply connections other than direct connections to the branch circuit (for example, use of power strips).- Use the Rackmount Guide and Alignment Template to

measure the 4 rack unit (4RU) space in the rack where you will install the

system.

Also, use that template to align the adapter brackets with the rack posts.

- Verify that you have a 4RU space in your rack.

Place the bottom edge of the Rackmount Guide and Alignment Template in the lowest available position in the rack. Align all arrows with holes on the rack post. Ensure that 4RU space is available in the rack.

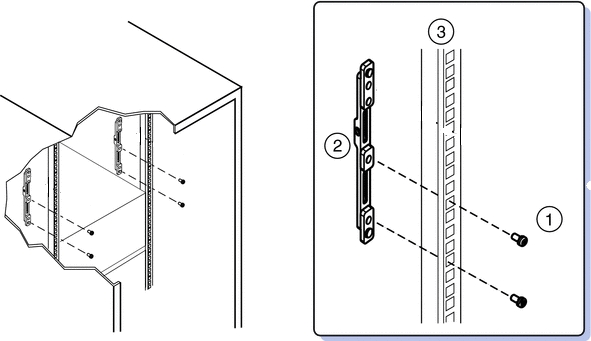

- Select the adapter brackets that match your rack.

The system ships with two sets of adapter brackets: one set [1] for racks with square holes and one set [2] for racks with round holes.

The adapter brackets are labeled to indicate whether they are for square-hole racks or round-hole racks. Additionally, arrows on the adapter brackets indicate how they should be oriented. Install all brackets with the arrow labeled "Top" pointing up.

- Attach the adapter brackets to the front rack posts.

The following figure shows the front adapter brackets being attached to a square-hole rack [1] and a round-hole rack [2].

- Place the brackets so that the bracket is aligned with the 4RU space where the server will be installed, and verify that the arrow labeled "Top" on the brackets points up.

- Select the screws that match your rack.

For a square-hole rack, use one M6 x 12 mm screw per adapter bracket.

For a threaded round-hole rack, use three M6 x 12 mm screws, or three 10-32 shoulder screws per adapter bracket.

- Attach the adapter brackets to the rear rack posts.

- Place the brackets so that the bracket is aligned with the space where the server will be installed and verify that the arrow labeled "Top" on the brackets points up.

- Select the screws that match your rack.

For a square-hole rack, use two M6 x 12 mm screws per adapter bracket.

For a threaded round-hole rack, use two M6 x 12 mm screws or two 10-32 shoulder screws per adapter bracket.

The following figure shows the rear adapter brackets being attached to a round-hole rack.

The following figure shows the rear adapter brackets being attached to a square-hole rack.

