Redwood: Create and Edit Work Orders Using a New User Experience

Efficient management of work orders is an important function in coordinating manufacturing and related material and resource management activities in preparation for production execution. When work orders need to be created outside a planning run, a production supervisor can create a work order for standard or nonstandard production, rework, or transform processes. As material, labor, and equipment availability and readiness can change unexpectedly, supervisors also need the flexibility to adapt work orders by changing work order priorities, substituting materials, and replacing or re-assigning production resources.

In a prior release, you could search for and perform mass actions on multiple work orders using the Redwood user experience. You can now also create and edit discrete and process manufacturing work orders with greater ease and efficiency using the Work Orders page in Redwood.

- Create a work order with minimal data – Enter minimal, mandatory information to quickly create a work order.

- Edit a work order with faster navigation and search – Directly navigate to tabs for work order details, operations, operation materials, operation resources, and operation outputs and search them for quick updates and actions.

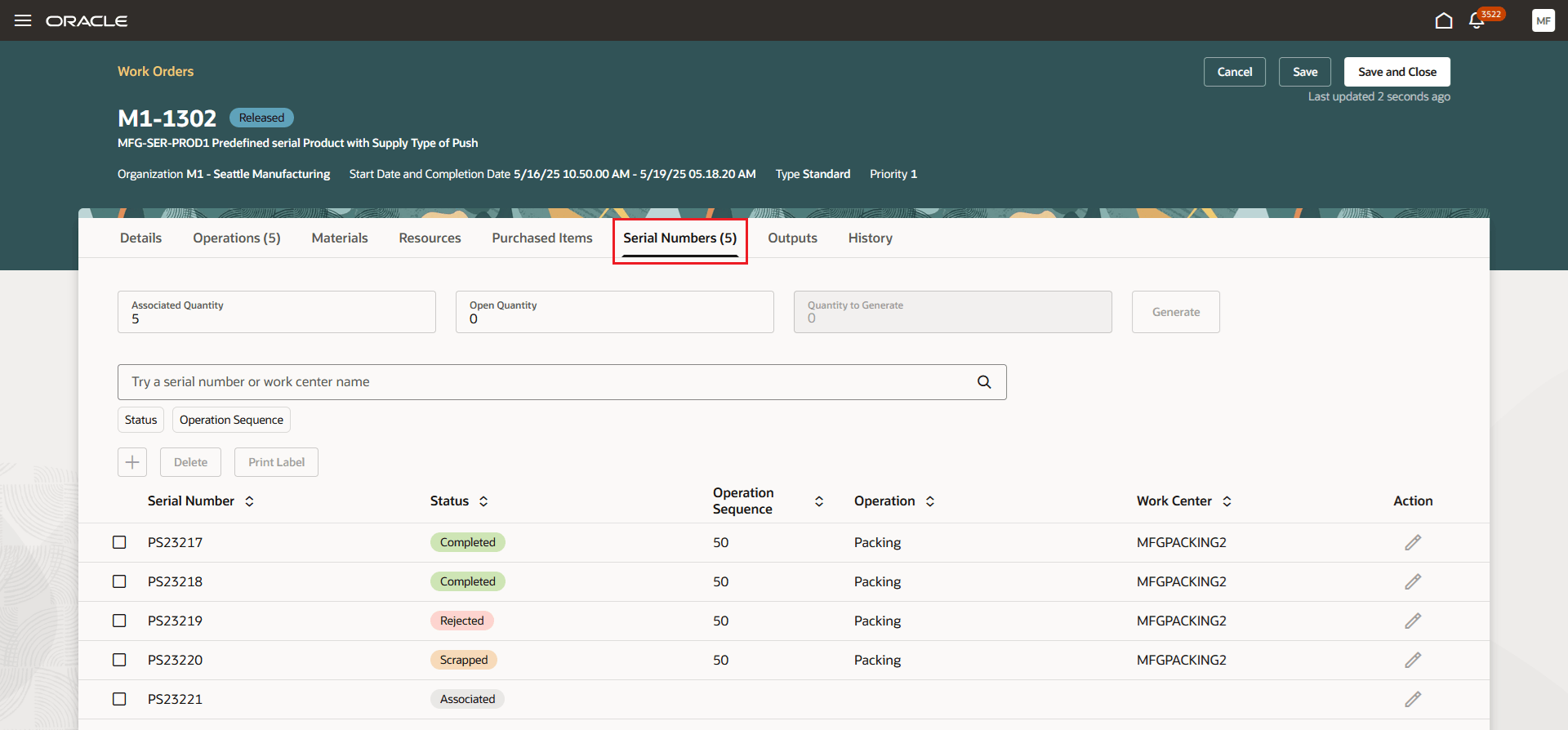

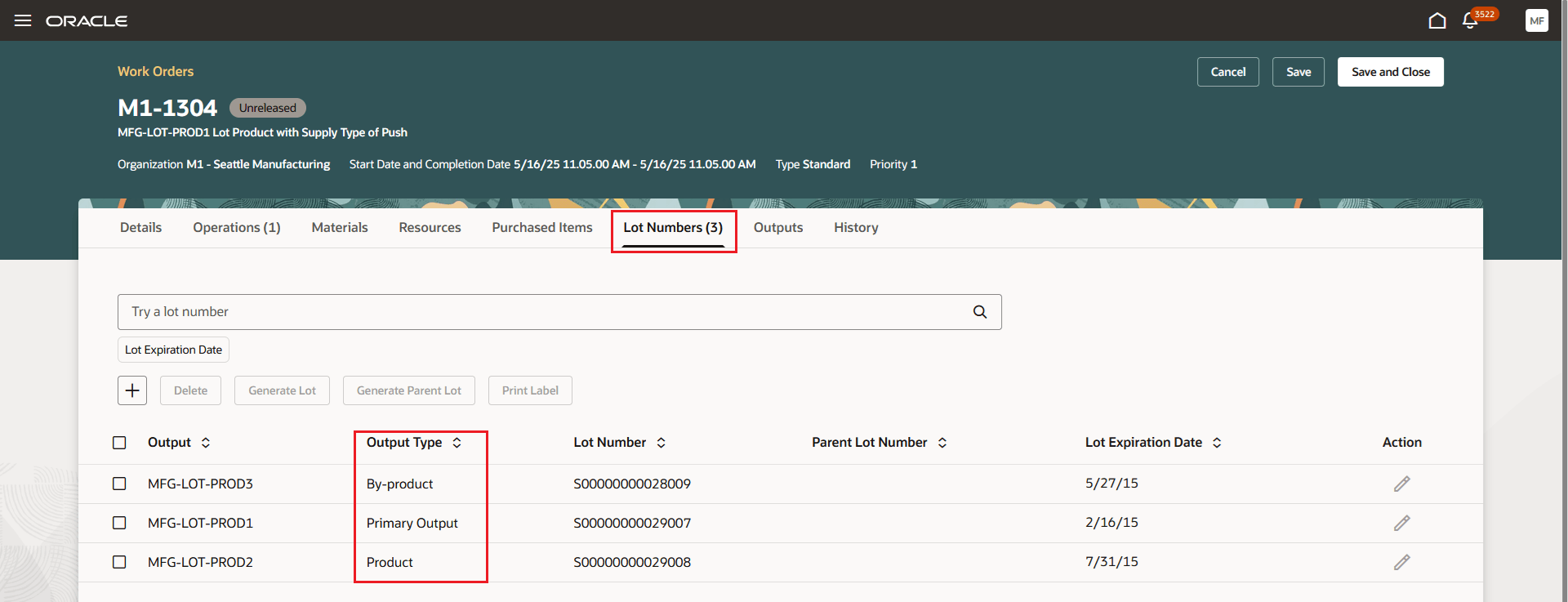

- Manage work order lots and serials – Generate, associate, or delete lot and serial numbers for the product or other outputs in a work order to support traceability and labeling requirements.

