Chapter 26: Generic Item Transaction History Outbound API

Purpose: CWDirect allows you to capture item transaction history to send to another system, such as a warehouse management system.

In this chapter:

• Item Transaction History Outbound Process

• Identifying Item Transaction History Triggers

• When are Item Transaction History Triggers Created?

• Item Transaction History Download Processing

• Item Transaction History Outbound Trigger Activities

• Item Transaction History Outbound Trigger Rules

• Item Transaction History Outbound XML Inclusion

• Item Transaction History Outbound XML Message (CWInvXActionOut)

• Item Transaction History Outbound Message: Sample XMLs

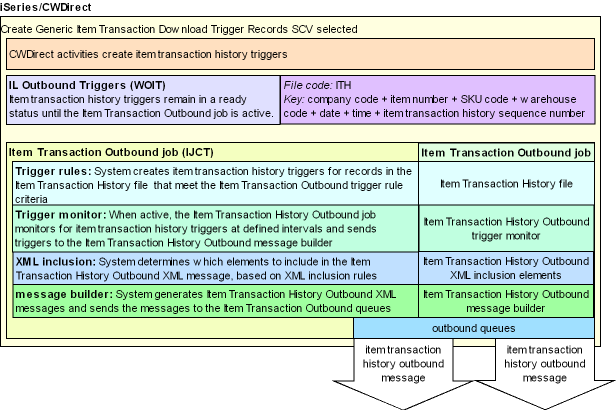

Item transaction history download information flow: This flowchart explains how item transaction history information is downloaded from CWDirect.

Item Transaction History Outbound Process

Purpose: The system creates item transaction history triggers in the IL Outbound Trigger file when an item transaction history record is created. The Item Transaction History Outbound job in the Working with Integration Layer Processes (IJCT) menu option monitors the IL Outbound file for item transaction history triggers to process and generates an Item Transaction History Outbound XML Message (CWInvXActionOut) to send to the remote system.

Identifying Item Transaction History Triggers

You can view item transaction history triggers in the IL Outbound Trigger file at the Work with Outbound Interface Transactions Screen.

Each trigger in the IL Outbound Trigger file contains a:

• File code: indicating the type of information to download and which IL process job processes the trigger. For item transaction history triggers, the File code is ITH.

• Key: indicating the specific record to download. For item transaction history triggers, the Key identifies the specific company, item and SKU, warehouse, date and time, and item transaction history sequence number associated with the item transaction history trigger. The SKU code is included only if the item is a SKUed item.

Example: The Key 555SYSPROSKU RED WMNS SMLL2051060518090503001 represents:

Key |

Represents |

555 |

company code |

SYSPROSKU |

item number |

RED WMNS SMLL |

SKU code |

205 |

warehouse code |

1060518 |

date |

090503 |

time |

001 |

item transaction history sequence number |

• Capture type: indicating the type of activity performed against the record. For item transaction history triggers, the Capture type is always A, indicating the item transaction history record was created. The system does not create an item transaction history trigger if you change or delete an item transaction history record.

When are Item Transaction History Triggers Created?

The Create Generic Item Transaction Download Trigger Records (J52) system control value controls whether the system creates item transaction history triggers in the IL Outbound Trigger file.

• If this system control value is set to Y, the system creates an item transaction history trigger in the IL Outbound Trigger file when an item transaction history record is created in the Item Transaction History file.

• If this system control value is set to N, the system does not create item transaction history triggers in the IL Outbound Trigger file.

Item Transaction History Download Processing

To generate an item transaction history outbound message, the system performs the following steps.

1. When an item transaction history record is created in the Item Transaction History file, the system evaluates the trigger rules defined for the Item Transaction History Outbound job to determine if an item transaction history trigger is created. Item Transaction History Outbound trigger rules define the criteria the item transaction history record must meet in order for the system to create an item transaction history trigger. See Item Transaction History Outbound Trigger Rules.

