Running the PO Calculations Process

This section provides overviews of the PO Calculations process, sourcing methods, and procurement card assignment hierarchy and discusses how to run the PO Calculations process.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

RUN_PO_POCALC1 |

Enter the selection criteria for the PO Calculations process. Enter the run control criteria for the PO Calculations process and to run the process. |

The PO Calculations Application Engine process (PO_POCALC) performs most of the processing necessary to create a purchase order. After running the PO Calculations process, you can review the results of the process and make changes using the Sourcing Workbench - Sourcing page before the purchase order is created. After you run the PO Calculations process, run the Create Purchase Orders process to create the purchase order.

If you select the Pre-Approve Supplier check box on the PO Calculations - Run Controls page, the system automatically approves the Supplier recommended by the PO Calculations process, so that you can run the PO Calculations process and the Create Purchase Order process without interruption. If you do not select the Pre-Approve Supplier check box, you must approve the Supplier manually in the Sourcing Workbench.

You can review the results of the PO Calculations process on the Sourcing Workbench - Sourcing Details page and change the recommended Supplier. If you change a Supplier through the Sourcing Workbench, run the PO Calculations process again to recalculate the staged row.

Various Functions of the PO Calculations Process

The PO Calculations process performs various functions:

Selects a Supplier using one of the four different sourcing methods.

When you select to override the suggested Supplier, the PO Calculations process recommends and selects the Supplier for purchase orders based on the sourcing method and the sourcing method settings for each item. You can select from four methods of Supplier selection: basic, flexible, schedule split, or cumulative split sourcing. All of these sourcing methods are available at the category level; and basic, flexible, and schedule split sourcing can be overridden at the item level. When a new item is created, the sourcing option appears by default from the category, but a different value can be specified at the item level. An option at the item level indicates whether you should use the item or the category sourcing method. The sourcing method to be used for each requisition is set based on the information at the item or category level at the time that the requisition is sourced, either online through the Requisition Selection - Sourcing page or through the AutoSelect Requisitions process.

Changes purchase order values using the business unit, Supplier, item, or contract, based on the PeopleSoft Purchasing default hierarchy.

Consolidates requisitions onto purchase orders when the Consolidate flag is Y.

Note: The PO Calculations process does not combine multiple requisition lines onto one purchase order line unless they have the same item ID and contract information. Requisition lines with different items or contract information are maintained as separate lines.

Calculates a due date if one is not provided.

The PO Calculations process calculates the due date based on the item Supplier lead time, if it is indicated; otherwise, it calculates the due date based on the item lead time. The PO Calculations process also validates the due date against the closure calendar and, if necessary, adjusts the due date based on the closure calendar.

Determines the purchase order currency.

When you add to an existing purchase order or when header level information is specified in the stage table, the PO Calculations process uses the currency from the headers. If no currency is specified, the PO Calculations process uses the currency from the Supplier location that is specified during online requisition selection when using Define PO. All prices, amounts, and price tolerances are converted to the purchase order currency. The PO Calculations process does not convert to the contract currency if it is different; the process does, however, convert to the contract currency when it updates contract release amounts.

Converts to the Supplier unit of measure (UOM) if necessary.

The PO Calculations process uses the transaction UOM whenever possible, but if you have elected to consolidate purchase requests, the process converts to the Supplier default UOM. The PO Calculations process also converts to the Supplier default UOM if you have chosen not to consolidate, but the Supplier location does not accept all UOMs and the transaction UOM is not a valid UOM for the Supplier. If the PO Calculations process finds a contract that indicates that the contract base price should be used and if that price is in a different UOM, then the PO Calculations process converts the contract price to the transaction UOM.

Note: No UOM conversion takes place for amount only lines. If a UOM conversion is necessary (conversion rate changed or requisition UOM is not valid for the Supplier) then an error will be issued.

Rounds to whole numbers, if indicated, on the item or item Supplier.

