Chapter 55: Working with Warehouse Lists (WWHL)

Warehouse lists are used to more efficiently allocate an order to ship from the warehouse closest to the shipping destination. Each list contains the warehouses the system will use to fulfill an order, and the sequence in which the warehouse will be considered. A warehouse list is usually created for each region to which you ship.

What does warehouse list control? If a warehouse list is associated with the SCF of the order ship to, the system performs the following:

• reserves items from the warehouses in the warehouse list, based on the settings of certain system control values; see Warehouse Reservation Processing.

• backorders items only in the warehouses in the warehouse list, based on the settings of certain system control values and whether a warehouse is an HDL warehouse; see Warehouse Backorder Processing.

• limits the item availability that displays on certain screens to the quantity available in the warehouse list, instead of the quantity available across all allocatable warehouses; see Determining Item Availability.

• when the system sells out an item with a soldout control code of either 2 or 3, the system limits the soldout calculation to the eligible warehouses instead of all allocatable warehouses; see Determining the Soldout Calculation.

• limits the expected ship date that displays on certain screens to the purchase orders that are associated with a warehouse in the warehouse list; see Determining the Expected Ship Date.

Example: If you ship from three warehouses, you might use the following shipping strategy to fulfill orders:

Destination |

Warehouse List Hierarchy |

Comments |

East Coast |

1. New York 2. Chicago |

For inventory shipped to the east coast, ship from the New York warehouse. If inventory is not available in the New York warehouse, then ship from the Chicago warehouse. |

Mid West |

1. Chicago 2. New York 3. Los Angeles |

For inventory shipped to the mid west, ship from the Chicago warehouse. If inventory is not available in the Chicago warehouse, then ship from the New York warehouse. If inventory is not available in the New York warehouse, then ship from the Los Angeles warehouse. |

West Coast |

1. Los Angeles 2. Chicago |

For inventory shipped to the west coast, ship from the Los Angeles warehouse. If inventory is not available in the Los Angeles warehouse, then ship from the Chicago warehouse. |

In this chapter:

• Warehouse Reservation Hierarchy

• System Control Values Related to Warehouse List Processing

• Warehouse Reservation Processing

• Warehouse Backorder Processing

• Evaluating Backorders for Reservation

• Unreserving Inventory using Warehouse Lists

• Determining Item Availability

• Determining the Soldout Calculation

• Determining the Expected Ship Date

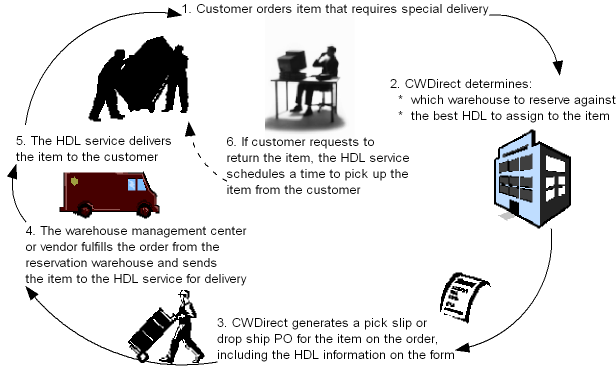

• HDL (Home Delivery Service) Processing

• Work with Warehouse Lists Screen

• Edit Warehouse List Details Screen

• Change Warehouse List Screen

• Display Warehouse List Screen

For more information:

• Assigning Warehouse List by SCF Range (MWHL)

• Submit Warehouse List Exception Reports (WHLE)

Warehouse Reservation Hierarchy

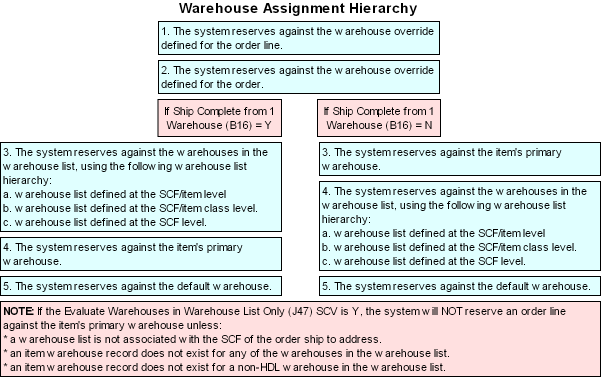

Purpose: The setting of the Ship Complete from 1 Warehouse (B16) system control value determines the hierarchy the system uses to assign a warehouse to an order line.

If the Ship Complete from 1 Warehouse (B16) system control value is set to Y:

1. A warehouse code for an individual order line: If you enter a warehouse code for an individual order line, the system will use this warehouse to reserve the order line. This warehouse assignment will override all other reserve warehouse logic. Note: You can only override the warehouse code for an individual order line using the F6 option on the Work with Order Lines Screen (Line-by-Line Format).

2. A warehouse code entered on the order header: If you enter a warehouse code in the Warehouse field on the Work with Order screen, the system will use this warehouse to reserve all lines on the order. This warehouse assignment will override all other warehouse assignments except a warehouse code entered for an individual order line.

3. Warehouse list:If you have not entered a warehouse code for an individual order line, or a warehouse code on the order header, the system will look for a warehouse list for the SCF of the order ship to address. A warehouse list can be assigned to an SCF at three levels. The system uses the following hierarchy to determine which warehouse list assigned to the SCF to use.

• SCF/Item: The system uses the warehouse list defined at the SCF/item level first.

• SCF/Item class: If a warehouse list has not been defined at the SCF/item level, the system uses the warehouse list at the SCF/item class level.

• SCF: If a warehouse list has not been defined at the SCF/item class level, the system uses the warehouse list at the SCF level.

• See Warehouse List Hierarchy for more information on how the system determines which warehouse in the warehouse list to use to reserve the item.

4. The item’s primary warehouse: If no reserve warehouse can be assigned based on individual order lines, a warehouse code entered on the order header, or a warehouse list, the system will reserve the item in the warehouse defined for the item in the Item file.

5. Default warehouse: If the item’s primary warehouse is not eligible for reservation (unallocatable or frozen), the system will reserve the item in the default warehouse. If an item warehouse record does not exist for the default warehouse, or the default warehouse is unallocatable or frozen, the system will place the item on backorder with the reason: No Item Warehouse or No allocatable warehouse.

6. Reevaluate warehouse list: If the Reevaluate Reservation Logic at Final Accept (M01) system control value is set to Y, during the final order accept the system reevaluates the items on the order to determine if all of the items can reserve (and ship) from one warehouse in the warehouse list, evaluating each warehouse in warehouse priority sequence.

• If one warehouse in the warehouse list can reserve all of the items, the system re-reserves all of the items on the order in this warehouse.

• If one warehouse in the warehouse list cannot reserve all of the items, the items retain the warehouse currently assigned.