2. Creates item transaction history triggers, based on CWDirect activities that create item transaction history records in the Item Transaction History file. See Item Transaction History Outbound Trigger Activities for a list of activities that create item transaction history triggers.

3. When active, the trigger monitor defined for the Item Transaction History Outbound job looks for unprocessed item transaction history triggers to process at defined intervals, based on the value defined in the Outbound delay time field.

The Item Transaction History Outbound trigger monitor:

• looks for item transaction history triggers with the File code ITH and a status of ready (R).

• sends each item transaction history trigger to the message builder defined for the Item Transaction History Outbound job.

4. The Item Transaction History Outbound message builder determines:

• which item transaction history record to download, based on the item transaction history trigger Key. The Key field for the item transaction history trigger consists of company code + item number + SKU code + warehouse code + date + time + item transaction history sequence number. The SKU code is included only if the item is a SKUed item. See Identifying Item Transaction History Triggers.

• which elements to include in the item transaction history outbound message, based on the XML inclusion rules. See Item Transaction History Outbound XML Inclusion.

• sends the generated item transaction history outbound message to the queue(s) defined for the Item Transaction History Outbound job that are active (the Enabled field is set to Y).

Item Transaction History Outbound Trigger Activities

The system creates an item transaction history trigger when a record is created in the Item Transaction History file. The system creates a record in the Item Transaction History file when you process an inventory transaction.

The following table indicates the types of inventory transactions that create a record in the Item Transaction History file. Additionally, you can create your own inventory transaction codes using the Work with Inventory Transaction Codes (WITC) menu option.

Code |

Description |

Effect on Inventory Levels |

A |

Adjustment |

Used in inventory transactions to increase on-hand if positive quantity is entered; decreases on-hand if negative quantity is entered. |

C |

Customer Return |

Used by the system when processing return merchandise via the Return Authorization module or Order Maintenance. Return transactions will always increase the on-hand quantity in the specified warehouse. |

E |

Express Bill |

Used by the system when processing an order that will not go through the normal pick and confirmation cycle (i.e., merchandise is already picked and shipped before the order is entered). |

G |

Item to Item Transfer |

Used in inventory transactions to transfer one item to another, such as when you stop offering an item independently and include it in a grab bag instead. (Note: Not available if you use FIFO Costing.) |

I |

Issue |

Used by the system to decrease on-hand for confirmed shipments. The system writes an issue transaction for non-inventory and drop ship items when the Create Item Transaction History for Non-Inventory Items (E39) system control value is set to Y. See Display Inventory Transaction History (DITH). |

M |

Make Up Finished Good |

Used in inventory transactions to increase on-hand amount for the finished good item and decreases on-hand for the components. |

O |

Reset On-Hand Quantity |

Used in inventory transactions to reset the on-hand quantity to the entered value. (Note: Not available if you use FIFO Costing.) |

P |

Physical |

Used by the physical inventory update program when adjusting on-hand based on physical counts entered. If the count is greater than on-hand, on-hand will be increased. If the count is less than on-hand, then on-hand will be decreased. |

R |

Receiving |

Used in the purchase order receipts program for merchandise received. Increments the on-hand. |

T |

Transfer |

Used in inventory transactions to increase on-hand in "to" location and decreases the on-hand in "from" locations. |

V |

Return to Vendor |

Used in inventory transactions to decrease on-hand amount if positive quantity is entered; increases on-hand if negative quantity is entered. When used by the system for vendor charge backs, decreases on-hand when you process a charge back; increases on-hand when you reverse a charge back. |

* |

FIFO Cost Change |

Used in inventory transactions to increase or decrease total inventory valuation to reflect a change to the unit cost of a FIFO layer if you use FIFO costing. |

Item Transaction History Outbound Trigger Rules

Item Transaction History Outbound trigger rules define the criteria a record in the Item Transaction History file must meet in order for the system to create an item transaction history trigger.

