18 Supply Chain Network

This chapter describes the functionality that allows you to set up and review the supply chain network model to be used by the IPOCS-Lifecycle Allocation and Replenishment calculations.

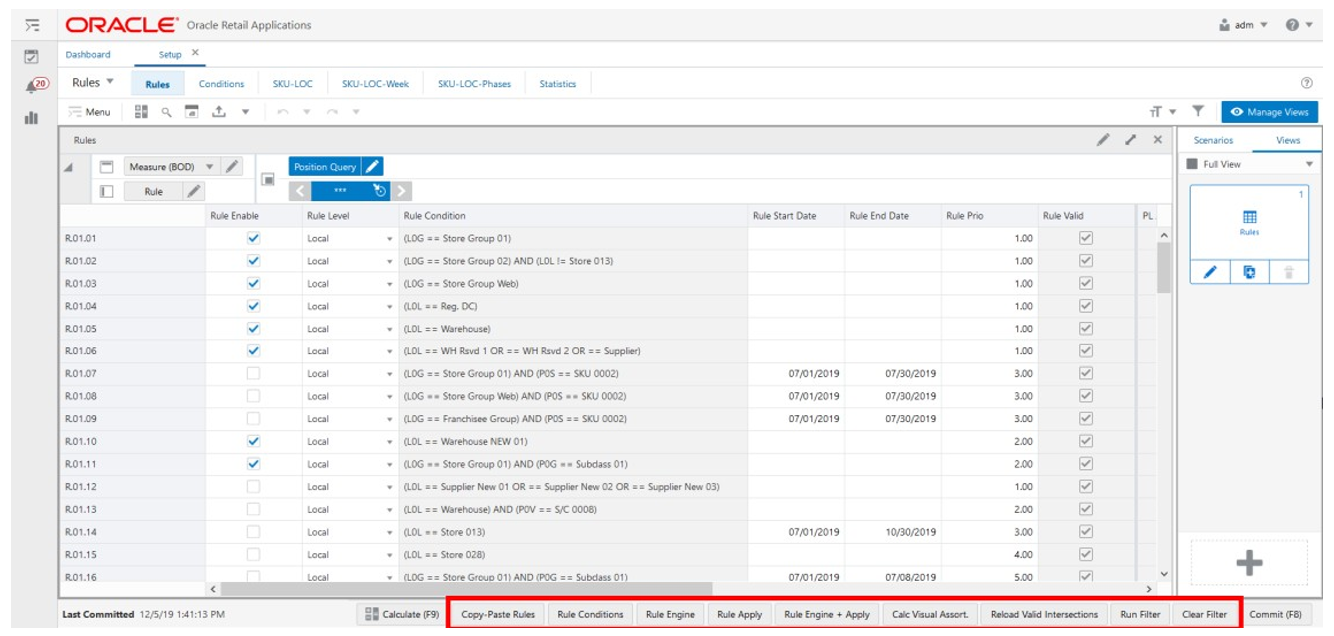

The Supply Chain Network Workspace is where you can set up the Bill of Distribution, Planning Calendars, and Lifecycle Calendars. Once they are defined you can configure rules and conditions to specify where they should be applied. The IPOCS-Lifecycle Allocation and Replenishment Rule Engine does the heavy work for you and calculates the correct Bill of Distribution, Planning Calendars, Assortment Calendars, and Lifecycle Calendars at the product and location level using the available assortment and lifecycle information.

You can further leverage the IPOCS-Lifecycle Allocation and Replenishment Rules Engine and specify the period where the rule should apply (start and end date if applicable) and the priority of the rule to allow IPOCS-Lifecycle Allocation and Replenishment to pick the most suitable rule based on the priority.

Figure 18-1 IPOCS-Lifecycle Allocation and Replenishment Setup Rules Illustration

Supply Chain Network Workspace, Steps, and Views

The following table lists the workspaces, steps, and views for the Supply Chain Network task.

Table 18-1 Setup Rules Workspace, Steps, and Views

| Workspace | Step | Tab | Views |

|---|---|---|---|

|

Overview |

|||

|

Scope |

|||

|

Bill of Distributions |

|||

|

Planning Calendars |

|||

|

Lifecycle Calendars |

|||

|

Setup |

|||

|

Review |

|||

|

Filter |

|||

Supply Chain Network Workspace

The Supply Chain Network workspace allows you to access all the views listed in the Supply Chain Network Workspaces, Steps, and Views. To build the Supply Chain Network workspace, perform these steps:

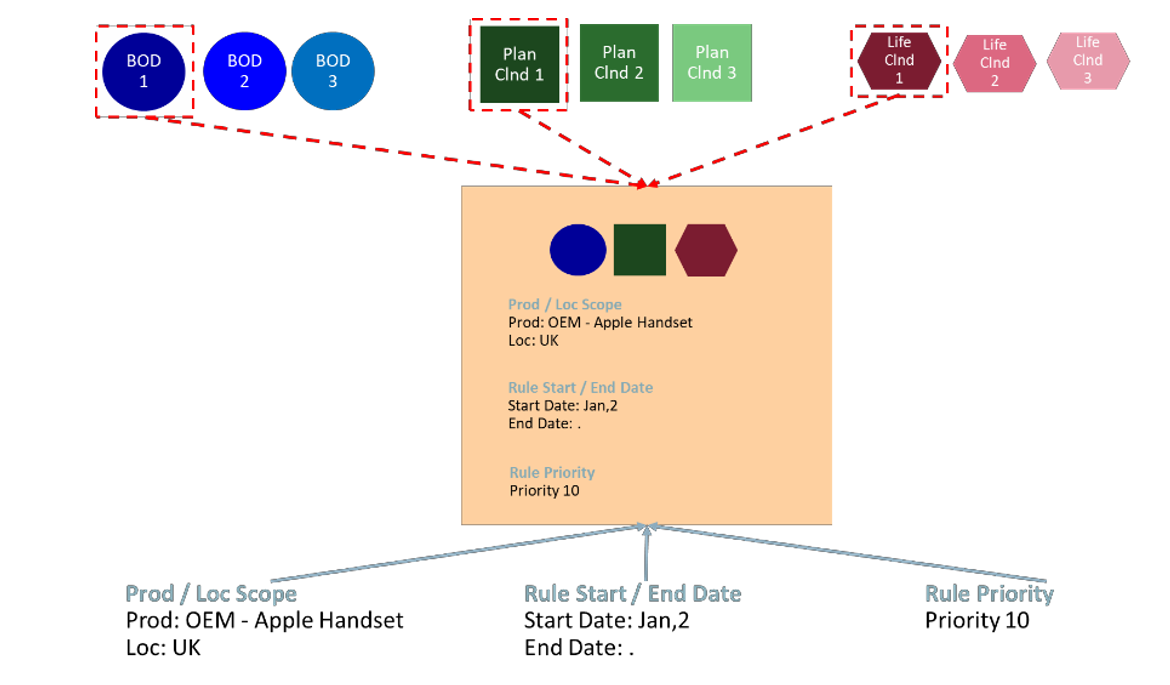

-

From the left sidebar menu, click Task Module to view the available tasks.

Figure 18-2 Task Module

-

Click the Business Rules Setup activity to access the available workspaces.

-

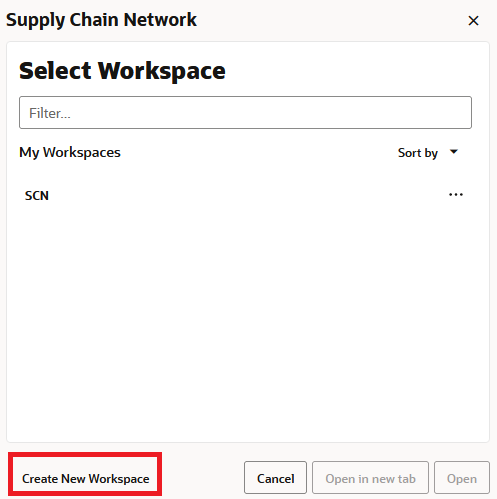

Click Supply Chain Network. The Supply Chain Network wizard opens.

-

You can open an existing workspace, but to create a new workspace, click Create New Workspace.

Figure 18-3 Supply Chain Network Wizard: Create New Workspace

-

Enter a name for your new workspace in the label text box and click OK.