If the Ship Complete from 1 Warehouse (B16) system control value is set to N:

1. A warehouse code for an individual order line: If you enter a warehouse code for an individual order line, the system will use this warehouse to reserve the order line. This warehouse assignment will override all other reserve warehouse logic. Note: You can only override the warehouse code for an individual order line using the F6 option on the Work with Order Lines Screen (Line-by-Line Format).

2. A warehouse code entered on the order header: If you enter a warehouse code in the Warehouse field on the Work with Order screen, the system will use this warehouse to reserve all lines on the order. This warehouse assignment will override all other warehouse assignments except a warehouse code entered for an individual order line.

3. The item’s primary warehouse: If no reserve warehouse can be assigned based on individual order lines or a warehouse code entered on the order header, the system will reserve the item in the warehouse defined for the item in the Item file.

4. Warehouse list:If no reserve warehouse can be assigned based on individual order lines, a warehouse code entered on the order header, or the item’s primary warehouse, the system will look for a warehouse list for the SCF of the order ship to address. A warehouse list can be assigned to an SCF at three levels. The system uses the following hierarchy to determine which warehouse list assigned to the SCF to use.

• SCF/Item: The system uses the warehouse list defined at the SCF/item level first.

• SCF/Item class: If a warehouse list has not been defined at the SCF/item level, the system uses the warehouse list at the SCF/item class level.

• SCF: If a warehouse list has not been defined at the SCF/item class level, the system uses the warehouse list at the SCF level.

• See Warehouse List Hierarchy for more information on how the system determines which warehouse in the warehouse list to use to reserve the item.

5. Default warehouse: If the warehouses in the selected warehouse list are not eligible for reservation (unallocatable or frozen), the system will reserve the item in the default warehouse. If an item warehouse record does not exist for the default warehouse, or the default warehouse is unallocatable or frozen), the system will place the item on backorder with the reason: No Item Warehouse or No allocatable warehouse.

When the system reserves against the item’s primary warehouse: If the Evaluate Warehouses in Warehouse List Only (J47) system control value is set to Y, the system will not reserve an order line against the item’s primary warehouse unless:

• a warehouse list is not associated with the SCF of the order ship to address.

• an item warehouse record does not exist for any of the warehouses in the warehouse list associated with the SCF of the order ship to address.

• an item warehouse record does not exist for a non-HDL warehouse in the warehouse list; see HDL (Home Delivery Service) Processing.

See Warehouse Reservation Processing for examples of how the system determines which warehouse to reserve against, based on the setting of certain system control values.

Warehouse assignment hierarchy illustration:

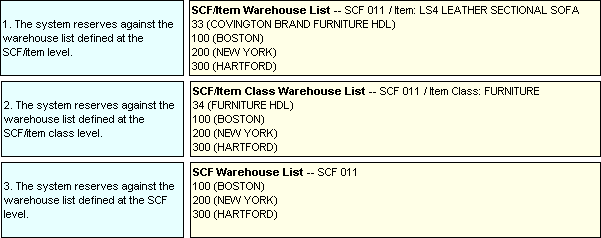

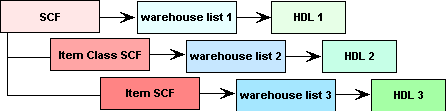

Purpose: You define a warehouse list for each SCF to which you ship. You can assign a warehouse list to an SCF at the SCF level, the SCF/item class level, or the SCF/item level.

The system uses the following hierarchy to determine which warehouse list to use:

• SCF/Item: The system uses the warehouse list defined at the SCF/item level first.

• SCF/Item class: If a warehouse list has not been defined at the SCF/item level, the system uses the warehouse list at the SCF/item class level.

• SCF: If a warehouse list has not been defined at the SCF/item class level, the system uses the warehouse list at the SCF level.

Why assign a warehouse list at different SCF levels? You may wish to assign a warehouse list at different SCF levels if some of your items are eligible for HDL delivery, meaning the item is delivered to the customer by a special delivery service; see HDL (Home Delivery Service) Processing. In this situation, you may wish to assign the standard warehouse list to the SCF level and a different warehouse list at the SCF/item or SCF/item class level that includes an HDL warehouse along with the regular warehouses in the warehouse list.

Example of warehouse list hierarchy setup:

SCF warehouse list |

SCF/item class warehouse list |

SCF/item warehouse list |

The system assigns this warehouse list to any item shipping to the SCF. 100 (BOSTON) 200 (NEW YORK) 300 (HARTFORD) |

The system only assigns this warehouse list to an item in the specified item class, such as APPLIANCES. 34 (APPLIANCES HDL) 100 (BOSTON) 200 (NEW YORK) 300 (HARTFORD) |

The system only assigns this warehouse list to the specified item, such as STVG4, STAINLESS STEEL 4 BURNER GAS STOVE. 35 (GAS APPLIANCES HDL) 100 (BOSTON) 200 (NEW YORK) 300 (HARTFORD) |

Note: The order in which the system reserves items against the warehouses in the warehouse list depends on the setting of certain system control values; see Warehouse Reservation Processing for an explanation and examples.

Warehouse list hierarchy illustration:

Warehouse List Hierarchy Example

The following warehouse lists are defined in the Work with Warehouse List (WWHL) menu option.

Warehouse list 11 |

Warehouse list 22 |

Warehouse list 33 |

whs 100 (BOSTON) whs 200 (NEW YORK) whs 300 (HARTFORD) |

whs 34 (APPLIANCES HDL) whs 100 (BOSTON) whs 200 (NEW YORK) whs 300 (HARTFORD) |

whs 33 (GAS APPLIANCES HDL) whs 100 (BOSTON) whs 200 (NEW YORK) whs 300 (HARTFORD) |

SCF code 011 is assigned the following warehouse lists in the Work with SCF Codes (WSCF) menu option.

SCF Code |

Whs list at SCF |

Whs list at SCF/item class |

Whs list at SCF/item |

011 |

11 |

22 for item class HG |

33 for item EF10 |

You enter the following items on an order that is shipping to zip code 01129.

Item |

Assigned Warehouse List |

AB10 (item class JW) |

The system assigns item AB10 to warehouse list 11 because a warehouse list has not been defined for the item at the SCF/item level or SCF/item class level. |

CD10 (item class HG) |

The system assigns item CD10 to warehouse list 22 because a warehouse list is defined for the item class associated with the item at the SCF/item class level. |

EF10 (item class HG) |

The system assigns item EF10 to warehouse list 33 because a warehouse list is defined for the item at the SCF/item level. |

Warehouse ranking attempts to ship an order out of the same warehouse, consolidating as much of the order as possible into one warehouse by assigning ranking points to each warehouse in the selected warehouse list. The system performs warehouse ranking if the Ship Complete from 1 Warehouse (B16) system control value is set to Y and a warehouse list is assigned to the SCF of the order ship to.

Warehouse ranking determines which warehouse an item will be reserved (and shipped) from. If two warehouses have equal rank, then the warehouse in the warehouse list with the higher priority is used to reserve the item.

Warehouse ranking does not apply to order lines that cannot be fully reserved in one warehouse; in this situation, the system assigns a warehouse to the order line based on the priority of each warehouse in the warehouse list.

