Loading Items Into the Putaway Staging Tables

After the items slated for putaway have been inserted into the staging interface tables (STAGED_INF_INV and STGCOST_INF_INV), launch the Load Staged Items process to perform these tasks:

If the item's UOM is valid for stocking, no conversion occurs.

Assign a staging ID to provide easy reference to the group of items that the system is processing.

If the receipt is pegged and no putaway location was specified in the receipt transaction (for example, a PO receipt), places the stock in the pegging location, if within the pegging lead days.

Also, determines which demand the receipt (that is, pegged supply) will satisfy if more than one demand line exists for the supply.

If you enable cross docking, calculate open demand and move sufficient quantity to cover demand to the cross docking location.

Assign a material storage location, if none was specified when the item was received.

If directed putaway is active, the Load Staged Items process calls the Directed Putaway function; otherwise, it uses the default location assigned for the item. The process also ensures that items requiring isolation are not mixed with other stock and, in capacity-checking environments, verifies that the location can hold the receipt quantity.

Insert the items into the putaway staging tables (STAGED_ITEM_INV and STAGED_COST_INV).

If the Perform Validation option is selected on the Setup Putaway page, validate the incoming data.

The manner in which the Load Staged Items process handles the item's UOM varies according to the situation:

If you do not define a stocking UOM for the item, or if the item is serial-controlled and the UOM is not the standard UOM, the process ends in error.

You can correct the error on the Correct Staged Errors page.

If the item's putaway material storage location is a fixed picking location and the stocking UOM for the item is different from that of the fixed picking location, the system converts the quantity to the picking location's UOM.

If the item's UOM is not a valid stocking UOM, the system converts the quantity to the standard UOM defined for the item.

For interunit transfers, the transfer price details are retrieved from the IN_DEMAND_TRPC table of the source inventory business unit. The material and landed cost portions of the transfer price are included in the cost of the item by cost element. The additional transfer costs (using the cost element Addl Trans) can be written off to an expense account or included in the cost of the item depending on your setting in the Expense Transfer Fees check box on the Inventory Definition - Business Unit Definition page.

If you are using multistep putaway processing, you can override the UOM using either the Review Plan page or the Stockroom Feedback page after the Load Staged Items process is complete.

Follow these high-level steps to load items into the putaway staging tables:

Run the Load Staged Items process.

Review and correct staging errors.

View putaway details for a staging ID.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

STAGED_REQ_INV |

Define parameters for the Load Staged Items process. |

|

|

STAGED_ITEM_E_INV |

Review and correct any errors found by the Load Staged Items process. |

|

|

Correct Staged Errors - Putaway Detail Page |

STAGED_ITEM_E_SEC |

View putaway information for items on the Correct Staged Errors page. |

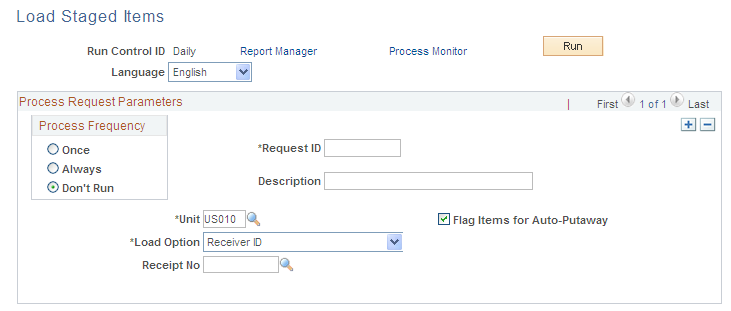

Use the Load Staged Items page (STAGED_REQ_INV) to define parameters for the Load Staged Items process.

Navigation:

This example illustrates the fields and controls on the Load Staged Items process page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Load Option |

Indicate which items the process should load into the putaway staging tables. Values are: All Items: Load all items for the business unit. User ID: Load items received by the specified user. Production ID: Load items associated with the specified production ID. Available if the installation includes PeopleSoft Manufacturing. Production Schedule: Load items associated with a production schedule. Select the production area, production type and item ID. Available if the installation includes PeopleSoft Manufacturing. Receiver ID: Load items associated with the specified receiver number. Transaction Source: Load items according to the transaction that inserted the item into the staging interface tables. Values are Adjustment, Component Kit Returns, Inventory, Purchasing, WIP Completion or WIP Component. |