-

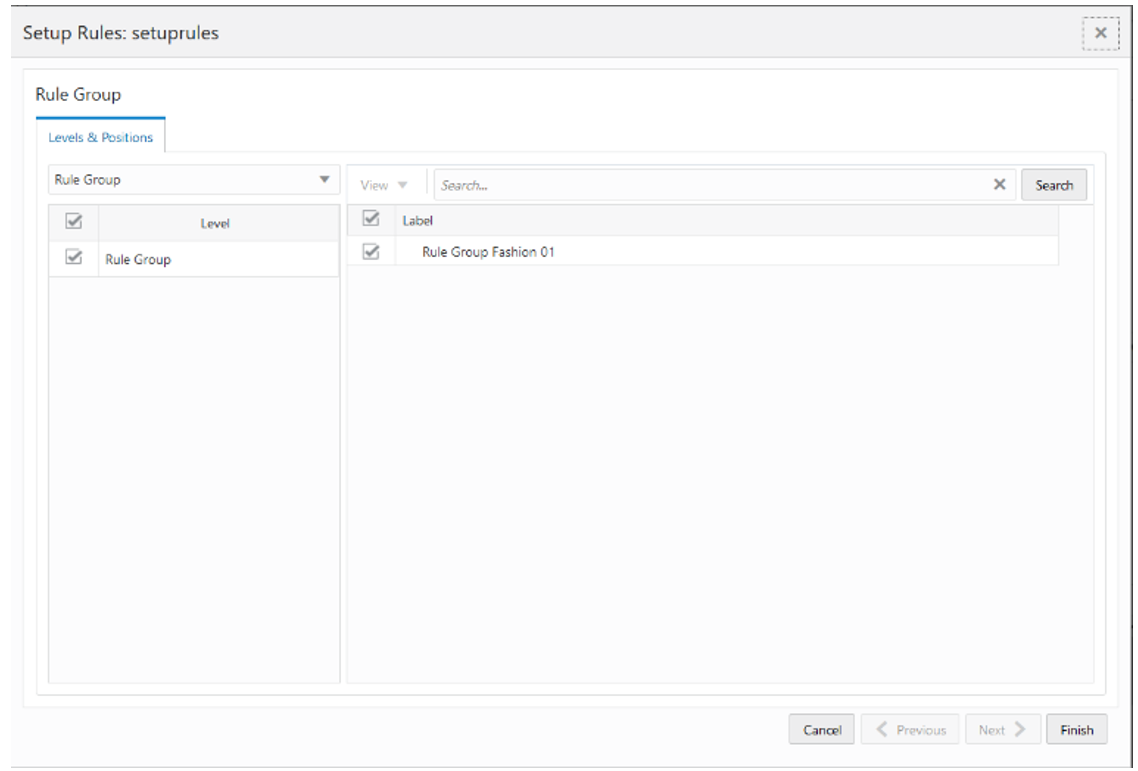

The Workspace wizard opens. Select the rule group you want to work with and click Finish.

Note:

Only the rule groups that are from the Setup rule group type are available for selection. The rule group type value is managed in the Manage Rule Groups workspace.

Figure 18-4 Workspace Wizard: Select Rule Group

-

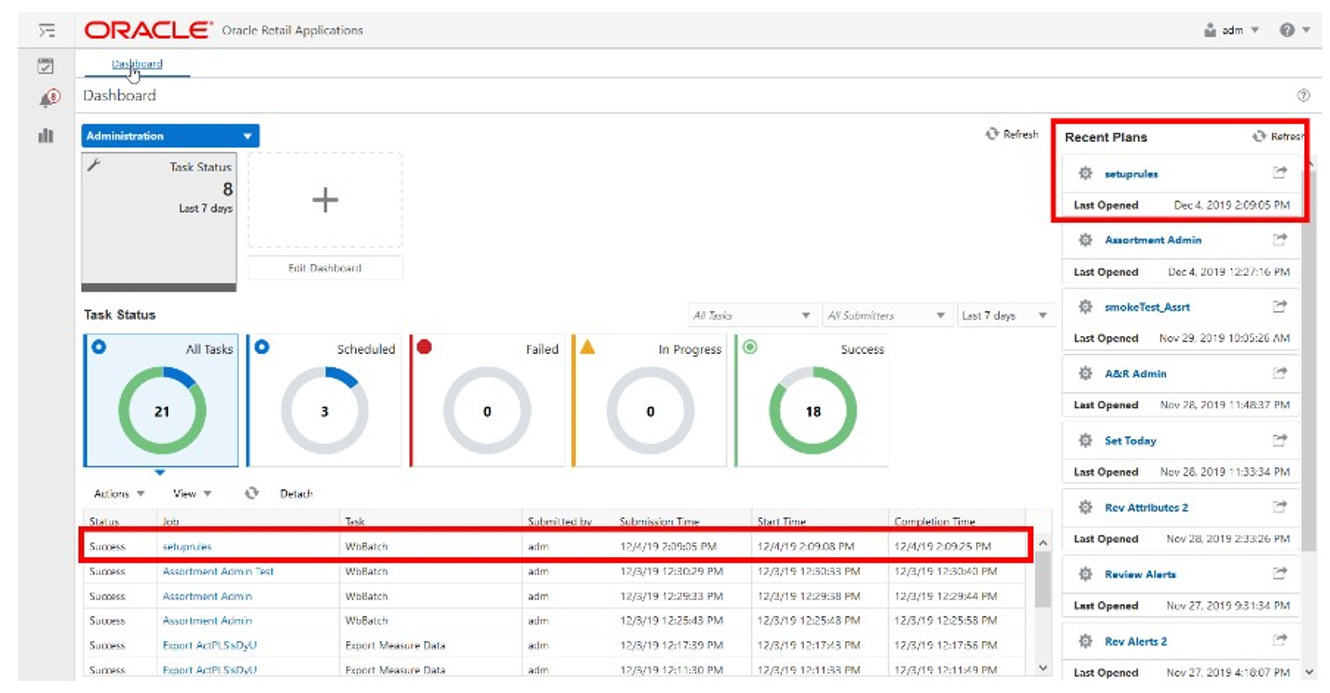

The wizard notifies you that the workspace is being prepared. Successful workspaces are available from the Dashboard.

Note:

The workspace is built using the selected rule group scope. The products, locations, source locations and attributes available in the workspace are the ones in the rule group scope that is managed in the Manage Rule Groups workspace.

Figure 18-5 Successful Workspace Build: Setup Rules

Overview Step

This step contains these views:

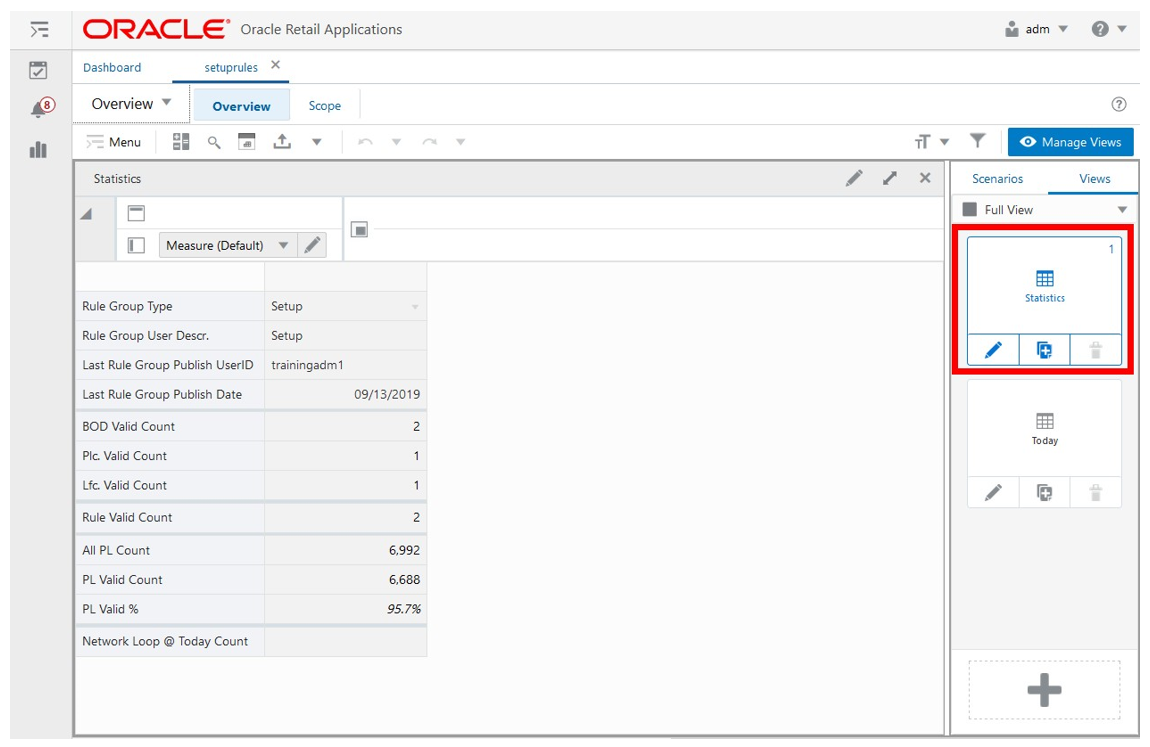

Statistics View

The Statistics View, under the Overview tab, allows you to check the statistics of the Setup Rules. The view has statistical information regarding the number of valid counts for each set up (for example, Bill of Distribution, Planning Calendar) and rules. It also provides the number of product and location combinations and the number of Network Loop errors.

Figure 18-6 Statistics View

Statistics View - Default Profile Measures

The Statistics View contains the following measures.