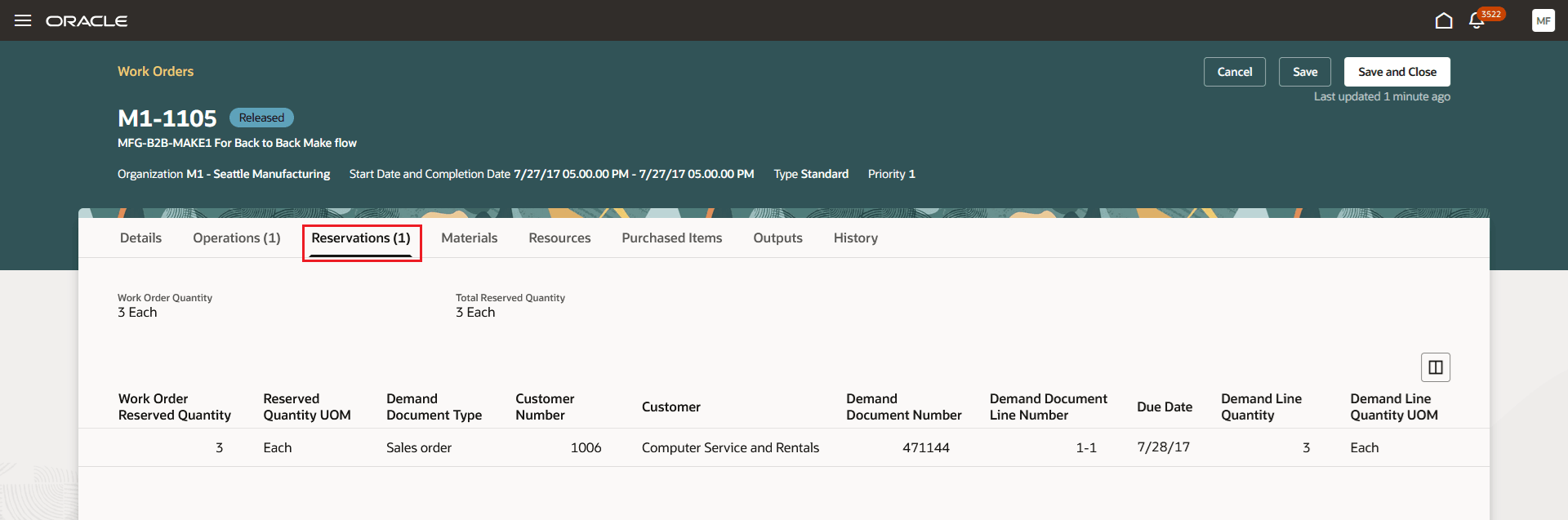

- Track work order details for connected supply chain processes – Access connected supply chain information for a work order, covering supply planning, scheduling, material reservations, supplier operations, purchased items, project-driven supply chain, contract manufacturing, and quality inspection.

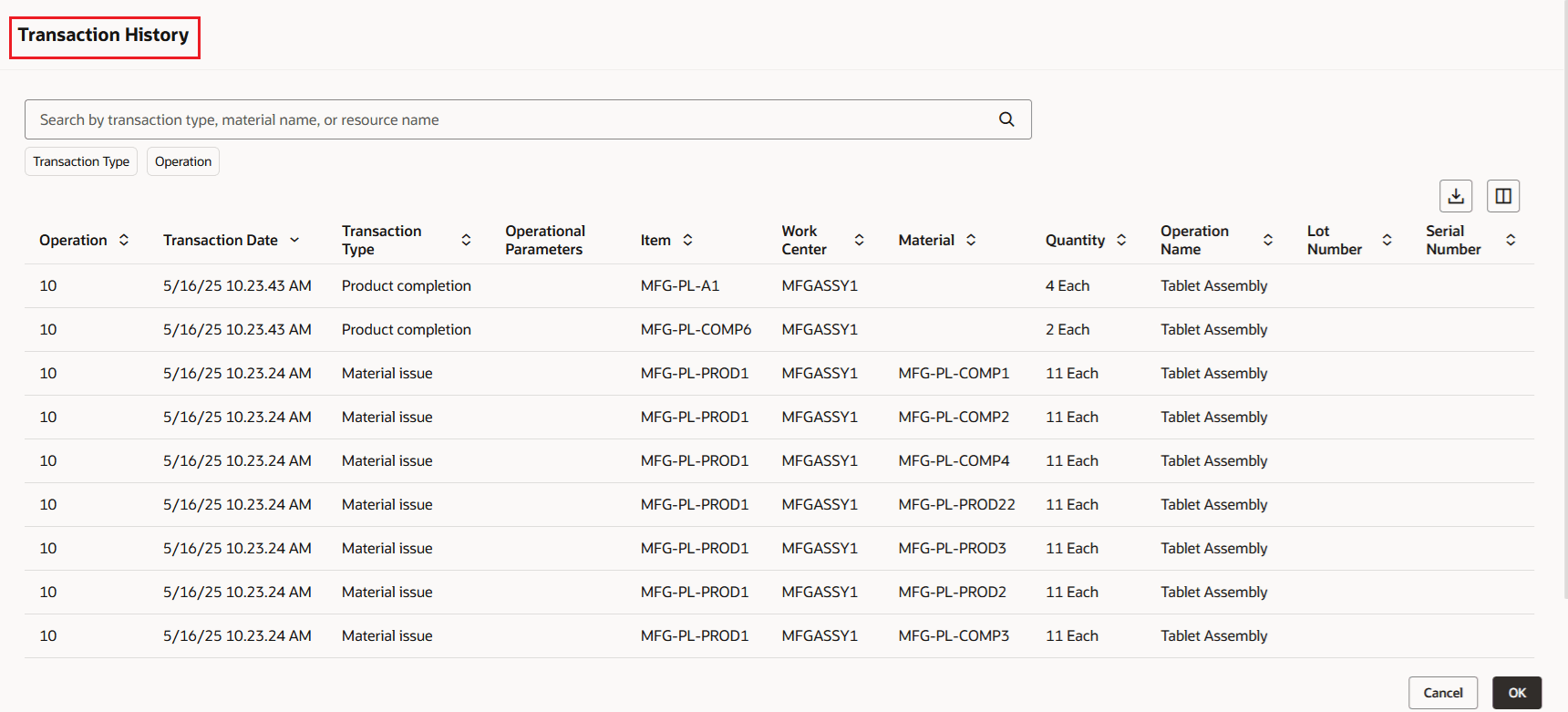

- Review work order summary and production transaction history – Track the lifecycle of a work order by reviewing the history of work order status changes and production transactions.

You can create and edit the following discrete work orders: Standard, Nonstandard, Rework, and Transform work order types.