If you specify whole number rounding at the item or item Supplier level for the transaction or standard UOM, the PO Calculations process rounds the quantity to whole numbers. If both UOMs require whole numbers and if the transaction quantity has decimals after the PO Calculations process has rounded the standard quantity, then the transaction is rejected. If the rounded transactions were split sourced, the PO Calculations process ensures that the sum of the split-sourced quantities still adds up to the schedule quantity. If the sum of the split-sourced quantities does not add up to the schedule quantity, then the transaction is rejected. The PO Calculations process does not adjust source documents (such as requisitions) for changes in quantity due to rounding.

Finds a contract.

If a contract is not specified in the transaction and the transaction source is a requisition or Par Location Replenishment, then the PO Calculations process attempts to find the most recent effective contract for which the transaction item matches on item, category, or open item reference for the already determined Supplier. If the contract does not meet minimum or maximum requirements, the PO Calculations process goes to the next most recent effective contract.

The system looks for a contract that is assigned to a specific purchase order if:

The transaction does not contain a PO_HDR_STG row.

This ensures that the system does not override the selection of a purchase order header.

The purchase order uses a contract with items associated to a line group.

A line group is a bundle of items that buyers use in PeopleSoft Sourcing to obtain better pricing for items. When a sourcing event is awarded to a purchase order and the items awarded are part of a line group, the system applies contract pricing from that line group to the specified Supplier.

The contract price and UOM match the transaction price and UOM.

If the transaction does not meet these requirements, then the PO Calculations process goes to the next most recent effective contract.

Because the PO Calculations process has not calculated the price at this point, it uses the item or Supplier base price when editing against minimum or maximum requirements. The contract maximums are verified at the line level. If you have multiple lines in a purchase order with the same item ID, then the sum of those line quantities and amounts is verified against the contract line maximums.

The contracts that the PO Calculations process reviews are restricted to the specified business unit when the contracts are set up in the system by business unit.

If a contract is specified on the stage table row (through online requisition or a contract release), the PO Calculations process ensures that the contract is still effective and that the maximum amounts and quantities have not been exceeded. If the contract is not still effective or the maximum amount or quantity is exceeded, then the PO Calculations process rejects the transaction. If a contract ID is specified, the PO Calculations process does not search for a different contract.

The PO Calculations process updates the contract release amounts. If you make a change in the Sourcing Workbench, run the PO Calculations process again before you run the Create Purchase Orders process. When you run the PO Calculations process again, the related contract updates are reversed.

Note: The PO Calculations process does not search for contract lines for items ordered by description. However, the PO Calculations process uses a contract that allows open items for both description-only and item ID lines.

When the PO Calculations process runs for a requisition and the process finds a blanket purchase order to use to fulfill the request, the PO Calculations process reserves the blanket purchase order. If you run the PO Calculations process again before running the Create Purchase Orders process, and the process finds a request for which the same blanket purchase order applies, the request line is assigned an error status. This is because the blanket purchase order is reserved by the previous run of PO Calculations process and cannot be accessed for sourcing the current request. To resolve the error, run the Create Purchase Order process to release the reserved blanket purchase order and recycle the row in Error status through the PO Calculations process.

Finds a Vendor rebate agreement.

If you are using the vendor rebate functionality, this process will determine and assign the appropriate vendor rebate agreement to the purchase order line. The PO Calculations process uses the same default hierarchy strategy when assigning a vendor rebate agreement as when creating a purchase order online.

Finds a procurement card or Supplier card to use as the payment method.

If you are using the procurement card functionality, this process will determine and assign the appropriate procurement card or Supplier card to the purchase order line. The PO Calculations process uses a hierarchy strategy when assigning the correct card number to a purchase order line.

Calculates the price.

If you select the calculate price option, the PO Calculations process recalculates the price. The process begins with the price from the item. If it finds a contract or if a contract is specified, and the contract indicates to use the contract base price, the PO Calculations process uses the contract base price as the starting price instead of the item price. If no contract exists, or if the contract does not indicate to use the contract base price, and the PO Calculations process finds an item Supplier price, it uses the item Supplier price as the starting price instead of the item price.

When finding an item Supplier price, the PO Calculations process searches the item Supplier prices in this order and stops at the first place that it finds a price:

Item Supplier price for the transaction UOM and transaction currency.