Rule Group Type

The Rule Group Type is a loaded read-only measure to display the rule group type that was set up for the rule group in the Manage Rule Group workspace.

Rule Group User Desc.

The Rule Group User Description is a loaded read-only measure to display your description that was set up for the rule group in the Manage Rule Group workspace.

Last Rule Group Publish User ID

The Last Rule Group Publish User ID is a loaded read-only measure to display you identifier that performed the last rule group’s change in the Manage Rule Group workspace.

Last Rule Group Publish Date

The Last Rule Group Publish Date is a loaded read-only measure to display the date and time when the last rule group’s change was performed in the Manage Rule Group workspace.

BOD Valid Count

The Bill of Distributions Valid Count is a calculated measure to display the total number of valid bills of distributions (BOD) that are set up for the rule group.

Plc. Valid Count

The Planning Calendar’s Valid Count is a calculated measure to display the total number of valid planning calendars (Plc) that are set up for the rule group.

Lfc. Valid Count

The Lifecycle Calendar’s Valid Count is a calculated measure to display the total number of valid lifecycle calendars (Lfc) that are set up for the rule group.

Rule Valid Count

The Rule Valid Count is a calculated measure to display the total number of valid rules that are set up for the rule group.

All PL Count

The All Product and Location Count is a calculated measure to display the total number of product and location combinations that have a lifecycle phase value.

PL Valid Count

The Product and Location Valid Count is a calculated measure to display the total number of product and location combinations that have a valid rule assigned.

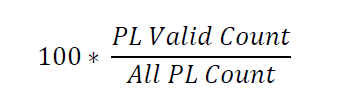

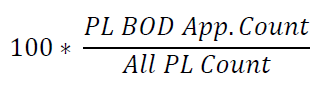

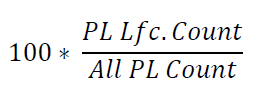

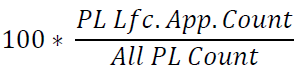

PL Valid %

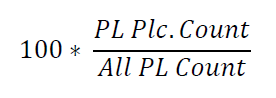

The Product and Location Valid Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations with a valid rule assigned represent the total of product and location combinations with a lifecycle phase value. The value of this measure is the result of the formula:

Figure 18-7 Calculation

Network Loop @ Today Count

The Network Loop @ Today Count is a calculated measure to display the total number of Network Loop errors caused by the BOD set up for the rule group.

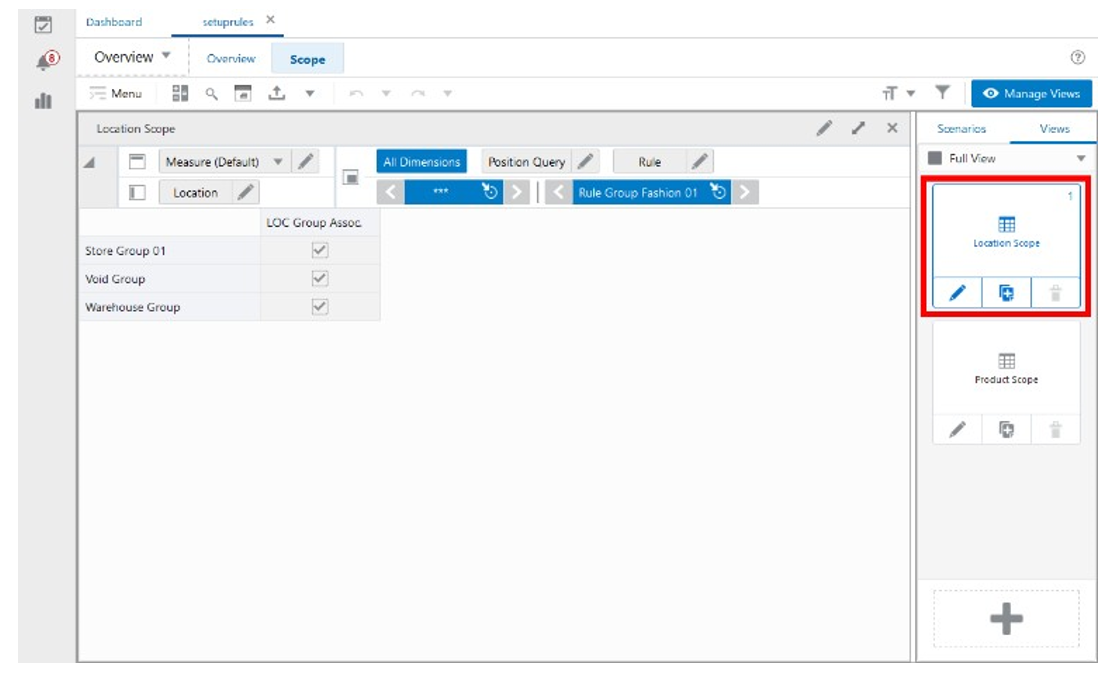

Location Scope View

The Location Scope View, under the Scope tab, allows you to check what specific locations are in the scope of a rule group and loaded into the workspace.

Figure 18-8 Location Scope View

Location Scope View - Default Profile Measures

The Location Scope View contains the following measure.

LOC Group Assoc.

The Location Group Associated is a loaded read-only measure used to indicate the location groups that are associated with the rule group. This measure is managed in the Manage Rule Groups workspace.

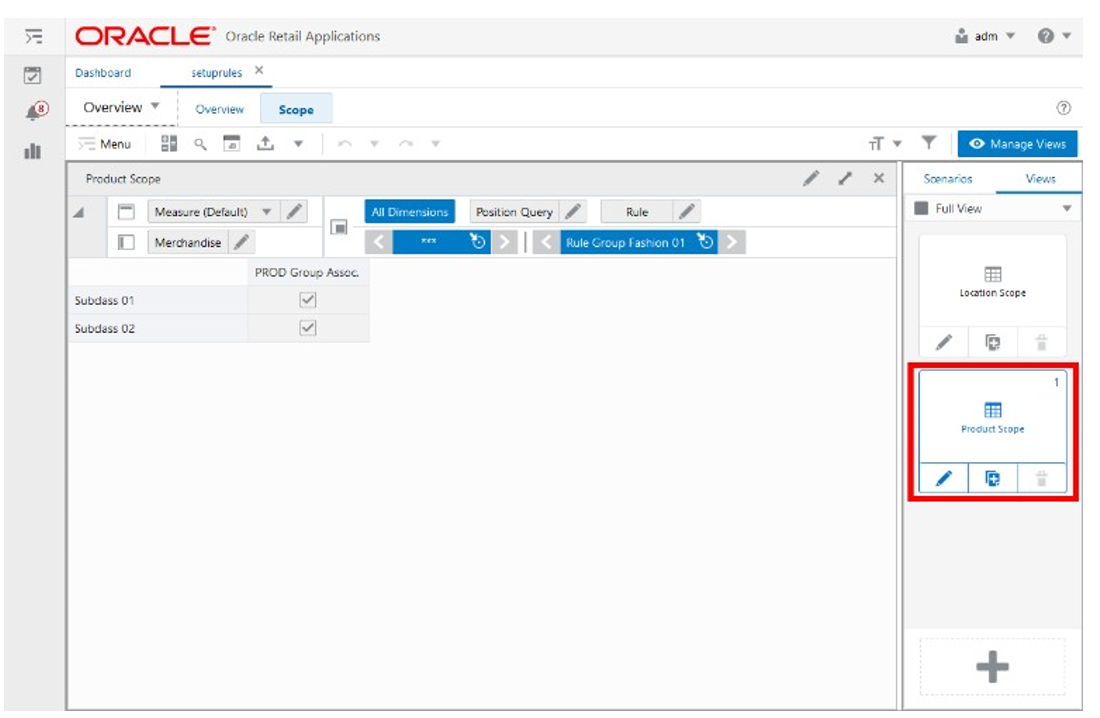

Product Scope View

The Product Scope View, under the Scope tab, allows you to check what specific products are in the scope of a rule group and loaded into the workspace.

Figure 18-9 Product Scope View

Product Scope View - Default Profile Measures

The Product Scope View contains the following measure.

PROD Group Assoc.

The Product Group Associated is a loaded read-only measure used to indicate the products groups that are associated with the rule group.