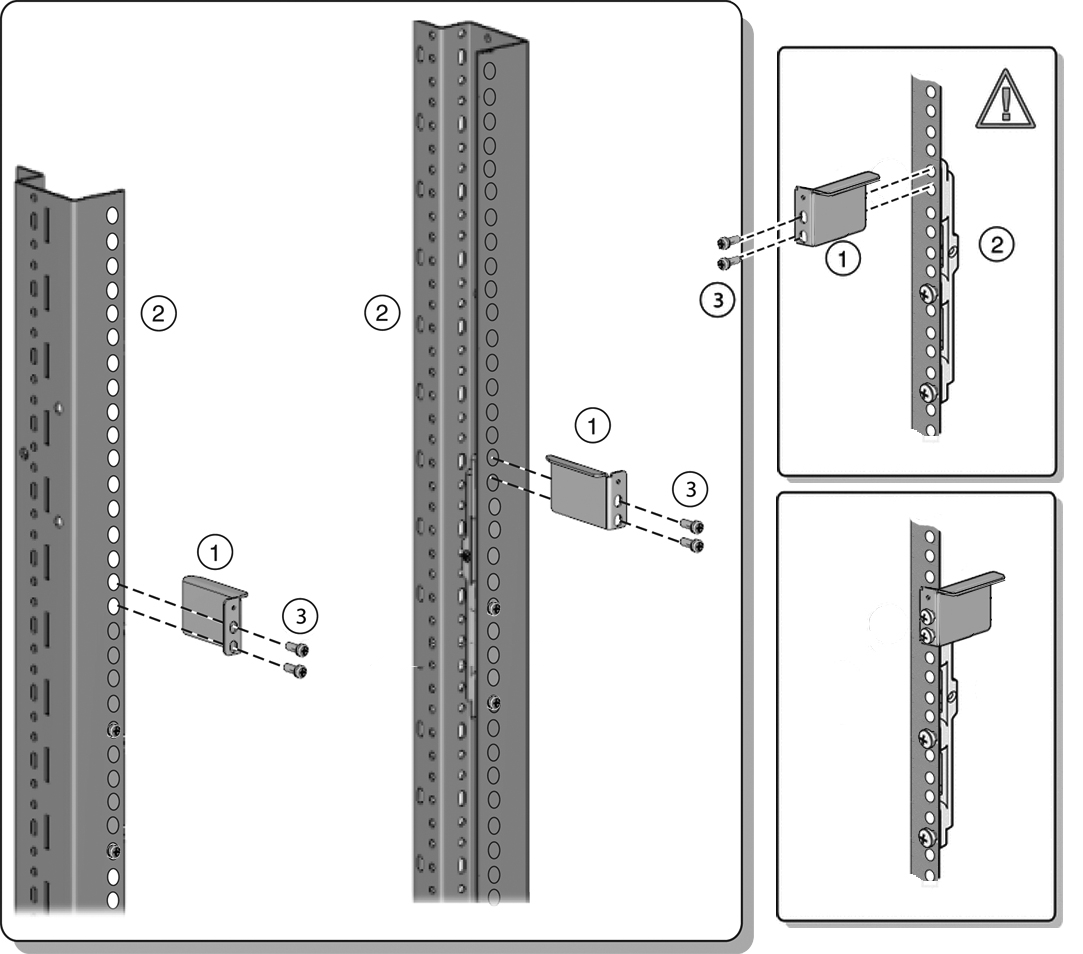

- Attach rear braces to the rear rack posts and to the

adapter brackets.

- Position the rear braces so that the tops of the braces [1] align with the 4U mark on each rear rack post.

- Install two M6 x 12 mm screws [3] or two 10-32 x 10

screws to attach each rear brace to the rack post and the adapter bracket.

Note:

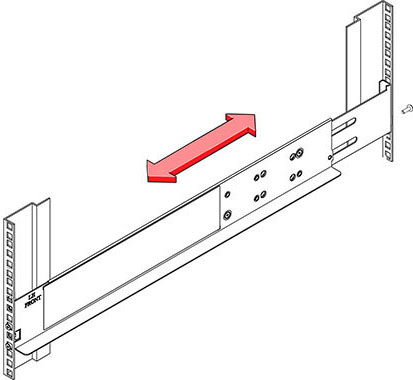

Before tightening the screws, slide the brackets [1] up as far as they will go. The holes on the brackets are oval-shaped so they can move up and down when the screws are loose. - Install the shelf rails into the rack.

Caution:

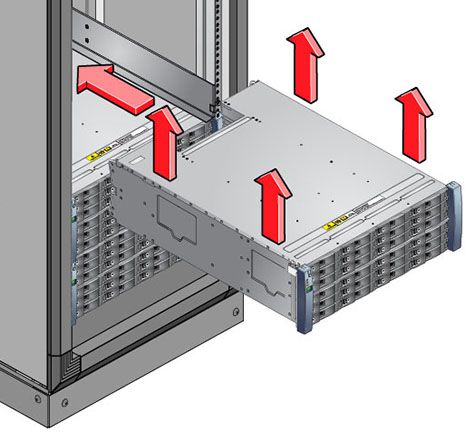

System failure. Orient the shelf rails properly, with the shelf facing inward and the gap toward the front of the rack; otherwise, the system might fall.- Expand the shelf rails [1] to fit between the front and rear rack posts.

