Chapter 110: Generic Inventory Transaction Upload

Purpose: Use the generic inventory transaction upload to import inventory transactions into CWDirect. Because each transaction arrives in a separate XML file, you can use this upload for either real-time updates to CWDirect, or for updates that you schedule on a periodic basis.

What types of transactions can you upload? The upload supports any type of transaction that you can process through Working with Inventory Transactions in Batch Mode (WITB) or Working with Inventory Transactions in Immediate Mode (WITI), such as transfers or adjustments. You cannot upload system transactions, such as a purchase order receipt or an issue (shipment); however, there is no restriction on user-defined inventory transaction codes, even if the code’s Allowable flag is set to N.

How do you upload the transactions? Each transaction must arrive as a separate XML file, which is processed by the INVTRAN_IN process in Working with Integration Layer Processes (IJCT). You can use CWIntegrate for a seamless integration with CWStore, but the INVTRAN_IN process will process transactions from any source as long as the XML files are correctly formatted and contain the required information.

In this chapter:

• Inventory Transaction Upload Process Overview

• Processing Partial Quantities

• Summary of Transaction Rules

• Inventory Transaction Upload XML Message (inCreateInvXaction)

• Inventory Transaction Upload Message: Sample XML

• Inventory Transaction Upload Errors

Inventory Transaction Upload Process Overview

Types of transactions: Use the inventory transaction upload to process the following types of transactions:

• adjustments to on-hand quantity (A)

• item-to-item transfers (G)

• make up kits (M)

• overlay on-hand quantity (O)

• transfers (T)

• returns to vendor (V)

• user-defined transaction codes, including the Inventory Transaction Code for ’Sync’ Processing (I85)

See the Summary of Transaction Rules for more information.

You cannot use the upload to process system transactions, which include:

• issues (I)

• purchase order receipts (R)

• customer returns (C)

• physical inventory count (P)

• express bill (E)

Additionally, if you use FIFO costing, you cannot process O (overlay) or G (item-to-item transfer) transactions. See FIFO Costing Overview.

Inventory transaction job: The INVTRAN_IN process in Working with Integration Layer Processes (IJCT) reads each XML message received into a queue specified for the INVTRAN_IN process:

• If the transaction is in error, the job creates a record in the Item Transaction Error file. You can correct the error and reprocess it, or just delete the error record. See Inventory Transaction Upload Errors. However, if the transaction is in error because no valid company is specified, then the job does not create an Item Transaction Error record and is not available through the Work with Inventory Transaction Errors Screen.

• If there are no errors, the job processes the transaction and makes the same updates as when you process a transaction through Working with Inventory Transactions in Batch Mode (WITB) or Working with Inventory Transactions in Immediate Mode (WITI). For example, it updates:

• inventory levels in the Item Warehouse and Item Location

• Item Transaction History

• General Ledger Interface file

What if part of the quantity is reserved? If part of the quantity required to process the transaction is currently reserved, the transaction will “unreserve” it.

Example: The current on-hand quantity of item AB100 in the warehouse and location specified is 20, of which 11 is currently reserved for open orders. You receive an inventory transaction that has the effect of reducing the on-hand quantity to 10. One unit on an open order is unreserved, or put into backorder status, in order to reset the on-hand quantity to 10.

Note: The system does not unreserve items in order to process an M (make up kit) transaction).

See Unreserving Inventory using Warehouse Lists for more information on how the system determines which warehouse to backorder the unreserved quantity against.

What if part of the quantity is printed on a pick slip? A transaction never changes the status of a printed order line, so it might not be possible to process the entire quantity of a transaction if any units in the Item Location are printed. The allow_partial flag controls whether to process a partial quantity of a transaction for most transaction types; see Processing Partial Quantities.

What about pending transactions? Even if there is a batch transaction pending against the Item Location, you can still process the inventory transaction upload.