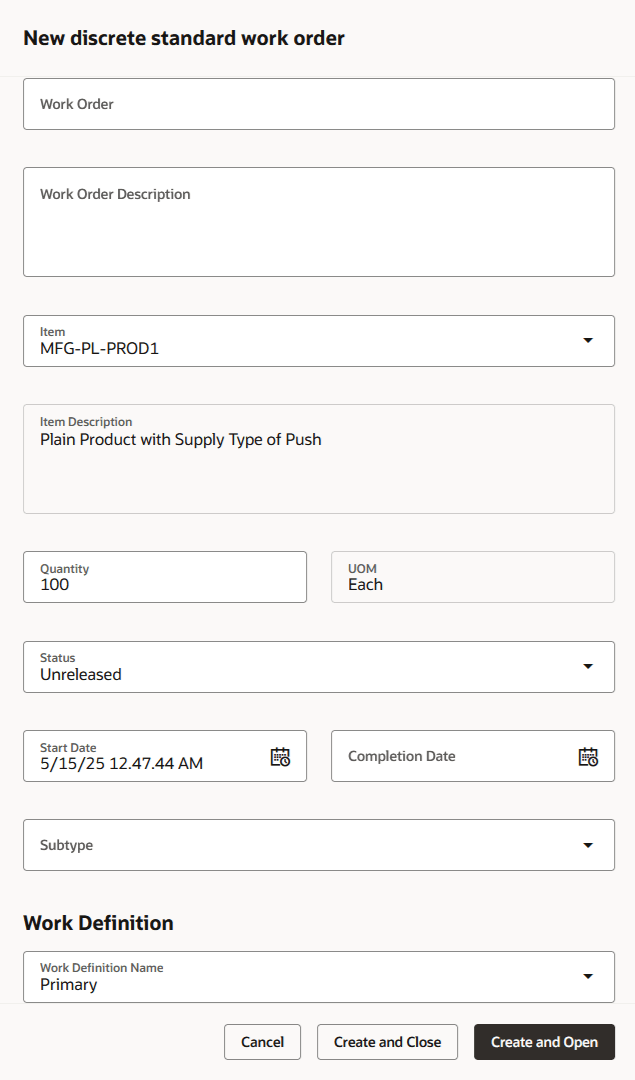

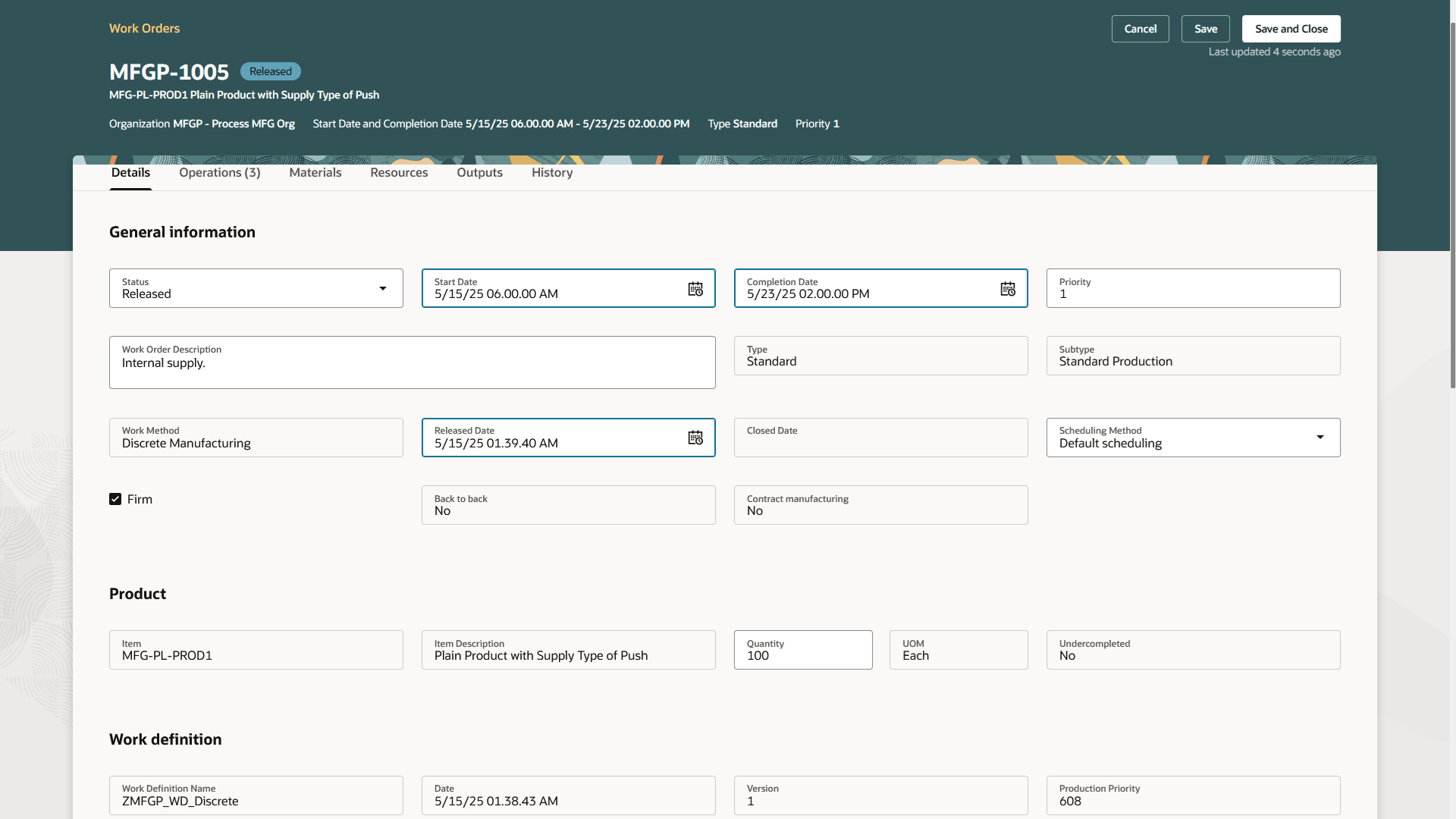

Create Discrete Standard Work Order

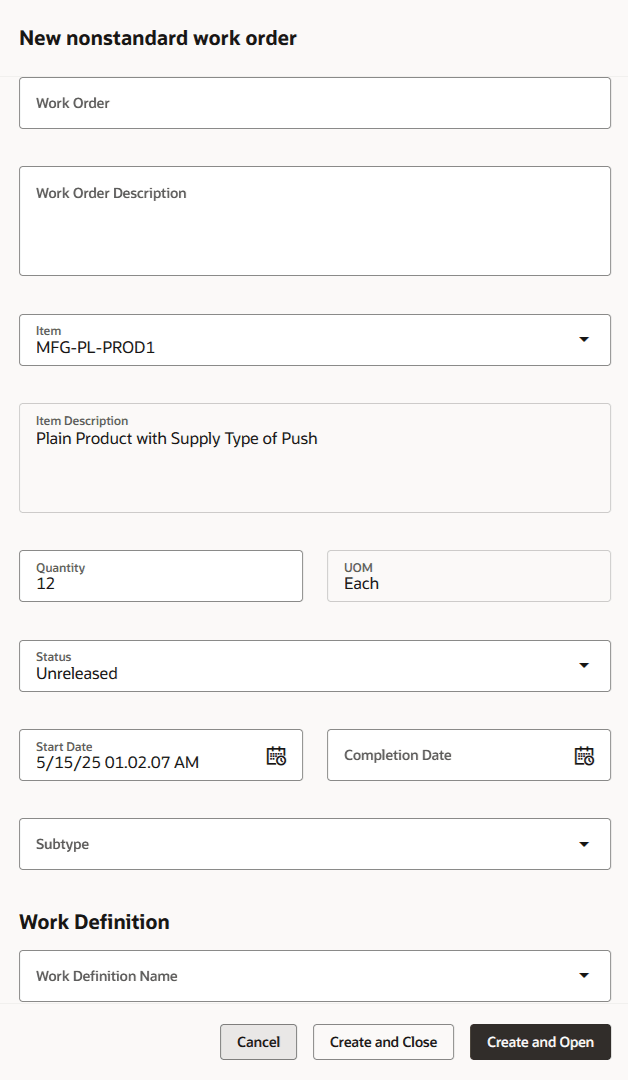

Create Nonstandard Work Order

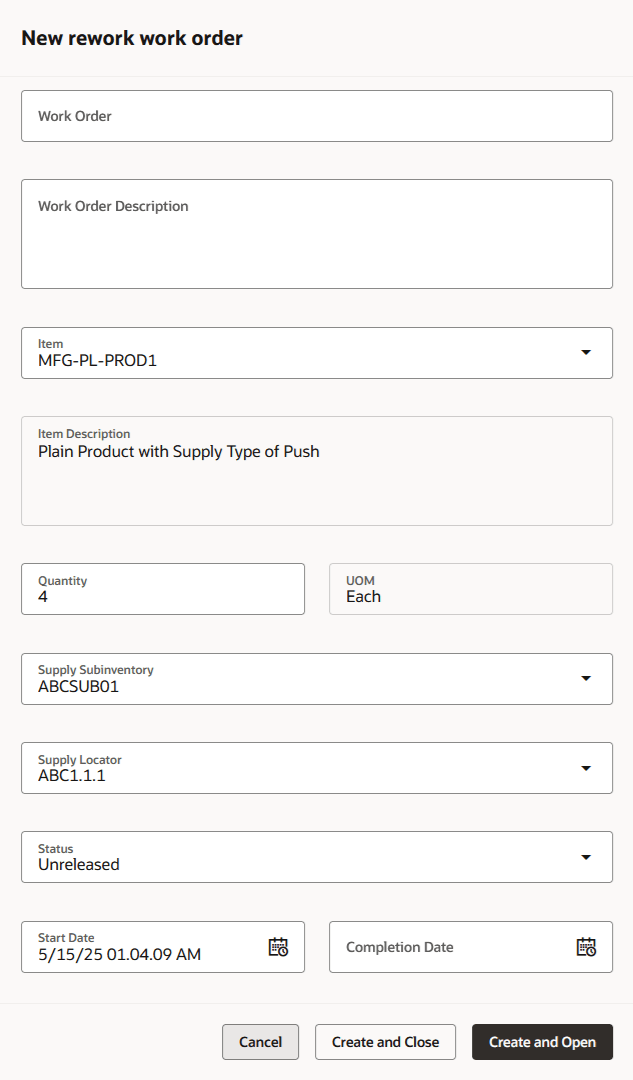

Create Rework Work Order

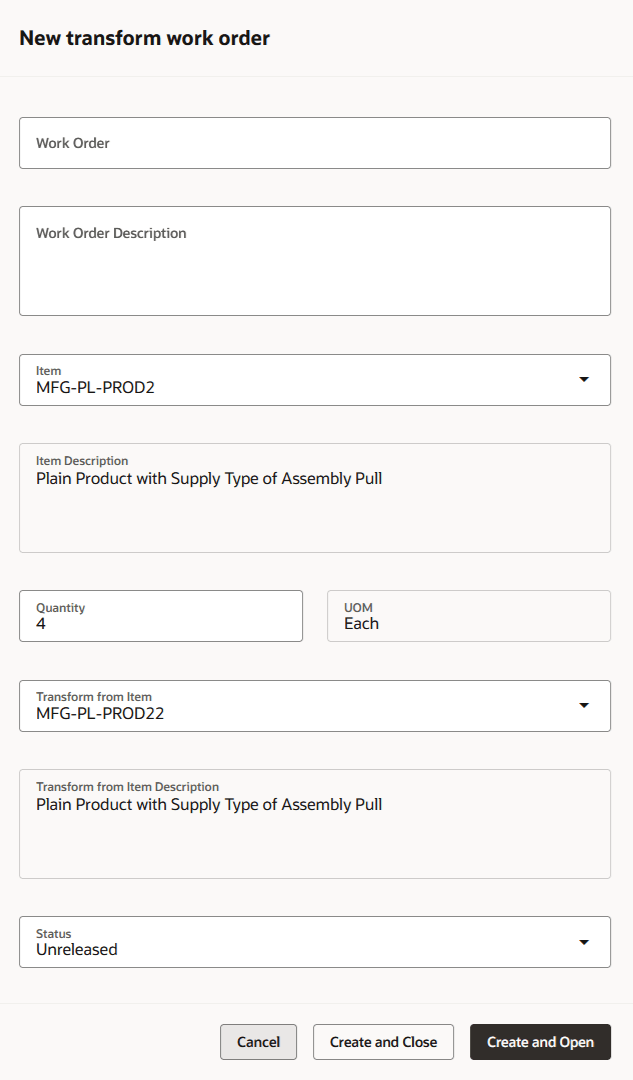

Create Transform Work Order

Edit Discrete Work Order

Discrete Work Order: Preassigned Lots

Discrete Work Order - Serials

Discrete Work Order - Reservations

You can also create and edit process work orders.

Create Process Standard Work Order

Edit Process Work Order

Process Work Order: Preassigned Lots

You can manage the work order operations, reservations, materials, resources, and outputs of the work order.