Flag Items for Auto-Putaway |

Select to use auto-putaway processing. |

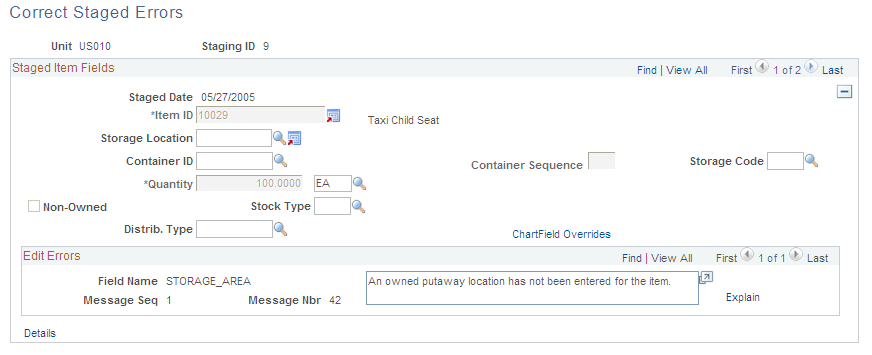

Use the Correct Staged Errors page (STAGED_ITEM_E_INV) to review and correct any errors found by the Load Staged Items process.

Navigation:

This example illustrates the fields and controls on the Correct Staged Errors page. You can find definitions for the fields and controls later on this page.

Field Errors

The Staged Item Fields group box lists fields that can be in error. Errors can be caused by data that is missing or incorrect.

Field or Control |

Description |

|---|---|

Item |

Define and approve the item ID as an inventory item. If the item is not approved, approve it on the Item Approval page, then return to this page to clear the error. If an identical item (including lot, serial, container, staged date) in the putaway location has a Restricted status, the system issues a warning; if the item's status is Hold or Rejected, the system issues an error. However, if the status of the location itself is Hold, or if the item is lot-controlled and the lot status is not Open, no warning or error occurs. For average, actual, and standard cost items, a default cost element must be specified on the Define Item - General: Common page. Specify the cost element and then return to this page to clear the error. If the item is standard cost, standard costs must be defined. Define a standard cost, then return to this page to clear the error. |

Storage Location |

Putaway material storage location information must exist before you can load staged items. The specified material storage location cannot have a suspended status. If you are putting the item into an existing container that already contains item quantity, the putaway location must match the material storage location of the container. If the item requires inspection, the putaway location must be an inspection location. |

Container ID Container Sequence |

Unless the business unit permits automatic container creation, you can only assign items to an existing container ID. If automatic container creation is permitted, you can assign multiple items to the same container by entering NEXT as the container ID and then entering a container sequence. The system assigns the Items with the same container sequence to the same container. If the item requires single-item storage, the item ID must match that defined for the container unless the Item ID field was left blank when creating the container. In the latter case, the item ID must match the first item put away into the container. |

Lot ID, Serial ID, and Configuration Code |

For lot- and serial-controlled items, the lot or serial ID is required and must not match the default filler value that you defined on the Installation Options - Inventory page. If the item is configured, a configuration code is required. If the item's lot already exists, the configuration code associated with the lot must match the configuration code for the putaway item. If the lot already exists and the lot status is not Open, the system issues a warning. If the business unit does not allow the automatic addition of new lots, you must create the new lot before using the Lot ID field here. |

Quantity |

This is a required field. If the item is serial-controlled, the quantity must be 1 and the UOM must be the item's standard UOM. |

Non-Owned |

If the items being staged are non-owned, you must put them into a non-owned material storage location. Similarly, you must put owned items into an owned location. However, if the receiving business unit is a VMI business unit, and the source business unit is not a VMI business unit, and the demand source is OM, then a non-owned location can be selected for an owned item. |

Stock Type |

If you selected the Non-Owned option, this field is required. |

ChartField Overrides |

Click to access the ChartField Overrides page, where you can override the credit accounting information for the received item. ChartField overrides are not allowed for interunit receipts and items staged from PeopleSoft Manufacturing. |

Details |

Click to access the Correct Staged Errors - Putaway Detail page (STAGED_ITEM_E_SEC) to view putaway information for items. |

Application Errors

Only application error messages appear in the Edit Errors group box. For errors due to invalid values or missing required fields, click Save and PeopleSoft Inventory identifies the field in error during the save validation.

You cannot change these fields:

For PeopleSoft Purchasing receipts: Item, Quantity, and Non-Owned.

For PeopleSoft Manufacturing completions: Item, Quantity and UOM, Dist Type, and Non-Owned.

For interunit receipts: Item, Quantity, and Non-Owned.

For RMA receipts: Item and Quantity.

To change the overall putaway quantity for items staged from PeopleSoft Purchasing, update the original receipt quantity using the Inventory Putaway Information page.