6 Installing the Recovery Appliance at the Site

This chapter describes how to move and install the hardware, from unpacking the Recovery Appliance to powering it on. This chapter contains these sections:

6.1 Reviewing Safety Guidelines

Before ZDLRA Rack arrives, the following safety precautions should be reviewed to ensure the site is safe, as well as ready for delivery.

Failing to observe these precautions can result in injury, equipment damage, or malfunction.

-

Do not block ventilation openings.

-

Do not install ZDLRA Rack in a location that is exposed to direct sunlight or near a device that may become hot.

-

Do not install ZDLRA Rack in a location that is exposed to excessive dust, corrosive gases, or air with high salt concentrations.

-

Do not install ZDLRA Rack in a location that is exposed to frequent vibrations. Install ZDLRA Rack on a flat, level surface.

-

Use a power outlet that uses proper grounding. When using shared grounding, the grounding resistance must not be greater than 10 ohms. Ensure that your facility administrator or a qualified electrical engineer verifies the grounding method for the building, and performs the grounding work.

-

Be sure that each grounding wire used for ZDLRA Rack is used exclusively for ZDLRA Rack. Also be sure to observe the precautions, warnings, and notes about handling that appear on labels on the equipment.

-

Do not place cables under the equipment or stretch the cables too tightly.

-

Do not disconnect power cords from the equipment while its power is on.

-

If you cannot reach the connector lock when disconnecting LAN cables, then press the connector lock with a flathead screwdriver to disconnect the cable. You could damage the system board if you force your fingers into the gap rather than using a flathead screwdriver.

-

Do not place anything on top of ZDLRA Rack or perform any work directly above the rack.

-

Do not let the room temperature rise sharply, especially in winter. Sudden temperature changes can cause condensation to form inside ZDLRA Rack. Allow for a sufficient warm-up period prior to server operation.

-

Do not install ZDLRA Rack near a photocopy machine, air conditioner, welding machine, or any other equipment that generates loud, electronic noises.

-

Avoid static electricity at the installation location. Static electricity transferred to ZDLRA Rack can cause malfunctions. Static electricity is often generated on carpets.

-

Confirm the supply voltage and frequency match the electrical ratings indicated for ZDLRA Rack.

-

Do not insert anything into any ZDLRA Rack opening, unless doing so is part of a documented procedure. ZDLRA Rack contains high-voltage parts. If a metal object or other electrically-conductive object enters an opening in ZDLRA Rack, then it could cause a short circuit. This could result in personal injury, fire, electric shock, and equipment damage.

-

When using single phase power distribution units (PDUs), note the following:

-

PDU A input 0 and PDU B input 2 must be on the same phase.

-

PDU A input 1 and PDU B input 1 must be on the same phase.

-

PDU A input 2 and PDU B input 0 must be on the same phase.

The inputs are labeled where they come out of the PDU. Connecting cables as described ensures the phases are balanced on both sides, A and B, in case of a failover.

-

See Also:

-

Important Safety Information for Sun Hardware Systems (816-7190) included with the rack

-

Oracle Engineered System Safety and Compliance Guide, Compliance Model No.: ESY27

6.2 Unpacking ZDLRA Rack

The unpacking location should be determined during the site planning process. The following image shows the ZDLRA Rack shipping crate.

6.2.1 Contents of the Shipping Kit

The ZDLRA Rack shipping kit contains the following tools and equipment to install and service the Recovery Appliance rack:

-

16 mm long No. 2 Phillips screw

-

T30 Torx cranked wrench key

-

T25 Torx cranked wrench key

-

6 mm hexagon Allen wrench key

-

SW 12 mm single-headed wrench

-

2 square jumper brackets with 4 M5 Torx screws

-

2 cable management hooks with 4 spring nuts

-

Side panel removal tool

-

Keys to the front door, rear door, and side panel locks

-

32 M6 cage nuts

-

32 M6 screws

-

Cage nut mounting tool

-

SW 17 mm single-headed wrench is included on the shipping pallet

Note:

The following items are not included in the shipping kit:

-

No. 2 Phillips screwdriver

-

Antistatic wrist strap

6.2.2 Removing ZDLRA Rack from the Shipping Crate

Note:

Oracle strongly recommends that you use professional movers when unpacking and installing ZDLRA Rack.

The following procedure describes how to unpack ZDLRA Rack:

-

Unpack ZDLRA Rack carefully from the packaging and shipping pallet as follows:

Note:

Before unpacking the rack from the shipping carton, refer to the labels on the carton and to the instructions that they provide.

-

Remove the shipping carton bands.

-

Remove the yellow fasteners and carton top.

-

Remove the carton sides and inner top.

WARNING:

Rocking or tilting the rack can cause the rack to fall over and cause serious injury or death.

-

-

Remove the shipping kit.