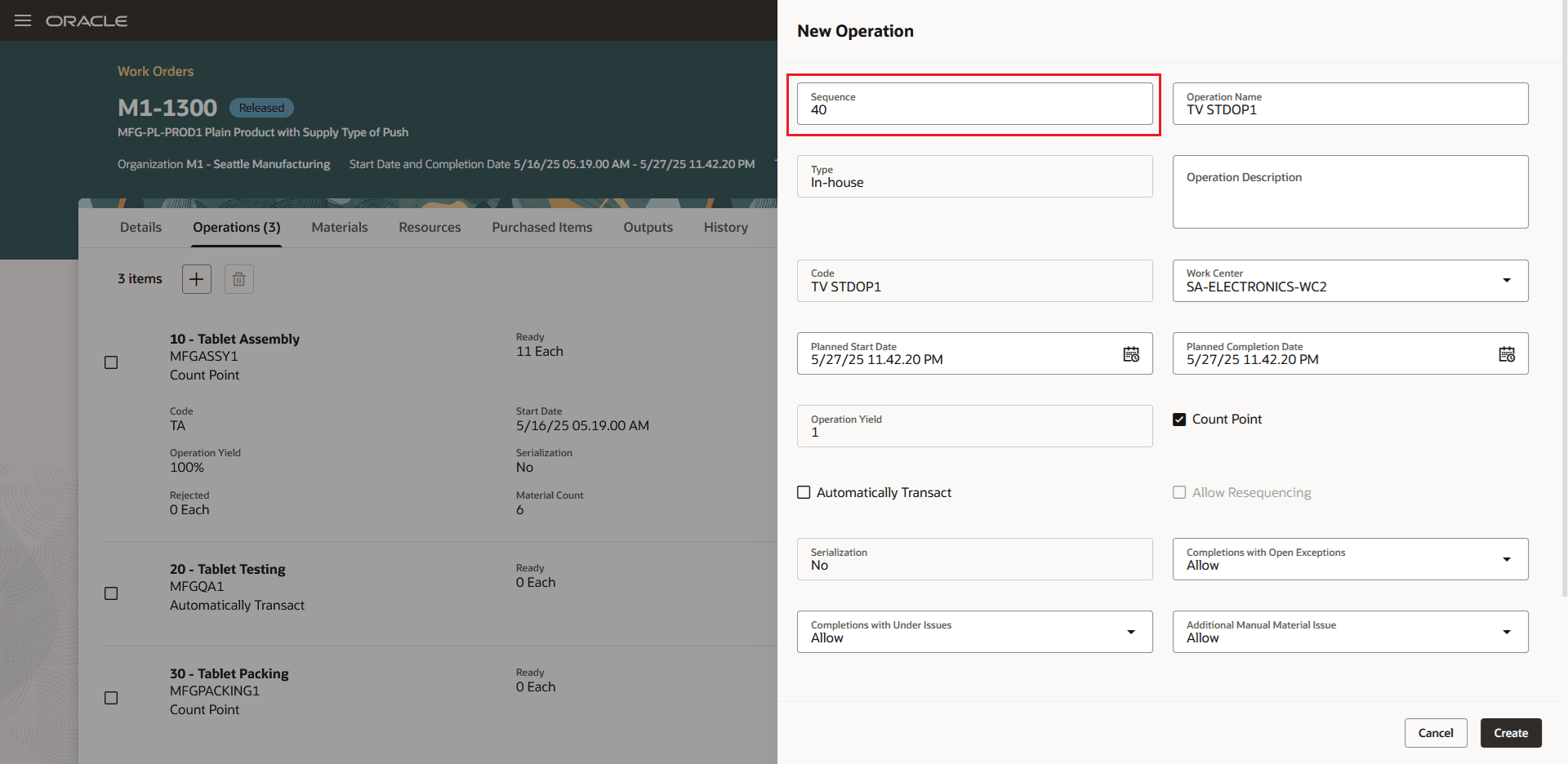

Work Order Operations

Work Order Operations: Add Operation

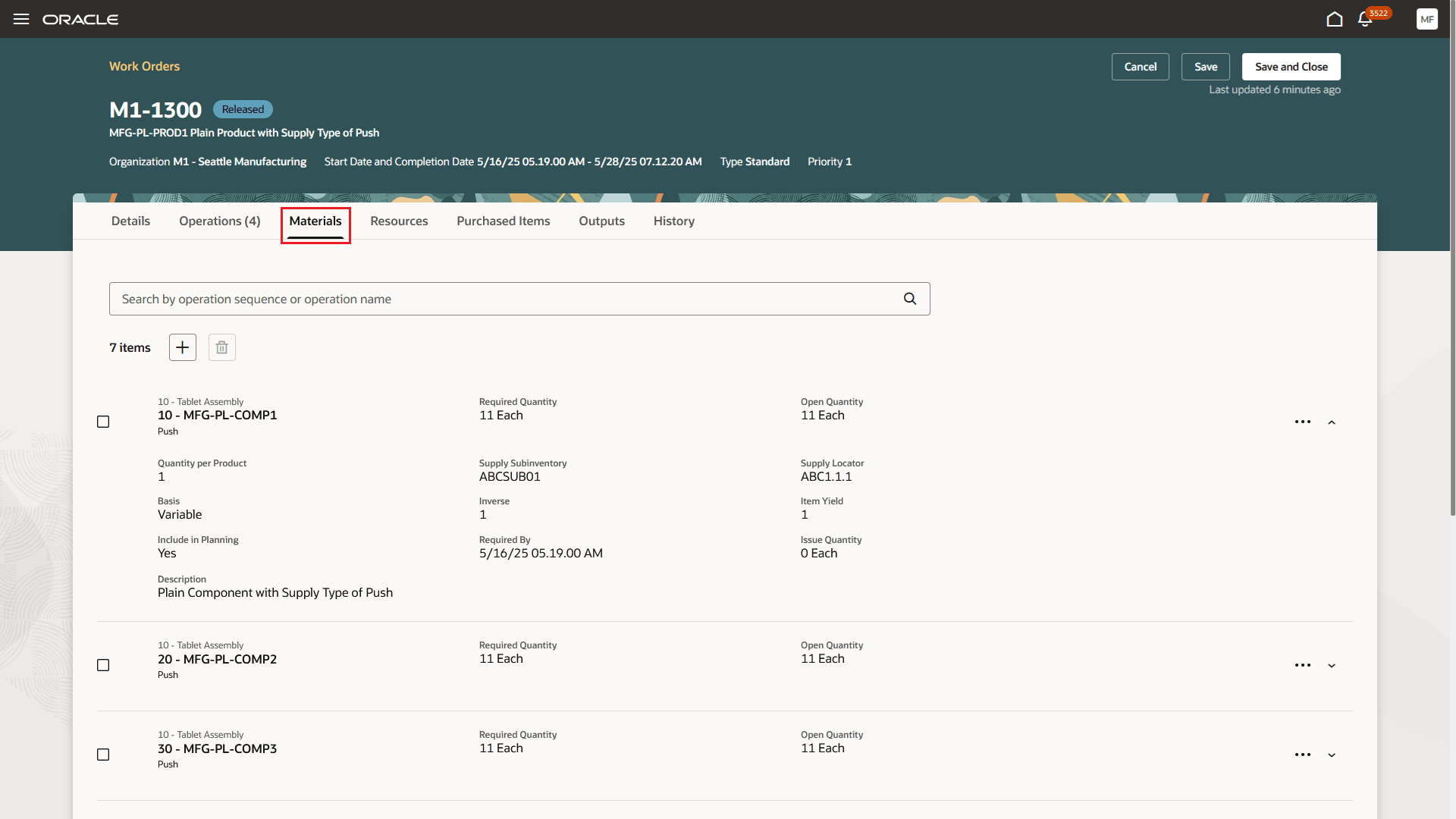

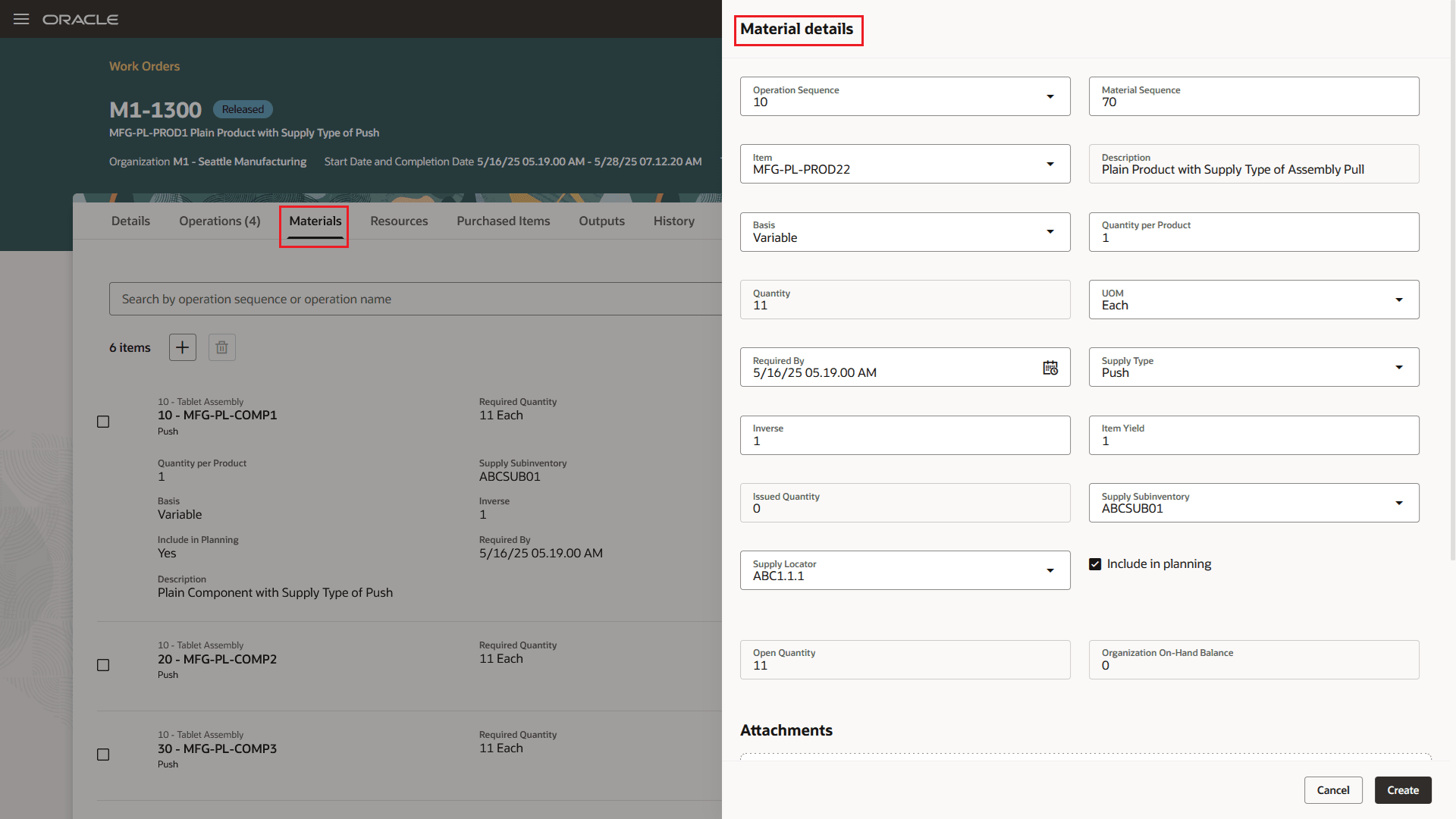

Work Order Operation Materials

Work Order Operation Materials: Add Material

Work Order Operation Materials: Substitute Materials

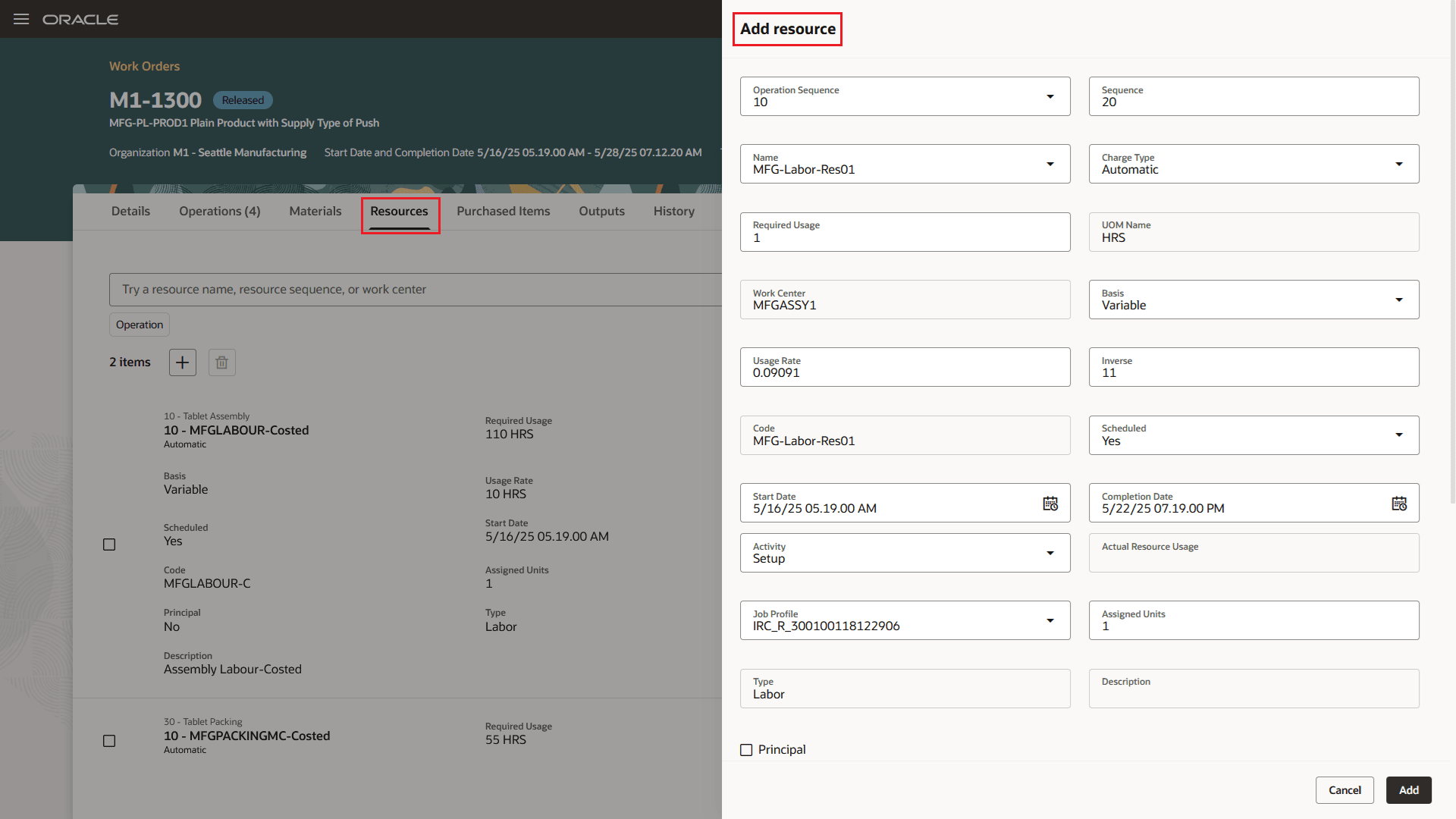

Work Order Operation Resources

Work Order Operation Resources: Add Resource

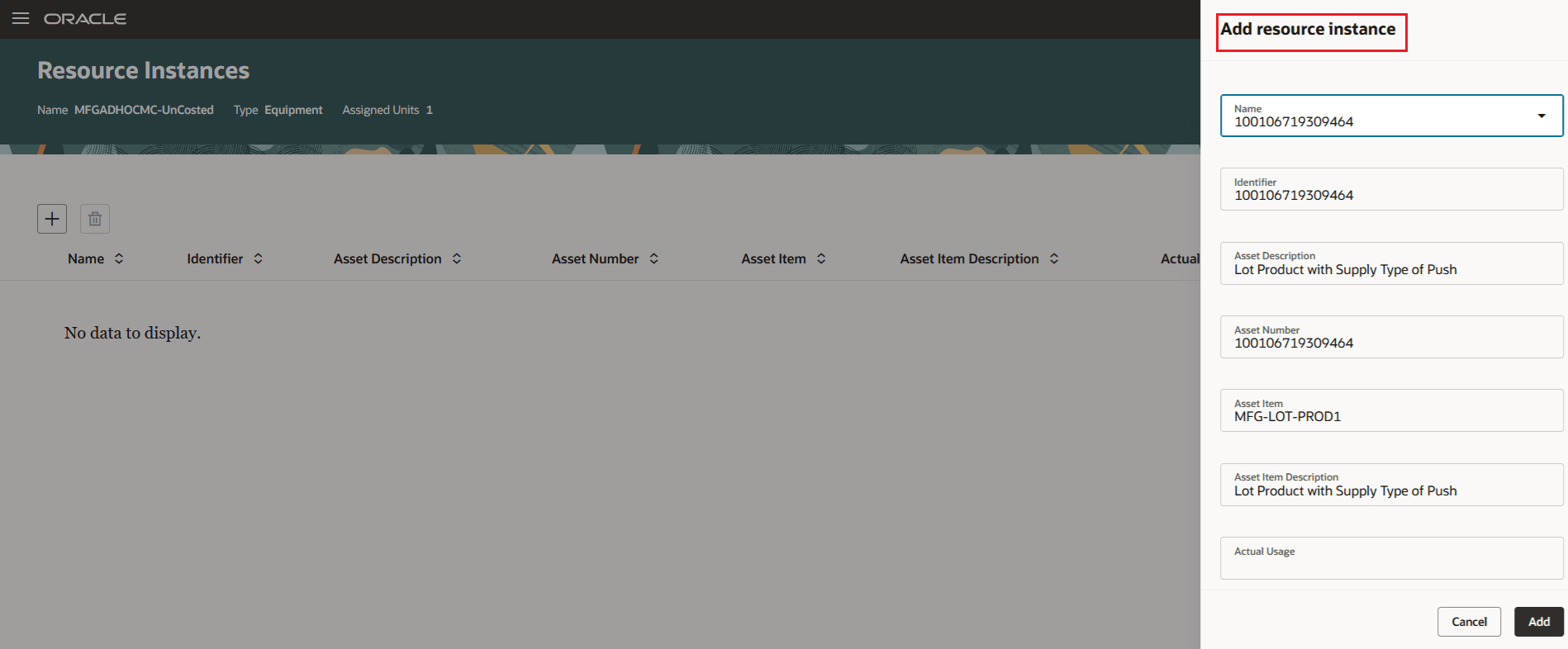

Work Order Operation Resource Instances: Add Resource Instance - Equipment type

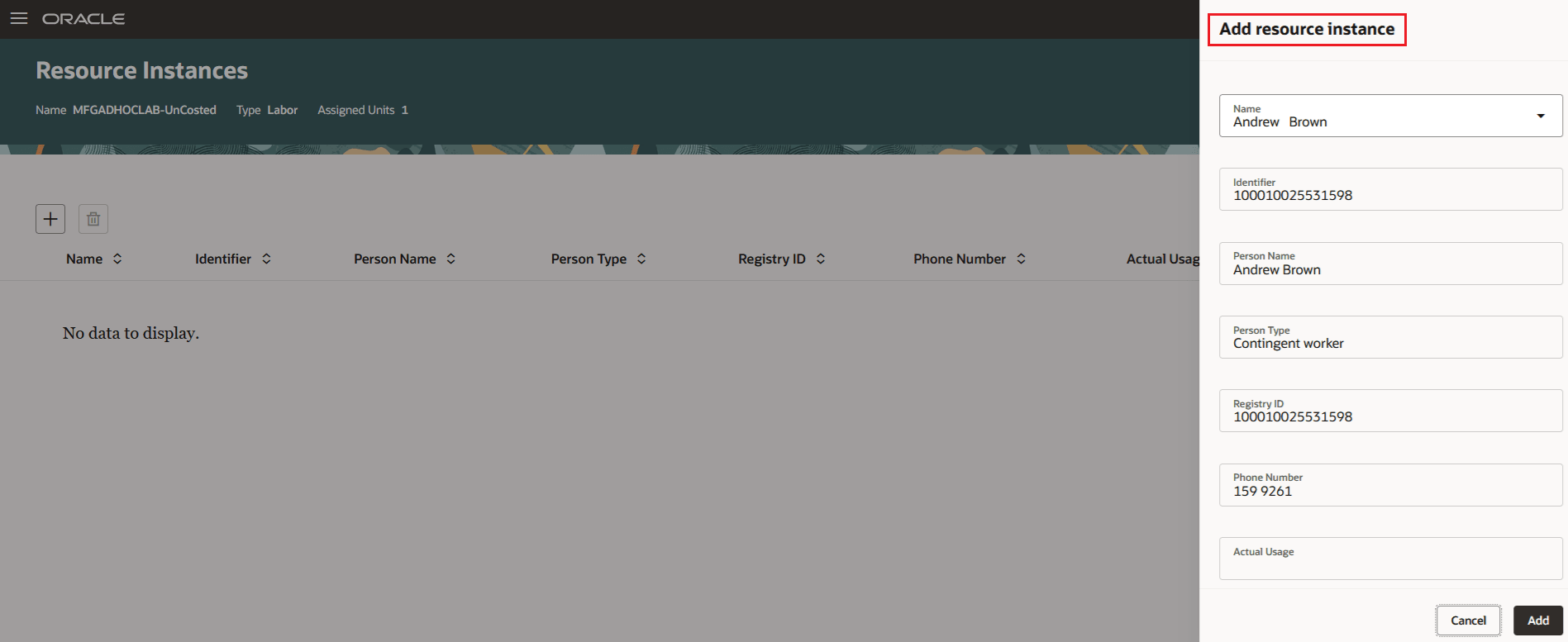

Work Order Operation Resource Instances: Add Resource Instance - Labor type

Work Order Operation Outputs