• If the record in the Item Transaction History file meets the Item Transaction History Outbound trigger rule criteria, the system creates an item transaction history trigger.

• If the record in the Item Transaction History file does not meet the Item Transaction History Outbound trigger rule criteria, the system does not create an item transaction history trigger.

You can define Item Transaction History Outbound trigger rules for fields in the Item Transaction History file. If you define more than one criterion, the item transaction history record must meet all of the criteria defined in order to generate a trigger.

Example: You define the following trigger rules for the Item Transaction History Outbound job:

Item Transaction History Outbound Trigger Rules |

|||

Field |

Test |

Value |

Results |

Company |

EQ |

555 |

The system creates an item transaction history trigger only if the item transaction history record is created in company 555. |

Warehouse |

LIST |

1 50 206 |

The system creates an item transaction history trigger only if the item transaction history record is associated with warehouse 1, 50, or 206. |

You can define trigger rules for the Item Transaction History Outbound job at the Outbound Interface Trigger Rules Screen; see Defining Outbound Interface Trigger Rules.

If you update the trigger rules for the Item Transaction History Outbound job, you must stop and restart the job before the changes take effect.

Note: When you create trigger rules, the system does not validate that your entry is a valid value for the field or is within the maximum field positions. Refer to your Field/File Listing to review field attributes for the Item Transaction History file.

Item Transaction History Outbound XML Inclusion

For each item transaction history trigger, the Item Transaction History Outbound message builder determines which elements to include in the item transaction history outbound message, based on XML inclusion rules.

You can define Item Transaction History Outbound XML inclusion rules at the Outbound Interface XML Inclusion Screen.

XML inclusion defines which elements to include in the item transaction history outbound message.

• If the element is included, that element and its parents are included in the generated item transaction history outbound XML message.

• If the element is excluded, that element and its children are excluded from the generated item transaction history outbound XML message.

The following table indicates which elements in the item transaction history outbound message are included, based on which elements you flag to include or exclude.

Include element in XML message? |

Element |

Y = Include ItemTransaction N = Exclude ItemTransaction and all of its children; the system sends a message with only the Message element and its attributes |

ItemTransaction |

Y = Include VendorItem and its parent ItemTransaction N = Exclude VendorItem |

VendorItem |

Y = Include UPC and its parent ItemTransaction N = Exclude UPC |

UPC |

Before you can generate item transaction history outbound messages, you must perform the necessary CWDirect setup and processing.

Information requiring setup includes:

System Control Value |

Description |

Create Generic Item Transaction Download Trigger Records (J52) |

Enter Y in this field to create item transaction history triggers in the IL Outbound Trigger file when a record is created in the Item Transaction History file. |

Enter the number of days to retain records in the IL Outbound Trigger file before purging them. Run the PURGIJT periodic function (program name ILR0026) to delete any records if: Last processed date is less than the current system date by the number of purge days and Status is X. Example: Today is 2/06, and you have set this value to 1. Any record whose Last processed date is 2/05 or earlier is purged. |

|

Create Item Transaction History for Non-Inventory Items (E39) |

Enter Y in this field if you want the system to write an issue (I) type transaction history record for non-inventory and drop ship items when they go through billing; otherwise, leave this field blank. |

Menu Option |

Description |

Allows you to review, delete, or resend IL outbound trigger records. |

|

When active, the Item Transaction History Outbound job creates an Item Transaction History Outbound XML Message (CWInvXActionOut) for each item transaction history trigger record in the IL Outbound Trigger file. You can also define: • trigger rules; see Item Transaction History Outbound Trigger Rules • XML inclusion rules; see Item Transaction History Outbound XML Inclusion • the queues where the item transaction history outbound message are sent; see Work with Integration Layer Process Queues Screen |

|

Allows you to review and create item transaction codes. |

|

Allows you to review item transaction history. |

Periodic Function |

Description |

Purge IJCT Download (program name ILR0026) |

Run this periodic function to purge processed IL outbound triggers, based on the days defined in the Outbound Interface Trigger File Purge Days (I14) system control value: Last processed date is less than the current system date by the number of purge days and Status is X. |

Item Transaction History Outbound XML Message (CWInvXActionOut)

The Item Transaction History Outbound XML message contains item transaction history information to send from CWDirect to another system.