- Insert the rear hooks of the shelf rails into the slots on the rear adapter brackets [2 and 3] first. Push down on the rail to engage the hooks.

- Insert the front hooks of the shelf rails into the

slots on the front adapter bracket. Push down on the rails to engage the hooks.

- Thread the four M4 x 10 flathead locking screws into

the four adapter brackets [1]).

These screws prevent the shelf rails from accidentally lifting out of the adapter brackets.

See also

Install the System into a Rack

Install the System into a Rack

Before you begin installing your Oracle Database Appliance (original version) into a rack, perform the steps in Install Rack-Mounting Hardware into a Rack.

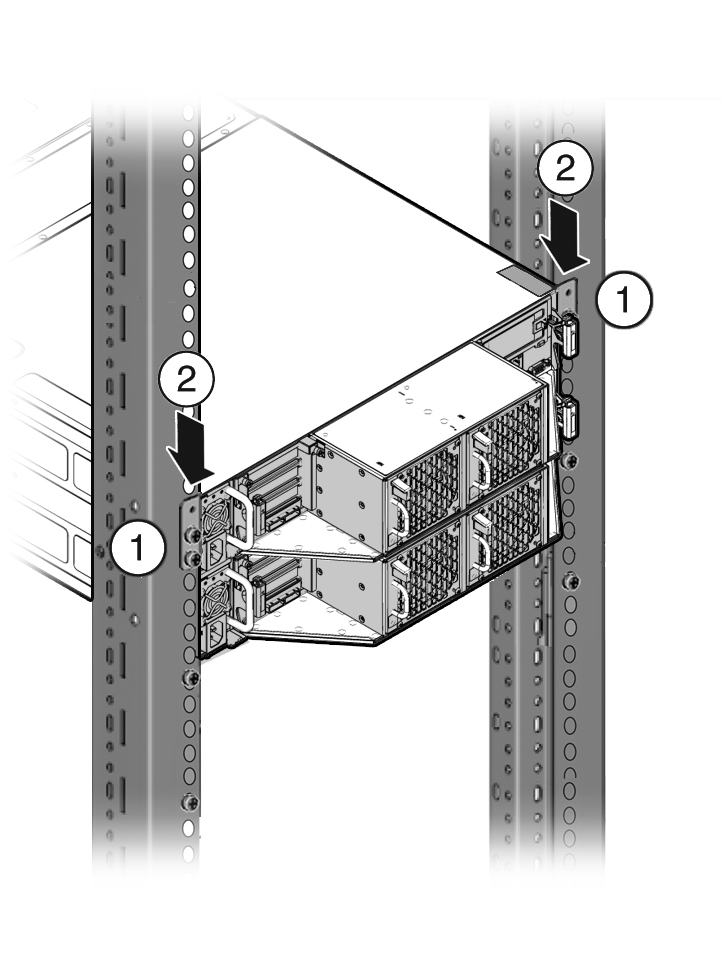

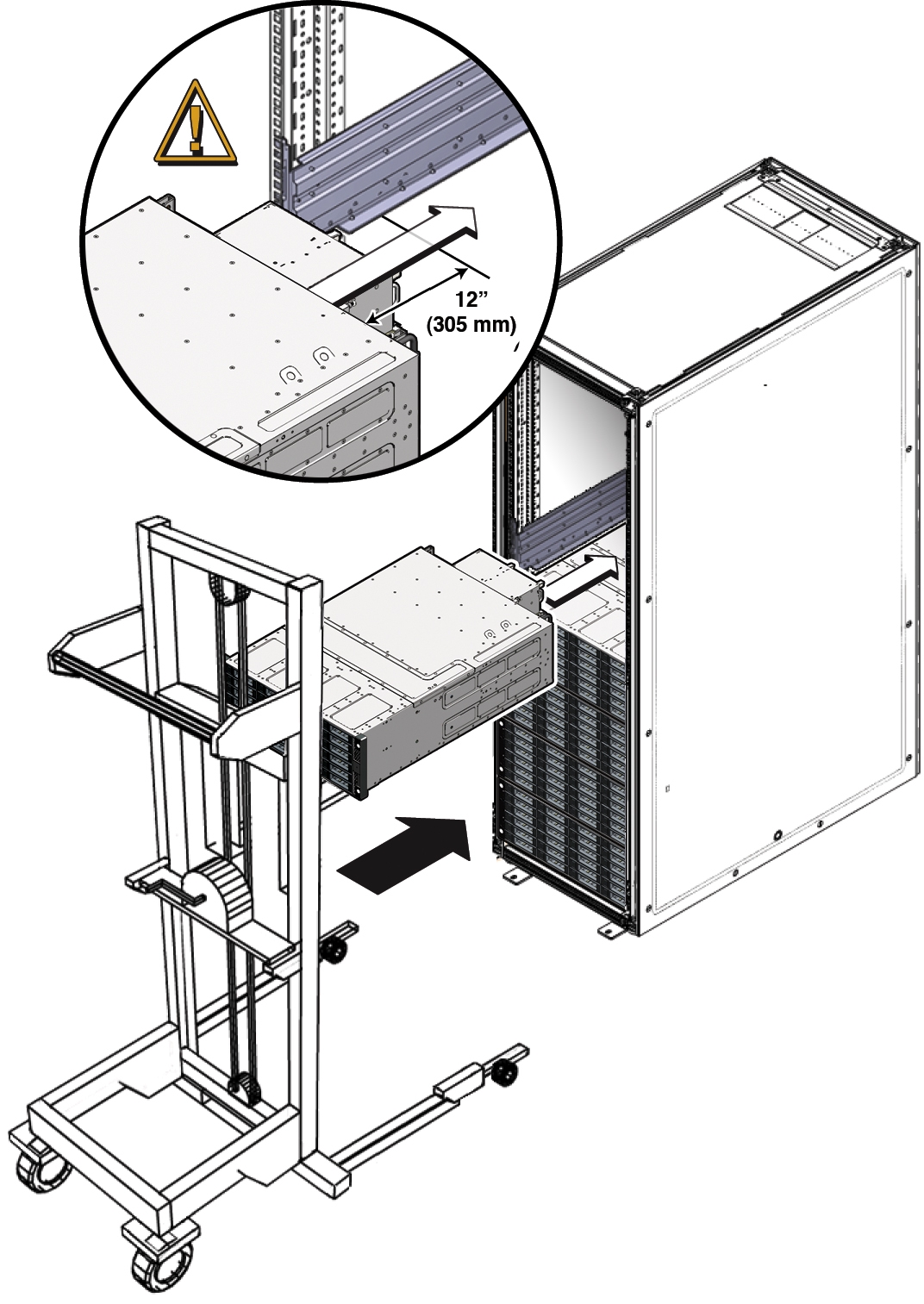

- Raise the system to slightly above the shelf surfaces.

Use a mechanical lift if possible.

Caution:

Personal injury or equipment damage. Use a mechanical lift to install the system, or follow the precautions in Removing Components to Reduce System Weight. Removing components reduces the weight from 160 pounds (72.6 kg) when fully loaded with components to approximately 96 pounds (43.5 kg).Caution:

Tip hazard. Always load equipment into a rack from the bottom up so that it does not become top-heavy and tip over. Deploy your rack’s anti-tilt bar to prevent the rack from tipping during installation. - Slide the system onto the shelf rails until the rack-mounting

ears contact the rack post. Adjust the top rear braces to fully insert the

system.

Caution:

Drop Hazard. Do not release the system until it is more than 12 inches (305 mm) into the rack, and is firmly supported by the shelf rails. The shelf rails do not safely support the system until it is more than 12 inches (305 mm) inside the rack.

