Understanding the Purchase Order Sourcing Business Process

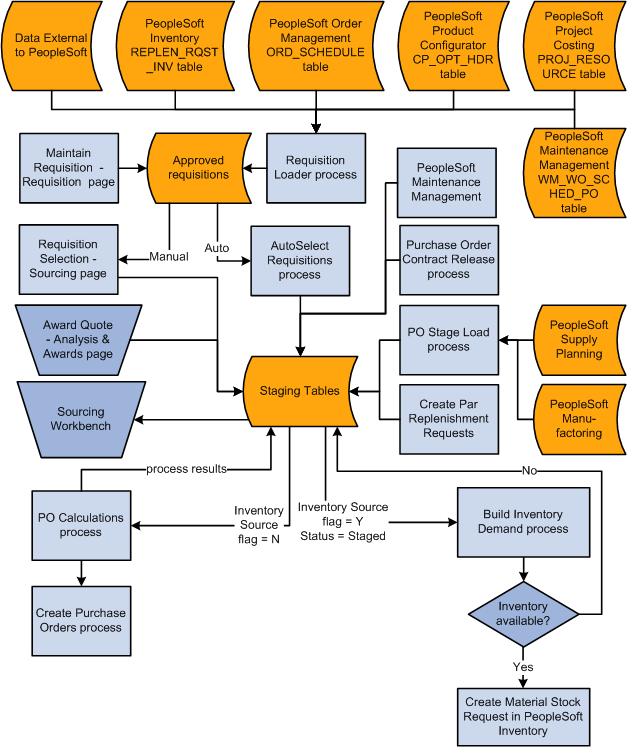

The purchase order sourcing business process creates purchase orders from item requests loaded to the PeopleSoft Purchasing staging tables from various sources.

This diagram provides an overview of the sourcing business process flow and illustrates item requests origins such as external data and PeopleSoft Inventory and Order Management:

These business processes also feed into the sourcing processes and are covered in other sections of this book:

Awarding requests for quotes (RFQs).

Awarded RFQs are loaded to the Purchasing staging tables for purchase order creation.

Staging contract releases for purchase order creation.

Staging par location (cart) replenishment requests for purchase order creation.

The primary PeopleSoft Purchasing sourcing staging tables are:

Term |

Definition |

|---|---|

PO_ITM_STG |

This core staging table provides line and schedule level information destined for the purchase order. The information in the table may be derived from the requisition, requests for quotes, supply planning, manufacturing, par replenishment, or contracts. Many fields on this table are work fields and should be ignored. These fields in the PO_ITM_STG table are particularly important: PO_STG_TYPE: R (requisition) is used for the AutoSelect Requisitions process (PO_REQSORC) or for online requisition selection when the Define purchase order option is not selected. O (other) is used for any other process. PO_STG_ID: This is the same as the requisition ID when the PO stage type is R. This field is derived from INSTALLATION_PO.LAST_PO_STG_ID, when the purchase order stage type is O. PO_PROCESS_ID: Indicates the process that placed the row into the staging table. CONSOLIDATE_FLG: Indicates whether similar rows (same item and supplier) can be consolidated into a purchase order during the PO Calculations process (PO_POCALC). OVERRIDE_SUGG_VNDR: Indicates whether or not the PO Calculations process can override the suggested supplier with the preferred supplier. INVENTORY_SRC_FLG: Indicates whether a given row is destined for inventory demand or for a purchase order. |

PO_ITM_STG_UD |

The PO Calculations process takes the information from PO_ITM_STG and copies it, along with each possible supplier from whom the item can be sourced, to PO_ITM_STG_UD. Due to the addition of suppliers, PO_ITM_STG_UD may contain multiple rows for each row in PO_ITM_STG. As the PO Calculations process performs its calculations, it stores the updated information in PO_ITM_STG_UD, leaving the original request information in PO_ITM_STG untouched. Once the sourcing process is complete, the supplier and purchase order ID results update PO_ITM_STG. |

PO_DISTRIB_STG |

This table provides distribution information. One row is placed here for each distribution destined for the purchase order. For requisitions, the information in this table comes directly from the requisition. Note: RFQ, supply planning, manufacturing, par replenishment, and contract requests also populate this table. Information in this table is copied to the PO_LINE_DISTRIB table. |

PO_HDR_STG |

This is an optional table built by online requisition selection, RFQs, and contract releases. It is used for manually consolidated requisitions to specify information destined for the Purchase Order Header table (PO_HDR). |