Example: There are currently 15 units of item AB100 in location A010101. You use Working with Inventory Transactions in Batch Mode (WITB) to create a pending transfer of 10 units to a different location. Before you accept the batch, you receive an inventory transaction upload to reset the on-hand quantity to 7 (an overlay (O) transaction). The uploaded transaction processes and the on-hand quantity is reset; if you subsequently process the batch that includes the transfer, it will create an item transaction error.

What if the Item Location is frozen? The system does not prevent the transaction from processing if the Item Location is currently frozen because of a physical inventory (the Physical freeze flag is set to Y).

The inventory transaction upload message can indicate the correct item and SKU through any one of the following:

1. item_number and sku_code (the sku_code is required if the item has SKUs, but should not be included for a non-SKU’d item): validated against the Item and SKU files

2. short_sku: validated against the Short SKU field in the SKU file

3. retail_reference_nbr: validated against the Reference # in the SKU file

4. upc_type and upc_code (both values must be specified): validated against the Item UPC file

In searching for an item and SKU, the system checks the values in the message in the order indicated above. If any value (or set of values, such as item_number and sku_code) is blank, it checks the next value, such as short_sku.

Once the system finds one of the values listed above in the message, it checks the related files to find a match. For example, if the message does not specify an item_number, but does specify the short_sku, the system checks the Short SKU field in the SKU file. If there is a match, the system continues processing the transaction. If there is no match, the system creates an item transaction error and stops attempting to resolve the item and SKU. Alternatively, if the message includes an incorrect item code and a correct short SKU, the system creates an error based on the item code; it never checks the short SKU.

For more information:

• item and SKU codes: Create Item Screen and Create SKU 1 of 2 (With Overrides) Screen

• short SKU number: Short SKU

• retail reference number: Reference #

• upc type and code: Work with UPC Codes Screen

Since a transaction never changes the status of a printed order line, you use the allow_partial flag to control whether to process a partial quantity of the transaction if part of the indicated quantity is in a printed status.

Example: There are currently 20 units of item AB100 in location A010101, of which 11 are printed on pick slips. You receive an inventory transaction for an adjustment with a quantity of -10. The system cannot subtract the entire 10 units from the on-hand quantity of 20, because that would reduce the on-hand quantity below the printed quantity. If the allow_partial flag is set to Y, the system adjusts the on-hand quantity to 11 and creates an item transaction error for the unadjusted quantity of -1; if the flag is set to N, the system creates an item transaction error for the entire adjustment quantity of -10.

Basic rules: When the system cannot process the entire transaction quantity because of conflict with the printed quantity:

• If the allow_partial flag is set to Y or 1, the system processes as many units of the transaction as it can.

• If the allow_partial flag is set to N, 0 or blank, the system creates an item transaction error for the entire transaction quantity.

• Regardless of the setting of the allow_partial flag, the system never processes a partial quantity for an O (reset on-hand) or M (make up kit) transaction; instead, the system always creates an item transaction error for the entire transaction quantity.

Sample transactions:

Example 1: |

Current on-hand quantity for location = 20 Current printed quantity for location = 11 Current reserved quantity for warehouse and location = 15 Inventory transaction: A (adjustment) for a quantity of -10 If allow_partial = N, 0 or blank: The system cannot process the full adjustment of -10, because that would reduce the on-hand quantity to 10, less than the printed quantity. The system creates an item transaction error of O/H LT Reserved/Printed for the full quantity of -10, and does not process any inventory updates. If allow_partial = Y or 1: The system adjusts the on-hand quantity down by 9 and creates an item transaction error of Unable To Adjust for the remaining quantity of -1. In order to reduce the on-hand quantity, the system also unreserves 4 of the reserved units; the unreserved units are now backordered. |

Example 2: |

Current on-hand quantity for location = 20 Current printed quantity for location = 5 Current reserved quantity for warehouse and location= 15 Inventory transaction: A (adjustment) for a quantity of -10 In this situation, the system is able to process the full transaction regardless of the setting of the allow_partial flag. The on-hand quantity is reset to 10, and 5 units are unreserved. No item transaction error occurs. |

The inventory transactions that you can upload are summarized in the following table.

