Redwood: Reserve Materials for a Manufacturing Work Order Using a New User Experience

Manufacturers can utilize material reservations to ensure that the specified quantity is available for a work order to ensure uninterrupted production. In a prior release, you could reserve materials automatically using a scheduled process for one or more work orders from a Redwood page. Using the Redwood user experience, you can now reserve materials manually for a work order operation using the Work Orders page or Edit Work Order page.

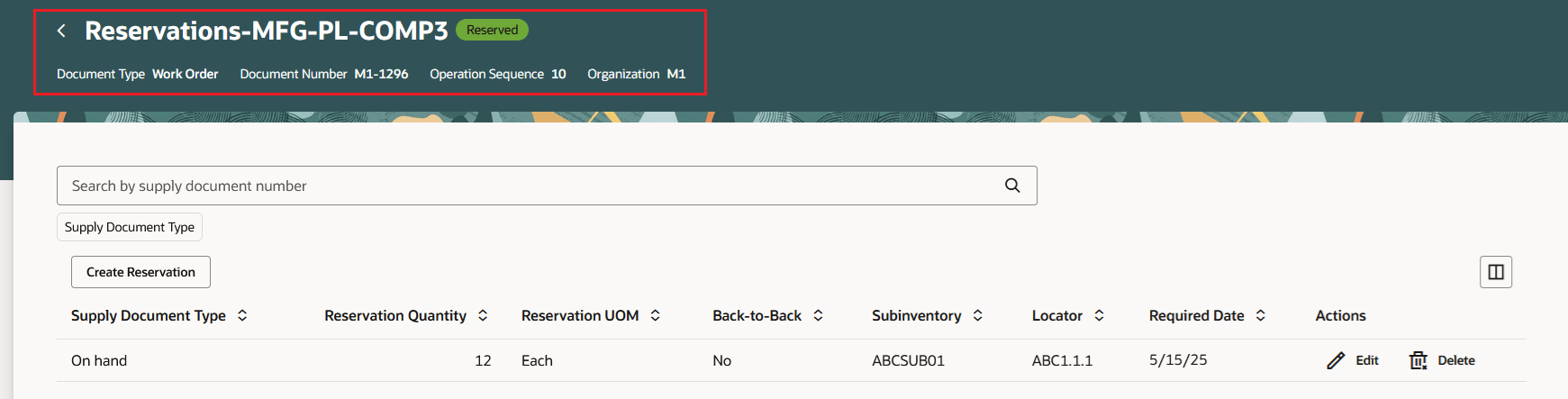

You can create a high-level material reservation at the organization level or a detailed material reservation at a subinventory, locator, lot, or serial level. For an existing reservation for a work order operation item, you can review and edit the reservation details that links demand in context of the work order operation to the supply.

