Creating Par Locations

To define par location groups, use the Define Groups (CART_GROUP_INV) component. To define par locations, use the Define Par Location (CART_TEMPLATE_INV) component.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

CART_GROUP_INV |

Define codes for par location groups. |

|

|

CART_HEADER_INV |

Define par location header information. |

|

|

CART_REPLEN_OPT |

Assign items to par locations and determine replenishment options. |

|

|

CART_TEMPLATE_INV |

Establish line-level replenishment controls for items in a par location. |

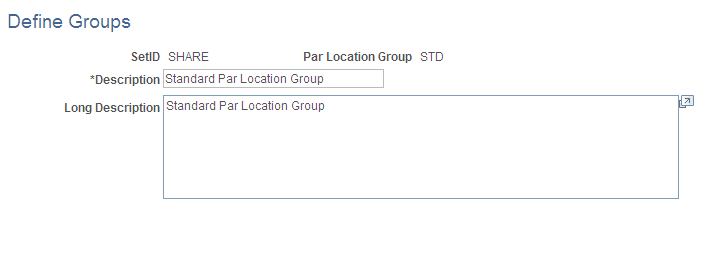

Use the Define Par Location Groups page (CART_GROUP_INV) to define codes for par location groups.

Navigation:

This example illustrates the fields and controls on the Define Groups page. You can find definitions for the fields and controls later on this page.

Enter a description for each physical or logical grouping of par locations. When you define par location attributes on the Define Par Location - Header page, you assign individual par locations to these groups.

To define par locations, use the Par Location Definition (CART_TEMPLATE_INV) component.

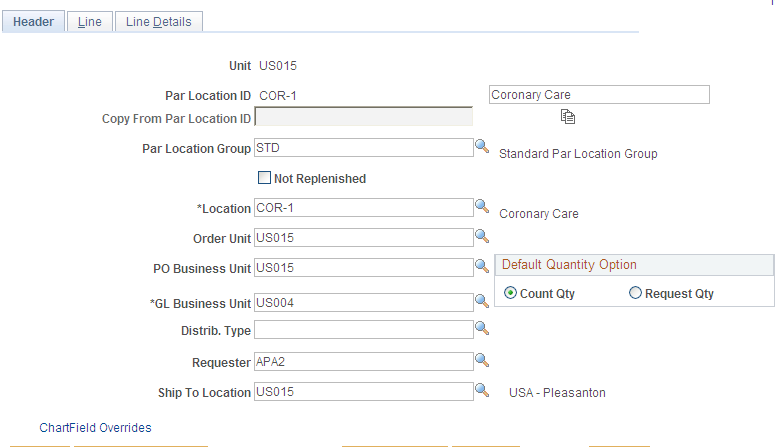

Use the Define Par Location - Header page (CART_HEADER_INV) to define par location header information.

Navigation:

This example illustrates the fields and controls on the Define Par Location — Header page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Delete |

Click to remove the par location from the system. This button appears only when you access the page through the Remove Par Location page. In addition, all fields are display-only when you access the page in this manner. You delete only the par location itself; the location that is associated with the par location remains in the system. You cannot delete a par location that has outstanding par location counts. |

Copy From Par Location ID |

To copy an existing par location's definition, select an ID, then click the Copy Par Location button. |

Par Location Group |

Assign the location to one of the par location groups that you defined on the Define Par Location Groups page. |

Not Replenished |

Select to define all of the items in the par location as not-replenished items. This selection overrides the item- or line-level setting. |

Location |

The par location to which received items are delivered. When you save the page, the system automatically adds this location to the business unit's location address table. |

Order Unit |

The PeopleSoft Inventory business unit that fulfills demand for items in the par location. |

PO Business Unit (PeopleSoft Purchasing business unit) |

The PeopleSoft Purchasing business unit that fulfills replenishment requests for stockless and nonstock items. This field is required for stockless and nonstock replenishment. |