Transaction |

Code |

transaction_quantity |

Partial Quantities? |

Guidelines |

Adjustment |

A |

either positive or negative |

allowed |

Complete just the Transaction element. Positive quantity: increases on-hand. Negative quantity: decreases on-hand. |

Item-to item transfer |

G |

positive |

allowed |

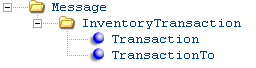

Complete both the Transaction and the TransactionTo elements. Decreases the on-hand quantity for the “from” item, and increases the on-hand quantity of the “to” item. Not allowed if you use FIFO costing; see FIFO Costing Overview. |

Make kit |

M |

positive |

not allowed |

Complete just the Transaction elements, specifying the kit item. Decreases the on-hand quantity for each of the component items, and increases the on-hand quantity of the kit item. Note: If the required quantity of any of the component items is partially reserved, the transaction will not process; the system does not unreserve a component item to make up a finished good. |

Overlay (reset on-hand quantity) |

O |

positive |

not allowed |

Complete just the Transaction element. Decreases or increases on-hand quantity, depending on whether the transaction quantity is higher or lower than the current on-hand quantity. Not allowed if you use FIFO costing; see FIFO Costing Overview. |

Transfer |

T |

positive |

allowed |

Complete both the Transaction and the TransactionTo elements. Decreases the on-hand quantity for the “from” item, and increases the on-hand quantity of the “to” item. |

Return to vendor |

V |

positive |

allowed |

Complete just the Transaction element. Decreases on-hand quantity. |

User-defined: matches Inventory Transaction Code for ’Sync’ Processing (I85) |

user-defined |

positive |

allowed |

Complete just the Transaction element. Resets the on-hand quantity to the transaction_quantity, adjusting upward or downward as necessary. Allowed through the inventory transaction upload, even if the inventory transaction code’s Allowable flag is set to N. |

User-defined: does not match Inventory Transaction Code for ’Sync’ Processing (I85) |

user-defined |

either positive or negative |

allowed |

Complete just the Transaction element. Positive quantity: increases on-hand. Negative quantity: decreases on-hand. Allowed through the inventory transaction upload, even if the inventory transaction code’s Allowable flag is set to N. |

To process the inventory transaction upload, you need to configure the INVTRAN_IN process in Working with Integration Layer Processes (IJCT), and send an XML message to a queue specified for the job. Also, the XML message you send must conform to the layout specified under Inventory Transaction Upload XML Message (inCreateInvXaction). Any additional requirements related to batch or interactive inventory transactions, such as specifying general ledger account numbers, must also be met.

If you will be processing sync transactions, specify the user-defined inventory transaction code in the Inventory Transaction Code for ’Sync’ Processing (I85) system control value.

Note: MICROS recommends that you send only alphanumeric inventory transaction codes through the inventory transaction codes. Non-alphanumeric characters might not process correctly, and might cause an error.

Inventory Transaction Upload XML Message (inCreateInvXaction)

The INVTRAN_IN process requires an XML file laid out as follows.

Important: Please note the following rules for numeric fields:

• Do not pass an alphanumeric value in a numeric field; doing so will cause the INVTRAN_IN process to go into a message wait status.

• Do not exceed the specified length of any numeric field; doing so will cause the value to be interpreted incorrectly.

General rules for alphanumeric fields:

• case-sensitive; an a is not equivalent to an A.

• will be truncated if they exceed the maximum length specified below; a transaction_code of Adjustment will be truncated to A and processed correctly.

For more information: See:

• Inventory Transaction Upload XML Message (inCreateInvXaction) for a sample message.

• XML Messages for a table that provides links to the DTD, schema, and a sample XML layout for each XML message.