This table illustrates the possible stage statuses (STAGE_STATUS) in the PO_ITM_STG and PO_ITM_STG_UD tables:

|

STAGE_STATUS |

Description |

Explanation of Status |

|---|---|---|

|

B |

Ready to create |

Set by the sourcing workbench pages once the selected supplier is approved, or by the PO Calculations process if the auto approve option is selected. Can be changed to R (recycle) or, for some sources, to X (reset and purge). |

|

C |

Completed |

Set by the Create Purchase Orders process once a purchase order has been created successfully and processing is complete. No changes are allowed. |

|

D |

Inv demand (inventory demand in process) |

Indicates that the Build Inventory Demand process is running. Set by the Build Inventory Demand process once started and while processing. No changes allowed. |

|

E |

Error |

Set by the PO Calculations process if any errors are found. Can be changed to R, or for some sources, to X. |

|

I |

In Process |

Set by the AutoSelect Requisitions process and other processes, such as the PO Stage Load process while building the rows in PO_ITM_STG. No changes are allowed. |

|

N |

Pending (needs approval) |

Set by the PO Calculations process once there are no errors and the purchase order is ready for building but still needs the supplier to be approved in the sourcing workbench pages. Can be changed to B (build), R, or for some sources, to X. |

|

P |

POCREATE in process |

Indicates that the Create Purchase Orders process is running. Set by the Create Purchase Orders process once started and while processing. No changes are allowed. |

|

R |

Recycle (error recycle) |

Set in the Sourcing Workbench pages once an error is reviewed and the user indicates that it should be recycled by the PO Calculations process. Can be changed for some sources to X. |

|

S |

Staged |

Set by the AutoSelect Requisitions process, online requisition selection, and processes such as the PO Stage Load process once the process completes and the staged row is ready to be sourced. Can be changed for some sources to X. |

|

V |

POCALC in process |

Indicates that the PO Calculations process is running. Set by the PO Calculations process once started and while processing. Can be changed to R, or for some sources, to X. |

|

W |

Warning issued |

Set by the Create Purchase Orders process once a purchase order has been created but contains a warning, and processing is complete. No changes are allowed. |

|

X |

Reset and purge |

Entered on the Sourcing Workbench - Selected Items page. This action is possible for some sources when the stage status is S, V, N, E, R, or B. Once the status is X, no changes are allowed. Note: Only transactions built by certain processes can be set to the X stage status. To set the stage status to X, the row must have one of these process codes: SRC (reqsorc), OLS (online source), PLL (planning load), SFL (shop floor load), CRT (cart (par) replenishment), CON (contract release) or WKM (work order management). If the row was built by the RFQ Load process, you cannot use the X stage status. |

When selecting requisitions for sourcing either manually using the Requisition Selection - Sourcing pages or automatically using the AutoSelect Requisitions process, consider that a requisition must meet these conditions before it can be eligible for selection.

|

Record |

Field |

Value |

|---|---|---|

|

REQ_HDR |

IN_PROCESS_FLG |

N (no) |

|

REQ_HDR |

HOLD_STATUS |

N (no) |

|

REQ_HDR |

BUDGET_HDR_STATUS |

V (valid) |

|

REQ_LINE |

IN_PROCESS_FLG |

N (no) |

|

REQ_LINE |

SOURCE_STATUS |

A (approved) |

|

REQ_LINE |

CURR_STATUS |

A (approved) |

|

REQ_LINE |

RFQ_IND |

N (no) |

|

REQ_LINE_SHIP |

BAL_STATUS |

I (in balance) |

|

REQ_LINE_DISTRIB |

QTY_OPEN or AMT_OPEN |

> 0 (greater than 0) |

Note: If the AMT_OPEN field value is > 0, QTY_OPEN can have a value other than > 0. If the QTY_OPEN field value is > 0, AMT_OPEN can have a value other than > 0. Only one of these two REQ_LINE_DISTRIB field values must be > 0.

If no requisitions appear on the Requisition Selection - Sourcing page, consider reviewing the selection criteria that you entered on the Requisition Selection page. The requisition must meet these conditions before it can be selected:

The requisition line current status must be approved.

The RFQ indicator on the requisition line must be N (no).

The In Process flag on the requisition line must be N. When one line on a requisition is selected for sourcing, the In Process flag on the requisition line is set to Y (yes), indicating that the line cannot be touched until sourcing is complete. Once sourcing is complete, the In Process flag is turned off (set to N) and can be changed.

The hold status on the requisition header must be N.

The budget header status on the requisition header must be V (valid).

The source status on the requisition line must be A (approved).

The balance status on the requisition schedule must be I (in balance).

The open quantity or open amount on the requisition distribution must be greater than zero.

If you have frequent problems with unselected requisitions, build a query that displays all fields used in the selection process to see why the requisition is not eligible for selection.

See the product documentation for PeopleTools: Query