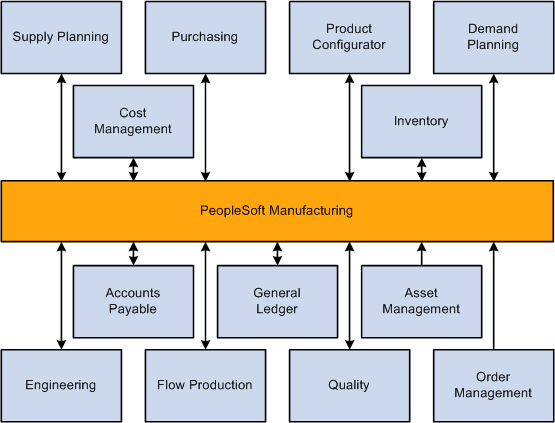

PeopleSoft Manufacturing Integrations

This diagram illustrates PeopleSoft Manufacturing integrations with other PeopleSoft Financial and Supply Chain Management (FSCM) applications. The integration points are explained below the diagram:

We discuss integration considerations in the appropriate topics in several PeopleSoft Documentation.

PeopleSoft Asset Management

PeopleSoft Manufacturing enables you to track assets and maintain service schedules by optionally linking asset information from PeopleSoft Asset Management to machine and tool resources in PeopleSoft Manufacturing.

PeopleSoft Cost Management

PeopleSoft Cost Management defines the costing and accounting structure for all PeopleSoft Manufacturing operations. You can define various costing methods for an item, such as standard, actual, perpetual, retroactive, and periodic cost. Robust cost analytics are provided to help you analyze the costs.

PeopleSoft Engineering

As part of our design-to-deploy solution, if you have PeopleSoft Engineering installed, you can take advantage of the integration between PeopleSoft Manufacturing and PeopleSoft Engineering to:

Maintain both engineering BOMs and manufacturing BOMs.

Maintain both engineering and manufacturing routings.

Transfer BOMs and routings between PeopleSoft Manufacturing and PeopleSoft Engineering.

Maintain document versions.

Make mass changes to manufacturing BOMs using ECOs.

View ECOs.

PeopleSoft Flow Production

If you are using PeopleSoft Flow Production, you can use streamlined replenish techniques to replenish production materials. Material can be replenished from an inventory location, feeder line, or supplier.

PeopleSoft Inventory

PeopleSoft Manufacturing uses PeopleSoft Inventory to define item attributes, issue raw materials and subassemblies, and store finished goods. The system automatically notifies PeopleSoft Inventory to replenish the WIP location when material is consumed and falls below user-defined levels during the backflush process.

PeopleSoft Manufacturing accesses these items in PeopleSoft Inventory:

Approved items in creating a BOM.

Approved items, item groups, and item families in the creation of master routings.

Material storage locations that are used to assign WIP locations to work centers.

PeopleSoft Product Configurator

PeopleSoft Product Configurator accesses routing information from PeopleSoft Manufacturing. The production configuration process takes the detailed configuration information that is captured during order management and sends requirements to PeopleSoft Manufacturing.

PeopleSoft Order Management

PeopleSoft Manufacturing can receive configured production orders that are created in PeopleSoft Order Management using PeopleSoft Product Configurator. PeopleSoft Manufacturing produces finished goods to fulfill orders that are taken by PeopleSoft Order Management.

PeopleSoft Purchasing

PeopleSoft Manufacturing accesses supplier information from PeopleSoft Purchasing for subcontracted tasks and operations on a routing, as well as for PeopleSoft Engineering. PeopleSoft Purchasing works closely with PeopleSoft Manufacturing to manage subcontracting operations. After production has been released, you can select the production IDs with subcontracted operations and send the information to PeopleSoft Purchasing, where purchase orders will be created. PeopleSoft Purchasing is used to provide raw materials for manufacturing.

PeopleSoft Quality

PeopleSoft Quality is used to record quality metrics during the manufacturing phase. PeopleSoft Quality accesses, from PeopleSoft Manufacturing, machine information to define machine stations where samplings occur and work center information to define work centers where samplings occur. If the installation includes PeopleSoft Quality, and you have defined quality configuration information and quality plans in PeopleSoft Quality for the manufactured item and its process, PeopleSoft Manufacturing enables you to transfer completions data to immediately initiate a quality data entry session in PeopleSoft Quality. Alarms will be triggered when PeopleSoft Quality identifies out-of-tolerance situations.

PeopleSoft Supply Planning

As part of our plan-to-produce solution, PeopleSoft Supply Planning accesses both planning BOMs manufacturing BOMs and routing and master routing information (work center, task, and operation) from PeopleSoft Manufacturing for supply planning and scheduling purposes.

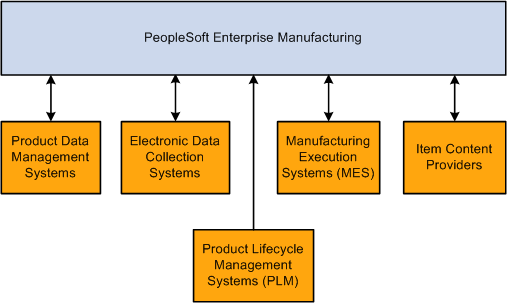

PeopleSoft Manufacturing and Third-Party Systems

This diagram illustrates PeopleSoft Manufacturing integrations with third-party systems using PeopleSoft enterprise integration points (EIPs). The third-party systems include product data management systems, electronic data collection (EDC) systems, product lifecycle management systems, manufacturing execution systems, and item content providers:

See Understanding the PDX Integration

Supplemental information about other third-party application integrations is located on the My Oracle Support website.

PeopleSoft Manufacturing EIPs

This section discusses the EIPs that are used by PeopleSoft Manufacturing to send and receive information.

|

EIP Name |

Description |

|---|---|

|

Actual Hours (PRODUCTION_ACTUAL_HOURS) |

You may also want to record actual hours information that is associated with specific production, and this information may have been captured by a third-party system. Use the Actual Hours EIP to import actual hours information from third-party systems. This is an inbound, asynchronous message. |

|

Bill of Material (BOM_SYNC) |

If you use a third-party item content provider or product data management system to manage BOMs, use this EIP to import updates to engineering and manufacturing BOMs from an external system. This is an inbound, asynchronous message. |

|

Item Master (ITEM_SYNC) |

Import item information. This is an inbound, asynchronous message. See Understanding BOM Maintenance |

|

Production Completions (PRODUCTION_ORDER_COMPLETION) |

If you use a third-party system to record completions for production, use this EIP to import information into PeopleSoft Manufacturing. This is an inbound, asynchronous message. See Understanding the Process of Recording Completions and Scrap Using Electronic Data Collection |

|

Production Order Issue (PRODUCTION_ORDER_ISSUE) |

Use this EIP to import edit or issue component information from a third-party system. This is an inbound, asynchronous message. |

|

Production Order Update (PRODUCTION_ORDER_UPDATE) |

Use this EIP to export production order or production schedule changes to an external system. This is an outbound, asynchronous message. |

|

Production Picking (PRODUCTION_PICKING) |

Import picking information from third-party systems. This is an inbound, asynchronous message. |

|

Production Serial Association (PRODUCTION_SERIAL_ASSOCIATION) |

Use this EIP to import production genealogy information from an external system. This is an inbound message. |