Item Supplier price for the transaction UOM and Supplier location currency (the PO Calculations process converts it to the transaction currency).

Item Supplier price for the default UOM and transaction currency (the PO Calculations process converts it to the transaction UOM).

Item Supplier price for the default UOM and Supplier location currency (the PO Calculations process converts it to transaction UOM and transaction currency).

Item price.

Once the PO Calculations process has the starting price, it then applies contract and Supplier price adjustments as indicated by the pricing rules. The process also creates value adjustments to show the starting price and each price adjustment.

The sourcing price tolerances are set at the business unit level on the Purchasing Definition - Business Unit Options page and follow the PeopleSoft Purchasing default hierarchy.

Calculates miscellaneous charges, freight, sales and use tax, and value-added tax (VAT).

Separates POs by Ship To Location

The PO Calculations process will separate POs by unique Ship To Location if the related Supplier / Business Unit setting indicates to do so with the following qualifications:

If the Define PO option is set (that is, via Requisition Selection) and the Supplier/BU setting is defined to create Separate POs based on Ship To, the resulting PO will have the same structure to match the Requisition structure even though the resulting PO schedules have a mix of Ship To Locations. In this case:

The PO is not split.

The PO Header “Use One Ship To” is turned off and the PO retains multiple Ship To’s.

PO Create will later send the Enterprise Components Notification Framework message to the buyer alerting that the PO was not split.

For POs with One-time addresses or Direct Shipments containing one or more Ship To locations and the Supplier or BU setting is defined to create separate POs for each Ship To location:

PO Calculations will split schedules based on unique Ship To locations with the Use One Ship To flag turned ON for each resulting PO.

The One-Time Addresses, Direct Shipments, or both will be retained in a separate PO with the Use One Ship To flag turned OFF. Notifications for this type of scenario will not be sent.

If the Automatic Item Substitution is selected at the BU Level Option, and the Auto Item Substitution field is selected and the Original Substitute Item field in the staging record is populated, then the sourcing process will use this Item ID when searching for Substitute Items. However, if the Original Substituted Item field in the staging record is not populated, it will use the Item ID value when searching for Substitute Items.

The Sourcing process performs the Item Substitute Usage Rules to search for Substitute Items and determines the most appropriate Substitute Item to use for the Original Substituted Item.

For information on Item Substitute Usage Rules, seeUnderstanding Item Substitution in Procurement Item Substitute Usage Rules.

If a substitute item was specified in the Requisition and PO Sourcing found a different Item Substitute (perhaps with a different date), PO Sourcing uses the most valid substitute item for the purchase order. PO Sourcing will update the Original Substituted Item and Description if it finds a valid substitute. The system does not check for substitutes of substitutes.

PO Sourcing bypasses Item Substitution if a Procurement Group is associated with the line and the Item is the Primary Unit for the Procurement Group or the Allocate Purchasing Group option is enabled in the Business Unit Options table.

PO Sourcing will follow the same UOM Conversion and Pricing logic done for Online Requisitions.

Example: Item 10012 is selected in a requisition. An applicable item substitute item does exist for this item. Because the BU level option indicates to substitute requester’s item with substitute, the item in the requisition is changed to 10012A. PO Sourcing will look to determine whether a valid substitute exists for item 10012, the original item in the requisition. If item 10012B is now the most valid item substitute, then this item will be used for the PO.

Technical Details of the PO Calculations Process

The PO Calculations process acts on the PO_ITM_STG table and creates PO_ITM_STG_UD and PO_ITM_STG_VND.

The PO_ITM_STG_UD table contains the recommended Supplier, any other eligible suppliers (for flexible sourcing), and the results of all the calculations (due date, price, UOM conversion, currency conversion, and so on). You can view the PO_ITM_STG_UD table data on the Sourcing Workbench - Sourcing Details page and change the recommended Supplier. If you use the Sourcing Workbench to change a Supplier, you must run the PO Calculations process on the staged row to recalculate values.

The PO_ITM_STG_VND table contains the details for the flexible sourcing method and can be viewed using the Flexible Sourcing page.