-

Attach the ramps to the shipping pallet as follows:

-

Remove the ramps from the pallet sides.

-

Obtain the parts bag from inside the cabinet.

-

Adjust the leveling bolts on the ramps and connect the ramps to the pallet wheel track.

-

Verify that leveling feet are up before moving rack.

-

-

Carefully roll ZDLRA Rack off the shipping pallet as follows:

-

Unfasten the exterior shipping brackets from the pallet.

-

Unfasten the interior shipping brackets from the pallet.

Note:

Use care when removing the shipping brackets from underneath ZDLRA Rack. Access to the inside shipping brackets might be limited.

-

Roll the cabinet down the ramps to the level floor. Oracle recommends having three people available to move the rack down the ramp: two people on both sides to help guide the rack and one person in back.

-

-

Save the shipping brackets used to secure the rack to the shipping pallet. Do not dispose of these brackets, because you cannot order replacement brackets.

-

Recycle the packaging properly. Follow local laws and guidelines to dispose of the material.

See Also:

-

Sun Rack II User's Guide at

https://docs.oracle.com/cd/E19657-01/html/E29153/index.html -

Oracle Rack Cabinet 1242 User's Guide at

http://docs.oracle.com/cd/E85660_01/html/E87280/index.htmlfor X7 systems

6.3 Placing ZDLRA Rack in Its Allocated Space

This section describes how to position, stabilize, and ground ZDLRA Rack.

6.3.1 Moving ZDLRA Rack

The following procedure describes how to move ZDLRA Rack:

-

Ensure the doors are closed and secured.

-

Ensure the leveling and stabilizing feet on the rack are raised and out of the way.

-

Push ZDLRA Rack from behind to the installation site.

When moving ZDLRA Rack to the installation site, the front casters do not turn; you must steer the unit by moving the rear casters. You can safely maneuver ZDLRA Rack by carefully pushing it. Figure 6-2 shows the correct way to push the rack.

Figure 6-2 Carefully Push ZDLRA Rack from Behind

Description of "Figure 6-2 Carefully Push ZDLRA Rack from Behind"Oracle recommends having two people to move the rack: one person in front and one person in back to help guide the rack. When transporting configured racks from one location to another, take care to move them slowly, 0.65 meters per second (2.13 feet per second) or slower.

Carefully examine the transportation path. Avoid obstacles such as doorways or elevator thresholds that can cause abrupt stops or shocks. Go around obstacles by using ramps or lifts to enable smooth transport.

WARNING:

-

Never attempt to move ZDLRA Rack by pushing on the side panels. Pushing on the side panels can tip the rack over. This can cause serious personal injury or death as well as damage to the equipment.

-

Never tip or rock ZDLRA Rack because the rack can fall over.

6.3.2 Stabilizing ZDLRA Rack

After moving ZDLRA Rack to the installation site, stabilize the rack to ensure that it does not move or tip over.

Oracle does not recommend using the shipping brackets to permanently mount the rack to the floor.

Caution:

Shipping brackets are not for use for bracing or anchoring the rack during seismic events.You can stabilize the rack by extending the rack leveling feet.

6.3.2.1 Stabilize ZDLRA Rack with Leveling Feet

The ZDLRA Rack contains four leveling feet that can be lowered to stabilize the rack. The leveling feet can be used even when the rack is permanently secured to the floor. The four leveling feet should share the rack load with at least one other support. The following is an acceptable method to share the rack load:

-

Casters and leveling feet

To adjust the leveling feet, do the following:

-

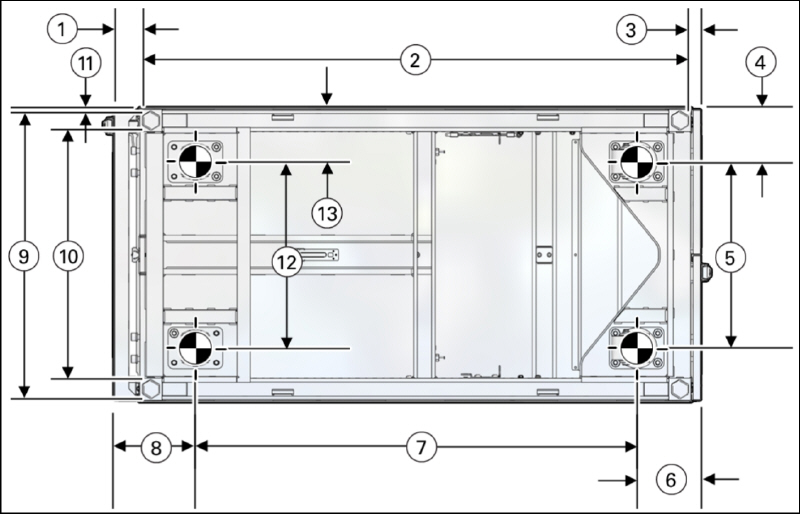

Locate the four leveling feet located at the bottom corners of the ZDLRA Rack. Figure 6-3 shows the location of the leveling feet on the bottom of the rack.