Assigning a warehouse rank: When you enter an order line for an item, the system:

1. Determines which warehouses in the warehouse list can completely fulfill the order line.

2. For each warehouse that can completely fulfill the order line, the system assigns the warehouse 1 ranking point. No ranking points are given for the ability to partially fulfill an order line.

3. As you add order lines to the order, ranking points for each warehouse accumulate.

4. If an order line can be completely fulfilled by more than one warehouse in the warehouse list, the system reserves the order line against the warehouse in the warehouse list with the highest rank. If the warehouses in the warehouse list have the same rank, the system reserves the order line against the warehouse in the warehouse list with the higher priority.

Note:

• The sequence in which order lines are entered has an effect on the ranking that is assigned.

• Warehouse ranking does not apply to order lines for inventory which is completely unavailable in all warehouses. If an order line is completely unavailable in all warehouses, the system determines which warehouse to backorder against. See Warehouse Backorder Processing.

5. If the Reevaluate Reservation Logic at Final Accept (M01) system control value is set to Y, during the final order accept the system reevaluates the items on the order to determine if all of the items can reserve (and ship) from one warehouse in the warehouse list, evaluating each warehouse in warehouse priority sequence.

• If one warehouse in the warehouse list can reserve all of the items, the system re-reserves all of the items on the order in this warehouse.

• If one warehouse in the warehouse list cannot reserve all of the items, the items retain the warehouse currently assigned.

Warehouse Ranking Example 1

Line 1: For an order being shipped to the east coast, you enter item AB1111. The item is available in both the New York warehouse and the Chicago warehouse, so both warehouses would receive 1 ranking point. Because both warehouses have the same rank, item AB1111 would be reserved in the New York warehouse, because it is the first warehouse on the list:

First order line: item AB1111 |

||

Warehouse List |

Rank |

Reserve Warehouse? |

New York |

1 |

YES |

Chicago |

1 |

|

Line 2: The next item you add to the order is AB2222. The item is available only in the Chicago warehouse, so only the Chicago warehouse would receive a second ranking point. The item would be reserved from the Chicago warehouse.

Second order line: AB2222 |

||

Warehouse List |

Rank |

Reserve Warehouse? |

New York |

1 |

|

Chicago |

1 + 1 = 2 |

YES |

Line 3: The third item you add to the order is AB3333. The item is available in both the New York and the Chicago warehouses, so both warehouses receive an additional ranking point. The item is reserved from the Chicago warehouse (even though the New York warehouse is the first on the list) because the Chicago warehouse has a higher rank.

Third order line: AB3333 |

||

Warehouse List |

Rank |

Reserve Warehouse? |

New York |

1 + 1 = 2 |

|

Chicago |

2 + 1 = 3 |

YES |

Results: For the complete order in Example 1, the first order line would be reserved in the New York warehouse, and the second and third order lines would be reserved in the Chicago warehouse.

Reevaluate warehouse list? If the Reevaluate Reservation Logic at Final Accept (M01) system control value is set to Y, during the final order accept the system reevaluates the items on the order to determine if all of the items can reserve (and ship) from one warehouse in the warehouse list, evaluating each warehouse in warehouse priority sequence. In this example, the system would re-reserve all order lines in the Chicago warehouse.

Warehouse Ranking Example 2

For the same order, if you entered the lines in a different sequence, the results would differ.

Line 1: If the first item you add to the order is AB2222, it will be reserved in the Chicago warehouse, because it is available only in the Chicago warehouse.

First order line: AB2222 |

||

Warehouse List |

Rank |

Reserve Warehouse? |

New York |

0 |

|

Chicago |

1 |

YES |

Line 2: The next item you add to the order is AB1111. The item is available in both the Chicago and New York warehouses, so each warehouse would receive an additional ranking point. The line would be reserved from the Chicago warehouse.

Second order line: AB1111 |

||

Warehouse List |

Rank |

Reserve Warehouse? |

New York |

1 |

|

Chicago |

1 + 1 = 2 |

YES |

Line 3: The third item you add to the order is AB3333. The item is available in both the New York and the Chicago warehouses, so both warehouses receive an additional ranking point. The item is reserved from the Chicago warehouse because the Chicago warehouse has a higher rank.

Third order line: AB3333 |

||

Warehouse List |

Rank |

Reserve Warehouse? |

New York |

1 + 1 = 2 |

|

Chicago |

2 + 1 = 3 |

YES |

Line 4: The fourth item you add to the order is AB4444. The item is completely unavailable in both the New York and the Chicago warehouses, so the system ignores warehouse rank and backorders the item in the New York warehouse, because the New York warehouse is the first warehouse on the list.

Fourth order line: AB4444 (Completely unavailable) |

||

Warehouse List |

Rank |

Reserve Warehouse? |

New York |

1 + 1 = 2 |

YES, because when an item is completely unavailable, the system does not consider rank, but backorders the item in the first warehouse on the list. |

Chicago |

2 + 1 = 3 |

|

Results: For the complete order in Example 2, the first three order lines would be reserved in the Chicago warehouse. The fourth line would be backordered in the New York warehouse.

Reevaluate warehouse list? If the Reevaluate Reservation Logic at Final Accept (M01) system control value is set to Y, during the final order accept the system reevaluates the items on the order to determine if all of the items can reserve (and ship) from one warehouse in the warehouse list, evaluating each warehouse in warehouse priority sequence. In this example, the system would re-reserve all order lines in the Chicago warehouse.

System Control Values Related to Warehouse List Processing

Purpose: The following system control values are related to warehouse list processing.

The setting of these system control values determines:

• whether you wish to ship items from the warehouse closest to the shipping destination, or ship items from the warehouse with the greatest inventory.

• whether you wish to ship items as quickly as possible, regardless of how many shipments are made, or consolidate the order into as few shipments as possible.

• whether you wish to ship items from the warehouse list only, or ship items from the warehouse list and the item’s primary warehouse.

• whether you wish the system to reevaluate and re-reserve item reservation on the order during the final order accept, or retain the current warehouse assigned to each item.

See Warehouse Reservation Processing for more information on the processing the system performs, based on the setting of these system control values.