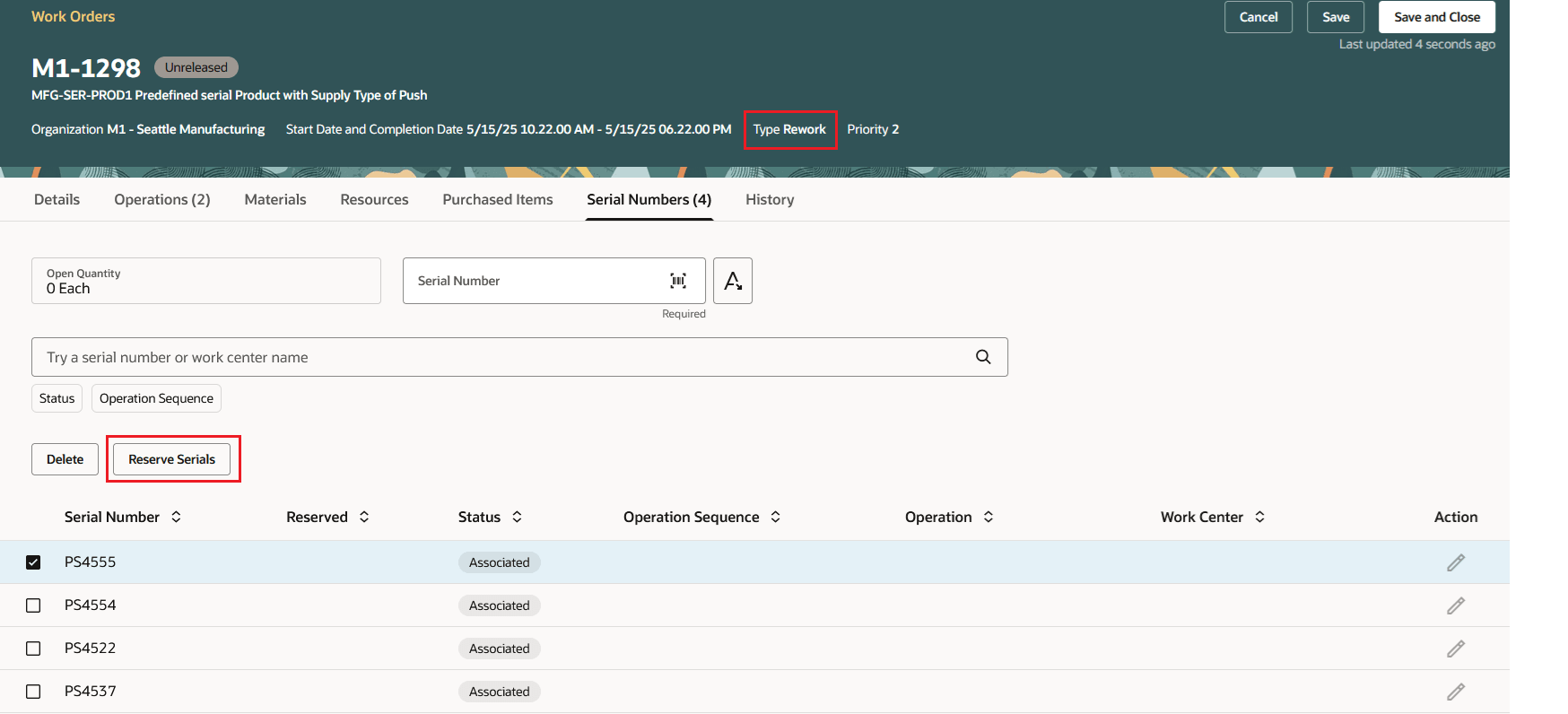

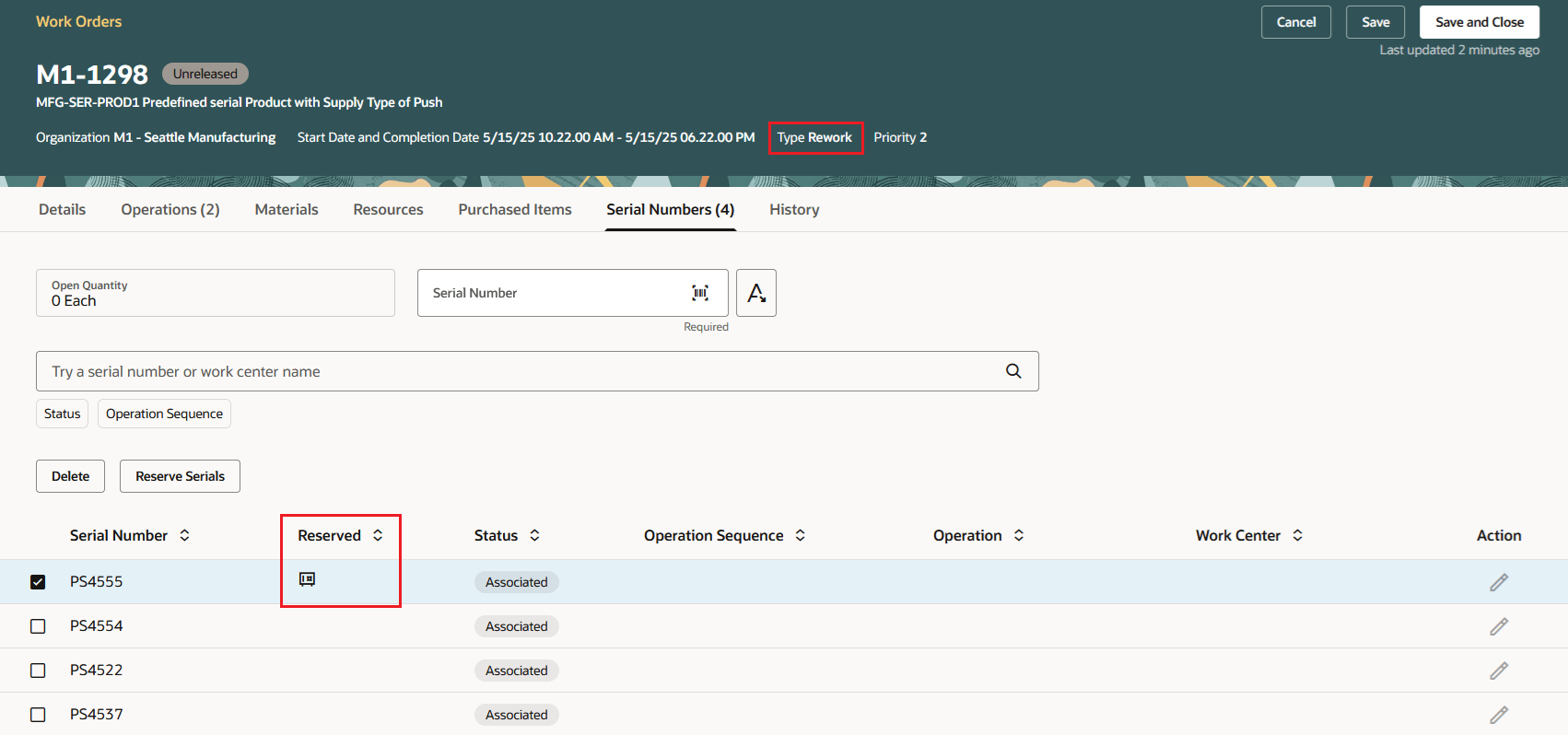

When rework is needed in serialized manufacturing, you can also reserve the serial numbers for a product in a rework work order.

