Review Anomaly and Prediction Events from Connected Equipment

Oracle Cloud Manufacturing extends intelligent event integration empowering manufacturing teams to identify and respond to early signs of equipment degradation - even when conditions appear normal. The new capability extends Manufacturing to receive anomaly and prediction events from connected equipment and/or third-party monitoring systems, ensuring that subtle deviations and emerging risks are no longer overlooked.

With this enhancement, production supervisors can:

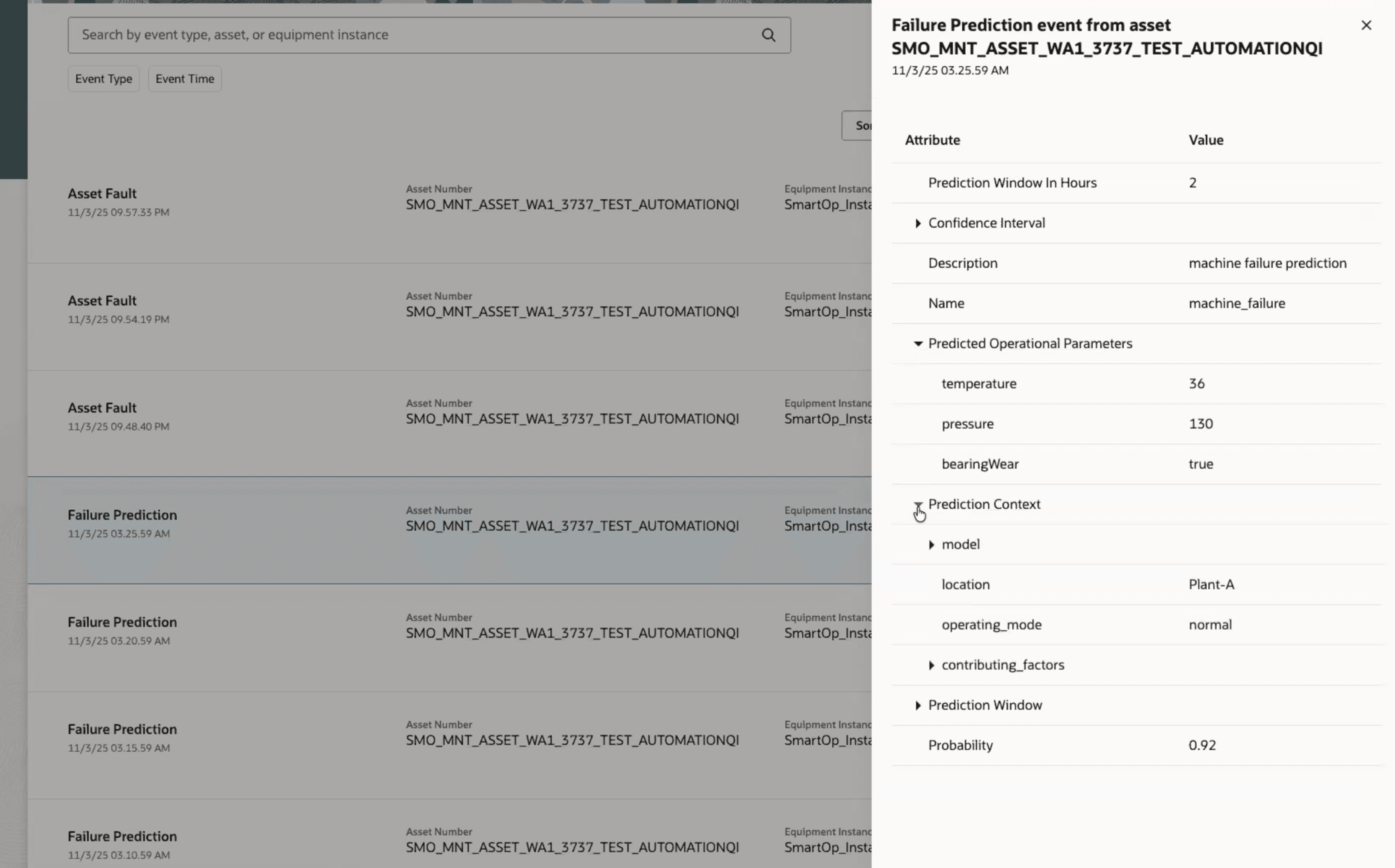

- Receive and review anomaly or prediction events when monitoring workstations at a work center, during production supervision.