System Control Value |

Description |

Defines whether the system attempts to fulfill an order from the warehouse closest to the shipping destination that has the greatest amount of inventory using Warehouse Ranking in the warehouse list associated with the SCF of the order ship to. Y = The system attempts to fulfill an order from the warehouse closest to the shipping destination that has the greatest amount of inventory, using warehouse ranking for the selected warehouse list. See Warehouse Ranking for an explanation of the logic the system uses to determine the warehouse rank of each warehouse in the selected warehouse list. N = The system looks to first reserve inventory in the item’s primary warehouse, as defined in the Item file. If a warehouse list is defined for the order ship to address, the system uses the warehouse list to reserve inventory only if the item’s primary location does not have enough inventory to fulfill the order. In addition, if the system uses the warehouse list to reserve inventory, the system does not perform Warehouse Ranking, but instead reserves inventory using the hierarchy assigned to the warehouses in the warehouse list. |

|

Defines whether the system attempts to allocate the entire order line, even if it means the item is reserved across multiple warehouses. Y = The system attempts to allocate the entire order line, even if it means the item will be reserved across multiple warehouses. N = The system attempts to allocate the entire order line; however, if the item cannot be fully reserved from one warehouse, the system allocates what it can in the one warehouse and then backorders the remaining unfulfilled quantity. |

|

Defines whether reservation and backorder processing only reserves and backorders in warehouses defined in the selected warehouse list. Y = The system only evaluates the warehouses in the selected warehouse list during reservation and backorder processing. However, if an item warehouse record does not exist for any of the warehouses in the selected warehouse list: • reservation processing will reserve inventory from the item’s primary warehouse. • backorder processing will backorder inventory against the item’s primary warehouse. N = The system evaluates the warehouses in the selected warehouse list and the item’s primary warehouse during reservation and backorder processing. The setting of the Ship Complete from 1 Warehouse (B16) system control value determines the order in which the system evaluates the item’s primary warehouse and the warehouses in the selected warehouse list. |

|

Defines whether the system reevaluates item reservation on a ship to order during the final order accept, and if possible, re-reserve items so that the items ship from a single warehouse in the warehouse list. Y = The system reevaluates item reservation on a ship to order during the final order accept. The system evaluates the warehouses in the selected warehouse list in warehouse priority sequence. • If all of the reserved items can reserve in one warehouse in the warehouse list, the system re-reserves all of the items in this warehouse. • If all of the reserved items cannot reserve in one warehouse in the warehouse list, the system retains the current warehouse assigned to each item. N = The system does not reevaluate item reservation during the final order accept. Note: If you enter Y in this system control value, you must also enter Y in the Ship Complete from 1 Warehouse (B16) system control value. |

Warehouse Reservation Processing

If a warehouse list is not defined for the SCF on the order, the system reserves the order from the primary warehouse only; see Warehouse Reservation Without Warehouse List.

If a warehouse list is defined for the SCF on the order, the System Control Values Related to Warehouse List Processing control which warehouse(s) the system reserves against; see Warehouse List Reservation.

Note: If you define a warehouse override, the system will reserve inventory against the warehouse override, regardless of the setting of these system control values; see Warehouse Reservation Hierarchy.

For more information: See:

• Warehouse Reservation Hierarchy for more information on the hierarchy the system uses to determine the warehouse to assign to an order line.

• Warehouse List Hierarchy for more information on the hierarchy the system uses to determine which warehouse list to select for an order.

• Warehouse Ranking for more information on how the system selects a warehouse in the warehouse list to reserve against, based on the warehouse selected for previous items on the order.

• Warehouse Backorder Processing for more information on the warehouse the system backorders against based on setting of certain system control values.

Warehouse Reservation Without Warehouse List

When a warehouse list is not defined for the SCF on the order, the system reserves the order from the primary warehouse only.

In this situation, the System Control Values Related to Warehouse List Processing do not apply:

• Ship Complete from 1 Warehouse (B16) = Can be set to N or Y

• Split Line Over Multiple Warehouses (B19) = Can be set to N or Y

• Evaluate Warehouses in Warehouse List Only (J47) = Can be set to N or Y

• Reevaluate Reservation Logic at Final Accept (M01) = Can be set to N or Y

Results:

1. Reserve the entire order line quantity in the item’s primary warehouse.

2. If the entire order line quantity cannot be reserved in the primary warehouse, then reserve as much inventory as possible from the primary warehouse and backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Warehouse Reservation: No Warehouse List

You enter the following order lines on an order shipping to zip code 02053. SCF 020 is not associated with a warehouse list.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) |

6 |

The system reserves 6 units in warehouse 206 and backorders 4 units in warehouse 206. |

CD10 |

26 |

206 (primary whs) 601 602 |

6 1 10 |

The system reserves 6 units in warehouse 206 and backorders 20 units in warehouse 206. |

Purpose: When a warehouse list is defined for the SCF on the order, the settings of the Ship Complete from 1 Warehouse (B16), Split Line Over Multiple Warehouses (B19), Evaluate Warehouses in Warehouse List Only (J47), and Reevaluate Reservation Logic at Final Accept (M01) system control values control which warehouse(s) the system reserves against.

SCV settings: |

For processing details see: |

• B16 = N • B19 = N • J47 = N • M01 = N |

|

• B16 = N • B19 = Y • J47 = N • M01 = N |

|

• B16 = N • B19 = Y • J47 = Y • M01 = N |

|

• B16 = N • B19 = N • J47 = Y • M01 = N |

|

• B16 = Y • B19 = N • J47 = N • M01 = N |

|

• B16 = Y • B19 = Y • J47 = N • M01 = N |

|

• B16 = Y • B19 = N • J47 = Y • M01 = N |

|

• B16 = Y • B19 = Y • J47 = Y • M01 = N |

|

• B16 = Y • B19 = does not apply • J47 = does not apply • M01 = Y |

Whs List Reservation: Whs Ranking, Reevaluate Reservation at Order Accept |

For more information: See Warehouse List Hierarchy for more information on how the system determines which warehouse list to assign to an order line.

Whs List Reservation: No Whs Ranking, Reserve Line in 1 Whs, Include Primary, Do not Reevaluate at Order Accept

In this scenario, the system tries to fully reserve the order in the primary warehouse and then in the warehouse in the warehouse list that is closest to the shipping destination. The system consolidates each order line into as few shipments as possible.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = N (warehouse ranking not performed)

• Split Line Over Multiple Warehouses (B19) = N (reserve line in one warehouse)

• Evaluate Warehouses in Warehouse List Only (J47) = N (include item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in the item’s primary warehouse.

2. If the entire order line quantity cannot be reserved in the primary warehouse, then reserve the entire order line quantity in one warehouse in the warehouse list, searching for one warehouse in warehouse priority sequence.

3. If the entire order line quantity cannot be reserved in one warehouse in the warehouse list, then reserve as much inventory as possible in the warehouse with the greatest inventory and backorder the remaining quantity in that warehouse. The system evaluates the primary warehouse and the warehouses in the warehouse list to determine which warehouse has the greatest inventory.

4. If the reservation warehouse is an HDL warehouse, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

5. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: No Whs Ranking, Reserve Line in 1 Whs, Include Primary, Do not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, 603, and 600. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 10 units in warehouse 602 since that is the first warehouse in the warehouse list that can fulfill the order quantity. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603 and backorders 1 unit in warehouse 603. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603 and backorders 20 units in warehouse 603. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 6 units in warehouse 7 and backorders 6 units in warehouse 7 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

16 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 1 8 |

The system reserves 8 units in warehouse 600 and backorders 8 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item IJ10. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 15 units in warehouse 600 and backorders 15 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: No Whs Ranking, Reserve Line in Multi Whs, Include Primary, Do Not Reevaluate at Order Accept

In this scenario, the system reserves the order first in the primary warehouse and then in the warehouse list, starting with the warehouse that is closest to the shipping destination. The system ships each order line as quickly as possible, from as many warehouses as is needed to fulfill the entire order line quantity.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = N (do not perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = Y (reserve line in multiple warehouses)

• Evaluate Warehouses in Warehouse List Only (J47) = N (include item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in the item’s primary warehouse.