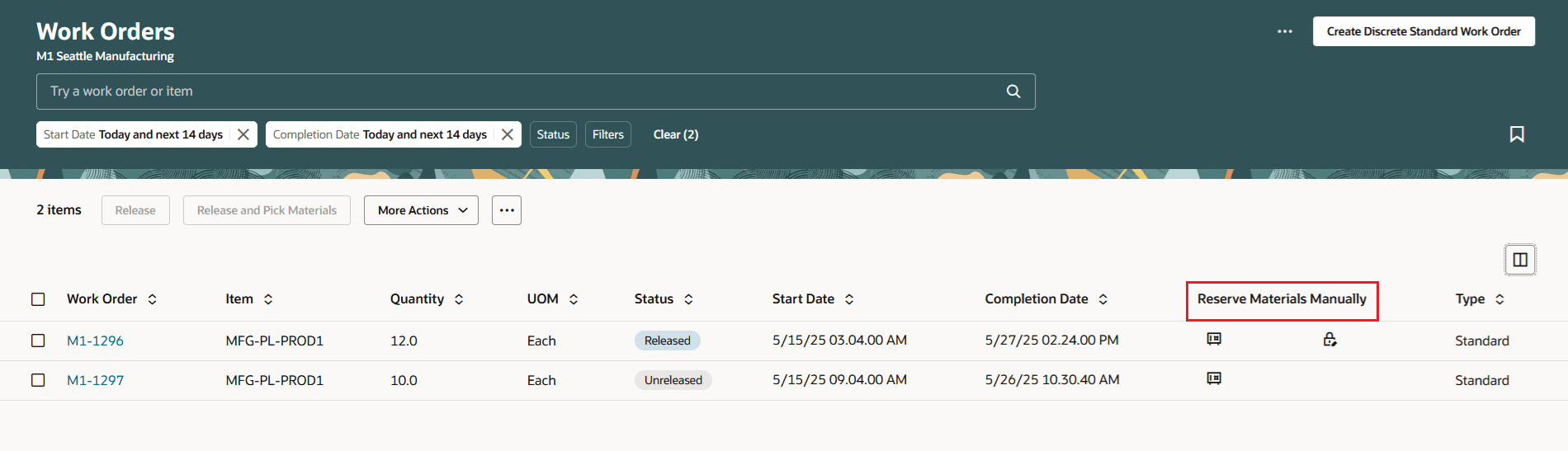

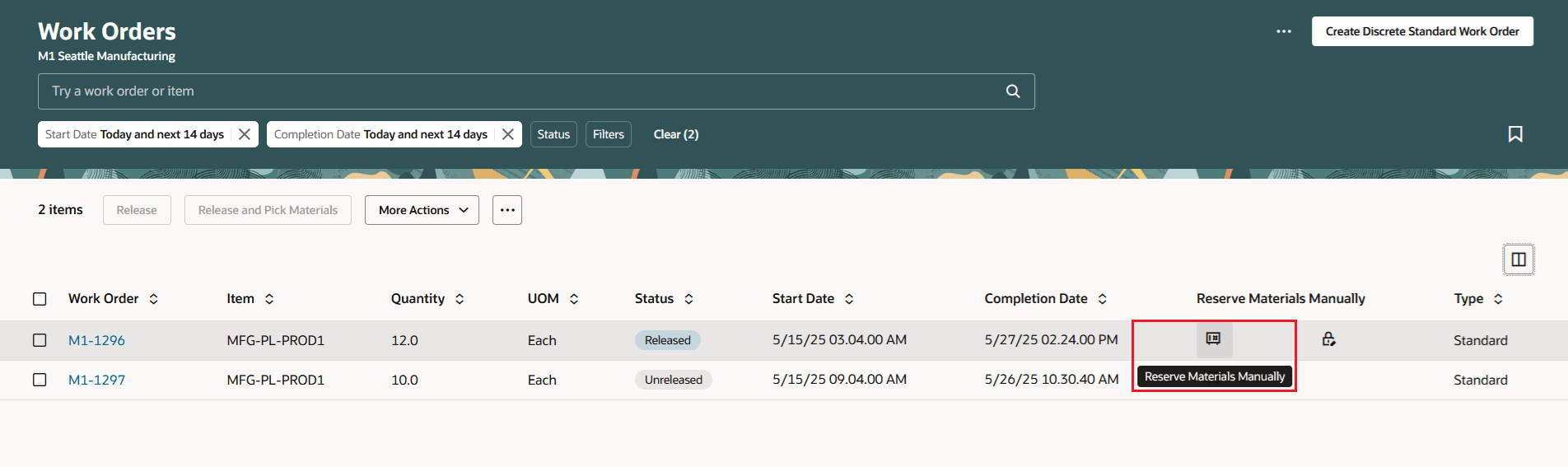

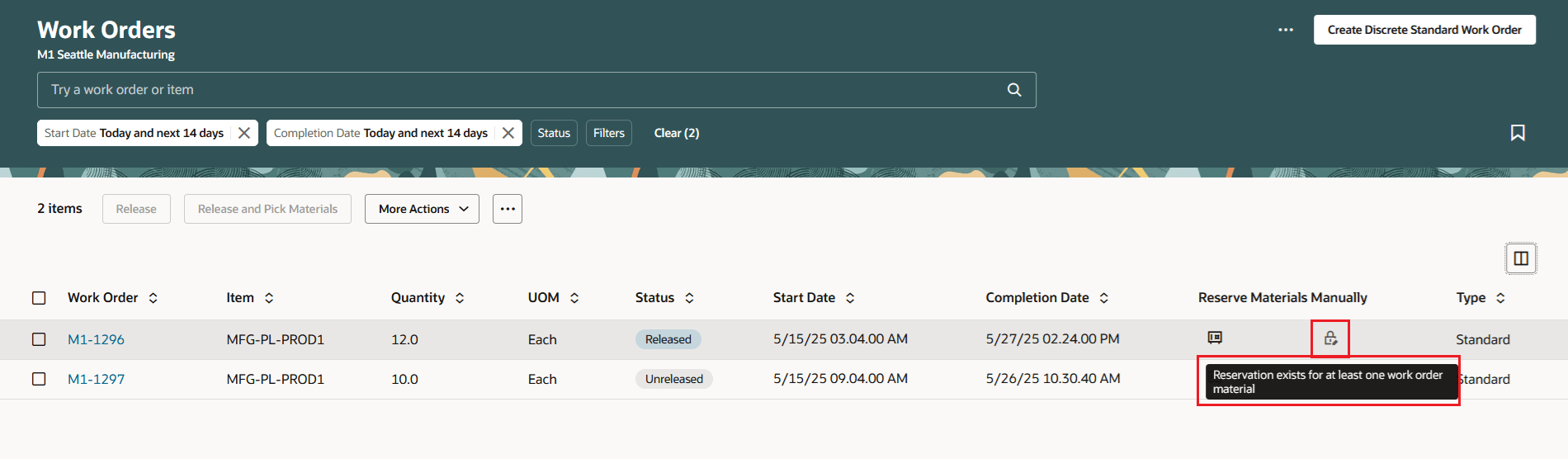

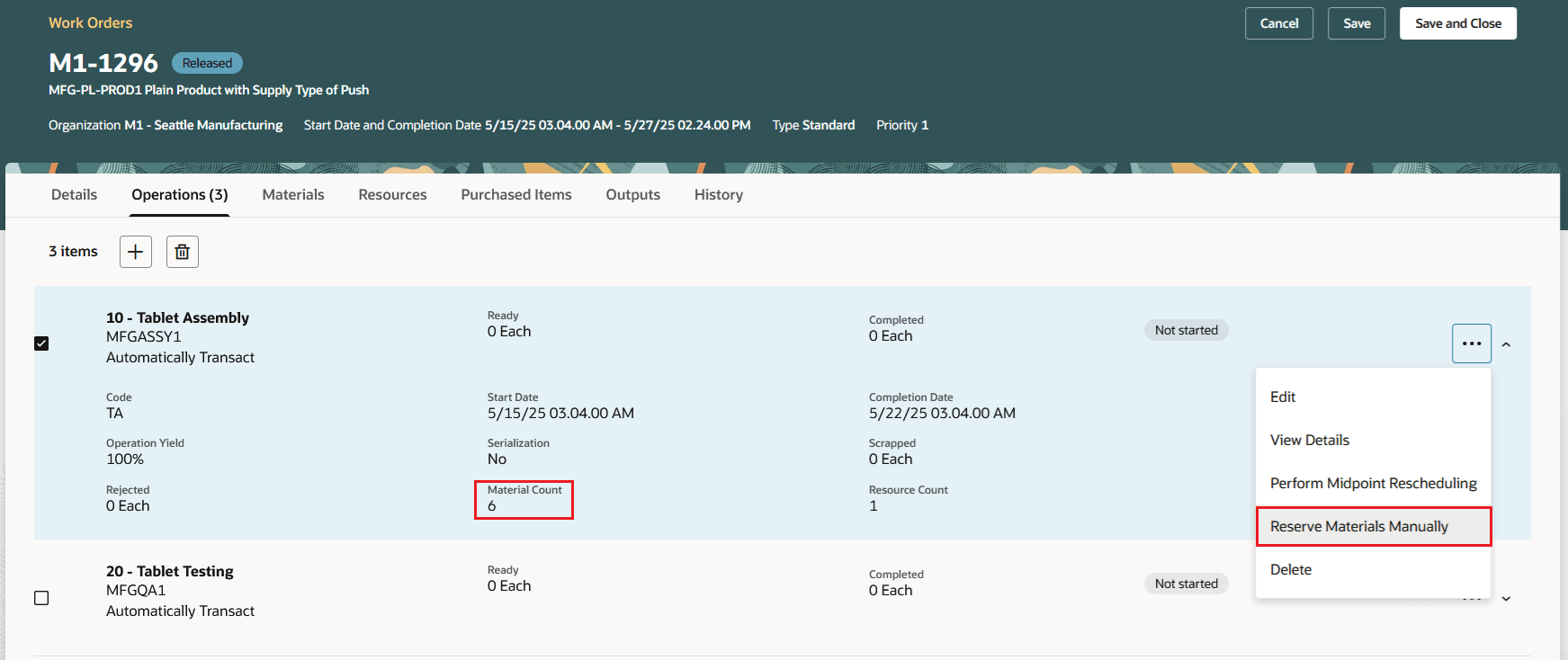

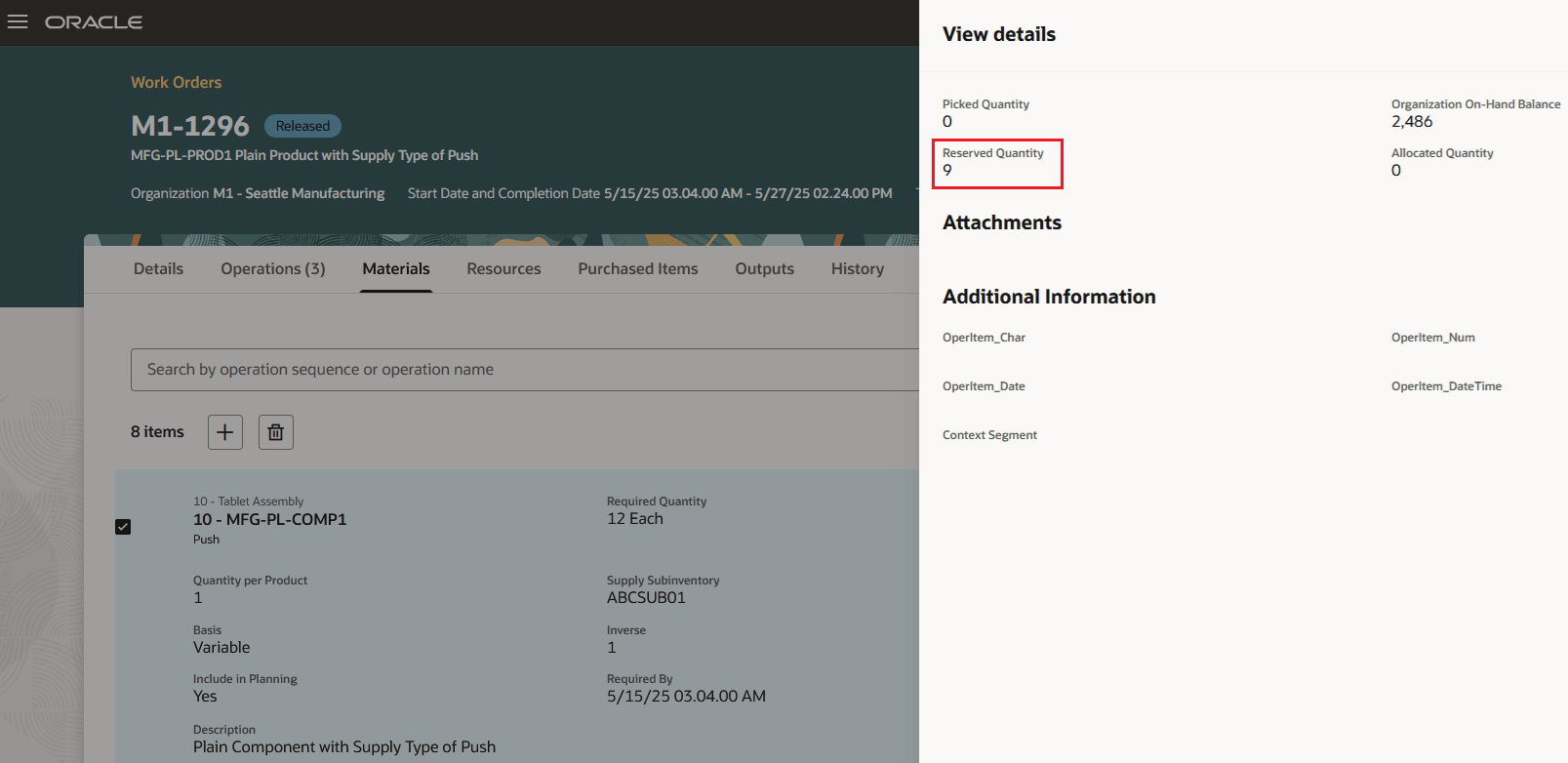

You can view the 'Reserve Materials Manually' action for the work order in the Manage Work Orders page. Also, if you have performed any reservations, you can see the icon that shows that reservation exists for at least one work order material. You can also perform manual reservation for the specific operation materials using the 'Reserve Materials Manually' action at the work order operation level. Once reservation is done, you can view the reserved quantity for the operation material.