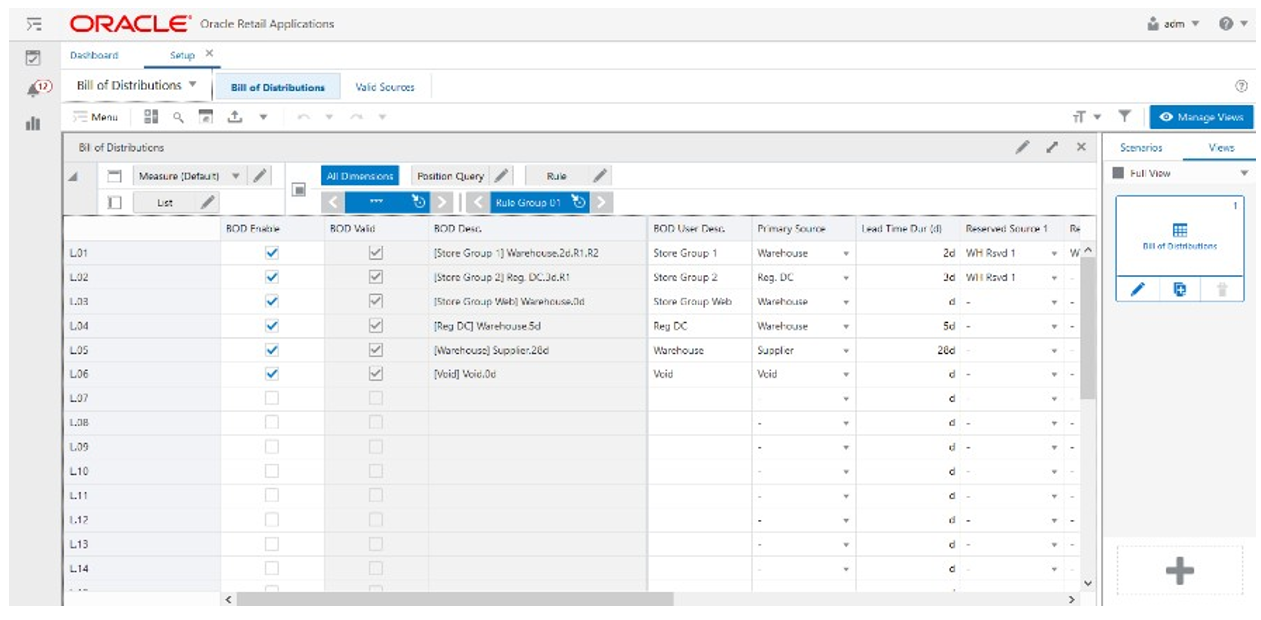

Bill of Distributions Step

This step contains these views:

In IPOCS-Lifecycle Allocation and Replenishment, the Bill of Distribution (BOD) defines the lead time for all supplying sources available throughout the supply chain network. The Lead time is defined by the number of days it takes for shipments from the source to arrive at the target.

Figure 18-10 IPOCS-Lifecycle Allocation and Replenishment Bill of Distributions Illustration

Bill of Distributions View

The Bill of Distributions View, under the Bill of Distributions tab, allows you to perform all possible setups for the source of supply chain network. The setup is then used in the rules and based on the rule set up it is associated with, down to item and location level (lowest level of Prod-Loc).

Figure 18-11 Bill of Distributions View

Bill of Distributions View - Default Profile Measures

The Bill of Distributions View contains the following measures.

BOD Enable

The Bill of Distributions Enable is an editable measure to enable or disable a bill of distribution. Each row (or list) represents a different BOD.

BOD Valid

The Bill of Distributions Valid is a calculated measure used to indicate if the set up of the BOD is valid or not. For example, if the primary source is missing then the BOD is not valid for IPOCS-Lifecycle Allocation and Replenishment.

BOD Desc

The Bill of Distributions Description is a calculated measure used to indicate the BOD description. The description is calculated based on the BOD user-defined description and the BOD set up. The pattern applied is the following:

-

When no Reserved source is set up:

[BOD User Desc]+ +[Primary Source]+.+[ Lead Time]

-

When only Reserved source 1 is set up:

[BOD User Desc]+ +[Primary Source]+.+[ Lead Time]+.R1

-

When only Reserved source 2 is set up:

[BOD User Desc]+ +[Primary Source]+.+[ Lead Time]+.R2

-

When both Reserved source are set up:

[BOD User Desc]+ +[Primary Source]+.+[ Lead Time]+.R1.R2

BOD User Desc

The Bill of Distributions User Description is an editable measure to input a user-defined BOD description. The final BOD description takes into consideration your defined description. The entered value must not contain a colon punctuation mark (:).

Primary Source

The Primary Source is an editable measure to select, from a picklist, a primary source for the BOD. The list of sources presented to you in the picklist are the sources that are enabled as a valid location source in the Valid Source Locations view.

Lead Time

The Lead Time is an editable measure to define the lead time, in number of days, for the BOD.

Reserved Source 1

The Reserved Source 1 is an editable measure to select, from a picklist, a reserved source for the BOD. The list of sources presented to you in the picklist are the sources that are enabled as valid reserved sources in the Valid Source Locations view.

Reserved Source 2

The Reserved Source 2 is an editable measure to select, from a picklist, an additional reserved source for the BOD. The list of sources presented in the picklist are the sources that are enabled as valid reserved sources in the Valid Source Locations view.

Alternative Source

The Alternative Source is an editable measure to select, from a picklist, an alternative source to the primary source for the BOD. The list of sources presented in the picklist are the sources that are enabled as Valid Source Locations in the Valid Source Locations view.

Rule BOD Count

The Rule Bill of Distributions Count is a calculated measure to display the total number of rules that are using the BOD.

PL BOD Count

The Product and Location Bill of Distributions Count is a calculated measure to display the total number of product and location combinations that are associated with the BOD.

PL BOD %

The Product and Location Bill of Distributions Percentage is a calculated measure used to indicate, in percentages, how much the product and location combinations associated with the BOD represent in the total of product and location combinations with a lifecycle phase value. The value of this measure is the result of the formula:

Figure 18-12 Calculation

BOD User Filter

The Bill of Distributions User Filter is an editable measure to select the BOD to filter the views by the selected BOD. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Setup Rules workspace.

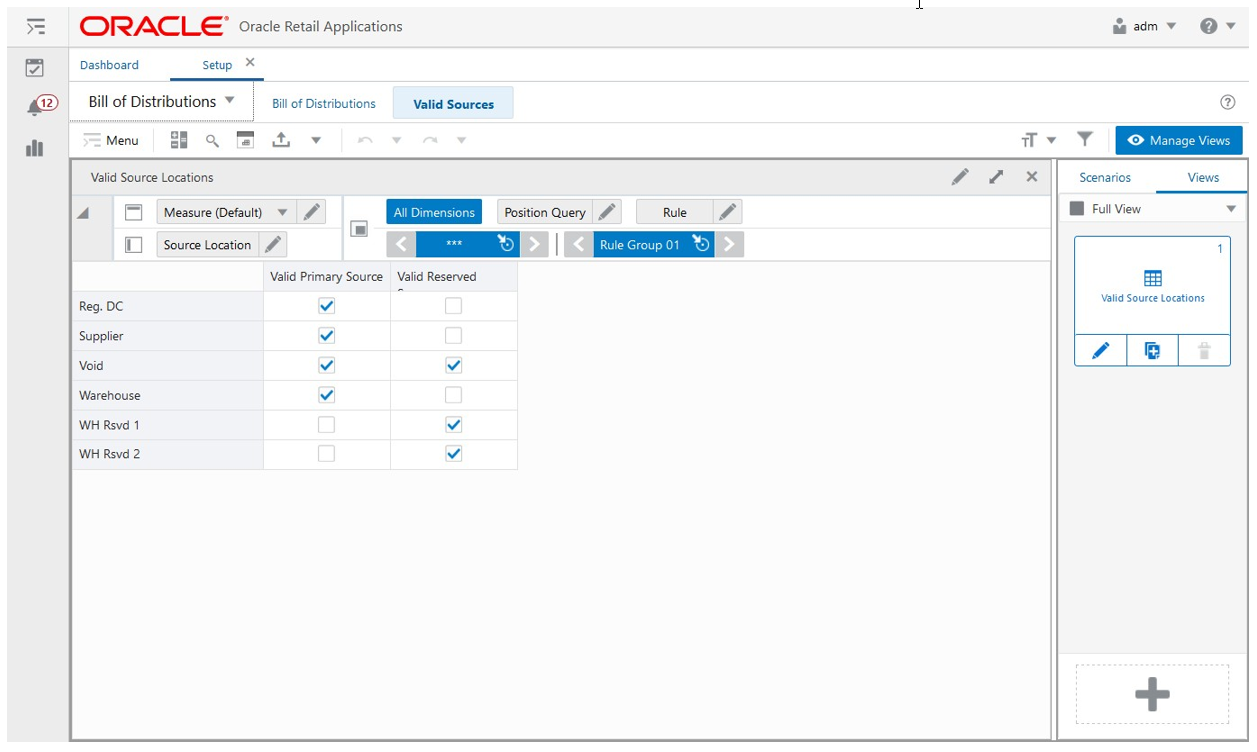

Valid Source Locations View

The Valid Source Locations View, under the Valid Sources tab, allows you to select which locations are primary sources or reserved sources. This set up is used by the Primary Source and Reserved Source measures in the Bill of Distributions view to display the correct source location to you.

Figure 18-13 Valid Source Locations View

Valid Source Locations View - Default Profile Measures

The Valid Source Locations View contains the following measures.

Valid Primary Source

The Valid Primary Source is an editable measure to define a location possible location to be used by the bill of distributions as the primary source or alternate source.