For more information: See:

• Item Transaction History Outbound Message: Sample XMLs for sample messages.

• XML Messages for a table that provides links to the DTD, schema, and a sample XML layout for each XML message.

Attribute Name |

Type |

Length |

Comments |

|

One Message element is required. |

|||

source |

alpha |

25 |

Identifies the source of the XML message. CWDIRECT indicates the XML message is from CWDirect. |

target |

alpha |

25 |

Identifies the target of the XML message. IDC indicates the XML message is sent to CWIntegrate. |

type |

alpha |

25 |

Identifies the type of information in the XML message. CWInvXActionOut indicates the message contains an item transaction history record. |

|

The Message element can include one ItemTransaction element. |

|||

company |

numeric |

3 |

A code for the company where the inventory transaction took place. From the Company field in the Item Transaction History file. |

item_number |

alpha |

12 |

A code for the item associated with the inventory transaction. From the ITM number field in the Item Transaction History file. |

item_desc |

alpha |

40 |

A description of the item associated with the inventory transaction. From the Description field in the Item file. |

sku_code |

alpha |

14 |

A code for the SKU defined for the item. From the SKU code field in the Item Transaction History file. |

sku_desc |

alpha |

40 |

A description of the SKU defined for the item. From the Description field in the SKU file. |

warehouse |

numeric |

3 |

A code for the warehouse where the inventory transaction was performed. From the Whs field in the Item Transaction History file. |

warehouse_name |

alpha |

30 |

A description of the warehouse where the inventory transaction was performed. From the Name field in the Warehouse file. |

ith_date |

numeric |

7 |

The date when the inventory transaction was performed. From the Date field in the Item Transaction History file. |

ith_time |

numeric |

6 |

The time when the inventory transaction was performed. From the Time field in the Item Transaction History file. |

sequence_number |

numeric |

3 |

The unique sequence number assigned to the item transaction history record. From the Sequence # field in the Item Transaction History file. |

cost |

numeric |

11.4 |

The cost of the item. The Costing Method (A25) system control value controls how the system determines the cost of an item. Average cost: If you use average costing, this is the unit cost of the item. The system uses the Average cost from the SKU file for both SKUed and non-SKUed items. Standard cost: If you use standard costing, this is the unit cost of the item. The system uses the Standard cost from the SKU file for both SKUed and non-SKUed items. FIFO cost: If you use FIFO costing, this is the extended cost of all units. In FIFO costing, a single transaction may derive unit costs from more than one FIFO cost layer, making it impossible to display a single unit cost in this field. From the Cost field in the Item Transaction History file. |

id |

alpha |

10 |

The identification number entered when the inventory transaction was created. In the case of item-to-item transfers (transaction code G), the system assigns this number; both the from and to transaction will share the same ID number. NONINVISSU displays for all non-inventory and drop ship inventory transaction records. AUTOTRANS displays for all transactions processed using the Working with Automated Inventory Transactions (WAIT) menu option. The work order number displays in this field for all finished good make up type transactions (transaction code M) that are created through the finished good work order process. From the Identification field in the Item Transaction History file. |

new_on_hand |

numeric |

7 |

The on-hand quantity after the transaction took place. This field is blank for non-inventory items and drop ship items, since inventory is not affected. This field is the same as the old_on_hand quantity for changes to FIFO cost (transaction code *). From the New on hand field in the Item Transaction History file. |