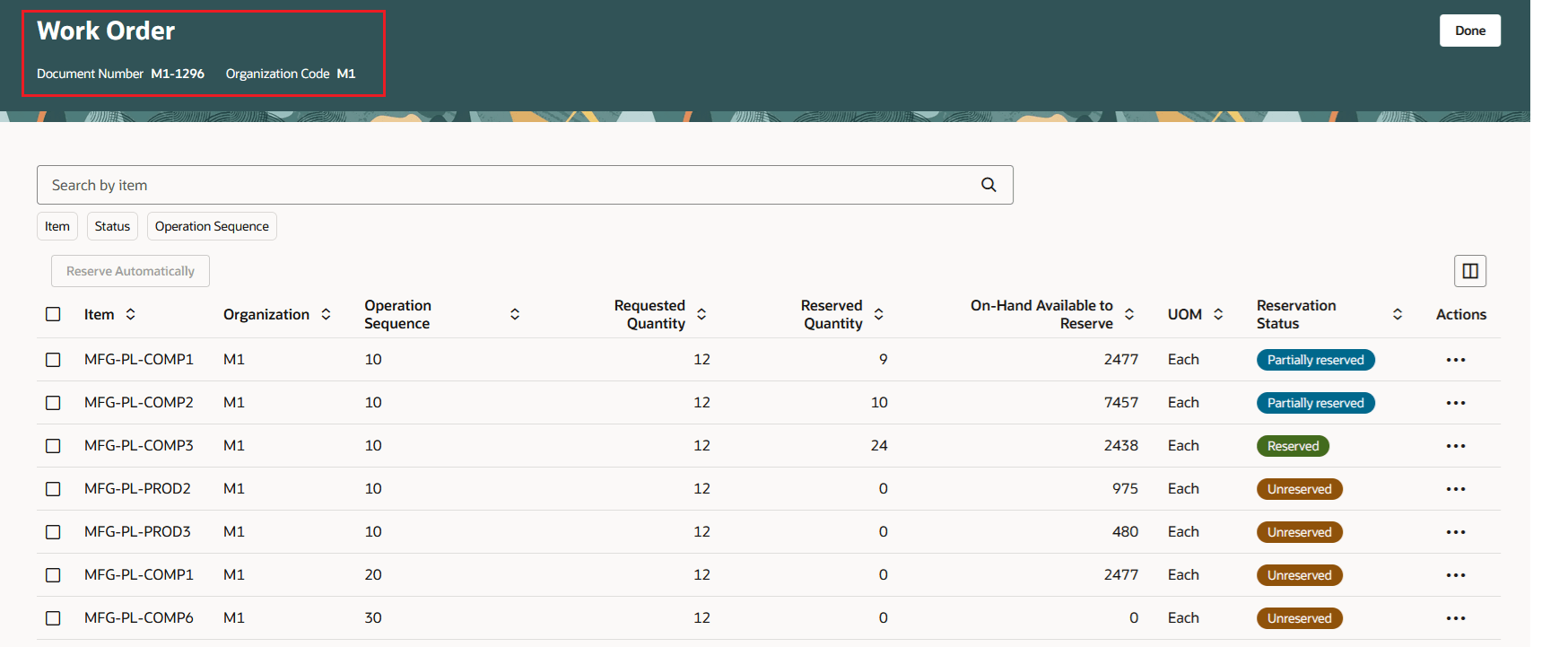

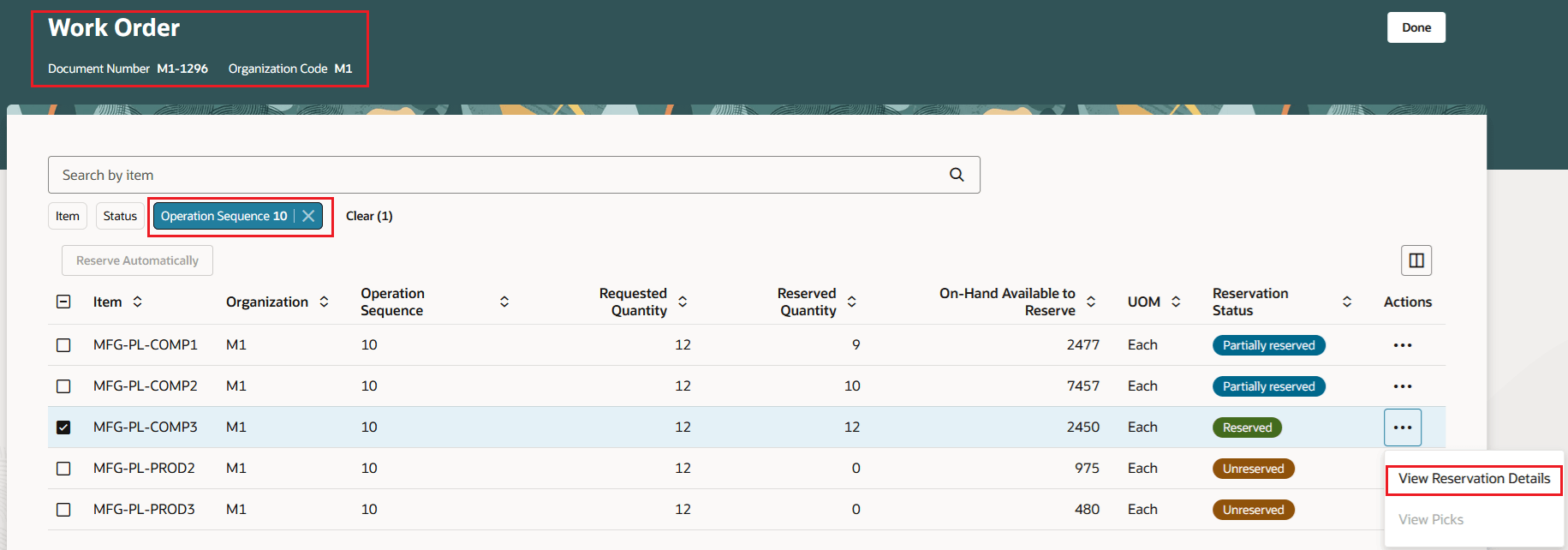

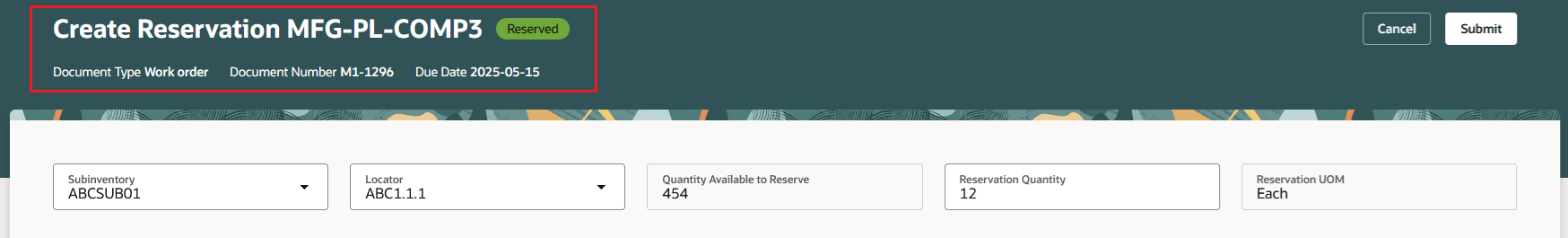

When you execute 'Reserve Materials Manually' action from the manufacturing work order, the Inventory reservation page is launched, where you can view the existing reservation, create new reservation for the work order materials, as well as update or delete the reservations.

Manufacturing: Manage Work Order - Reserve Materials Manually

Manufacturing: Manage Work Order - Reserve Materials Manually Action

Manufacturing: Manage Work Order - Material Reservation Information

Manufacturing: Edit Work Order Operation - Reserve Materials Manually Action

Manufacturing: Work Order Operation Material Reserved Quantity

Inventory: Work Order Materials Reservation Details

Inventory: Work Order Materials Reservation - View Reservation Details

Inventory: Work Order Material Reservation Details

Inventory: Work Order Material Reservation

Manufacturing: Rework Wok Orders - Reserve Serials Action

Manufacturing: Rework Work Order Serial Reservation

Material reservations using the Redwood user experience ensures a smooth production flow without the risk of material shortage.

Here's the demo of these capabilities:

Steps to Enable

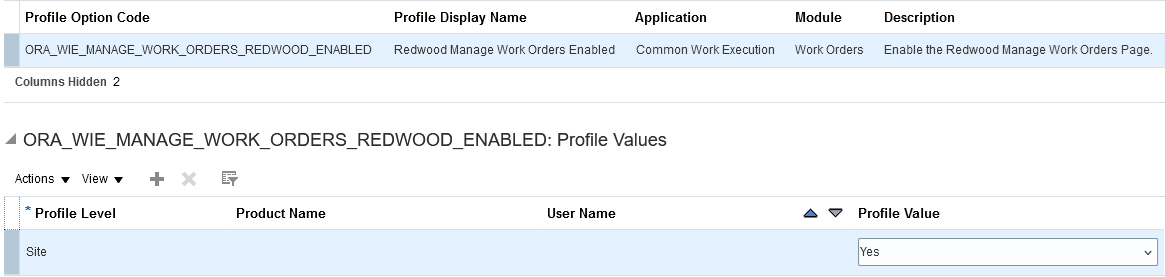

This feature is available by enabling the Redwood experience for work orders. Follow these steps to enable or disable the profile option:

- In the Setup and Maintenance work area, search for the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIE_MANAGE_WORK_ORDERS_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is Y.

- Y = Enables the feature.

- N = Disables the feature.

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