Valid Reserved Source

The Valid Reserved Source is an editable measure to define a possible location to be used by the bill of distributions as a reserved source.

Planning Calendars Step

This step contains these views:

-

Planning Calendars View

-

Day of Week View

-

Daily Exceptions View

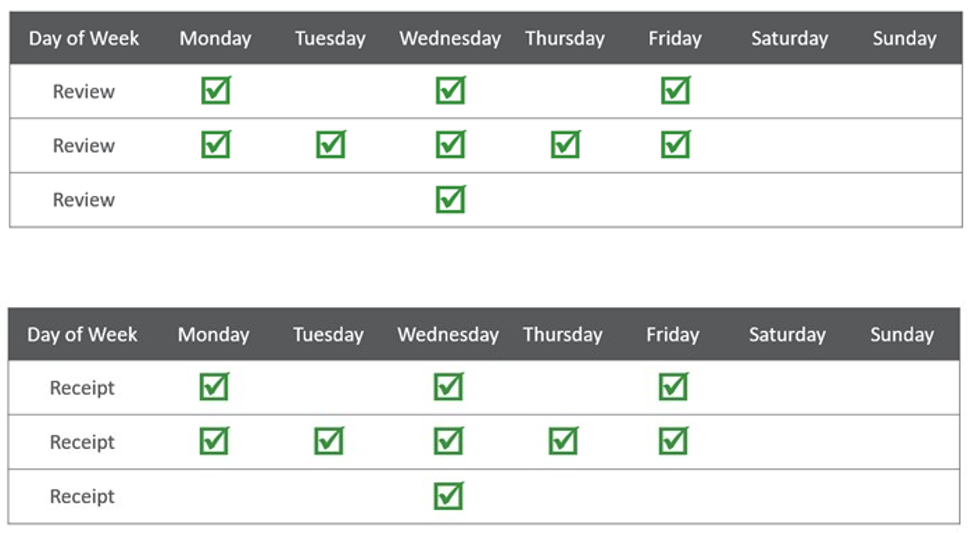

In IPOCS-Lifecycle Allocation and Replenishment the Planning Calendar (Plc) is used to specify the location’s ordering/receiving patterns along with the associated planning horizon that IPOCS-Lifecycle Allocation and Replenishment should plan for. IPOCS-Lifecycle Allocation and Replenishment works with two types of calendars:

-

Review Calendar: Use this calendar for point-in-time replenishments

-

Receipt Calendar: Use this calendar for time-phased replenishments

Both calendars allow for two methods to set up a Planning Calendar:

-

Day of Week: Main method to select the review or receipt dates, by selecting a day of the week, (for example, Monday) regardless of the dates

-

Exception: Method to configure exceptions by selecting specific dates (days) that are an exception to the day of week set up.

Figure 18-14 Planning Calendar Day of Week Setup Illustration (Review & Receipt)

Figure 18-15 Planning Calendar Exception Setup Illustration (Review & Receipt)

The planning calendar set up is used in the rules and based on the rule set up it is associated with down to the item and location levels (lowest level of Prod-Loc). This set up is also used by the IPOCS-Lifecycle Allocation and Replenishment Engine to plan what the next review day or receipt day is.

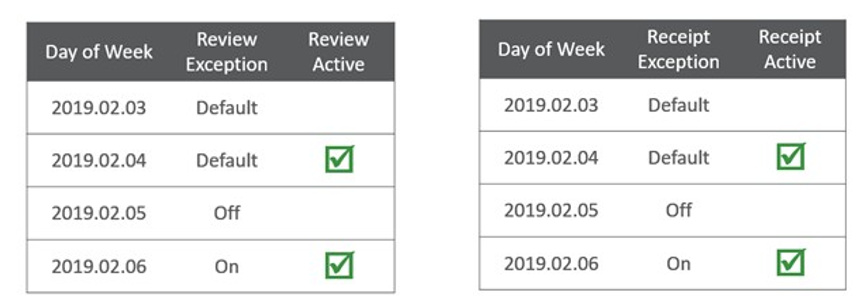

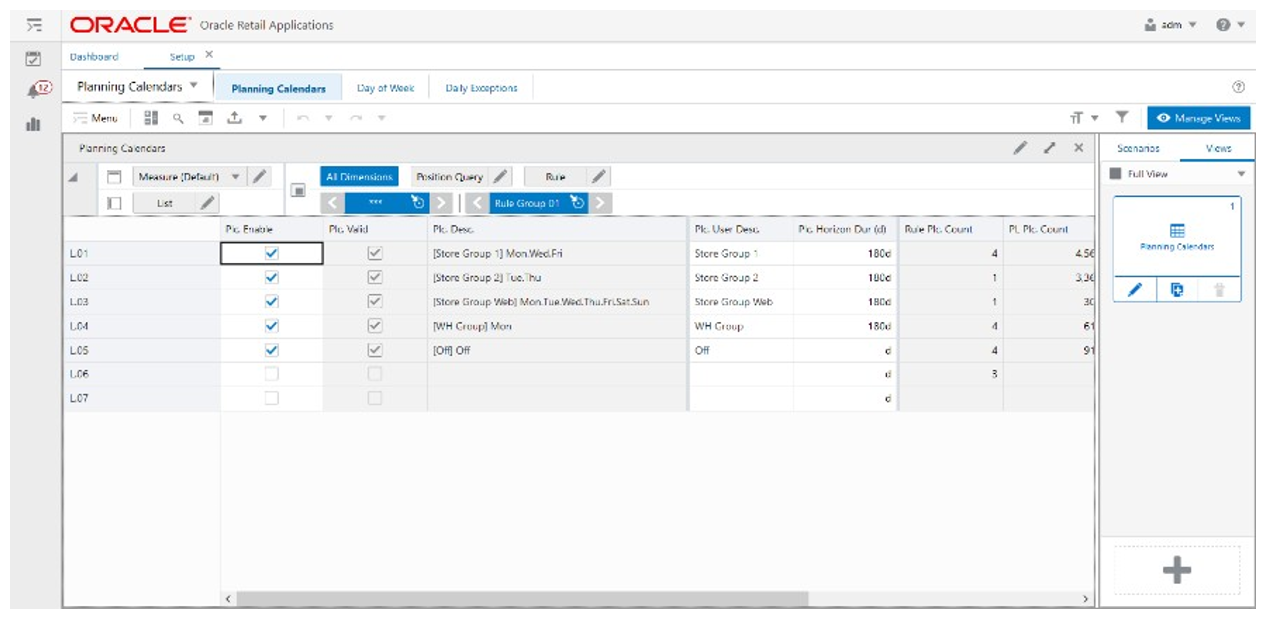

Planning Calendars View

The Planning Calendars View, under the Planning Calendars tab, allows you to set up a planning calendar and specify the time horizon to be used. The set up of the planning calendar is completed by the set up in the views Day of Week and Daily Exceptions.

Figure 18-16 Planning Calendars View

Planning Calendars View - Default Profile Measures

The Planning Calendars View contains the following measures.

Plc. Enable

The Plc. Enable is an editable measure to enable or disable a planning calendar. Each row (or list) represents a different planning calendar.

Plc. Valid

The Plc. Valid is a calculated measure that indicates if the set up of the planning calendar is valid or not. IPOCS-Lifecycle Allocation and Replenishment assumes that a planning calendar valid if it is enabled.

Plc. Desc

The Plc. Desc is a calculated measure used to indicate the planning calendar description. The description is calculated based on the planning calendar user-defined description and the planning calendar set up. The pattern applied is the following:

[Plc. User Desc]+ +[List of selected Review Days separated by .]

Plc. User Desc

The Plc. User Desc is an editable measure to input a user-defined planning calendar description. The final planning calendar description takes into consideration the user-defined description. The entered value must not contain a colon punctuation mark (:).

Plc. Horizon Dur (d)

The Plc. Horizon Dur (d) is an editable measure to input the time horizon for the planning calendar. The time horizon is a numeric value expressed in a number of days.

Rule Plc. Count

The Rule Plc. Count is a calculated measure to display the total number of rules that are using the planning calendar.

PL Plc. Count

The PL Plc. Count is a calculated measure to display the total number of product and location combinations that associated with the planning calendar.

PL Plc. %

The PL Plc. % is a calculated measure used to indicate, in percentage, how much the product and location combinations associated with the planning calendar represent the total of product and location combinations with a lifecycle phase value. The value of this measure is the result of the formula:

Figure 18-17 Calculation

Daily Ex. Copy & Paste

The Daily Ex. Copy & Paste is an editable measure to select whether the planning calendar is the source or destination for the copy/paste exception functionality (Copy-Paste Exceptions action button). Valid values are:

-

Copy

The option selected in the planning calendar used as a source of the copy for the daily exception. The copy copies all information in the view Daily Exceptions.

-

Paste

The option selected in the planning calendar used as a destination of the copy for the daily exception. The paste overrides all the information in the view Daily Exceptions.