If the PO Calculations process has not run, PO_ITM_STG_UD and PO_ITM_STG_VNDR do not exist. If the PO Calculations process has run, but an error was encountered for a staged row, a row may or may not exist in PO_ITM_STG_UD and PO_ITM_STG_VND.

For basic and cumulative split sourcing, if the PO_POCALC process runs and the staged row has no errors, then 1 row exists in PO_ITM_STG_UD for each row in PO_ITM_STG.

One row also exists in PO_ITM_STG_VND.

For flexible sourcing, if the PO_POCALC process runs and the staged row has no errors, then multiple rows may exist in PO_ITM_STG_UD for one row in PO_ITM_STG, one row for each possible Supplier.

Each row is for the full quantity in PO_ITM_STG. PO_ITM_STG_VND also has a corresponding row for each Supplier.

For schedule split sourcing, if the PO_POCALC process runs and the staged row has no errors, then multiple rows may exist in PO_ITM_STG_UD for one row in PO_ITM_STG.

Together, they add up to the full quantity in PO_ITM_STG or possibly more than the full quantity due to UOM rounding.

If the PO Calculations process does not return the expected results, confirm that you have set the Define PO option, Inventory Source option, and the price tolerances appropriately.

You can review requested prices and tolerances on the Sourcing Workbench - Sourcing Details page. Sourcing price tolerances are set at the business unit level on the Purchasing Definition - Business Unit Options page and can be overridden in the requisition.

To use these sourcing methods, select the Override Suggested Supplier option on the Sourcing Controls page. If this option is deselected, the system uses the Supplier provided in the transaction.

Basic Sourcing

Basic sourcing, also referred to as sourcing method basic, can be set at the category level and overridden at the item level.

Here is how the Supplier order location is determined:

If a priority item ship to Supplier exists, the PO Calculations process uses this value for the Supplier ID and order location.

If a priority item ship to Supplier does not exist, the PO Calculations process identifies the best Supplier by using the Item Region Supplier page, while getting the region from the Ship To Location (SHIPTO_TBL).

If the item region Supplier does not exist, the system finds the best Supplier by using the priority Supplier from item Supplier definition (ITM_Supplier).

Once a Supplier is determined and if the Supplier was not selected from the Item Ship To Supplier or the Item Region Supplier tables, the system must determine the appropriate Supplier location to associate with the staged line.

The Supplier location is first provided by default from the ship to order location.

If the Supplier location is not in the Ship To Order Location table, the system checks the Region Order Location table (REGION_VNDR_LOC) to change the Supplier location associated with the ship to location's region.

If a priority item Supplier exists, but neither the ship to order location or region order location exist for that Supplier, the PO Calculations process uses the priority item Supplier, with its default order location.

If a Supplier still isn't found, the Supplier and Supplier order location are obtained from the category priority Supplier for the category.

In basic sourcing, the pricing location comes from the Supplier pricing location indicated by the order location.

Flexible Sourcing

Flexible Supplier sourcing, also referred to as sourcing method Flexible, can be set at the category level and overridden at the item level. With flexible sourcing, the PO Calculations process selects a Supplier based on best price, lead time, item Supplier, and ship to priority Supplier.

With flexible sourcing, the PO Calculations process calculates due dates, prices, item ship to, and item Supplier priority, and then determines the best Supplier for the item based on the weight that you give each criterion. The eligible suppliers come from the item Supplier.

The PO Calculations process bases the Supplier selection on these available criteria:

Term |

Definition |

|---|---|

Lead Time |

The PO Calculations process assigns a percentage rank value to each Supplier based on the number of lead days. The percentage rank is calculated as this Supplier lead days divided by the total lead days for all eligible suppliers. |

Price |

The PO Calculations process assigns a percentage rank value to each Supplier in the order of price. The percentage rank is calculated as this Supplier price divided by the total price for all eligible suppliers. |

Item Ship To Supplier Priority |

The PO Calculations process assigns a percentage rank value to each Supplier in the order of item ship to Supplier priority. The percentage rank is calculated as this Supplier item ship to priority divided by the total item ship to priority for all eligible suppliers. |

Item Supplier Priority |

The PO Calculations process assigns a percentage rank value to each Supplier in the order of item Supplier priority. The percentage rank is calculated as the Supplier item Supplier priority divided by the total item Supplier priority for all eligible suppliers. |

The weight of the criteria is set by percentage. You can select how much weight to give to lead time, price, ship to, and Supplier at the category level, at the item level, and on the PO Calculations page. The higher the percentage that you give to one of the criterion, the more weight that criterion has. For example, suppose that you want to select the Supplier based only on lead time, you can give lead time a percentage weight of 100 percent and the Supplier with the best lead time, regardless of price, ship to, or Supplier priority, is selected.