Figure 6-3 Location of Leveling Feet on ZDLRA Rack

Description of "Figure 6-3 Location of Leveling Feet on ZDLRA Rack"-

1: Distance from the edge of the mounting feet to the side of the rack is 33.75 mm (1.33 inches)

-

2: Width from the outside edges of the leveling feet is 532.5 mm (20.96 inches)

-

3: Width from the inside edges of the leveling feet is 429 mm (16.89 inches)

-

4: Distance from the edge of the feet to the front rack surface is 73.75 m (2.90 inches)

-

5: Depth of the outside edges of the leveling feet is 1058.5 mm (41.67 inches)

-

6: Distance from the edge of the leveling feet to the rear rack surface is 32.5 mm (1.28 inches)

-

7: Distance from the center of front casters to the side of the rack is 86.7 mm (3.41 inches)

-

8: Width between the center of the front casters is 426.6 mm (16.80 inches)

-

9: Distance from the center of the rear casters to the rear of the rack is 173.7 mm (6.83 inches)

-

10: Depth between the front and rear casters is 828.6 mm (32.62 inches)

-

11: Distance between the rear casters and the rear of the rack is 162.4 mm (6.39 inches)

-

12: Distance from the center of rear casters to the side of the rack is 96.4 mm (3.80 inches)

-

13: Width between the center of the rear casters is 407.2 mm (16.03 inches)

-

-

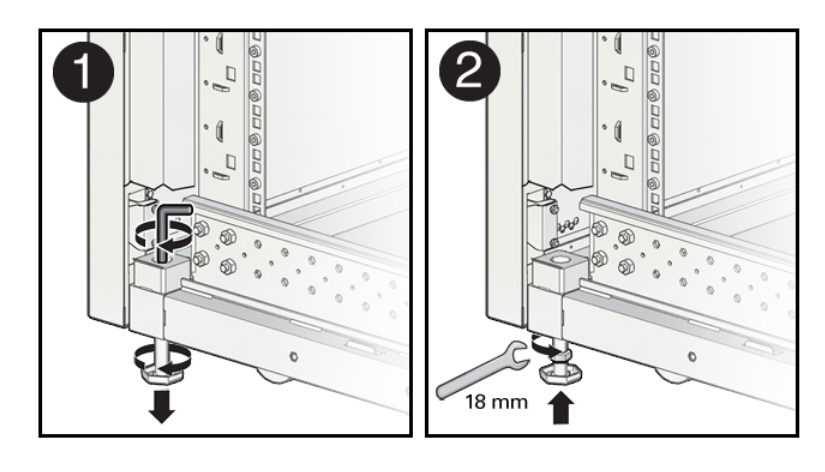

Lower the leveling feet to the floor to share the load with the casters, as shown in Figure 6-4 using the SW 12 mm wrench.

Figure 6-4 Securing ZDLRA Rack Using the Leveling Feet

Description of "Figure 6-4 Securing ZDLRA Rack Using the Leveling Feet"

6.3.2.2 Stabilize ZDLRA Rack X7 with Leveling Feet

The rack contains four leveling feet that can be lowered to stabilize the rack.

The leveling feet can be used even when the rack is permanently secured to the floor. The four leveling feet share the load with the casters. This increases the footprint of the rack which improves stability and helps prevent rack movement.

To adjust the leveling feet, do the following:

-

Locate the four leveling feet located at the bottom corners of ZDLRA Rack. The following figure shows the location of the leveling feet on the bottom of ZDLRA Rack. The image dimensions include the doors attached to the rack.

Figure 6-5 Location of Leveling Feet on ZDLRA Rack X7

Description of "Figure 6-5 Location of Leveling Feet on ZDLRA Rack X7"-

1: Distance from the edge of the feet to the Front door surface is 58 mm (2.3 inches)

-

2: Depth of the outside edges of the leveling feet is 1113 mm (43.8 inches)

-

3: Distance from the edge of the leveling feet to the rear door surface is 26 mm (1.0 inches)

-

4: Distance from the center of rear casters to the side of the rack is 96.5 mm (3.8 inches)

-

5: Width between the center of the rear casters is 407 mm (16.0 inches)

-

6: Distance from the center of the rear casters to the rear door surface is 142 mm (5.6 inches)

-

7: Depth between the front and rear casters is 889 mm (35.0 inches)

-

8: Distance between the center of the front casters and the Front door surface is 166 mm (6.5 inches)

-

9: Width from the outside edges of the leveling feet is 583 mm (23.0 inches)

-

10: Width from the inside edges of the leveling feet is 513 mm (20.2 inches)

-

11: Distance from the edge of the mounting feet to the side of the rack is 8.5 mm (0.3 inches)

-

12: Width between the center of the front casters is 410 mm (16.1 inches)

-

13: Distance from the center of front casters to the side of the rack is 95 mm (3.7 inches)

-

-

Stabilize the rack by lowering the four leveling feet to the floor, using a 6-mm hex wrench or your fingers, as shown in the following image.