-

-

The option selected to clear the measure. An example of this would be to select a copy of the planning calendar 01 and then select paste to the planning calendar 02. Then when the Copy-Paste Exception action button runs all daily exceptions from Planning Calendar 01, it is copied to Planning Calendar 02. The results can be selected in the view Daily Exceptions.

Note:

Only one planning calendar should be selected as a source (Copy) but multiple planning calendar can be selected as a destination (Paste).

Plc. User Filter

The Plc. User Filter is an editable measure to select the planning calendar to filter the views by the selected planning calendar. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Setup Rules workspace.

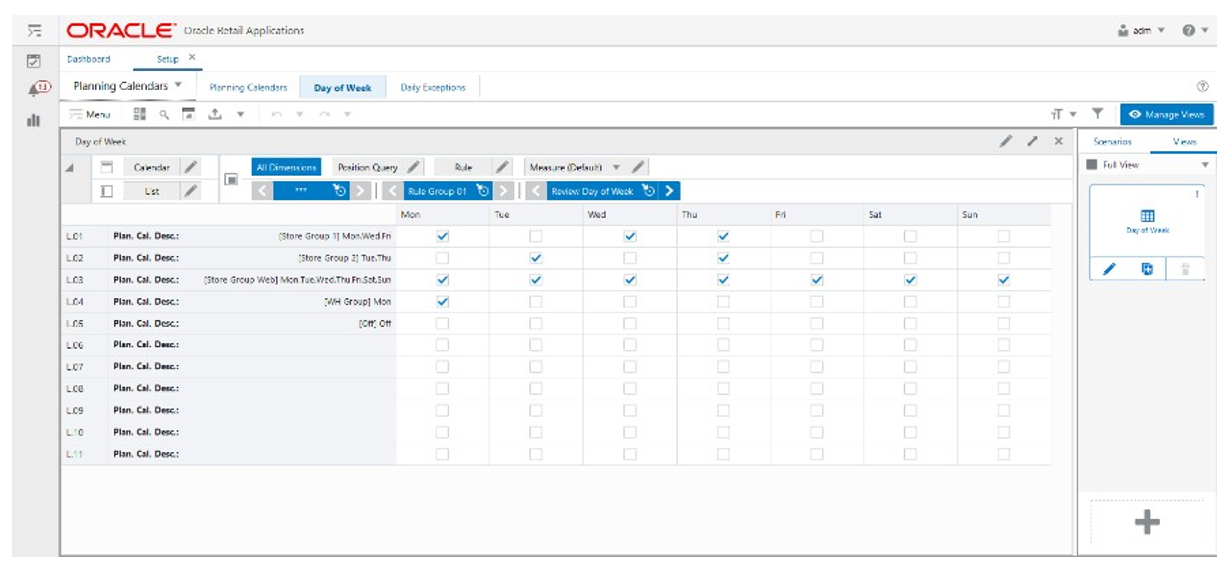

Day of Week View

The Day of Week View, under the Day of Week tab, allows you to set up what the week must be in terms of the review and receipt days for the planning calendar. This set up is also used by IPOCS-Lifecycle Allocation and Replenishment Engine to know what the next review day is, or what the next receipt day is.

Figure 18-18 Day of Week View

Day of Week View - Default Profile Measures

The Day of Week View contains the following measures.

Review Day of Week

This is an editable measure to select the days of the week, in the planning calendar, to be used for the replenishment days.

Receipt Day of Week

This is an editable measure to select the days of the week, in the planning calendar, to be used as received deliveries days.

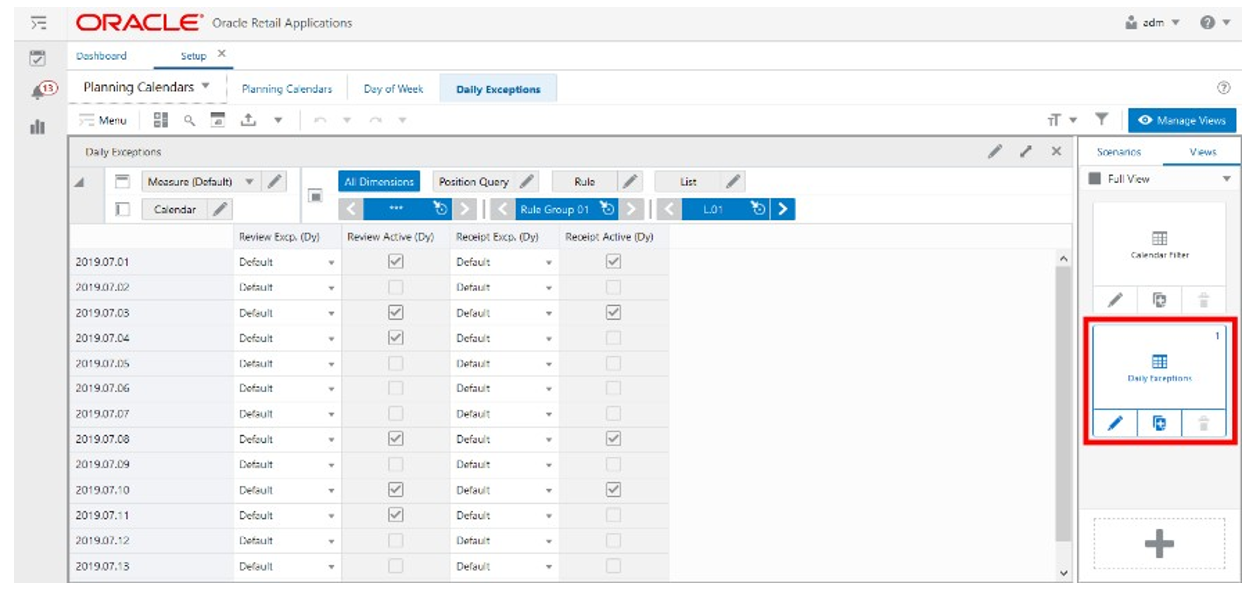

Daily Exceptions View

The Daily Exceptions View, under the Daily Exceptions tab, allows you to set up exception days on top of the set up already completed for the days of week. For example, if Fridays are selected as review days but there is a specific Friday where the review can not be completed, then you can use this view to override the particular Friday date to be a no-review day. By default, all dates assume the set up from the Day of Week view.

Figure 18-19 Daily Exceptions View

Daily Exceptions View - Default Profile Measures

The Daily Exceptions View contains the following measures.

Review Excp. (Dy)

The Review Exception (Day) is an editable measure to set up a review day exception, in the planning calendar, for a particular date. Valid values are:

-

Default

This option assumes the review day set up from the Day of Week view.

-

On

This option overrides the review day set up from the Day of Week and forces the date to be a review day.

-

Off

This option overrides the review day set up from the Day of Week and forces the date to be a no-review day.

Review Active (Dy)

The Review Active (Day) is a calculate measure used to indicate whether the date is a review day or not (might be a forced exception or the default day from the Day of Week view). When selected, the date is a review day. When clear, the date is not a review day.

Receipt Excp. (Dy)

The Receipt Exception (Day) is an editable measure to set up a receipt day exception, in the planning calendar, for a particular date. Valid values are:

-

Default

This option assumes the receipt day set up from the Day of Week view.

-

On

This option overrides the receipt day set up from the Day of Week and forces the date to be a receipt day.

-

Off

This option overrides the receipt day set up from the Day of Week and forces the date to be a no-receipt day.

Review Active (Dy)

The Review Active (Day) is a calculated measure used to indicate whether the date is a receipt day or not (might be a forced exception or the default day from the Day of Week view). When selected the date is a receipt day. When clear, the date is not a receipt day.

Lifecycle Calendars Step

This step contains these views:

In IPOCS-Lifecycle Allocation and Replenishment the Lifecycle represents all the phases that every item goes through during its lifetime. A full lifecycle is when an item goes from discovery to maturity and then end of life.

Figure 18-20 IPOCS-Lifecycle Allocation and Replenishment Lifecycle Illustration

The IPOCS-Lifecycle Allocation and Replenishment Lifecycle calendar defines the timing of the lifecycle phases, and it is linked to an item assortment plan at the location. The assortment start date is used as an Anchor Date to trigger the start of the lifecycle assortment. The end date defines when an item should stop selling and stop being replenished.

The IPOCS-Lifecycle Allocation and Replenishment approaches for replenishment may vary throughout the different lifecycle phases:

-

Discovery

This rule measures how long the sales forecast takes to stabilize during the initial sales period. Sales are generally highly volatile.

-

Example: Setting 3-4 weeks after (end of) initial allocation or 2% Sell Through of Total Initial Inventory

-

Setting the end of Discovery too early could misdiagnose poor sales for an item

-

Setting the end of Discovery too early could misdiagnose poor sales for an item

-

-

Maturity

Item sales growth is continuous and forecasting in general is less volatile and more reliable.

-

End of Life

The item is close to the planned assortment end date and typically sales begin to diminish. In some cases, the item is sold at a Clearance Price during the end of life.