Once the PO Calculations process ranks the suppliers for each of the four criteria, it applies the ranking of each of these criteria to determine the best Supplier. In the case of a tie between suppliers, the process uses the item Supplier priority ranking as a tiebreaker.

The mathematical formula that the process uses is:

((Lead Time / Sum of lead times) * Lead time User rank) + ((Price / Sum of prices) * Price User Rank) + ((Shipto Priority / Sum of Shipto Priorities) * User rank) + ((Supplier Priority / Sum of Supplier Priorities) * User rank)

Note: When you use flexible sourcing, method Flexible, pricing is always done at the schedule level, never at the line level.

Schedule Split Sourcing

Schedule split sourcing, also known as sourcing method Split, can be set at the category level and overridden at the item level. With schedule split sourcing, you can split orders to multiple suppliers at the schedule level, based on predefined percentages. For example, suppose that you want to source 60 percent of all orders for an item or category to Supplier A and 40 percent to Supplier B. Set the sourcing rules to define which suppliers supply this item or category and the percentage that goes to each Supplier.

The PO Calculations process selects suppliers for schedule split sourcing based on where the source method is set.

If you specify the source method on the item, then the item suppliers are used along with their percentage allocation.

If you specify the source method on the category, then the category suppliers are used with their percentage allocation.

You must select the Use Category Source Controls option at the item category level for the system to use category sourcing controls.

The other sourcing methods source 100 percent of the quantity to the selected Supplier. With schedule split sourcing, each schedule is split so that a portion of the quantity is sourced to each item Supplier.

If the Supplier minimum order quantity is not met, the transaction is rejected.

Note: If you are using the schedule split sourcing method, all established item Supplier relationships must be defined with an allocation value greater than zero and a cumulative total of 100. Schedule split sourcing splits orders among multiple suppliers, not among multiple Supplier locations. Schedule split sourcing cannot split orders among multiple locations for the same Supplier.

Cumulative Split Sourcing

Cumulative split sourcing, also referred to as historic split sourcing and sourcing method Cumulative, like schedule split sourcing, enables you to split orders to multiple suppliers based on predefined percentages. Unlike schedule split sourcing, this method sources the purchase order line to the first Supplier in the priority list until the Supplier's order percentage for the item category is met. Over time, the percentage sourced to each Supplier should be close to the percentage that you define on the Item Supplier Priority page.

Based on the setting in the Accumulate Level field on the Item Categories - Category Definition 3 page, the percentage that you define on the Item Supplier Priority page is accumulated based on each run of the PO Calculations process or based on each schedule. You can override this setting using the Accumulate Level field on the PO Calculations - Run Controls page.

If you select Run, all schedules for the item category being processed in the process run are grouped together when finding a Supplier. All schedules for the category are sourced from the same Supplier.

If you select Schedule, the process examines each schedule individually when finding a Supplier and accumulates the percentage for each Supplier based on each schedule. The schedules are assigned to the same Supplier until that Supplier's predefined percentage is met, then they are assigned to the next Supplier until the second Supplier's predefined percentage is met, and so forth through all the available suppliers. It then cycles back to the first Supplier. Each schedule could have a different Supplier.

The schedule accumulate level offers greater and more accurate control, while the run accumulate level offers better performance.

PeopleSoft Purchasing maintains records on historical order amounts to determine to which Supplier the purchase order line should be sourced. This is the only source method that is available only at the category level. The suppliers are selected from the category suppliers.