Attribute Name |

Type |

Length |

Comments |

source |

alpha |

25 |

Identifies the source of the XML message. IDC indicates the XML message is from CWIntegrate. |

target |

alpha |

25 |

Identifies the target of the XML message. RDC indicates the XML message is sent to CWDirect. |

type |

alpha |

25 |

Identifies the type of information in the XML message. inCreateInvXaction is the recommended value to indicate the message contains an inventory transaction. |

numeric |

7 |

Will be stored in the Item Transaction History file. Must be a positive number. |

|

numeric |

10 |

Will be stored in the Item Transaction History file. If the identification number exceeds 10 positions, it will be truncated. Not valid with G (item-to-item transfer) transactions. |

|

alpha |

1 |

Indicates the type of transaction. Valid transactions are: • A = adjustment • G = item-to-item transfer • M = make up kit • O = overlay current on-hand quantity • V = return to vendor • any user-defined transaction codes, as specified through Work with Inventory Transaction Codes (WITC). See Inventory Transaction Upload Process Overview and Inventory Transaction Code for ’Sync’ Processing (I85) for more information. |

|

|

|

|

Note: • If the information in the transaction code exceeds the maximum length of 1 position, it will be truncated. For example, if this attribute is set to Adjustment, it will be truncated to A. • This attribute is case-sensitive. A value of a is not the same as a value of A. • G (item-to-item transfer) and O (overlay current on-hand quantity) transactions are not allowed if you use FIFO costing; see FIFO Costing Overview. • MICROS recommends that you send only alphanumeric inventory transaction codes through the inventory transaction codes. Non-alphanumeric characters might not process correctly, an might cause an error. |

numeric |

2 |

Must match a valid transaction reason code, as specified through Work with Inventory Transaction Reason Codes (WIT1); required if the inventory transaction code’s Reason required flag is set to Y. |

|

numeric |

5 |

A negative quantity is indicated by a minus sign (-) preceding the number. Note: If the minus sign is not positioned before the number, the transaction quantity will not process correctly. Depending on how the quantity is formatted, the transaction might go into error status or be processed with an incorrect quantity. |

|

|

|

|

The actual effect on inventory varies with the transaction; for example: • a transfer (T) always decreases the “from” location and increases the “to” location; the transaction quantity should always be positive. Item-to-item transfers (G) are the same. • a return to vendor (V) always decreases inventory; the transaction quantity should always be positive. • an adjustment (A) can be either positive or negative; the quantity is added to or subtracted from the current on-hand quantity. Note: An overlay (O) or sync (Inventory Transaction Code for ’Sync’ Processing (I85)) resets current on-hand quantity, so the net result can be either a decrease or an increase; however, the transaction quantity should always be positive. See Summary of Transaction Rules for more information. |

alpha |

1 |

Indicates whether to process the transaction even if the full transaction quantity cannot be processed because some of that quantity is currently printed. Valid values are: • Y or 1 = process a partial quantity if the full quantity cannot be processed • N, 0 or blank = do not process a partial quantity; put the transaction in error if the full quantity cannot be processed See Processing Partial Quantities for a discussion. |

|

alpha |

1 |

Indicates whether to create an Item Warehouse record if it does not already exist in order to process the transaction. Valid values are: • Y or 1 = create an Item Warehouse record if it does not already exist • N, 0 or blank = do not create a new Item Warehouse record; put the transaction in error if the Item Warehouse does not exist Note: In the case of a transfer (T) or item-to-item transfer (G) transaction, this value refers to the warehouse specified in the TransactionTo element; otherwise, it refers to the warehouse specified in the Transaction element. |

|

alpha |

1 |

Indicates whether to create an Item Location record if it does not already exist in order to process the transaction. Valid values are: • Y or 1 = create an Item Location record if it does not already exist • N, 0 or blank = do not create a new Item Location record; put the transaction in error if the Item Location does not exist Note: • In order to create both a new Item Warehouse and a new Item Location, both this flag and the create_item_warehouse flag must be set to Y or 1. • In the case of a transfer (T) or item-to-item transfer (G) transaction, this value refers to the location specified in the TransactionTo element; otherwise, it refers to the location specified in the Transaction element. |

