Creating Capacity Planning Reports

Planning reports show how effectively targets and performance goals were met. Reports display targets achieved, variances from the production budget, and areas for improvement.

To create a capacity planning report:

-

Go to Advanced Manufacturing > Capacity Planning > Capacity Planning Reports.

-

Select a Capacity Plan from the list.

-

Click Display Plan to update the work center summary table for review.

-

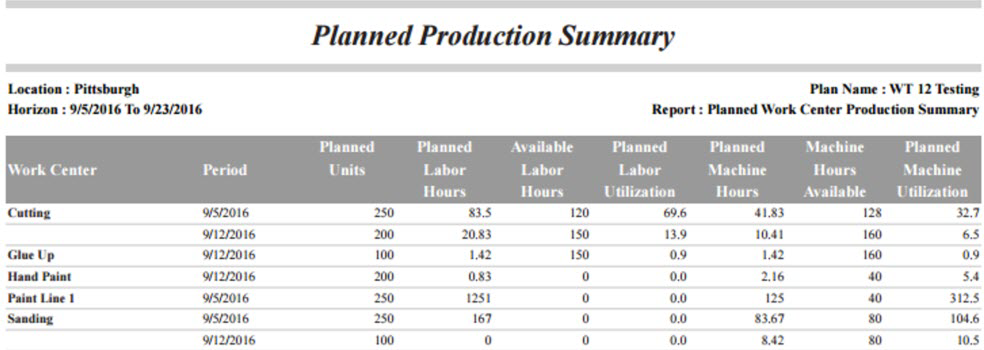

The Work Center - where the work is being done.

-

Units Planned - represents the number of items to be produced in this plan.

-

Planned Labor Hours - the number of hours labor is assigned to the plan.

-

Labor Hours Available - the number of labor hours available to the plan.

-

Planned Labor Utilization % - the percentage of total labor hours to be used in the plan.

-

Planned Machine Hours - the number of hours machines are assigned to the plan. This number is positive even when available hours is zero.

-

Machine Hours Available - the number of machine hours available to the plan.

-

Planned Machine Utilization % - the percentage of total machine hours to be used in the plan.

-

-

Select a Report type:

-

Work Center Planned Production Summary - Display planned production load for a work center. Load is the sum of the number of times all planned and actual orders are run on the work center in a specified period.

-

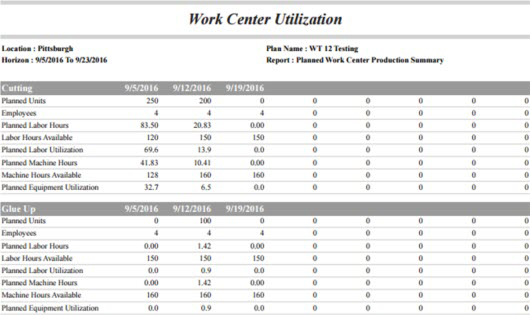

Work Center Utilization by Period - Review available work center hours against recorded work center use. The system reports utilization measurements for both labor and machines by work center.

-

-

Click Print Report.