-

Example: Set as 80% Sell Through of Total Initial Inventory or for a specific date

-

The total forecast from the beginning of the end of life to the assortment end date is the key driver for replenishment for this phase of the lifecycle

-

The end of replenishment may be linked to the Assortment End Date, to a user-defined end of replenishment date or calculated by the system based on an elapsed time starting from the anchor date.

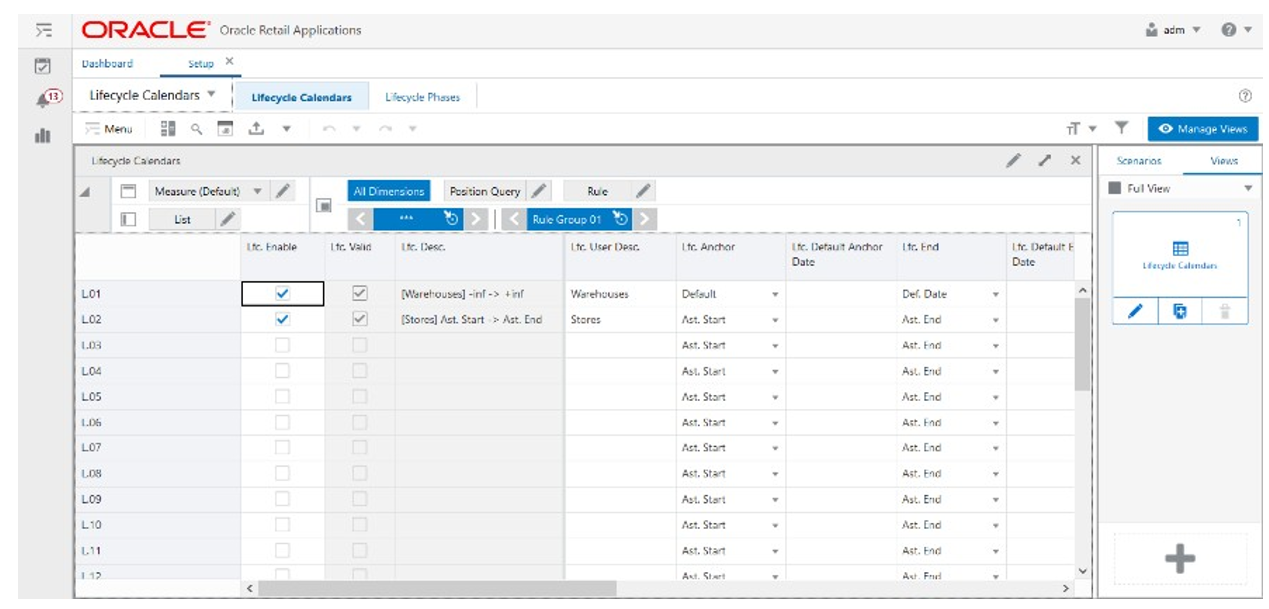

Lifecycle Calendars View

The Lifecycle Calendars View, under the Lifecycle Calendars tab, allows you to set up a lifecycle calendar where the start and end dates and the number of phases are specfied. The Phases setup is completed in the Lifecycle Phases view.

Figure 18-21 Lifecycle Calendars View

Lifecycle Calendars View - Default Profile Measures

The Lifecycle Calendars View contains the following measures.

Lfc. Enable

The Lifecycle Enable is an editable measure to enable or disable a lifecycle calendar. Each row (or list) represents a different lifecycle calendar.

Lfc. Valid

The Lifecycle Valid is a calculated measure used to indicate if the set up of the lifecycle calendar is valid or not. IPOCS-Lifecycle Allocation and Replenishment assumes a lifecycle calendar is valid if the total number of phases for the lifecycle calendar has a valid set up in the Lifecycle Phases view. For example, if a lifecycle calendar is set up to have four phases and only three of them are valid, then the lifecycle calendar is not valid. The lifecycle calendar is only valid when all four out of the four of four phases are valid.

Lfc. Desc

The Lifecycle Description is a calculated measure used to indicate the lifecycle calendar description. The description is calculated based on the lifecycle calendar user-defined description and the lifecycle calendar set up. The pattern applied is the following:

[Lfc. User Desc]+ + #START# + -> + #END#, where:

-

#START# value is as follows

-

If the measure Lfc. Anchor is set to assortment start date then it is the text Ast. Start.

-

If the measure Lfc. Anchor is set to Default and the anchor date exists (measure Lfc. Default Anchor Date is not empty) then it is the date indicated in the measure Lfc. Default Anchor Date.

-

If the measure Lfc. Anchor is set to Default and the anchor date does not exist (measure Lfc. Default Anchor Date is empty) then it is the text -inf (infinite).

-

-

#END# value is as follows

-

If the measure Lfc. End is set to assortment start date then it is the text Ast. End.

-

If the measure Lfc. End is set to Default Date and the default end date exist (measure Lfc. Default End Date is not empty) then it is the date indicated in the measure Lfc. Default End Date.

-

If the measure Lfc. End is set to Default Date and the default end date does not exists (measure Lfc. Default End Date is empty) then it is the text +inf (infinite).

-

If the measure Lfc. End is set to Default then it is the value indicated in the measure Lfc. Default End Dur (d).

-

Lfc. User Desc

The Lifecycle User Description is an editable measure to input a user-defined lifecycle calendar description. The final lifecycle calendar description takes into consideration the user-defined description. The entered value must not contain a colon punctuation mark (:).

Lfc. Anchor Method

The Lifecycle Anchor Method is an editable measure to select how IPOCS-Lifecycle Allocation and Replenishment should calculate the lifecycle calendar start date. Valid values are:

-

Default

This option sets the lifecycle calendar start date to the date indicated in the measure Lfc. Default Anchor Date. If the measure Lfc. Default Anchor Date is empty, then the start date is assumed as -∞ (infinite).

-

Ast. Start

This option sets the lifecycle calendar start date to the same date as the assortment start date.

Lfc. Default Anchor Date

The Lifecycle Default Anchor Date is an editable measure to define a default start date for the lifecycle calendar when the Lfc. Anchor measure is set up as default.

Lfc. End Method

The Lifecycle End Method is an editable measure to select how IPOCS-Lifecycle Allocation and Replenishment should calculate the lifecycle calendar end date. Valid values are:

-

Def. Date

This option sets the lifecycle calendar end date to the date indicated in the measure Lfc. Default End Date. If the measure Lfc. End Anchor Date is empty then the end date is assumed as -∞ (infinite).

-

Def. Dur.

This option sets the lifecycle calendar end date to the lifecycle start date plus the number of days indicated in the measure Lfc. Default End Dur (d). If the measure Lfc. Default End Dur (d) is empty then 0 days is assumed.

-

Ast. End

This option sets the lifecycle calendar end date to the same date as the assortment end date.

Lfc. Default End Date

The Lifecycle Default End Date is an editable measure to define a default end date for the lifecycle calendar when the Lfc. End measure is set up as Def. Date.

Lfc. Default End Dur (d)

The Lifecycle Default End Duration (day) is an editable measure to defined default duration in days for the lifecycle calendar when the Lfc. End measure is set up as Def. Dur.

Lfc. Number of Phases

The Lifecycle Number of Phases is an editable measure to define how many phases the lifecycle calendar has. The number of phases indicated in this measure is the number of rows (phases) available in the view Lifecycle Phases to set up the phases.

Rule Lfc. Count

The Rule Lifecycle Count is a calculated measure to display the total number of rules that are using the lifecycle calendar.

PL Lfc. Count

Product and Location Lifecycle Count is a calculated measure to display the total number of product and location combinations that are associated with the lifecycle calendar.

PL Lfc. %

The Product and Location Lifecycle Percentage is a calculated measure used to indicate, in percentages, how many product and location combinations associated with the lifecycle calendar are represented in the total of product and location combinations with a lifecycle phase value. The value of this measure is the result of the formula:

Figure 18-22 Calculation

Lfc Duplicate Phases

The Lifecycle Duplicate Phases is an editable measure to select whether the lifecycle calendar is the source or destination for the copy/paste lifecycle functionality (Copy-Paste LFC action button). Valid values are:

-

Copy

The option selected in the lifecycle calendar to be used as the source of the copy.

-

Paste

The option selected in the planning calendar to be used as destination of the copy.

-

-

The empty option selected to clear the measure.

Note:

Only one lifecycle calendar should be selected as a source (Copy) but multiple lifecycle calendars can be selected as a destination (Paste).

Lfc. User Filter

The Lifecycle User Filter is an editable measure to select the lifecycle calendar to filter the views by the selected lifecycle calendar. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Setup Rules workspace.