GL Business Unit |

The PeopleSoft General Ledger business unit for this par location. The default value comes from the general ledger unit that you defined on the Inventory Definition - Business Unit Definition page. If you change the default, stock is issued to this par location from a PeopleSoft Inventory unit that reports to a different general ledger unit, and the system records an interunit expensed issue. |

Requester |

PeopleSoft Purchasing uses this field to build the requisition and purchase order. This field is required for stockless and nonstock replenishment. |

Ship To Location |

Required for stockless and nonstock replenishment. PeopleSoft Purchasing uses this value to identify the loading dock for receiving shipments. |

Use the Define Par Location - Line page (CART_REPLEN_OPT) to assign items to par locations and determine replenishment options.

Navigation:

This example illustrates the fields and controls on the Define Par Location - Line page. You can find definitions for the fields and controls later on this page.

On the Define Par Location-Line page, assign one or more items to this par location. Use the Add icon (plus sign) to insert additional items. Use the View All link to display all of the items within this par location.

Field or Control |

Description |

|---|---|

Par Replenishment Option |

Select a par replenishment option for each item. The Create Par Replenishment Requests process replenishes each item according to the par replenishment option that you specify here. The default value comes from the Inventory Definition - Business Unit Options: Replenishment Options page. The options are:

|

Cancel Backorder |

(Stock Par Replenishment Option only) Select to cancel backorders automatically when the entire quantity cannot be fulfilled by the PeopleSoft Inventory business unit. The default value is derived from the Setup Fulfillment page or the Setup Item Fulfillment page. |

Consolidated Non-Stock |

(Non-Stock Par Replenishment Option only) Select to consolidate multiple requisitions onto a single purchase order. |

Item ID |

Select an item for this par location line. Values depend upon the replenishment option. |

Charge Code |

(Optional) Select a charge code. Default values are from the Define Business Unit Item - General: Usage page or the Define Item - General: Usage page, depending upon the item's replenishment option. |

Replenishment Control |

Use this group box to indicate how the Create Par Replenishment Requests process should calculate order quantity when using the Count Qty option on the Count Par Location Levels page. The options are:

Note: Depending upon the item's replenishment method, the Create Par Replenishment Requests process may adjust the optimal quantity, FOQ, and maximum quantity to account for existing on-order quantity. |

Count Required |

Select this check box to require an exact count quantity for par location counts. |

Optimal Qty, FOQ, and Maximum Qty |

Enter the item quantity for this par location. The fields available are based on your entry in the Replenishment Control group box. |

UOM |

Enter the item's unit of measure to be used when the Create Par Replenishment Requests process generates a material stock request, purchase order, or requisition. Note: If this item is used within the Consumer Usage component of PeopleSoft Inventory, then the UOM defined here must be the standard UOM entered on the Define Item - General: Common page (Items, Define Items and Attributes, Define Item, General). For stock items, a default value can populate this field as follows:

For stockless and non-stock items, the default value that can populate this field is the default UOM of the item's priority 1 supplier. To find this UOM, select the priority 1 supplier for this item using the Purchasing Attributes - Item supplier page (Items, Define Items and Attributes, Purchasing Attributes, Item supplier) and then click the Item supplier UOM link to access the supplier's UOM & Pricing Info page. The Default check box is selected for one UOM. If an item/supplier combination does not exist, then the default value for this page is the standard UOM from the Define Item - General: Common page. |

Compartment |

Enter a compartment code to represent a physical storage location in the par location. This information is required if you store an item in multiple places within one par location. |

Count Order |

Enter a count order to indicate the line's sort order. PeopleSoft Inventory uses this number to sequence items for par location counts. |

To establish line level replenishment controls, use the Par Location Definition (CART_TEMPLATE_INV) component.