When you dispatch the purchase order, the total order amount is updated on the category Supplier and on the category to maintain the historical information. The Cumulative Sourcing Update process (PO_POHISTUD) maintains the historical information when you modify category or category-Supplier-level information.

Understanding the Procurement Card Assignment Hierarchy

The PO Calculations process determines the correct procurement card or Supplier card to use on the purchase order as a payment method if you are using the procurement card functionality. This table illustrates how the procurement card or Supplier card is assigned to a purchase order:

|

If Consolidate Req Lines |

If Suggested Supplier Can Be Overridden |

If Chosen (or final) Supplier Accepts Cards |

If Supplier Card is Available |

If Use Procurement Card Specified on Req |

Procurement Card That Will Appear on PO |

|---|---|---|---|---|---|

|

N |

N Supplier must be entered in requisition. |

N Chosen Supplier does not accept any cards. |

N Supplier cannot accept Supplier card if they don't accept any cards. |

Not applicable Supplier does not accept any cards. |

None |

|

N |

Y |

N |

N |

Not applicable Supplier does not accept any cards. |

None |

|

N |

Y |

Y Chosen Supplier accepts cards. |

Y |

Not applicable Supplier card is always used. |

Supplier card |

|

N |

Y |

Y |

N |

N |

None Use buyer default procurement card if it is valid. |

|

N |

Y |

Y |

N |

Y |

Use the specified procurement card if it is valid. If none used, use the buyer default procurement card if it is valid. |

|

Y |

Y |

N |

N |

Not applicable Supplier does not accept any cards. |

None |

|

Y |

Y |

Y |

Y |

Not applicable Supplier card is always used. |

Supplier Card |

|

Y |

Y |

Y |

N |

N |

None Use buyer default procurement card if it is valid. |

|

Y |

Y |

Y |

N |

Y |

Use the specified procurement card if it is valid. If none used, use the buyer default procurement card if it is valid. |

You can use pricing from contracts for requisitions and purchase orders. Using the Default Contract on Req and Default Contract on PO check boxes on the Business Unit Options page, you can make contracts available for use with requisitions and purchase orders.

For more information about how contracts are assigned pricing, see Creating Requisitions Online.

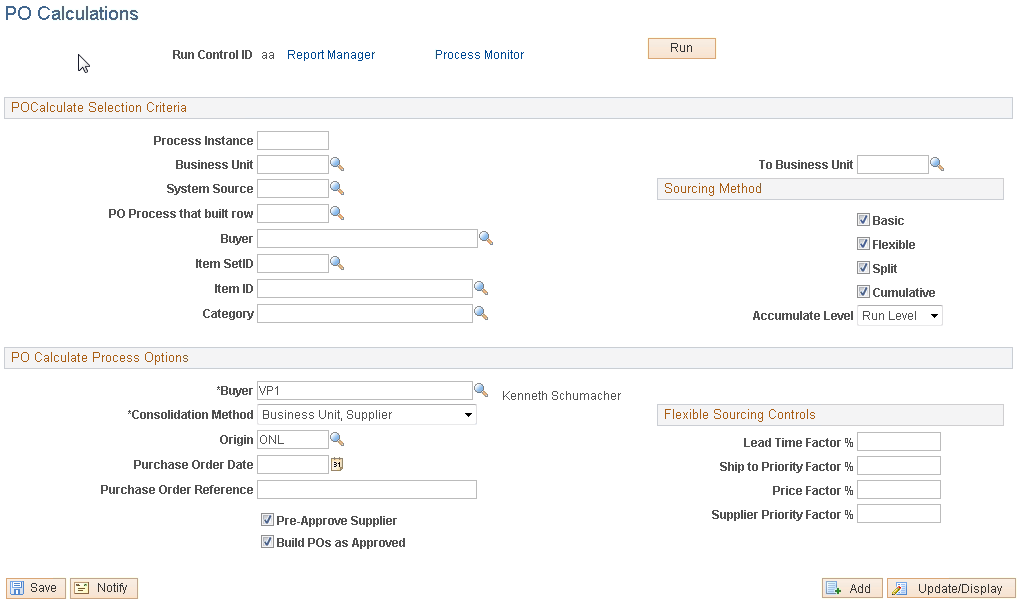

Use the PO Calculations page (RUN_PO_POCALC1) to enter the selection criteria for the PO Calculations process.