old_on_hand |

numeric |

7 |

The on-hand quantity before the transaction took place. This field is blank for non-inventory items and drop ship items, since inventory is not affected. This field is the same as the old_on_hand quantity for changes to FIFO cost (transaction code *). From the Old on hand field in the Item Transaction History file. |

quantity |

numeric |

7 |

The number of units that the transaction affected. From the Qty field in the Item Transaction History file. |

batch |

numeric |

7 |

The number of the batch containing the inventory transaction. The system assigns batch numbers in both immediate and batch inventory transactions. From the Batch # field in the Item Transaction History file. |

transaction_nbr |

numeric |

5 |

The number of transactions within the batch. From the Trans# field in the Item Transaction History file. |

from_carton |

numeric |

7 |

The carton number before this transaction took place. From the From carton# field in the Item Transaction History file. |

to_carton |

numeric |

7 |

The carton number after this transaction took place. From the To carton# field in the Item Transaction History file. |

order_number |

numeric |

8 |

The order number affected by the inventory transaction. From the Order # field in the Item Transaction History file. |

order_ship_to |

numeric |

3 |

The order ship to affected by the inventory transaction. From the ITH order ship to # field in the Item Transaction History file. |

order_detail_seq |

numeric |

5 |

The unique sequence number assigned to the order detail line number affected by the inventory transaction. From the ITH order detail seq # field in the Item Transaction History file. |

invoice_nbr |

numeric |

7 |

The invoice number affected by the inventory transaction. From the Invoice # field in the Item Transaction History file. |

po_nbr |

numeric |

7 |

The purchase order number affected by the inventory transaction. From the PO # field in the Item Transaction History file. |

price |

numeric |

7.2 |

The price of the item. From the Price field in the Item Transaction History file. |

control_nbr |

alpha |

10 |

From the ITH control number field in the Item Transaction History file. |

lpn_nbr |

numeric |

6 |

The number the system assigned to the case, carton, or pallet to track the inventory through the warehouse if you use radio frequency (RF). License plate numbers do not appear for R (receipt) inventory transactions, when the license plate number is actually created. This number displays only if the LPN Tracking (E16) system control value is selected. From the ITH LPN number field in the Item Transaction History file. |

idt_line_nbr |

numeric |

3 |

The invoice line number affected by the inventory transaction. From the ITH IDT line # field in the Item Transaction History file. |

actual_date |

numeric |

7 |

The date when the inventory transaction was performed. From the ITH Actual date field in the Item Transaction History file. |

actual_time |

numeric |

6 |

The time when the inventory transaction was performed. From the ITH Actual time field in the Item Transaction History file. |

location |

alpha |

7 |

The warehouse location affected by the inventory transaction. The location is blank for drop shipments, non-inventory transactions, and FIFO cost changes (* transactions). The system creates two inventory transaction history records for transfer transactions. One record contains the from location; the other contains the to location. Each completed RF transaction will create four records: two each for the pull and the put. From the Location field in the Item Transaction History file. |

transaction_code |

alpha |

1 |

A code that identifies types of inventory transactions. Certain codes are supplied by CWDirect, and you can also create your own. System-supplied codes are: • A Adjustment • C Customer Return • G Item to Item Transfer • E Express Bill • I Issue (shipment, including express bill orders) • M Make Up Finished Good • O Reset On-Hand Quantity • P Physical • R Receiving • T Transfer • V Return to Vendor • * FIFO Cost Changes Any RF transactions will have a code of T. The system uses a transaction code of * for changes to the cost of a FIFO layer. The system does not create a * transaction history record when you update the standard or average cost of an item. From the Tran code field in the Item Transaction History file. |

transaction_code_description |

alpha |

30 |

A description of the inventory transaction code. From the Description field in the Item Transaction Code file. |

transaction_ reason |

numeric |

2 |

A code that represents the reason the inventory transaction was performed. Not all transactions have reason codes. From the Tran reason field in the Item Transaction History file. |