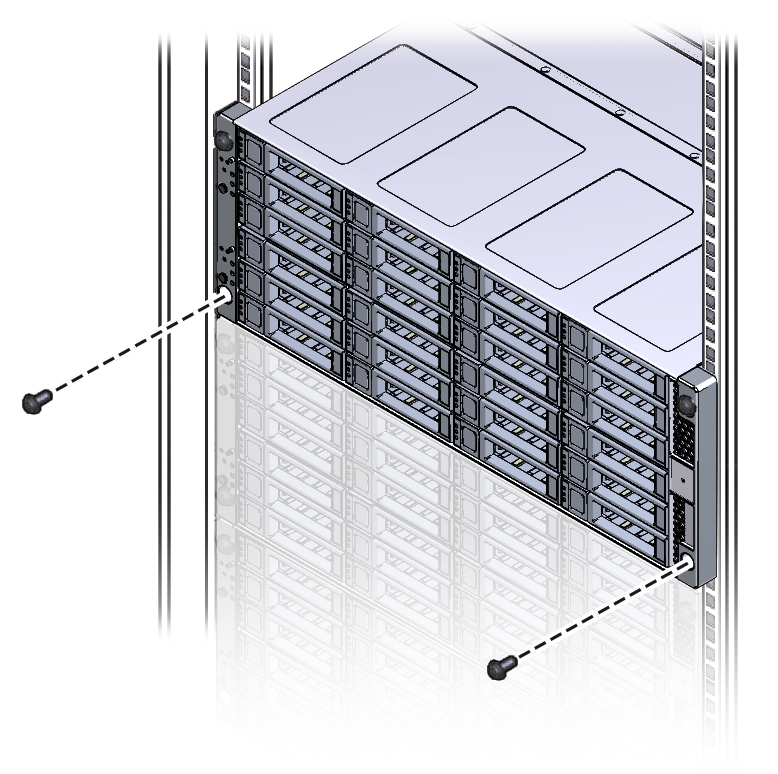

- Use four screws to attach the front of the system to

the front of the rack.

On a threaded, round-hole rack, use four M6 x 12 mm screws or four 10-32 x 10 mm screws.

On a square-hole rack, use four M6 x 16 mm screws.

Note:

On square-hole racks, the screws pass through the rack and thread into the adapter bracket. On round-hole racks, the screws thread into the rack rails.

- To adjust the rear braces, do the following:

- If you removed components from the system, replace

them.

For instructions, see the Service Manual, which is part of the product documentation.

Installing Shipping Brackets

This section includes the following information about installing the shipping brackets for Oracle Database Appliance (original version):

-

If you plan to ship the system in a rack to another destination, see Install Shipping Brackets.

If your system is shipped to you in a rack, you must remove the shipping brackets before placing the system into service. For instructions, see the Oracle Database Appliance Service Manual.

Transportation Kit Contents

The following figure shows the hardware that is included in the Oracle Database Appliance (original version) transportation kit.

| Callout | Description |

|---|---|

|

1 |

Front shipping bracket. |

|

2 |

Screws and cage nuts: For the rear shipping bracket:

|

|

3 |

Rear shipping bracket. |

Install Shipping Brackets

If you plan to move or ship Oracle Database Appliance (original version) in a rack to another location, you need to install the shipping brackets.

- Remove the two short screws that fasten the bottom of the system

to the rack.