2. If the entire order line quantity cannot be reserved in the primary warehouse, then reserve as much inventory as possible in the primary warehouse and fulfill the remaining quantity using the warehouse list, in warehouse priority sequence, until the remaining quantity has been reserved.

3. If the entire order line quantity cannot be reserved in the primary warehouse and the warehouses in the warehouse list, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

4. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: No Whs Ranking, Reserve Line in Multi Whs, Include Primary, Do Not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, and 603. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 6 units in warehouse 206, 1 unit in warehouse 601, and 3 units in warehouse 602. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 6 units in warehouse 206, 1 unit in warehouse 601, 10 units in warehouse 602, and 9 units in warehouse 603. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 6 units in warehouse 206, 1 unit in warehouse 601, 10 units in warehouse 602, and 25 units in warehouse 603. The system backorders the remaining 3 units in warehouse 601 since that is the first warehouse in the warehouse list. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 6 units in warehouse 7 and 4 units in warehouse 600. The system backorders 2 units in warehouse 207 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

12 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 0 8 |

The system reserves 6 units in warehouse 7 and 6 units in warehouse 600. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 10 units in warehouse 206, 15 units in warehouse 600, 1 unit in warehouse 601, and 2 units in warehouse 602. The system backorders 2 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: No Whs Ranking, Reserve Line in Multi Whs, Exclude Primary, Do Not Reevaluate at Order Accept

In this scenario, the system tries to fully reserve the order in the warehouse in the warehouse list that is closest to the shipping destination. The system ships each order line as quickly as possible, from as many warehouses as is needed to fulfill the entire order line quantity.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = N (do not perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = Y (reserve line in multiple warehouses)

• Evaluate Warehouses in Warehouse List Only (J47) = Y (exclude item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in the warehouses in the warehouse list, starting with the warehouse with highest priority and continuing through the warehouses in the warehouse list until the entire order line quantity is reserved.

2. If the warehouses in the warehouse list cannot fulfill the entire order line quantity, then reserve as much inventory as possible in the warehouses in the warehouse list and backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

3. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the item’s primary warehouse, even if the primary warehouse is an HDL warehouse.

4. If an item warehouse record does not exist for any of the warehouses in the selected warehouse list:

• Reserve the entire order line quantity in the item’s primary warehouse.

• If the entire order line quantity cannot be reserved in the primary warehouse, then reserve as much inventory as possible in the primary warehouse and backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: No Whs Ranking, Reserve Line in Multi Whs, Exclude Primary, Do Not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, and 603. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 1 unit in warehouse 601 and 9 units in warehouse 602. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 1 unit in warehouse 601, 10 units in warehouse 602, and 15 units in warehouse 603. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 1 unit in warehouse 601, 10 units in warehouse 602, and 25 units in warehouse 603. The system backorders the remaining 9 units in warehouse 601 since that is the first warehouse in the warehouse list. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 4 units in warehouse 600. The system backorders 8 units in warehouse 207 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

12 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 0 8 |

The system reserves 8 units in warehouse 600. The system backorders 4 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item IJ10. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 15 units in warehouse 600, 1 unit in warehouse 601, and 2 units in warehouse 602. The system backorders 12 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: No Whs Ranking, Reserve Line in 1 Whs, Exclude Primary, Do Not Reevaluate at Order Accept

In this scenario, the system tries to fully reserve the order in the warehouse in the warehouse list that is closest to the shipping destination. The system consolidates each order line into as few shipments as possible.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = N (do not perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = N (reserve line in one warehouse)

• Evaluate Warehouses in Warehouse List Only (J47) = Y (exclude item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in the first warehouse in the warehouse list that can fulfill the entire quantity.

2. If one warehouse in the warehouse list cannot fulfill the entire order line quantity, then reserve as much inventory as possible in the warehouse in the warehouse list that contains the greatest inventory and then backorder the remaining quantity in that warehouse.

3. If the reservation warehouse is an HDL warehouse, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

4. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the item’s primary warehouse, even if the primary warehouse is an HDL warehouse.

5. If an item warehouse record does not exist for any of the warehouses in the selected warehouse list:

• Reserve the entire order line quantity in the item’s primary warehouse.

• If the entire order line quantity cannot be reserved in the primary warehouse, then reserve as much inventory as possible from the primary warehouse and backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: No Whs Ranking, Reserve Line in 1 Whs, Exclude Primary, Do Not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, and 603. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 10 units in warehouse 602 since that is the first warehouse in the warehouse list that can fulfill the order quantity. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603 and backorders 1 unit in warehouse 603. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603 and backorders 20 units in warehouse 603. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 4 units in warehouse 600. The system backorders 8 units in warehouse 207 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

12 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 0 8 |

The system reserves 8 units in warehouse 600. The system backorders 4 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 15 units in warehouse 600 and backorders 15 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: Whs Ranking, Reserve Line in 1 Whs, Include Primary, Do not Reevaluate at Order Accept

In this scenario, the system tries to fully reserve the order in the warehouse in the warehouse list that can fulfill the greatest amount of inventory across all order lines, and then in the primary warehouse. The system consolidates each order line into as few shipments as possible.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = Y (perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = N (reserve line in one warehouse)

• Evaluate Warehouses in Warehouse List Only (J47) = N (include item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in one warehouse in the warehouse list, using Warehouse Ranking.

2. If the entire order line quantity cannot be reserved in one warehouse in the warehouse list, then reserve the entire order line quantity in the item’s primary warehouse.

3. If the entire order line quantity cannot be reserved in the primary warehouse, then reserve as much inventory as possible in the warehouse with the greatest inventory and backorder the remaining quantity in that warehouse. The system evaluates the primary warehouse and the warehouses in the warehouse list to determine which warehouse has the greatest inventory.

4. If the reservation warehouse is an HDL warehouse, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

5. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: Whs Ranking, Reserve Line in 1 Whs, Include Primary, Do not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, 603, and 600. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 10 units in warehouse 602 since that is the first warehouse in the warehouse list that can fulfill the order quantity. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603 and backorders 1 unit in warehouse 603. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603 and backorders 20 units in warehouse 603. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 6 units in warehouse 7 and backorders 6 units in warehouse 7 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

12 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 8 |

The system reserves 8 units in warehouse 600 and backorders 4 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item IJ10. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 15 units in warehouse 600 and backorders 15 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: Whs Ranking, Reserve Line in Multi Whs, Include Primary, Do not Reevaluate at Order Accept

In this scenario, the system tries to fully reserve the order in the warehouse in the warehouse list that can fulfill the greatest amount of inventory across all order lines. If an entire order line cannot be fully reserved in one warehouse, the system reserves in the primary warehouse and other warehouses in the warehouse list. The system ships each order line as quickly as possible, from as many warehouses as is needed to fulfill the entire order line quantity.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = Y (perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = Y (reserve line in multiple warehouses)

• Evaluate Warehouses in Warehouse List Only (J47) = N (include item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in one warehouse in the warehouse list, using Warehouse Ranking.