transaction_ reason_desc |

alpha |

30 |

A description of the inventory transaction reason. From the Description field in the Item Transaction Reason file. |

user |

alpha |

10 |

The user ID of the person who performed the transaction. PKMS displays if the transaction was processed through the PIX async. From the User field in the Item Transaction History file. |

gla_account_nbr |

numeric |

8 |

The general ledger number to which this transaction was posted. From the Account # field in the Item Transaction History file. |

gla_account_nbr_desc |

alpha |

30 |

A description of the general ledger number. From the Description field in the General Ledger Account file. |

vendor_charge_ back |

numeric |

9 |

A system-assigned number identifying a vendor charge back, when you return merchandise back to the vendor and receive a credit for the return. This number is sequentially assigned from the Vendor Charge Back # field in the Number Assignment file. From the Vendor chrg back nbr field in the Item Transaction History file. |

short_sku |

numeric |

7 |

The short SKU number assigned to the item. From the Short SKU field in the SKU file. |

retail_reference |

numeric |

10 |

The retail reference number assigned to the item. From the SKU retail X-Ref # field in the SKU file. |

long_sku_style |

alpha |

20 |

The long SKU style code assigned to the item. From the SKU L/S style field in the SKU file. |

|

The VendorItems element can include one or more VendorItem elements. |

|||

vendor_nbr |

numeric |

7 |

The vendor number assigned to the item associated with the inventory transaction. From the Vendor # field in the Vendor Item file. |

vendor_item |

alpha |

20 |

A code for the vendor item number assigned to the item for this vendor. From the Item field in the Vendor Item file. |

vendor_item_desc |

alpha |

30 |

A description of the vendor item. From the Description field in the Vendor Item file. |

|

The UPCs element can include one or more UPC elements. |

|||

upc |

numeric |

14 |

The UPC code assigned to the item associated with the inventory transaction. From the UPC field in the Item UPC file. |

Item Transaction History Outbound Message: Sample XMLs

Samples of the Item Transaction History Outbound XML Message (CWInvXActionOut) are presented below.

Adjustment (A) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL SKU DESCRIPTION" warehouse="205" warehouse_name="205 WAREHOUSE NAME" ith_date="1060518" ith_time="90503" sequence_number="1" cost="15000" new_on_hand="10" quantity="10" batch="698" price="500" actual_date="1060518" actual_time="90503" location="2050101" transaction_code="A" transaction_code_desc="ADJUSTMENT" user="KBOTTGER" gla_account_nbr="900" gla_account_nbr_desc="900 GL ACCOUNT DESCRIPTION" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202 SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202 SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

Customer return (C) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL SKU DESCRIPTION" warehouse="30" warehouse_name="30 WAREHOUSE NAME" ith_date="1060518" ith_time="92709" sequence_number="1" cost="15000" new_on_hand="1" quantity="1" order_number="8200" order_ship_to="1" order_detail_seq="1" invoice_nbr="2652" price="500" idt_line_nbr="1" actual_date="1060518" actual_time="92710" location="RETURNS" transaction_code="C" transaction_code_desc="CUSTOMER RETURN" user="KBOTTGER" gla_account_nbr="55550" gla_account_nbr_desc="55550 GL ACCT NUMBER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

Item to item transfer (G) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_code_desc="SYSPROSKU RED WMNS SMLL SKU DESCRIPTION" warehouse="800" warehouse_name="800 WAREHOUSE" ith_date="1060518" ith_time="105557" sequence_number="1" cost="15000" id="I000000004" new_on_hand="93" old_on_hand="83" quantity="-10" batch="701" price="500" actual_date="1060518" actual_time="105557" location="MAIN" transaction_code="G" transaction_code_desc="ITEM TO ITEM TRANSFER" user="KBOTTGER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

Make up finished good (M) transaction:

Main finished good item:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="FINISHEDGOOD" item_desc="FINISHEDGOOD ITEM DESCRIPTION" warehouse="40" warehouse_name="40 WAREHOUSE" ith_date="1060518" ith_time="110406" sequence_number="1" cost="250000" new_on_hand="5" old_on_hand="4" quantity="1" batch="704" price="3000" actual_date="1060518" actual_time="110418" location="A010101" transaction_code="M" transaction_code_desc="MAKE UP FINISHED GOOD" user="KBOTTGER" short_sku="1352">

<VendorItems>

<VendorItem vendor_nbr="101" vendor_item="101 FINISHEDGOOD" vendor_item_desc="101FINISHEDGOOD VENDOR ITEM" />

</VendorItems>

<UPCs />

</ItemTransaction>

</Message>

Finished good component 1:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="FINISHED1" item_desc="FINISHED1 ITEM DESCRIPTION" warehouse="40" warehouse_name="40 WAREHOUSE" ith_date="1060518" ith_time="110410" sequence_number="1" cost="50000" new_on_hand="20" old_on_hand="21" quantity="-1" batch="704" price="3000" actual_date="1060518" actual_time="110410" location="A010101" transaction_code="M" transaction_code_desc="MAKE UP FINISHED GOOD" user="KBOTTGER" short_sku="1063">

<VendorItems />

<UPCs />

</ItemTransaction>

</Message>

Finished good component 2:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="FINISHED2" item_desc="FINISHED2 ITEM DESCRIPTION" warehouse="40" warehouse_name="40 WAREHOUSE" ith_date="1060518" ith_time="110410" sequence_number="1" cost="50000" new_on_hand="20" old_on_hand="21" quantity="-1" batch="704" price="3000" actual_date="1060518" actual_time="110414" location="A010101" transaction_code="M" transaction_code_desc="MAKE UP FINISHED GOOD" user="KBOTTGER" short_sku="1064">

<VendorItems />

<UPCs />

</ItemTransaction>

</Message>

Finished good component 3:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="FINISHED3" item_desc="FINISHED3 ITEM DESCRIPTION" warehouse="40" warehouse_name="40 WAREHOUSE" ith_date="1060518" ith_time="110410" sequence_number="1" cost="50000" new_on_hand="20" old_on_hand="21" quantity="-1" batch="704" price="3000" actual_date="1060518" actual_time="110415" location="A010101" transaction_code="M" transaction_code_desc="MAKE UP FINISHED GOOD" user="KBOTTGER" short_sku="1065">

<VendorItems />

<UPCs />

</ItemTransaction>

</Message>

Reset on-hand quantity (O) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL SKU DESCRIPTION" warehouse="205" warehouse_name="205 WAREHOUSE NAME" ith_date="1060518" ith_time="110911" sequence_number="1" cost="15000" new_on_hand="100" old_on_hand="6" quantity="100" batch="705" price="500" actual_date="1060518" actual_time="110912" location="2050101" transaction_code="O" transaction_code_desc="ON HAND" user="KBOTTGER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWM VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

Physical (P) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL SKU DESCRIPITION" warehouse="800" warehouse_name="800 WAREHOUSE NAME" ith_date="1060518" ith_time="95234" sequence_number="1" cost="15000" new_on_hand="84" old_on_hand="89" quantity="-5" price="500" actual_date="1060518" actual_time="95234" location="MAIN" transaction_code="P" transaction_code_desc="PHYSICAL" user="KBOTTGER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

Receiving (R) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROITEM" item_desc="SYSPROITEM DESCRIPTION" warehouse="205" warehouse_name="205 WAREHOUSE NAME" ith_date="1060518" ith_time="111401" sequence_number="1" cost="15000" new_on_hand="107" old_on_hand="7" quantity="100" po_nbr="1382" price="500" actual_date="1060518" actual_time="111412" location="2050101" transaction_code="R" transaction_code_desc="RECEIPT" user="KBOTTGER" gla_account_nbr="55559" gla_account_nbr_desc="55559 GL ACCT NUMBER" short_sku="1871" retail_reference="12301974" long_sku_style="LSSYSPROITEM">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROITEM" vendor_item_desc="202SYSPROITEM VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="5182006" />