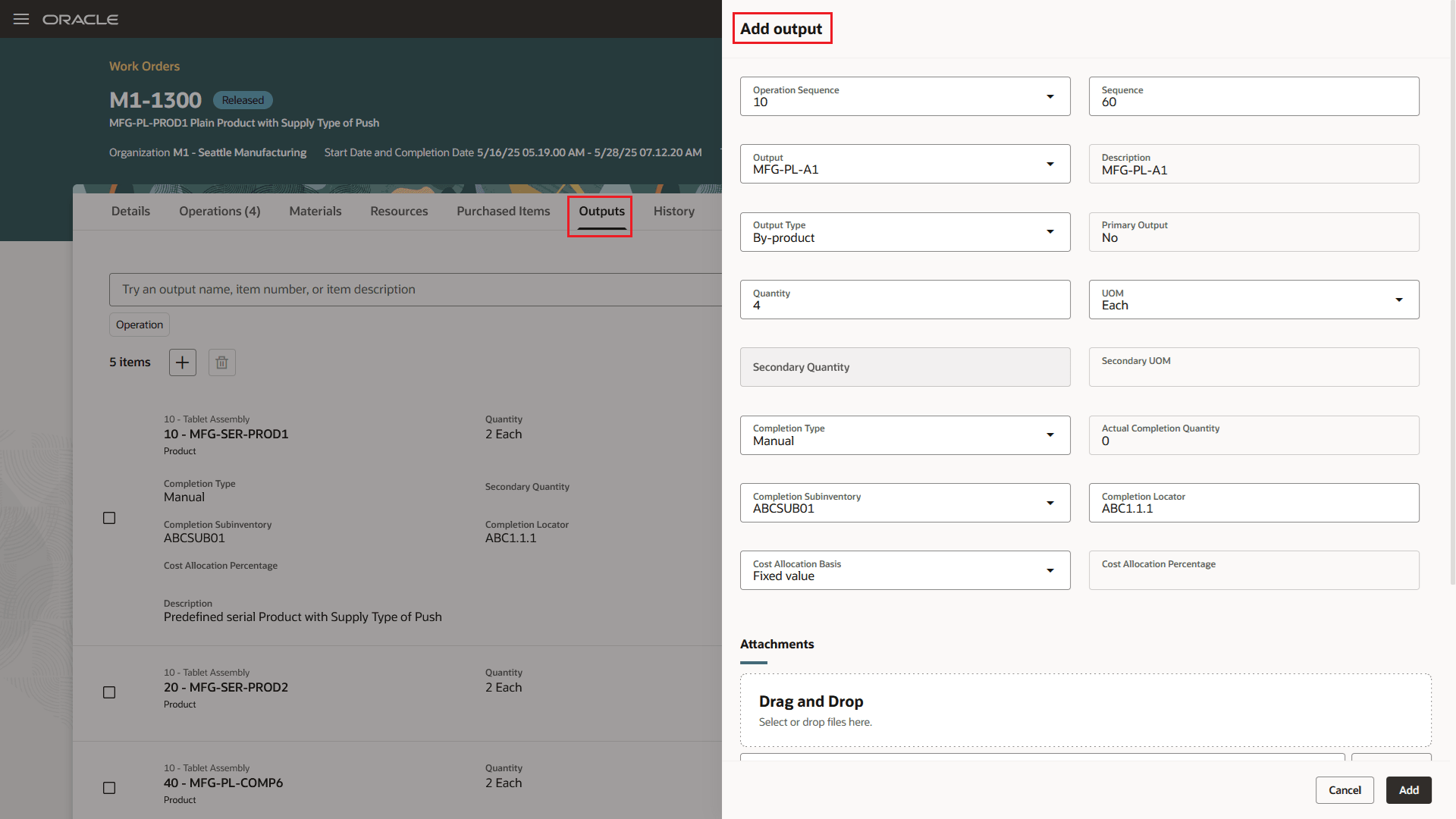

Work Order Operation Outputs: Add Output

Work Order History

Work Order Transaction History

Work Order Inspections

Streamlined work order management using Redwood pages improves productivity in organizing and tracking production and adapting to changing requirements.

Here's the demo of these capabilities:

Steps to Enable

This feature is available by enabling the Redwood experience for Work Orders. Follow these steps to enable or disable the profile option:

- In the Setup and Maintenance work area, search for the Manage Administrator Profile Values task.

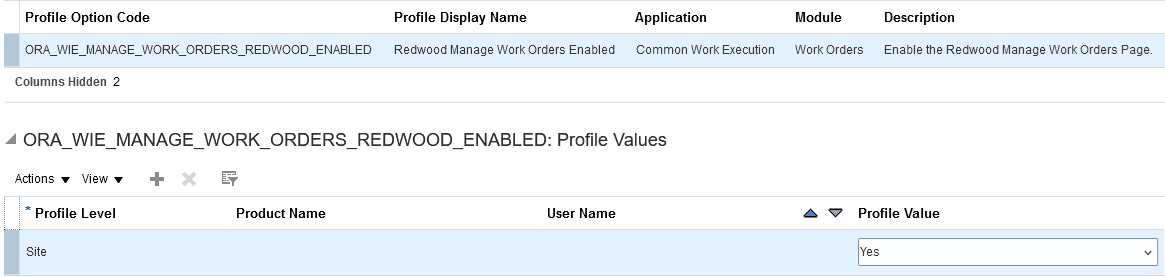

- On the Manage Administrator Profile Values page, search for and select the ORA_WIE_MANAGE_WORK_ORDERS_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is Y.

- Y = Enables the feature.

- N = Disables the feature.

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

Profile Option for Accessing Manage Work Orders Using the Redwood User Experience

Tips And Considerations

- For an improved end-to-end user experience, you can also enable the following Redwood pages:

- Work Execution landing page -- Use the Redwood Work Execution Landing Page Enabled profile option. On the landing page, you can directly search for a work order to view its information. Refer to the 25A feature Redwood: Manage and Execute Production Using a New Home Experience for more information.