Failure Prediction Event

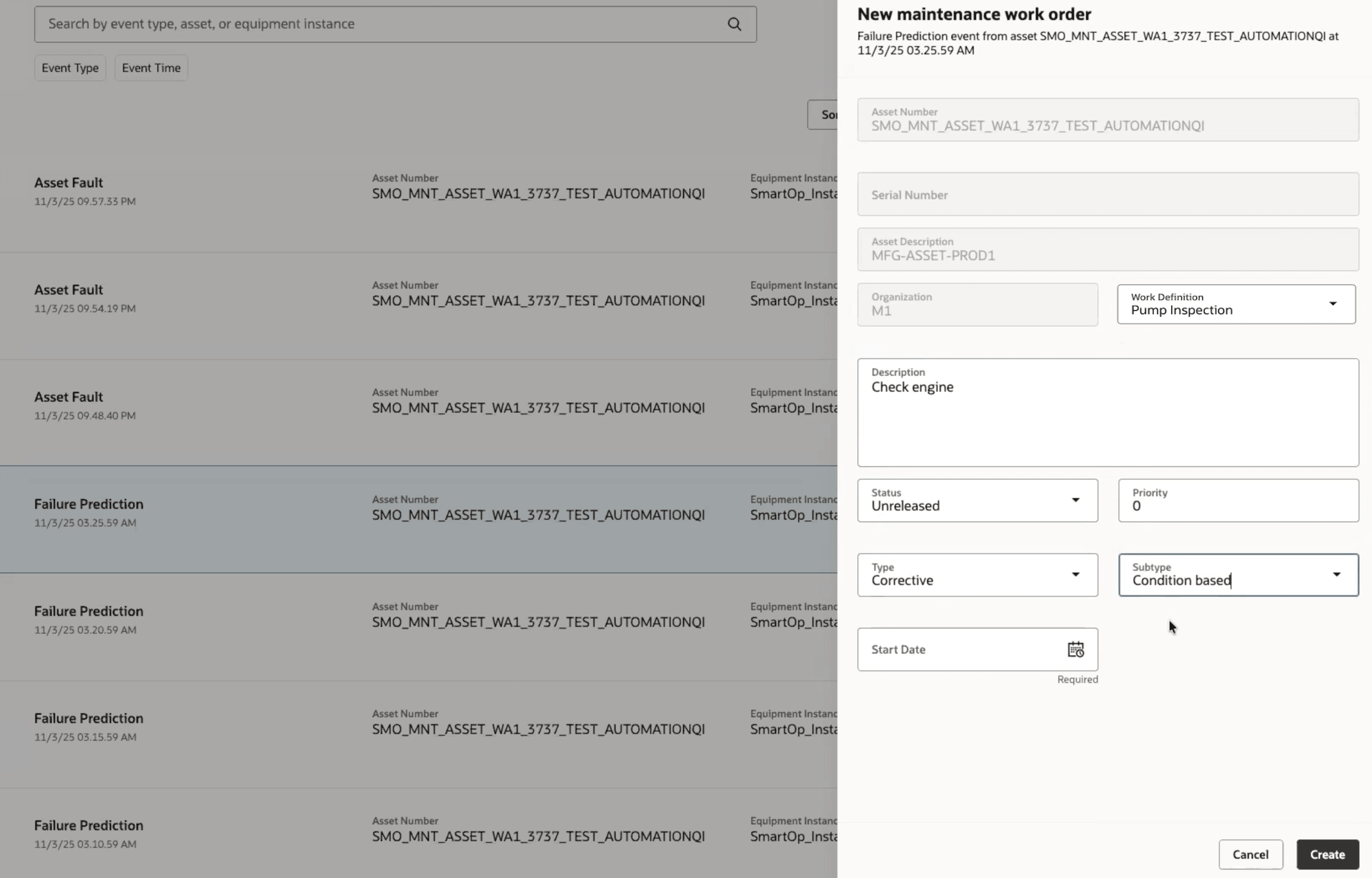

- Assess and disposition events to trigger appropriate maintenance actions such as inspections, work requests, or work orders.

Create Maintenance Work Order for a Failure Prediction Event

- Act on predictive signals before fault thresholds are breached, minimizing the risks to production and output resulting from quality issues and unplanned downtime.

Manufacturing teams can detect hidden issues earlier, reduce reactive repairs, improve Mean Time Between Failures (MTBF), and sustain high Overall Equipment Effectiveness (OEE). The result is improved asset availability, fewer disruptions, and production at optimal efficiency.

Here's the demo of these capabilities:

Steps to Enable and Configure

To enable this feature you need to log a Service Request (SR).

This feature requires additional services (“SCM Core Service-Smart Operations”) to be provisioned on your instance. To enable this service, you need to log a Service Request (SR).

- Select Product Module: Oracle Maintenance Cloud Service.

- Select Category: Maintenance Work Orders.

- Select Subcategory: Maintenance Work Orders.

- Select Component: Installation Issue (INSTALL).

- Select Severity: 3-Minimal Loss of Service.

- Copy and paste this text into description area of the SR: Enable the SCM Core Service-Smart Operations.

Please note that this service can be enabled on instances that are available on Oracle Public Cloud regions.

In addition, you can access the user guide and the implementation guide to learn more about this feature and how to set it up.

Tips And Considerations