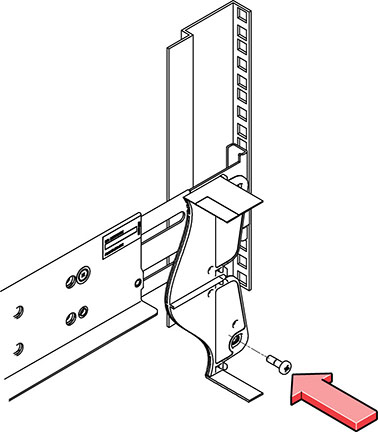

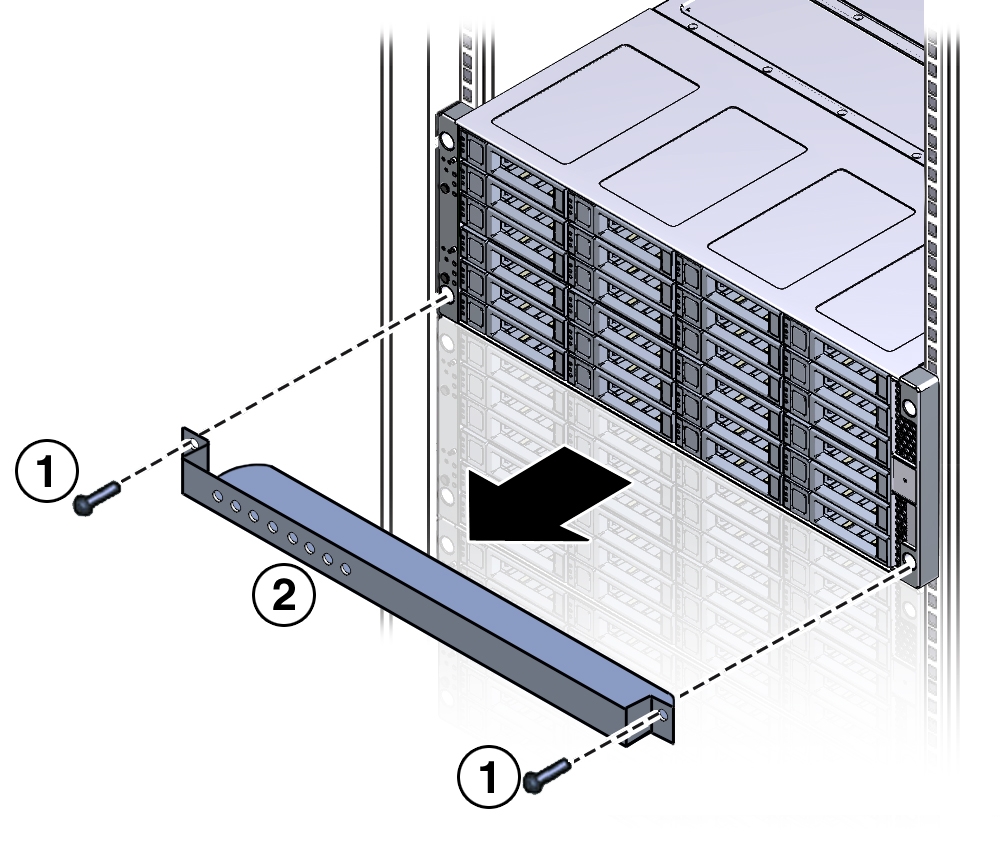

- Insert the front shipping bracket [2] under the front of the system

with the supporting flange underneath the system.

- Use the two long screws (either the M6 x 30 mm screws or the 10-32

x 1.25 inch screws) [1] to fasten the shipping bracket [2] to the front of

the system.

Tighten the two long screws to secure the shipping bracket and the system to the rack.

Note:

The front shipping bracket includes eight threaded holes used for storing unused screws. When the shipping brackets are not installed, the front shipping bracket holds the long screws used to install them. When the shipping brackets are installed, it stores the short screws that were used to secure the system to the front of the rack before the front shipping bracket was installed. - Insert the short screws into the four empty storage holes on the

front shipping bracket.

Store the screws so they can be used when the shipping bracket is removed.

- Remove the bottom two screws that hold the rear adapter brackets

in place.

