Creation Type

Action that trigged the creation of this inventory adjustment record. The same ‘Creation Type’ values needs to be added to the ‘Task’ screen with the exception of ‘Manual’ so both screens may reference the same table. Valid Creation types are:

| Creation Type | Definition |

|---|---|

|

Trigger |

Adjustment was done while executing a task that was created with a trigger. |

| CC Rules | Adjustment was done while executing a task that was created by running a ‘CC Task Template’. |

| Recount | Adjustment was done while executing a task that was created by generating a recount (rejecting an inventory adjustment record in ‘Pending’ status) |

| Manual | Adjustment was done manually with RF_CC Location or RF_CC LPN (no task is executed). |

- Recount Reference: Used to keep track of counts that are done to the same

location by generating a recount (rejecting a particular inventory adjustment). The

first time a user rejects a record in ‘Pending’ status, the system must set the

Recount Reference number equal to the Group Nbr of that record. This rejection will

automatically trigger a CC task for the same location. Once this CC task is

executed, the corresponding inventory adjustment record must be created with the

Recount Reference of the first rejection (first Group Number)’.

- Task: TheTask number that was executed to create the corresponding inventory adjustment. Value should be blank if the count was performed manually with RF_CC Location or RF_CC LPN.

- Task Type: The Task Type that was created to create the inventory adjustment. Value should be blank if the count was performed manually with RF_CC Location or RF_CC LPN.

- Cost Adjustment: Sum of (item.unit_cost*adjusted_qty) for all the items in the location.

- Loc Dtl Count: ‘Yes/No’ value that indicates whether or not a particular non-active location count was done at the detail level.

- Warnings: Displays the number of warnings for a specific inventory adjustment record at the location (RF_CC Location) or LPN levels (RF_CC LPN) as a hyperlink. Click the hyperlink display a list of all the warnings for that specific inventory adjustment record.

| Warning | Scenario |

|---|---|

| Attribute Discrepancy |

- You enter a different batch and/or expiration date or serial number during Cycle Count. - Warning should only be displayed for the detail record(s) for which different attribute was entered. |

| Inventory Expired |

- You enter a passed expiration date during Cycle Count. - Warning should only be displayed for the detail record(s) for which an expired expiration date was entered. |

| Mixed batches in restricted Locn |

- You scan multiple batches in a location with ‘Restrict Batch’ flag enabled during Cycle Count. - Warning should be displayed for ALL records in the location. - Inv. Adjustment records with this warning cannot be approved. |

| Mixed SKUs in Single-SKU Locn |

- You scan multiple items in a location with ‘Allow Multi SKU’ flag disabled during Cycle Count. - Warning should be displayed for ALL detail records in the location. - Inv. Adjustment records with this warning cannot be approved. |

| Permanent SKU mismatch |

- You scan an item different than the item assigned to a location with ‘Item Assignment Type’ = ‘Permanent’ during Cycle Count. - Warning should be displayed for ALL detail records in the location. - Inv. Adjustment records with this warning cannot be approved. |

| Location Mismatch |

- You scan an LPN that is systematically in a different location, i.e. LPN’s Expected location <> Cycle counted location. - Warning should be displayed for all the details of the LPN that is scanned in a different location. |

- Reason Code: Display the value configured in Company Parameter ‘CYCLE_COUNT_REASON_CODE’.

- Create User: User who creates the inventory adjustment record.

- Create Timestamp: Time at which inventory adjustment was completed. For the CC_Location scenario, time at which ‘Ctrl-E: End Location count’ is entered to finish the count. For the CC_LPN scenario, time at which ‘Ctrl-P’ is entered to finish the LPN count.

- Mod User: User who modifies the record. Set equal to Create User when record is created. Set equal to user who Rejects, Accepts or Cancels the record.

- Mod Timestamp: Time at which the record is modified. Set equal to Create Timestamp when record is created. Update timestamp when user Rejects, Accepts or Cancels the record.

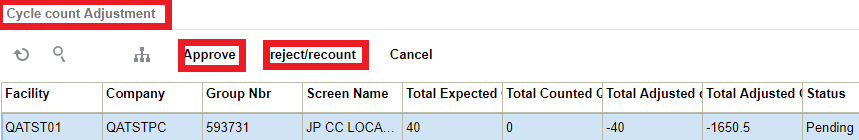

Approving and Rejecting Adjustments in Deferred Mode

The Deferred Mode allows supervisors to approve/reject inventory adjustments made by users who have previously Cycle Counted locations.

To approve/reject records, make sure it is in “Pending” status and click the “Approve” or “Reject/Recount” buttons.

Approving a record applies the inventory adjustments by adding/subtracting inventory from the locations as well as posting records in the Inventory History screen (referenced by the Group Number).

Rejecting a record will cancel the inventory adjustment and trigger a new CC task so that the location is re-counted.

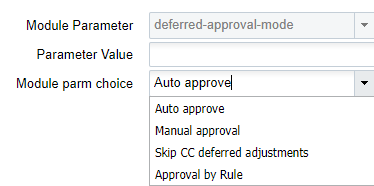

Deferred Approval Mode set up in RF Cycle Count Transactions

Previously, when performing a Cycle Count with RF Cycle Count Location or RF Cycle Count IBLPN, you would use the screen parameter “auto-approve-mode (update 18C).” This screen parameter is now called “deferred-approval-mode.”

The deferred_approval_mode parameter makes it easy for you to distinguish the approval modes available while you are performing cycle counting operations.

From Modules, select Cycle Count Location or Cycle Count IBLPN, then Screens, and Screen Parameters to view and select your module parameter choice.

The available settings for the Deferred-Approval-Mode screen parameter are defined in the following table:

| Mode | Definition |

|---|---|

| Manual Approve | When "deferred-approval-mode" is set with Manual Approve, "RF Cycle Count Locn/IBLPN" writes the count information in the CC Deferred Adjustment UI and will leave the information for the supervisor to approve or cancel the count if supervisor is logged in with company and facility combination and mode is configured with deferred mode. |

| Auto Approve | When "deferred-approval-mode" is set with Auto Approve, RF Cycle Count Locn/IBLPN" writes the count information in the CC Deferred Adjustment UI and will get Auto Approved after passing through all the validations if user is logged in with a company and facility combination and mode is configured with deferred mode. |

| Skip CC Deferred Adjustment |

|

| Approval by Rule |

|