- Reservations - Use the Redwood Page for Reservations and Picks Enabled profile option. View reservation details for work order supplies to back-to-back order or configured item sales order demand.

- Supplier Operations - Use the Redwood Manage Work Orders Enabled profile option.

- Purchased Item Details - Use the Redwood Manage Work Orders Enabled profile option.

- Quality Inspection Results - Use the Redwood Inspections Enabled profile option. View the inspection history for a work order.

- For more search filters and actions related to work order management, enable the Redwood Manage Work Orders Enabled profile option to use the Work Orders page in the Redwood user experience. Refer to the 25B feature Redwood: Search and Perform Mass Actions for Work Orders Using a New User Experience for more information about the search and actions available on the Work Orders page.

- Before using this feature, make sure that you submit the scheduled process to create the index definition and perform initial ingest to OSCS. You can also submit the process if the index is already created and you want to ingest it again. This clears the index and reingests the data.

-

Program name: ESS job to create index definition and perform initial ingest to OSCS

-

Index Name to Reingest: fa-scm-mfg-work-order

-

-

Work orders can be created or executed using the user interface, REST APIs, or File-Based Data Import (FBDI). Not all modes of work order creation or update trigger the near real-time ingest of the index. You can update the index by running a separate scheduled process. This scheduled process doesn't clear the index but only updates the existing index with the changes from these transactions. Oracle recommends that you ingest these updates at least once a day, or as often as your business requires, to keep the index current.

-

Program Name to Run Bulk Ingest: ESS job to run Bulk ingest to OSCS

-

Index Name to Reingest: MFG_WO_BULK_INGEST

-

- You can perform manual scheduling of work orders using the workOrders REST API and the Scheduling Method parameter.

- The primary output shall be assigned to the same operation as per the process work definition. You can't reassign the operation of the primary output in a process work order.

- Secondary quantity and secondary UOM for the Dual UOM controlled Item is not covered for process work order operation material.

- For rework work order, the assembly component is not shown in the operation materials.

Key Resources

- Watch the Create and Edit Work Order Using a New User Experience demo.

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

Manufacturing Privileges:

- Manage Work Execution Work Area (WIP_MANAGE_WORK_EXECUTION_WORK_AREA_PRIV)

- Manage Work Order Headers (WIP_MANAGE_WORK_ORDER_HEADERS_PRIV)

- Manage Work Order Operations (WIP_MANAGE_WORK_ORDER_OPERATIONS_PRIV)

- Manage Supplier Operations (WIP_MANAGE_SUPPLIER_OPERATIONS_PRIV)

- Manage Work Order Lot Numbers (WIP_MANAGE_WORK_ORDER_LOTS_PRIV)

- Manage Work Order Serials (WIP_MANAGE_WORK_ORDER_SERIALS_PRIV)

- View Production Exceptions (WIP_VIEW_PRODUCTION_EXCEPTIONS_PRIV)

- Manage Production Exceptions (WIP_MANAGE_PRODUCTION_EXCEPTIONS_PRIV)

- Review Supplier Operation Details (WIP_REVIEW_SUPPLIER_OPERATION_DETAILS_PRIV)

- View Work Orders (WIP_VIEW_WORK_ORDERS_PRIV)

Other Privileges:

- View Inventory Organizations List of Values by Web Service (RCS_VIEW_INV_ORG_LOV_WEB_SERVICE_PRIV)

- View Units Of Measure List of Values by Web Service (RCS_VIEW_UNITS_OF_MEASURE_LOV_WEB_SERVICE_PRIV)

- View Unit Of Measure Conversion List of Values by Web Service (RCS_VIEW_UNITS_OF_MEASURE_CONVERSION_LOV_WEB_SERVICE_PRIV)

- Manage On-Hand Quantity (INV_MANAGE_ONHAND_QUANTITY_PRIV)

- View Maintenance Work Orders by Service (MNT_GET_WORK_ORDERS_BY_SERVICE_PRIV)

- Get Maintenance Work Order Materials by Service (MNT_GET_MAINTENANCE_WORK_ORDER_MATERIALS_BY_SERVICE_PRIV)

- View Qualification Profiles (MNT_VIEW_QUALIFICATION_PROFILES_PRIV)

- View Item Lot and Item Serial List of Values by Web Service (INV_VIEW_LOT_SERIAL_LOV_WEB_SERVICE_PRIV)

- Manage Subinventory and Locator (INV_MANAGE_SUBINVENTORY_AND_LOCATOR_PRIV)

- View Subinventory and Locator List of Values by Web Service (INV_VIEW_SUBINVENTORY_LOCATOR_LOV_WEB_SERVICE_PRIV)

- View Inventory Movement Request Web Service (INV_VIEW_INVENTORY_MOVEMENT_REQUEST_WEB_SERVICE_PRIV)

- View Inventory Reservation Using Responsive Inventory (INV_VIEW_INVENTORY_RESERVATION_PWA_PRIV)

- Configure Inventory Barcode Formats (INV_CONFIGURE_INVENTORY_BARCODE_FORMATS_PRIV)

- Create Manufacturing Reservation (INV_CREATE_MANUFACTURING_RESERVATION_PRIV)

- View Pick Slip Grouping Rule List of Values Web Service (WSH_VIEW_PICK_SLIP_GROUPING_RULE_LOV_WEB_SERVICE_PRIV)

- View Shipment Using Responsive Shipping (WSH_VIEW_SHIPMENT_USING_RESPONSIVE_SHIPPING_PWA_PRIV)

- View Receipt Summary and Transaction History using Responsive Receiving (RCV_VIEW_RECEIPT_SUMMARY_TXN_HISTORY_PWA_PRIV)

- Get Item Rest (EGP_GET_ITEM_REST_PRIV)

- Create Item Structure (EGP_CREATE_ITEM_STRUCTURE_PRIV)

- Review Quality Issue (ENQ_REVIEW_QUALITY_ISSUE_PRIV)

- Manage Quality Issue (ENQ_MANAGE_QUALITY_ISSUE_PRIV)

- View Inspection Results (QA_VIEW_INSPECTION_RESULTS_PRIV)

- Get Electronic Signature Preferences by Service (EDR_GET_ESIGNATURE_PREF_SERVICE_PRIV)

- View Supplier List of Values Using REST Service (POZ_VIEW_SUPPLIER_LOV_REST_SERVICE_PRIV)

- View Purchase Order (PO_VIEW_PURCHASE_ORDER_PRIV)

- Manage Requisition (POR_MANAGE_REQUISITION_PRIV)

- View Requisition (POR_VIEW_REQUISITION_PRIV)

- View Supplier List of Values Using REST Service POZ_VIEW_SUPPLIER_LOV_REST_SERVICE_PRIV

In addition to the preceding privileges, you should have the following data security configured for your role and user:

- Manage Subinventory (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Manage Subinventory (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- Manage Inventory Locator (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- Manage Inventory Locator (ORA_WIE_PRODUCTION_SUPERVISOR_JOB

- Manage Shipment (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Manage Shipment (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- Manage Item and Inventory Organization Parameter (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Manage Item and Inventory Organization Parameter (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- Manage On-Hand Quantity (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Manage Item Lot and Item Serial (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Manage Item Lot and Item Serial (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- Manage Maintenance Organization (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Manage Inventory Reservation (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Manage Inventory Reservation (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- Manage Inventory Movement Request (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- Manage Inventory Movement Request (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- View Purchasing Document Header Transactional, Read (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- View Purchasing Document Header Transactional, Read (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Read, Update, Delete, Maintain Quality Issue (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- Read, Update, Delete, Maintain Quality Issue (ORA_WIE_PRODUCTION_OPERATOR_JOB)

- View Quality Issue, Read (ORA_WIE_PRODUCTION_SUPERVISOR_JOB)

- View Quality Issue, Read (ORA_WIE_PRODUCTION_OPERATOR_JOB)