- Connected asset events received via industrial communication protocols need to be converted into a payload that Oracle Fusion Cloud Maintenance can ingest and take actions on. The accepted payload specifications are documented here: REST API for Oracle Fusion Cloud SCM. Predictions use the new CA_FAILURE_PREDICTION event type, anomalies use the CA_ANOMALY event type. Payload can be ingested via REST or MQTT.

- Predictions can contain predicted operational parameters. These operational parameters should be configured in Oracle Maintenance. You can use the Operational Parameters task list entry and follow the instructions to create Operational Parameters.

- This feature does not accept time series data. It's required that high frequency data is prescreened and condensed by an external Industrial IoT framework.

Access Requirements

Users need this privileges and duty roles to create/edit/delete/view Operational Rules:

- Manage Operational Rules (SMO_MANAGE_OPERATIONAL_RULES_PRIV): For Create/Read/Update/Delete operations.

- View Operational Rules (SMO_VIEW_OPERATIONAL_RULES_PRIV): For Read Only operation.

- Access HCM Common Components (HRC_ACCESS_HCM_COMMON_COMPONENTS_PRIV)

- Manage HCM Rules (HRC_MANAGE_HCM_RULES_PRIV)

- Access to SMO rules management (ORA_DR_SMO_MANAGE_OPERATIONAL_RULES_MFG_DUTY)

Users need this privilege to create/edit/delete/view Operational Parameters:

- Manage Operational Parameters (SMO_MANAGE_OPERATIONAL_PARAMETERS_PRIV): For Create/Read/Update/Delete operations.

- View Operational Parameters (SMO_VIEW_OPERATIONAL_PARAMETERS_PRIV): For Read Only operation.

Users need this privileges and duty roles to access event logs:

- View Operational Events (SMO_VIEW_EVENT_LOGS_PRIV)

- View Operational Events (ORA_DR_SMO_VIEW_OPERATIONAL_EVENTS_MFG_DUTY)