2. If the entire order line quantity cannot be reserved in one warehouse in the warehouse list, then reserve as much inventory as possible in the item’s primary warehouse and fulfill the remainder of the order line using the warehouse list, in warehouse priority sequence, until all units of the order line have been reserved.

3. If the entire order line quantity cannot be reserved in the warehouse list and the primary warehouse, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

4. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: Whs Ranking, Reserve Line in Multi Whs, Include Primary, Do not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, and 603. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 10 units in warehouse 602 since that is the first warehouse in the warehouse list that can fulfill the order quantity. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 6 units in warehouse 206, 1 unit in warehouse 601, 10 units in warehouse 602, and 9 units in warehouse 603. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 6 units in warehouse 206, 1 unit in warehouse 601, 10 units in warehouse 602, and 25 units in warehouse 603. The system backorders the remaining 3 units in warehouse 601. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 6 units in warehouse 7 and 4 units in warehouse 600. The system backorders 2 units in warehouse 7 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

12 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 1 8 |

The system reserves 6 units in warehouse 7 and 6 units in warehouse 600. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 10 units in warehouse 206, 15 units in warehouse 600, 1 unit in warehouse 601, and 2 units in warehouse 602. The system backorders 2 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: Whs Ranking, Reserve Line in 1 Whs, Exclude Primary, Do Not Reevaluate at Order Accept

In this scenario, the system tries to fully reserve the order in the warehouse in the warehouse list that can fulfill the most inventory, across all order lines. The system consolidates each order line into as few shipments as possible.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = Y (perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = N (reserve line in one warehouse)

• Evaluate Warehouses in Warehouse List Only (J47) = Y (exclude item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in one warehouse in the warehouse list, using Warehouse Ranking.

2. If no warehouse in the warehouse list can fulfill the entire order line quantity, reserve as much of the order line as possible in the warehouse in the warehouse list with the greatest inventory, then backorder the remaining quantity in that warehouse.

3. If the reservation warehouse is an HDL warehouse, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

4. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the item’s primary warehouse, even if the primary warehouse is an HDL warehouse.

5. If an item warehouse record does not exist for any of the warehouses in the selected warehouse list:

• Reserve the entire order line quantity in the item’s primary warehouse.

• If the entire order line quantity cannot be reserved in the primary warehouse, then reserve as much inventory as possible in the primary warehouse and backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: Whs Ranking, Reserve Line in 1 Whs, Exclude Primary, Do Not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, and 603. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 10 units in warehouse 602 since that is the first warehouse in the warehouse list that can fulfill the order quantity. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603. The system backorders 1 unit in warehouse 603 since that is the warehouse in the warehouse list where the available inventory was reserved. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 25 units in warehouse 603. The system backorders the remaining 20 units in warehouse 603 since that is the warehouse in the warehouse list where the available inventory was reserved. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 4 units in warehouse 600 and backorders 8 units in warehouse 207 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

12 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 0 8 |

The system reserves 8 units in warehouse 600 and backorders 4 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 15 units in warehouse 600 and backorders 15 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: Whs Ranking, Reserve Line in Multi Whs, Exclude Primary, Do Not Reevaluate at Order Accept

In this scenario, the system reserves the order in the warehouse in the warehouse list that can fulfill the most inventory, across all order lines. The system ships each order line as quickly as possible, from as many warehouses as is needed to fulfill the entire order line quantity.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = Y (perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = Y (reserve line in multiple warehouses)

• Evaluate Warehouses in Warehouse List Only (J47) = Y (exclude item’s primary warehouse)

• Reevaluate Reservation Logic at Final Accept (M01) = N (do not reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in one warehouse in the warehouse list, using Warehouse Ranking.

2. If no warehouse on the list can fulfill the entire order line quantity, then fulfill the order line quantity using the warehouse list, in warehouse priority sequence, until the remaining quantity has been reserved.

3. If the entire order line cannot be reserved in the warehouses in the warehouse list, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list.

4. If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the item’s primary warehouse, even if the primary warehouse is an HDL warehouse.

5. If an item warehouse record does not exist for any of the warehouses in the selected warehouse list:

• Reserve the entire order line quantity in the item’s primary warehouse.

• If the entire order line quantity cannot be reserved in the primary warehouse, then reserve as much inventory as possible in the primary warehouse and backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse.

Example Whs List Reservation: Whs Ranking, Reserve Line in Multi Whs, Exclude Primary, Do Not Reevaluate at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, and 603. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

10 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 10 units in warehouse 602 since that is the first warehouse in the warehouse list that can fulfill the order quantity. |

CD10 |

26 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 1 unit in warehouse 601, 10 units in warehouse 602, and 15 units in warehouse 603. |

EF10 |

45 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 1 unit in warehouse 601, 10 units in warehouse 602, and 25 units in warehouse 603. The system backorders the remaining 9 units in warehouse 601 since that is the first warehouse in the warehouse list. |

GH10 |

12 |

7 (primary, HDL) 600 (4th whs in list, HDL) |

6 4 |

The system reserves 4 units in warehouse 600 and backorders 8 units in warehouse 207 since a non-HDL warehouse does not exist in the warehouse list for item GH10. |

IJ10 |

12 |

7 (primary, HDL) 601 (1st whs in list) 600 (4th whs in list, HDL) |

6 0 8 |

The system reserves 8 units in warehouse 600 and backorders 8 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list. |

KL10 |

30 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 600 (4th whs in list, HDL) |

10 1 2 15 |

The system reserves 15 units in warehouse 600, 1 unit in warehouse 601, and 2 units in warehouse 602. The system backorders 12 units in warehouse 601 since that is the first non-HDL warehouse in the warehouse list for item KL10. |

Whs List Reservation: Whs Ranking, Reevaluate Reservation at Order Accept

In this scenario, the system tries to reserve the order in the warehouse in the warehouse list that can fulfill the greatest amount of inventory across all order lines. The settings of the Split Line Over Multiple Warehouses (B19) and Evaluate Warehouses in Warehouse List Only (J47) system control values control which warehouse(s) the system reserves against as you enter the items on the order. During the final order accept, the system reevaluates the items on the order to see if all of the items can ship from one warehouse in the warehouse list, evaluating the warehouses in warehouse list priority sequence.

• If all of the reserved items can ship from one warehouse in the warehouse list, the system re-reserves the items in that one warehouse.

• If all of the reserved items cannot ship from one warehouse in the warehouse list, the system retains the current warehouse assigned to each item.