|

alpha |

10 |

This information will be stored in the Item Transaction History file, and is truncated if it exceeds 10 positions. |

|

numeric |

8 |

Indicates the general ledger account number to use for the Inventory Offset journal source posting; see Posting Changes to Inventory Value for an overview. Not valid with G (item-to-item transfer) transactions. |

|

company |

numeric |

3 |

If this value does not represent a valid company code on your system, the transaction will not process, and the error will not be visible through Working with Inventory Transaction Errors (WITE). |

alpha |

12 |

Defined in and validated against the Item file; see Performing Initial Item Entry (MITM). See Resolving the Item and SKU for information on how the system identifies the correct item and SKU. Note: • If the information in the item code exceeds the maximum length of 12 positions, it will be truncated. • This attribute is case-sensitive. A value of a is not the same as a value of A. |

|

alpha |

14 |

Required if the item_number is specified and the item has SKUs. See Resolving the Item and SKU for more information. Note: • A split SKU should have blank space between each of the SKU elements. • If the information in the SKU code exceeds the maximum length of 14 positions, it will be truncated. • This attribute is case-sensitive. A value of a is not the same as a value of A. |

|

numeric |

7 |

Can be used to identify the correct item and SKU; see Resolving the Item and SKU for information. The system assigns the short SKU number, which you can review at the second Display SKU screen; see Performing Initial Item Entry (MITM). |

|

numeric |

15 |

Can be used to identify the correct item and SKU; see Resolving the Item and SKU for information. You can assign a Reference # at the Create Item (Base Information) Screen or the Create SKU 2 of 2 (With Overrides) Screen. |

|

alpha |

3 |

Can be used, along with the upc_code, to identify the correct item and SKU; see Resolving the Item and SKU for information. You use the Work with UPC Codes Screen work with UPC types and codes. |

|

numeric |

14 |

Can be used, along with the upc_type, to identify the correct item and SKU; see Resolving the Item and SKU for information. You use the Work with UPC Codes Screen work with UPC types and codes. |

|

numeric |

3 |

Required. Validated against the Warehouse file; see Creating and Maintaining Warehouses (WWHS) for more information. The create_item_warehouse flag indicates whether to create the Item Warehouse record if it does not already exist. |

|

alpha |

7 |

Required. Validated against the Location file; must represent a valid location in the warehouse indicated. See Creating and Maintaining Locations (WLOC) for more information. The create_item_location flag indicates whether to create the Item Location record if it does not already exist. Note: • If the location exceeds the maximum length of 7 positions, it will be truncated. • This attribute is case-sensitive. A value of a is not the same as a value of A. |

|

alpha |

2 |

Updates the SKU file if the item will be sold out as a result of an item-to-item (G) transfer. Validated against the Soldout Control file; see Working with Soldout Controls (WSLD). If a soldout control code is indicated, it must represent a valid code even if it is not required for the transaction. Note: • If the code exceeds the maximum length of 2 positions, it will be truncated. • This attribute is case-sensitive. A value of a is not the same as a value of A. |

|

|

Note: This element is used only for T (transfer) and G (item-to-item transfer) transactions. See Summary of Transaction Rules. |

|||

numeric |

3 |

Specifies the company for the target of the transfer; required if the company for the source of the transfer is different from the one for the target. |

|

alpha |

12 |

Used only for G (item-to-item transfer) transactions. See Resolving the Item and SKU for information on how the system identifies the correct item and SKU. Note: • If the information in the item code exceeds the maximum length of 12 positions, it will be truncated. This attribute is case-sensitive. A value of a is not the same as a value of A. |

|

alpha |

14 |

Used only for G (item-to-item transfer) transactions. Required if the item_number is specified and the item has SKUs. See Resolving the Item and SKU for more information. Note: • If the information in the SKU code exceeds the maximum length of 14 positions, it will be truncated. This attribute is case-sensitive. A value of a is not the same as a value of A. |