Profile Option for Accessing Manage Work Orders Using the Redwood User Experience

Tips And Considerations

- You must enable the plant parameter 'Allow reservations for work order materials' to perform actions that reserve materials automatically, reserve materials manually, and reserve serials, as well as to view reservation information.

- For an improved, end-to-end user experience, you need to enable the following Redwood page:

- Work Orders and Work Order Details - Use the Redwood Manage Work Orders Enabled profile option. Refer to the 25C feature Redwood: Create and Edit Work Orders Using a New User Experience for more information. If this profile option is not enabled, you can't launch the Redwood user interface for managing work orders.

Key Resources

- Watch the Reserve Materials for a Manufacturing Work Order Using a New User Experience Demo.

- See Inventory Management: Manage Reservations Using a Redwood Page.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

Manufacturing Privileges:

- Create Manufacturing Reservation (INV_CREATE_MANUFACTURING_RESERVATION_PRIV)

- View Reservations (INV_VIEW_INVENTORY_RESERVATION_PWA_PRIV)

Inventory Privileges:

- Manage Inventory Reservation and Picks (INV_MANAGE_INVENTORY_RESERVATION_AND_PICKS_PRIV)

- Manage Inventory Reservation Web Service (INV_MANAGE_INVENTORY_RESERVATION_WEB_SERVICE_PRIV)

- Manage Inventory Reservation Using Responsive Inventory (INV_MANAGE_INVENTORY_RESERVATION_PWA_PRIV)

- View Inventory Reservation Using Responsive Inventory (INV_VIEW_INVENTORY_RESERVATION_PWA_PRIV)

In addition to the preceding privileges, you should have the following data security configured for your role and user:

- Reserve work order materials: INV_MANAGE_INVENTORY_RESERVATION_DATA