Items on backorder: Items that are fully on backorder are not included in the reevaluation that happens during the final order accept; see Warehouse Backorder Processing for more information on the warehouse the system backorders against based on the setting of certain system control values and see Evaluating Backorders for Reservation for more information on how the system determines which backordered items receive stock first.

Items that are partially reserved: If an order line contains an item that is partially reserved and partially on backorder, the system includes the reserved quantity of the item in the reevaluation that happens during the final order accept.

Set items: When the Reevaluate Reservation Logic at Final Accept (M01) system control value is set to Y, the system also ensures that at least one component item ships from the warehouse in which the main set item appears on the pick slip.

The related system control values are set as follows:

• Ship Complete from 1 Warehouse (B16) = Y (perform warehouse ranking)

• Split Line Over Multiple Warehouses (B19) = can be Y or N

• Evaluate Warehouses in Warehouse List Only (J47) = can be Y or N

• Reevaluate Reservation Logic at Final Accept (M01) = Y (reevaluate at order accept)

Results:

1. Reserve the entire order line quantity in one warehouse in the warehouse list, using Warehouse Ranking.

2. If the entire order line quantity cannot be reserved in one warehouse in the warehouse list, then look at the settings of the Split Line Over Multiple Warehouses (B19) and Evaluate Warehouses in Warehouse List Only (J47) system control values to determine the warehouse(s) to reserve against.

3. During the final order accept, reevaluate the reserved items on the order to see if all of the items can ship from one warehouse in the warehouse list, evaluating the warehouses in warehouse list priority sequence.

• If all of the reserved items on the order can ship from one warehouse in the warehouse list, re-reserve the items on the order to that warehouse. Any items on backorder retain the warehouse currently assigned.

• If all of the reserved items on the order cannot ship from one warehouse in the warehouse list, retain the warehouse assigned to each item.

Example Whs List Reservation: Whs Ranking, Reevaluate Reservation at Order Accept

You enter the following order lines on an order shipping to zip code 01129. SCF 011 is associated with warehouse list 6, which contains warehouses 601, 602, and 603. The default warehouse is 207.

Item |

Order Qty |

Item Warehouses |

Avail Qty |

Results |

AB10 |

1 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 1 unit in warehouse 601 since that is the first warehouse in the warehouse list that can fulfill the order quantity. |

BO10 |

1 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

0 0 0 0 |

The system backorders 1 unit in warehouse 206. |

CD10 |

2 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 10 25 |

The system reserves 2 units in warehouse 602 since that is the first warehouse in the list that can fulfill the order quantity. |

EF10 |

3 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 2 5 |

The system reserves 3 units in warehouse 603 since that is the first warehouse in the list that can fulfill the order quantity. |

GH10 |

4 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

6 1 1 1 |

The system backorders 4 units in warehouse 206. |

SETM |

1 |

206 (primary whs) |

0 |

Master set item The system assigns warehouse 206 to the master set item. |

SET1 |

1 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

10 1 2 1 |

Set Component 1 The system reserves 1 unit in warehouse 601 since that is the first warehouse in the list that can fulfill the order quantity. |

SET2 |

2 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

20 1 2 3 |

Set Component 2 The system reserves 2 units in warehouse 602 since that is the first warehouse in the list that can fulfill the order quantity. |

SET3 |

3 |

206 (primary whs) 601 (1st whs in list) 602 (2nd whs in list) 603 (3rd whs in list) |

16 1 2 3 |

Set Component 3 The system reserves 3 units in warehouse 603 since that is the first warehouse in the list that can fulfill the order quantity. |

During the final order accept, the system reevaluates the items on the order to see if all of the reserved items can ship from one warehouse in the warehouse list. In this example, warehouse 603 in the warehouse list can ship all of the items. The system: • re-reserves the 1 unit of AB10 from warehouse 601 to warehouse 603 • re-reserves the 2 units of CD10 from warehouse 602 to warehouse 603 • re-reserves the master set item from warehouse 601 to warehouse 603 • re-reserves the 1 unit of SET1 from warehouse 601 to warehouse 603 • re-reserves the 2 units of SET2 from warehouse 602 to warehouse 603 |

||||

Warehouse Backorder Processing

Purpose: When you enter an order line for an item on backorder, the system determines which warehouse to backorder against.

Once the system determines which warehouse to backorder against, the system updates the order line with the backorder warehouse. However, the backordered warehouse may not be the actual warehouse that fulfills the backorder quantity. See Evaluating Backorders for Reservation for more information on how the system determines which backordered order lines are eligible for reservation, based on the warehouse whose inventory levels increased.

Note: When you run batch purchase order layering, the system updates the expected ship date for a backordered order line, but does not update the backorder warehouse on the order line, even if the warehouse associated with the purchase order can fulfill the backordered order line. For example, if the backorder warehouse on an order line is the item’s primary warehouse, and you enter a purchase order for a warehouse that is part of the warehouse list associated with the order line, the system does not update the backorder warehouse on the order line to the warehouse in the warehouse list, even though the order line may be fulfilled by the warehouse in the warehouse list and not the primary warehouse.

The following tables indicate the warehouse the system backorders against, based on the setting of the Ship Complete from 1 Warehouse (B16), Split Line Over Multiple Warehouses (B19), and Evaluate Warehouses in Warehouse List Only (J47) system control values.

• Warehouse Reservation Without Warehouse List

For more information: See:

• Warehouse Reservation Hierarchy for more information on the hierarchy the system uses to determine the warehouse to assign to an order line.

• Warehouse List Hierarchy for more information on the hierarchy the system uses to determine which warehouse list to select for an order.

• Warehouse Ranking for more information on how to the system selects a warehouse in the warehouse list to reserve against, based on the warehouse selected for previous items on the order.

• Warehouse Reservation Processing for more information on how the system determines which warehouse(s) to reserve against, based on the setting of certain system control values.

Warehouse Backorders -- Warehouse List Not Defined for SCF

SCV B16 |

SCV B19 |

SCV J47 |

Results |

N or Y |

N or Y |

N or Y |

Backorder in the item’s primary warehouse, even if the primary warehouse is an HDL warehouse. |

Warehouse backorder example: You enter the following order lines on an order shipping to zip code 02053. SCF 020 is not associated with a warehouse list.

Item |

BO Qty |

Item Warehouses |

HDL? |

Results |

B01 |

10 |

206 (primary whs) 600 |

N Y |

The system backorders 10 units in warehouse 206. |

B02 |

10 |

207 (primary whs) 601 |

Y N |

The system backorders 10 units in warehouse 207. |

B03 |

10 |

207 (primary whs) 600 |

Y Y |

The system backorders 10 units in warehouse 207. |

Warehouse Backorders -- Warehouse List Defined for SCF

Warehouse backorder scenario 1:

SCV B16 |

SCV B19 |

SCV J47 |

Results |

N = whs ranking not performed |

N = reserve line in one whs |

N = include item’s primary whs |

Complete backorder: • Backorder in the item’s primary warehouse. • If the primary warehouse is an HDL warehouse, then backorder in the first non-HDL warehouse in the warehouse list. • If an item warehouse record does not exist for a non-HDL warehouse in the warehouse list, then backorder in the primary warehouse, even if the primary warehouse is an HDL warehouse. Partial backorder: • Backorder the remaining quantity in the reservation warehouse. • If the reservation warehouse is an HDL warehouse, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list. • If a non-HDL warehouse does not exist in the warehouse list, then backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse |

Y = whs ranking performed |

N = reserve line in one whs |

N = include item’s primary whs |

Warehouse backorder scenario 1 example: You enter the following order lines for items on backorder.