|

numeric |

7 |

Used only for G (item-to-item transfer) transactions. Can be used to identify the correct item and SKU; see Resolving the Item and SKU for information. The system assigns the short SKU number, which you can review at the second Display SKU screen; see Performing Initial Item Entry (MITM). |

|

numeric |

15 |

Used only for G (item-to-item transfer) transactions. Can be used to identify the correct item and SKU; see Resolving the Item and SKU for information. You can assign a Reference # at the Create Item (Base Information) Screen or the Create SKU 2 of 2 (With Overrides) Screen. |

|

alpha |

3 |

Used only for G (item-to-item transfer) transactions. Can be used, along with the upc_code, to identify the correct item and SKU; see Resolving the Item and SKU for information. You use the Work with UPC Codes Screen work with UPC types and codes. |

|

upc_code |

numeric |

14 |

Used only for G (item-to-item transfer) transactions. Can be used, along with the upc_type, to identify the correct item and SKU; see Resolving the Item and SKU for information. You use the Work with UPC Codes Screen work with UPC types and codes. |

numeric |

3 |

Required for T (transfer) and G (item-to-item transfer) transactions. Validated against the Warehouse file; see Creating and Maintaining Warehouses (WWHS) for more information. The create_item_warehouse flag indicates whether to create the Item Warehouse record if it does not already exist. |

|

alpha |

7 |

Required for T (transfer) and G (item-to-item transfer) transactions. Validated against the Location file; must represent a valid location in the warehouse indicated. See Creating and Maintaining Locations (WLOC) for more information. The create_item_location flag indicates whether to create the Item Location record if it does not already exist. Note: • If the location exceeds the maximum length of 7 positions, it will be truncated. This attribute is case-sensitive. A value of a is not the same as a value of A. |

|

Inventory Transaction Upload Message: Sample XML

A sample of the Inventory Transaction Upload XML Message (inCreateInvXaction) is presented below.

<Message source="idcqa79" target="idcqa79" type="inCreateInvXaction">

<InventoryTransaction transaction_code="O" transaction_quantity="50" allow_partial="Y" create_item_warehouse="Y" create_item_location="Y" entered_by_user="CWSTORE">

<Transaction company="5" item_number="UITEM2" warehouse="10" location="STORE" />

</InventoryTransaction>

</Message>

Inventory Transaction Upload Errors

Overview: Use Working with Inventory Transaction Errors (WITE) to review and work with errors that occur through the inventory transaction upload in the Inventory Transaction Upload XML Message (inCreateInvXaction). These errors are distinguished from system-generated errors (that is, errors that did not occur through the upload) by the fact that the I flag for upload errors is set to Y. Unlike with system-generated errors, you can change the information in an upload error by entering 2 next to the error at the Work with Inventory Transaction Errors Screen.

Important:

• Do not pass an alphanumeric value in a numeric field; doing so will cause the INVTRAN_IN process to go into a message wait status.

• Do not exceed the specified length of any numeric field; doing so will cause the value to be interpreted incorrectly.

Error |

Possible Reason(s) |

ID & G/L Must Be Blank |

• Either the identification_nbr or the gla_account_nbr were specified for a G (item-to-item transfer) transaction. |

Invalid From item/loc |

• The item location specified in the Transaction element does not exist, and the create_item_location flag in the Transaction element is not set to Y or 1. |

Invalid From Item/Whs |

• There is no record of the item/SKU in the warehouse specified in the Transaction element, and the create_item_ flag is not set to Y or 1. |

Invalid From location |

• The location specified in the Transaction element does not exist in the warehouse indicated. • There is no location specified. Note: This attribute is case-sensitive; a value of a is not the same as a value of A. |

Invalid From warehouse |

• The warehouse specified in the Transaction element does not exist, or it exceeds the maximum number of positions. • There is no warehouse specified. |

Invalid General Ledger# |

• The gla_account_nbr does not exist in the General Ledger Account file, or it exceeds the maximum number of positions. |