Caution:

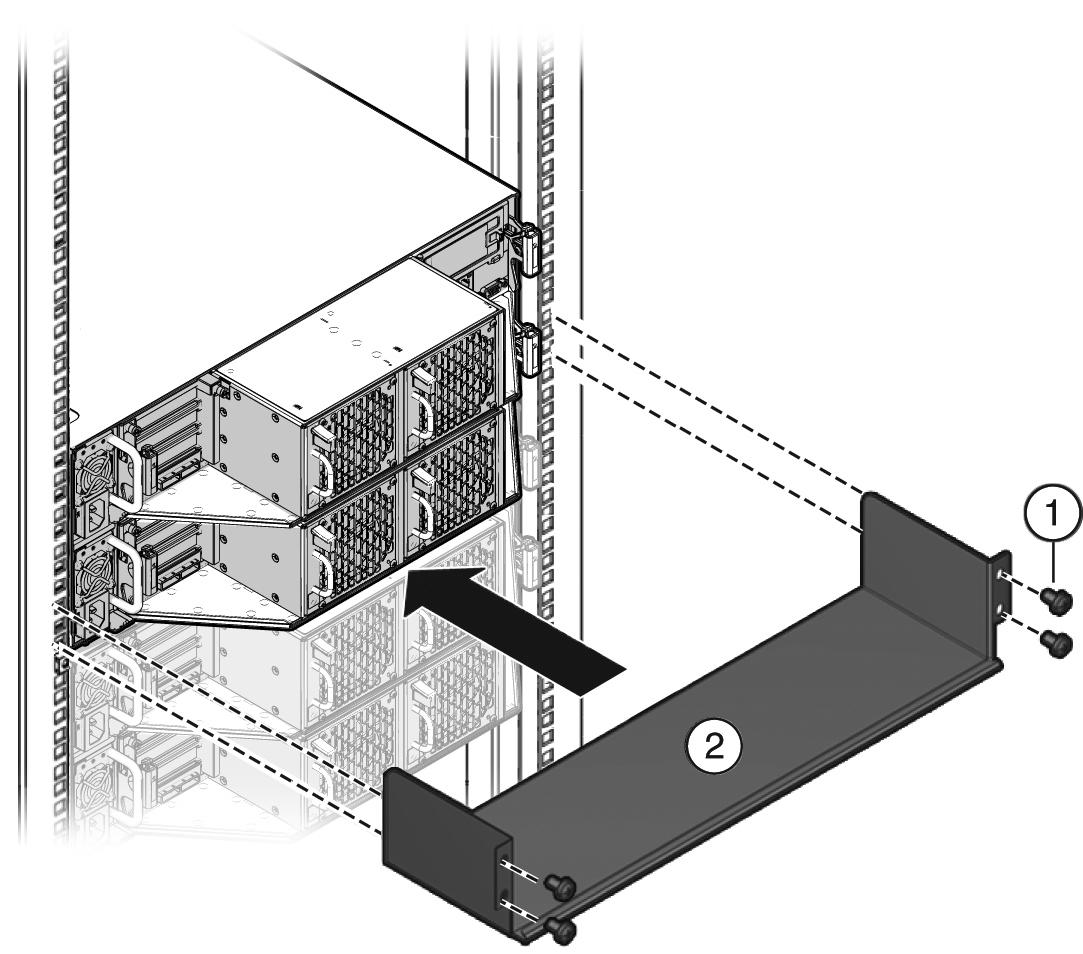

Equipment damage. Do not remove the bottom screws unless you are certain that at least one upper screw is in place; otherwise, the system might fall. - Insert the rear shipping bracket [2] under the back of the system

with the side panels facing up.

Use four screws [1] (either the M6 x 16 mm screws or the 10-32 x 10 mm screws) to fasten the rear shipping bracket to the rack. Do not finish tightening these screws. The screws should be tight enough to hold the bracket in place, but you should still be able to move the bracket slightly.

The bracket should be fastened to the posts, but loose enough to move slightly.

- Lift the rear shipping bracket up so that it rests firmly against

the bottom of the system, then finish tightening the screws that hold the

bracket in place.

If necessary, loosen the screws enough so that you can move the bracket, then push the bracket against the bottom of the system and tighten the screws.

Caution:

Equipment damage. To prevent damage to the system during shipping, the bottom shipping bracket must be positioned firmly against the bottom of the system.