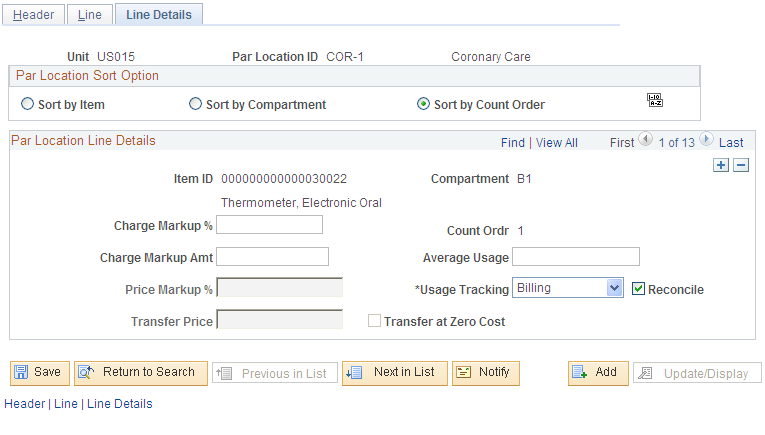

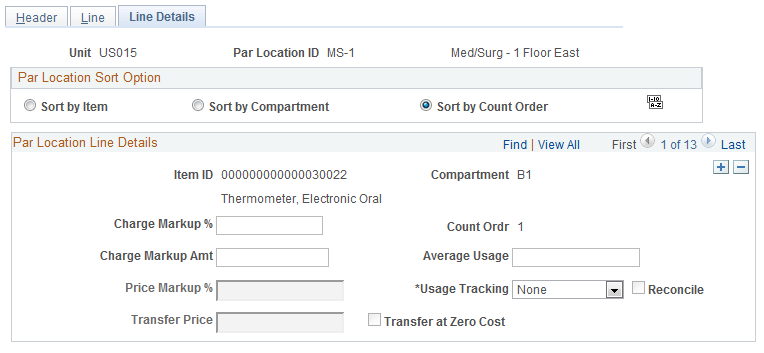

Use the Define Par Location - Line Details page (CART_TEMPLATE_INV) to establish line-level replenishment controls for items in a par location.

Navigation:

This example illustrates the fields and controls on the Define Par Location - Line Details page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Par Location Sort Option |

Select a radio button in this group box to display par location lines in the desired order. The system renumbers the count order to reflect the sort option. |

Charge Markup % (charge markup percentage) and Charge Markup Amt (charge markup amount) |

If you use charge markups, you can enter a markup percentage, a flat markup amount, or both. If you integrate with a third-party billing or costing system, the outbound material usage data includes this information. |

Price Markup % (price markup percentage) |

Enter a value if you use percentage markups. When generating material stock requests for stock-replenished items, PeopleSoft Inventory uses this value as the default to determine the transfer price of an inventory issue and applies the markup price to items upon shipment. The system counts the price markup percentage amount as a gain on the transfer. |

Transfer Price |

Enter a value for stock-replenished items if you use transfer pricing. |

Transfer at Zero Cost |

Select to ship interunit transfers at zero cost. The source business unit records a loss for the entire cost of the shipped items. This feature enables you to ship promotional or sample items at no cost to the destination par location. |

Average Usage |

Enter a value or have the Calculate Average Usage process (IN_PAR_USAGE) calculate the average use for stockless, non-stock, and stock-replenished items. |

Usage Tracking |

Indicate whether items are tracked using a third-party billing or costing system. Select one of the following values: Billing: Track item usage for patient billing. This method compiles patient and procedure usage information to bill patients directly for items used. Costing: Track item usage for cost accounting. This method compiles patient and procedure usage information to set procedure costs. None: Do not track item usage for billing or costing purposes. Note: Items that are tracked for billing or costing purposes must be assigned charge codes. Items that are also replenished to the par location require counts. |

Reconcile |

Select to include items in the material usage reconciliation of their par locations. You can only reconcile items that are tracked for billing or costing. In addition, items that are replenished to their par locations must use either the Par or Min/Max replenishment control options. |