Enter the run control criteria for the PO Calculations process and to run the process.

Navigation:

This example illustrates the fields and controls on the PO Calculations page. You can find definitions for the fields and controls later on this page.

PO Calculate Selection Criteria

Selecting field values in this group box limits the selection of staged rows to those that meet the criteria selected. These fields are optional.

Sourcing Method

All sourcing methods are selected by default. The selected methods are included when you run the PO Calculations process. If you do not want to include a particular sourcing method, deselect the check box.

If you do not select any of the sourcing methods, only staged rows with a Supplier provided and the Override Suggested Supplier check box deselected are included when you run the PO Calculations process.

Field or Control |

Description |

|---|---|

Accumulate Level |

This is not a selection criteria for the process, but rather is used in conjunction with the cumulative sourcing method. Select a value to determine how to accumulate the percentages for cumulative split sourcing. Select Schedule level if you want each schedule to be examined individually when finding a Supplier. With this accumulate level, the schedules are assigned to the same Supplier until that Supplier's predefined percentage is met, then they are assigned to the next Supplier until the second Supplier's predefined percentage is met, and so forth through all the available suppliers. Then it cycles back to the first Supplier. Each schedule could have a different Supplier. Select Run if you want all schedules for that category being processed during the run to be grouped together when finding a Supplier. With the run accumulate level, all schedules for the category will be sourced from the same Supplier. Note: The schedule accumulate level offers greater and more accurate control, but the run accumulate level offers better performance. |

PO Calculate Process Options

Field or Control |

Description |

|---|---|

Buyer |

(Required) Select the buyer to be used on the purchase order header in the event that the PO Calculations process cannot determine the buyer. The buyer name is carried at the line level on the requisition, so a requisition can have multiple buyers. When the PO Calculations process creates the purchase order header, it must assign a buyer name.

|

Consolidation Method |

Determines whether purchase orders are consolidated by business unit, Supplier, and buyer or by business unit and Supplier only. The consolidation method applies only to staged rows identified for consolidation. For example, suppose that you choose to consolidate by business unit and Supplier, then all rows with the same Supplier and business unit are grouped onto one purchase order. Alternately, if you add buyer to the consolidation criteria, all rows that have the same buyer, Supplier, and business unit are grouped on a purchase order. |

Origin |

(Optional) Select an origin to be used on the purchase orders. |

Purchase Order Date |

Enter a date to be used on the purchase orders, for purchase orders that do not already have a date assigned. If you leave this field blank, the PO Calculations process uses the current system date. |

Purchase Order Reference |

(Optional) Enter a purchase order reference to be used on the purchase orders. This is a free-form field. |

Pre-Approve Supplier |

Select this check box to approve the Supplier that the PO Calculations process selects. If selected, the system automatically approves the Supplier recommended by the PO Calculations process, so that you can run the PO Calculations process and the Create Purchase Order process without interruption. If you do not select the Pre-Approve Supplier check box, you must approve the Supplier manually using the Sourcing Workbench. If you change a Supplier using the Sourcing Workbench, you must run the PO Calculations process again for the staged row to be recalculated. |

Build POs as Approved (build purchase orders as approved) |

Select this check box to have purchase orders created with an Approved status when you run the Create Purchase Orders process. If selected, the process examines auto approval criteria set at the business unit level. If the auto approval criteria are met, the status is set to Approved. If the auto approval criteria are not met, the status is set to Pending Approval, and the purchase order enters the workflow approval business process. If you do not select this check box, the purchase order is created with a status of Open. |

Flexible Sourcing Controls

Field or Control |

Description |

|---|---|

Lead Time Factor %, Ship to Priority Factor %, Price Factor %, and Supplier Priority Factor % |

Used for flexible sourcing. To override the category and item settings, enter the percentage weight that you want the PO Calculations process to give the lead time, ship to, price, and Supplier factors when the application process is evaluating suppliers for flexible sourcing. The sum of all four factor fields must add up to 100 percent. |