</UPCs>

</ItemTransaction>

</Message>

Transfer (T) transaction:

From warehouse:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL SKU DESCRIPTION" warehouse="205" warehouse_name="205 WAREHOUES NAME" ith_date="1060518" ith_time="111808" sequence_number="1" cost="15000" new_on_hand="90" old_on_hand="100" quantity="-10" batch="706" price="500" actual_date="1060518" actual_time="111812" location="2050101" transaction_code="T" transaction_code_desc="TRANSFER" user="KBOTTGER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

To warehouse:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL" warehouse="800" warehouse_name="800 WAREHOUSE NAME" ith_date="1060518" ith_time="111812" sequence_number="1" cost="15000" new_on_hand="103" old_on_hand="93" quantity="10" batch="706" price="500" actual_date="1060518" actual_time="111812" location="MAIN" transaction_code="T" transaction_code_desc="TRANSFER" user="KBOTTGER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

Return to vendor (V) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL" warehouse="800" warehouse_name="800 WAREHOUSE NAME" ith_date="1060518" ith_time="100641" sequence_number="1" cost="15000" new_on_hand="84" old_on_hand="85" quantity="1" order_detail_seq="1" price="500" actual_date="1060518" actual_time="100641" location="MAIN" transaction_code="V" transaction_code_desc="RETURN TO VENDOR" user="KBOTTGER" vendor_charge_back="26" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

FIFO cost changes (*) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL SKU DESCRIPTION" warehouse="205" warehouse_name="205 WAREHOUSE NAME" ith_date="1060518" ith_time="125430" sequence_number="1" cost="5000" new_on_hand="10" old_on_hand="10" po_nbr="1385" actual_date="1060518" actual_time="125430" transaction_code="*" transaction_code_desc="FIFO COST CHANGE" user="KBOTTGER" gla_account_nbr="20033" gla_account_nbr_desc="20033 GL ACCT NUMBER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS" />

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

Shipment (I) transaction:

<Message source="CWDirect" target="IDC" type="CWInvXActionOut">

<ItemTransaction company="555" item_number="SYSPROSKU" item_desc="SYSPROSKU ITEM DESCRIPTION" sku_code="RED WMNS SMLL" sku_desc="SYSPROSKU RED WMNS SMLL" warehouse="205" warehouse_name="205 WAREHOUSE NAME" ith_date="1060518" ith_time="91728" sequence_number="1" cost="15000" new_on_hand="8" old_on_hand="10" quantity="2" order_number="8200" order_ship_to="1" order_detail_seq="1" invoice_nbr="2651" price="500" idt_line_nbr="2" actual_date="1060518" actual_time="91728" location="2050101" transaction_code="I" transaction_code_desc="SHIPMENT" user="KBOTTGER" gla_account_nbr="55553" gla_account_nbr_desc="55553 GL ACCT NUMBER" short_sku="1872" retail_reference="12301974" long_sku_style="LSSYSPROSKURWS">

<VendorItems>

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKU" vendor_item_desc="202SYSPROSKU VENDOR ITEM" />

<VendorItem vendor_nbr="202" vendor_item="202SYSPROSKURWS" vendor_item_desc="202SYSPROSKURWS VENDOR ITEM" />

</VendorItems>

<UPCs>

<UPC upc="518200690153" />

<UPC upc="51806" />

</UPCs>

</ItemTransaction>

</Message>

| Inventory Transaction Analysis Detail Report | Contents | SCVs | Search | Glossary | Reports | XML | Index | Part D: Inventory Transaction Set-Up |

WH03_09 CWDirect 18.0 August 2015 OTN