Invalid Item/SKU |

The item and SKU could not be resolved; see Resolving the Item and SKU. For example: • The item_number does not exist in the Item file. • There is no item_number indicated. • The sku_code does not exist in the SKU file for the indicated item. • There is no sku_code indicated for a SKU’d item. Note: These attributes are case-sensitive; a value of a is not the same as a value of A. |

Invalid Sold Out Control |

• The so_control specified in the Transaction element does not exist in the Soldout Control file. Note: • This attribute is case-sensitive; a value of a is not the same as a value of A. • The system validates the soldout control code, even if it will not be used to process the transaction. A soldout control code is used only when a G transaction sells out the “to” item. |

Invalid To item/location |

• The create_item_location flag for a G (item-to-item transfer) or T (transfer) transaction is set to N, 0 or blank, and an Item Location record does not already exist for the item_number and location specified in the TransactionTo element. |

Invalid To Item/SKU |

• The item and SKU in the TransactionTo element could not be resolved (G (item-to-item transfer) or T (transfer) transactions only); see Resolving the Item and SKU. |

Invalid To item/warehouse |

• A G (item-to-item transfer) or T (transfer) transaction has the create_item_ flag set to N, 0 or blank, and an Item Warehouse record does not already exist for the item_number and warehouse specified in the TransactionTo element. |

Invalid To location |

• A G (item-to-item transfer) or T (transfer) transaction did not specify a valid location in the TransactionTo element. |

Invalid To warehouse |

• A G (item-to-item transfer) or T (transfer) transaction did not specify a valid warehouse in the TransactionTo element. |

Invalid Transaction Code |

• The transaction_code does not exist in the Item Transaction Code file. • There is no transaction_code indicated. Note: This attribute is case-sensitive; a value of a is not the same as a value of A. |

Invalid Transaction Reas |

• The transaction_reason does not exist in the Item Transaction Reason file. • There is no transaction_reason indicated. • The transaction_reason exceeds the maximum number of positions. |

Item Must Be Finish Good |

• For an M transaction, the item is not a finished-good item, identified by an F in the Kit type field. |

List Price Mismatch |

• For a G (item-to-item transfer) transaction, the item specified in the Transaction element and the TransactionTo do not have the same List price. See Create Item (Base Information) Screen and Create SKU 2 of 2 (With Overrides) Screen for more information on specifying the List price. |

Missing Quantity |

• No transaction_quantity is specified. |

Negative on hand |

• The transaction_quantity exceeds the on-hand quantity of the item/SKU. • The transaction quantity exceeded the unprinted quantity for an M (make up kit) transaction. See Processing Partial Quantities. |

O/H LT Reserved/Printed |

• The transaction quantity exceeded the unprinted quantity, and the system did not process the transaction at all (see Processing Partial Quantities); or, the transaction would have reset the on-hand quantity to a negative number, even if there is not a reserved or printed quantity. |

Trans Code Not Allowed |

• The transaction_code is a system code, which is not permitted through the inventory transaction upload. System codes are: • R = purchase order receipt • I = issue • P = physical inventory • C = customer return • express bill (E) • The transaction_code is O (overlay) or G (item-to-item transfer), and your Costing Method (A25) system control value is set to FIFO. These types of transactions are not allowed with FIFO costing; see FIFO Costing Overview. |

Trans Reason Required |

• There is no transaction_reason is specified, but the inventory transaction requires one, as specified through Work with Inventory Transaction Codes (WITC). |

Unable To Adjust |

The transaction quantity exceeded the unprinted quantity, but the system was able to process a partial quantity of the transaction. See Processing Partial Quantities. Note: The error for an M (make up kit) transaction is Negative on hand. |

| Chapter 109: Point of Sale Integration Overview | Contents | SCVs | Search | Glossary | Reports | XML | Index | Chapter 111: Generic Item Download API |

ST01_02 CWDirect 18.0 August 2015 OTN