Item |

BO Qty |

Item Warehouses |

HDL? |

Rsv Qty |

Results |

B01 |

10 |

206 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

N Y N |

0 |

The system backorders 10 units in warehouse 206. |

B02 |

10 |

207 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

Y Y N |

0 |

The system backorders 10 units in warehouse 601. |

B03 |

10 |

207 (primary whs) 600 (1st whs in list) |

Y Y |

0 |

The system backorders 10 units in warehouse 207. |

B04 |

5 |

206 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

N Y N |

5 in whs 600 |

The systems backorders 5 units in warehouse 601. |

B05 |

5 |

207 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

Y Y N |

5 in whs 601 |

The system backorders 5 units in warehouse 601. |

B06 |

5 |

207 (primary whs) 600 (1st whs in list) |

Y Y |

5 in whs 600 |

The system backorders 5 units in warehouse 207. |

Warehouse backorder scenario 2:

SCV B16 |

SCV B19 |

SCV J47 |

Results |

Y = whs ranking performed |

Y = reserve line in multiple whs |

N = include item’s primary whs |

Complete or partial backorder: • Backorder in the first non-HDL warehouse in the warehouse list. • If a non-HDL warehouse does not exist in the warehouse list or an item warehouse record does not exist for the non-HDL warehouses in the warehouse list, then backorder in the item’s primary warehouse, even if the primary warehouse is an HDL warehouse. |

N = whs ranking not performed |

Y = reserve line in multiple whs |

N = include item’s primary whs |

|

N = whs ranking not performed |

Y = reserve line in multiple whs |

Y = exclude item’s primary whs |

|

Y = whs ranking performed |

Y = reserve line in multiple whs |

Y = exclude item’s primary whs |

Warehouse backorder scenario 2 example: You enter the following order lines for items on backorder.

Item |

BO Qty |

Item Warehouses |

HDL? |

Rsv Qty |

Results |

B01 |

10 |

206 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

N Y N |

0 |

The system backorders 10 units in warehouse 601. |

B02 |

10 |

207 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

Y Y N |

0 |

The system backorders 10 units in warehouse 601. |

B03 |

10 |

207 (primary whs) 600 (1st whs in list) |

Y Y |

0 |

The system backorders 10 units in warehouse 207. |

B04 |

5 |

206 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

N Y N |

5 in whs 600 |

The systems backorders 5 units in warehouse 601. |

B05 |

5 |

207 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

Y Y N |

5 in whs 601 |

The system backorders 5 units in warehouse 601. |

B06 |

5 |

207 (primary whs) 600 (1st whs in list) |

Y Y |

5 in whs 600 |

The system backorders 5 units in warehouse 207. |

Warehouse backorder scenario 3:

SCV B16 |

SCV B19 |

SCV J47 |

Results |

N = whs ranking not performed |

N = reserve line in one whs |

Y = exclude item’s primary whs |

Complete backorder: • Backorder in the first non-HDL warehouse in the warehouse list. • If a non-HDL warehouse does not exist in the warehouse list or an item warehouse record does not exist for the non-HDL warehouses in the warehouse list, then backorder in the item’s primary warehouse, even if the primary warehouse is an HDL warehouse. Partial backorder: • Backorder the remaining quantity in the reservation warehouse. • If the reservation warehouse is an HDL warehouse, then backorder the remaining quantity in the first non-HDL warehouse in the warehouse list. • If an item warehouse record does not exist for any of the warehouses in the selected warehouse list, then backorder the remaining quantity in the primary warehouse, even if the primary warehouse is an HDL warehouse. |

Y = whs ranking performed |

N = reserve line in one whs |

Y = exclude item’s primary whs |

Warehouse backorder scenario 3 example: You enter the following order lines for items on backorder.

Item |

BO Qty |

Item Warehouses |

HDL? |

Rsv Qty |

Results |

B01 |

10 |

206 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

N Y N |

0 |

The system backorders 10 units in warehouse 601. |

B02 |

10 |

207 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

Y Y N |

0 |

The system backorders 10 units in warehouse 601. |

B03 |

10 |

207 (primary whs) 600 (1st whs in list) |

Y Y |

0 |

The system backorders 10 units in warehouse 207. |

B04 |

5 |

206 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

N Y N |

5 in whs 600 |

The systems backorders 5 units in warehouse 601. |

B05 |

5 |

207 (primary whs) 600 (1st whs in list) 601 (2nd whs in list) |

Y Y N |

5 in whs 601 |

The system backorders 5 units in warehouse 601. |

B06 |

5 |

207 (primary whs) 600 (1st whs in list) |

Y Y |

5 in whs 600 |

The system backorders 5 units in warehouse 207. |

Evaluating Backorders for Reservation

Purpose: When inventory levels increase, such as through purchase order receipts or inventory transactions, the Evaluate Backorders Async uses the order date and the backorder priority on the order line to determine which backordered items receive stock first, allocating inventory to backordered lines that have the earliest order date and the highest backorder priority.

The Evaluate Backorder process evaluates all order lines that are backordered, including:

• order lines that are completely backordered.

• order lines that are partially backordered.

• order lines that contain a backorder quantity that is less than the amount that has been adjusted in to the warehouse.

• order lines that contain a backorder quantity that is greater than the amount that has been adjusted in to the warehouse, meaning the adjusted in quantity will not be able to reserve the entire backorder quantity on the order line.

Once the inventory is reserved, the system:

• updates the backorder quantity, reserved quantity, and available quantity in the item warehouse.

• updates the reserved order lines.

• If the order line has been fully reserved, removes the backorder warehouse from the order line; otherwise, the backorder warehouse remains on the order line.

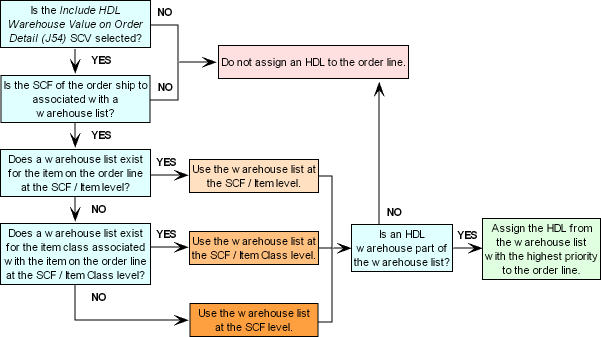

The system will continue to reserve backordered order lines until the stock has been completely allocated or all order lines have been evaluated.