Figure 6-6 Securing ZDLRA Rack Using the Leveling Feet

Description of "Figure 6-6 Securing ZDLRA Rack Using the Leveling Feet"

6.3.3 Attaching a Ground Cable (Optional)

The ZDLRA Rack power distribution units (PDUs) achieve earth ground through their power cords. Final chassis ground is achieved by way of the ground prong when you connect the power cord to a socket. For additional grounding, attach a chassis earth ground cable to ZDLRA Rack. The additional ground point enables electrical current leakage to dissipate more efficiently.

WARNING:

The PDU power input lead cords and the ground cable must reference a common earth ground. If they do not, then a difference in ground potential can be introduced. If you are unsure of your facility's PDU receptacle grounding, then do not install a ground cable until you confirm that there is a proper PDU receptacle grounding. If a difference in ground potential is apparent, then you must take corrective action.

Note:

A grounding cable is not shipped with the system.

-

Ensure the installation site has properly grounded the power source in the data center. The facility PDU must have earth ground.

-

Ensure all grounding points, such as raised floors and power receptacles, reference the facility ground.

-

Ensure that direct, metal-to-metal contact is made for this installation. During manufacturing, the ground cable attachment area might have been painted or coated.

-

Attach the ground cable to one of the attachment points located at the bottom rear of the system frame as shown in Figure 6-7. The attachment point is an adjustable bolt that is inside the rear of the ZDLRA Rack cabinet on the right side.

Figure 6-7 Earth Ground Attachment Bolt Location

Description of "Figure 6-7 Earth Ground Attachment Bolt Location"

See Also:

Oracle Exadata Database Machine Extending and Multi-Rack Cabling Guide if ZDLRA Rack will be connected to another ZDLRA Rack.

6.4 Installing the Fiber Channel Adapters

The optional QLogic fiber channel adapters are shipped separately from the Recovery Appliance rack. Install them only when Recovery Appliance uses an Oracle tape system for backup.

You install a fiber channel adapter in the first PCIe slot of each compute server.

See Also:

Oracle Server X7-2 Service Manual for instructions for installing a PCI card in slot 1:

https://docs.oracle.com/cd/E72435_01/html/E72445/grdej.html#scrolltoc

Oracle Server X6-2 Service Manual for instructions for installing a PCI card in slot 1:

https://docs.oracle.com/cd/E62159_01/html/E62171/z40007611438967.html

Oracle Server X5-2 Service Manual for instructions for installing a PCI card in slot 1:

http://docs.oracle.com/cd/E41059_01/html/E48312/napsm.z40007611438967.html#scrolltoc

6.5 Acclimating the Recovery Appliance

Oracle recommends an acclimation period of 24 hours for the Recovery Appliance.

This applies to all hardware, including racks and cables. Acclimation to the surrounding environment prevents damage as a result of condensation.

6.6 Powering on the System for the First Time

Before powering on the system for the first time, it is necessary to inspect the rack and connect the power cords. This section contains the following topics:

Note:

After powering on Recovery Appliance, configure it as described in Configuring a Recovery Appliance Rack.

6.6.1 Inspecting Recovery Appliance After It Is in Place

You should examine the Recovery Appliance physical system after it is in place, but before power is supplied.

To inspect the Recovery Appliance rack:

-

Check the rack for damage.

-

Check the rack for loose or missing screws.

-

Check the rack for the ordered configuration. Refer to the Customer Information Sheet (CIS) on the side of the packaging.

-

Check that all cable connections are secure and firmly in place:

-

Check the power cables. Ensure that the connectors are the correct type for the data center facility power source.

-

Check the network data cables.

-

-

Check the site location tile arrangement for cable access and airflow.

-

Check the data center airflow that leads into the front of the rack.

See Also:

6.6.2 Connecting Power Cords

WARNING:

Confirm that all breaker switches are off before connecting the power cords. When off (0), the breakers extend beyond the side of the PDU.

There is one switch for each group and six switches for each PDU.

To connect power cords to the Recovery Appliance rack:

- Open the rear cabinet door.

- Ensure that the correct power connectors have been supplied.

- Unfasten the power cord cable ties. The ties are for shipping only and are no longer needed.

- Route the power cords to the facility receptacles through the bottom, as shown in Figure 6-8.

- Secure the power cords in bundles as shown in Figure 6-8.

- Ensure that the breaker switches are OFF before connecting the power cables.

- Plug the PDU power cord connectors into the facility receptacles.