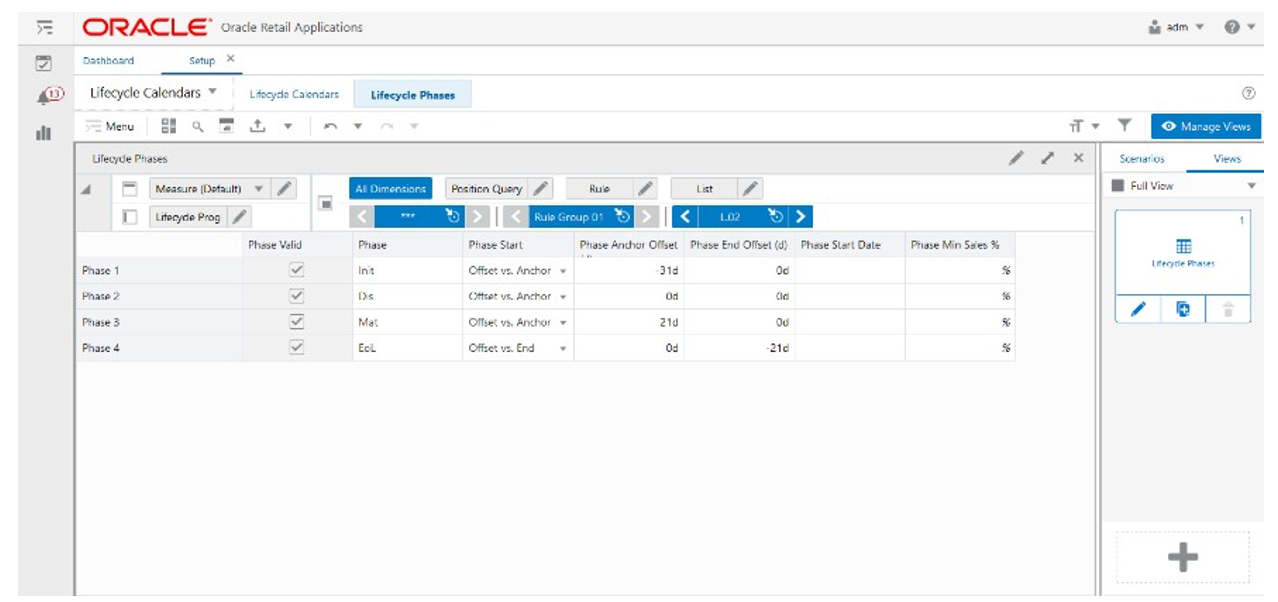

Lifecycle Phases View

The Lifecycle Phases View, under the Lifecycle Phases tab, allows you to configure each one of the phases for the total of phases specified in the lifecycle calendar. In this view, you can name the phases and set up the start and duration of each phase.

The lifecycle phases are considered as Prod-Loc Attributes in IPOCS-Lifecycle Allocation and Replenishment that can be used to set up replenishment parameter rules based on lifecycle phases.

This allows the IPOCS-Lifecycle Allocation and Replenishment to work on associating the correct replenishment parameters down to the item-location level (lowest level) based on the lifecycle phase. Using lifecycle phases simplifies the replenishment parameter management by completing it at the lifecycle phase level.

Figure 18-23 Lifecycle Phases View

Lifecycle Phases View - Default Profile Measures

The Lifecycle Phases View contains the following measures.

Phase Valid

The Phase Valid is a calculated measure used to indicate if the set up of the lifecycle phase is valid or not. IPOCS-Lifecycle Allocation and Replenishment assumes a lifecycle phase is valid when the Phase and Phase Start measures are populated.

Phase

The Phase is an editable measure to input a user-defined lifecycle phase description or name.

Phase Start Method

The Phase Start Method is an editable measure to select how the IPOCS-Lifecycle Allocation and Replenishment calculates the phase start date. Valid options are:

-

Offset versus Anchor

In this option the phase start date is calculated based on the lifecycle start date plus the number of days indicated in the measure Phase Anchor Offset (d).

-

Offset versus End

In this option the phase start date is calculated based on the lifecycle end date plus the number of days indicated in the measure Phase End Offset (d).

-

Date

In this option the phase start date is set to the date indicated in the measure Phase Start Date.

-

Seas. Sales %

In this option the phase starts on the date that the sales reached the percentage indicated in the measure Phase Min Sales %.

-

First

In this option the phase starts first before all other phases in the lifecycle calendar. Based on the previously listed options, the lifecycle phase is assigned to the item and location combination when the IPOCS-Lifecycle Allocation and Replenishment system date reaches the start date assigned to the phase.

Phase Anchor Offset (d)

The Phase Anchor Offset (day) is an editable measure to define the number of days to offset from the lifecycle calendar start date. This value is only used when the Phase Start is set to Offset vs Anchor. Negative values can also be used if the offset days need to be moved backward to the past.

Phase End Offset (d)

The Phase End Offset (day) is an editable measure to define the number of days to offset from the lifecycle calendar end date. This value is only used when the Phase Start is set to Offset versus End. Negative values can also be used if the offset days need to be moved backward to the past.

Phase Start Date

The Phase Start Date is an editable measure for you define a specific date to start the lifecycle phase. This value is only used when the Phase Start is set to Date.

Phase Min Sales %

The Phase Min Sales % is an editable measure to define the minimum sales percentage that IPOCS-Lifecycle Allocation and Replenishment uses to identify the lifecycle phase start date. This value is only used when the Phase Start is set to Seas. Sales %.

Rules Step

This step contains these views:

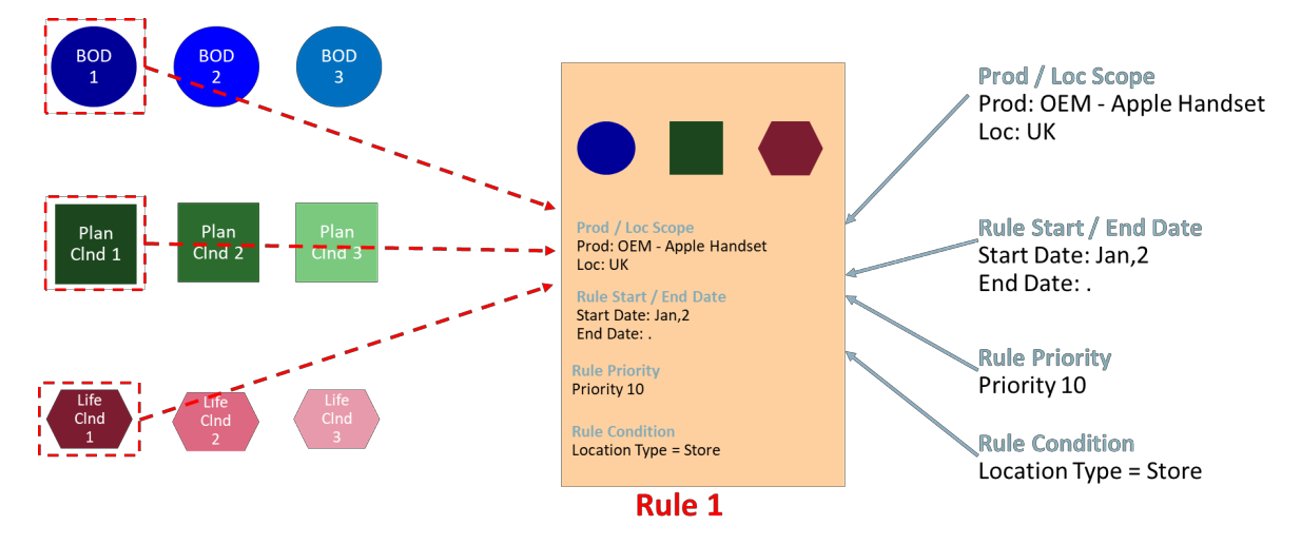

IPOCS-Lifecycle Allocation and Replenishment Rules Concept for the Setup Rules Task

IPOCS-Lifecycle Allocation and Replenishment provides a powerful engine that enables you to create a set of rules to apply all set up completed, within the Setup Task (BOD, Planning Calendar, and lifecycle calendar), down to the item and location levels. You can define multiple rules at a higher level using product, location and product-location attributes and then allow the IPOCS-Lifecycle Allocation and Replenishment Rule Engine to calculate at the lowest level, product and location combinations, and define the correct set up to be applied.

IPOCS-Lifecycle Allocation and Replenishment rules allows you to specify the period when the rule should be applied (if applicable) and the rules’ priority. The rule priority allows IPOCS-Lifecycle Allocation and Replenishment to choose the correct rule to be applied if a product and location combination fits in more than one set up rule (the higher the number, the higher the priority). The rule start and end date are used by IPOCS-Lifecycle Allocation and Replenishment to determine if the rule should be considered or discarded. If the IPOCS-Lifecycle Allocation and Replenishment system date falls within the start date and end date (or rule dates are empty) then it is considered. Otherwise, it is discarded.

Following are two examples and illustrations of rules for the set up task:

-

Rule 1

This rule should be configured to apply the Bill of distribution BOD1, the planning calendar PLC1 and the lifecycle calendar Clnd1.

-

The scope of the rule is the scope of the rule group where it is being configured (for example, Apple Handset products and the country UK).

-

The condition where the rule applies is for all items in the scope and for all locations which type is STORE.

-

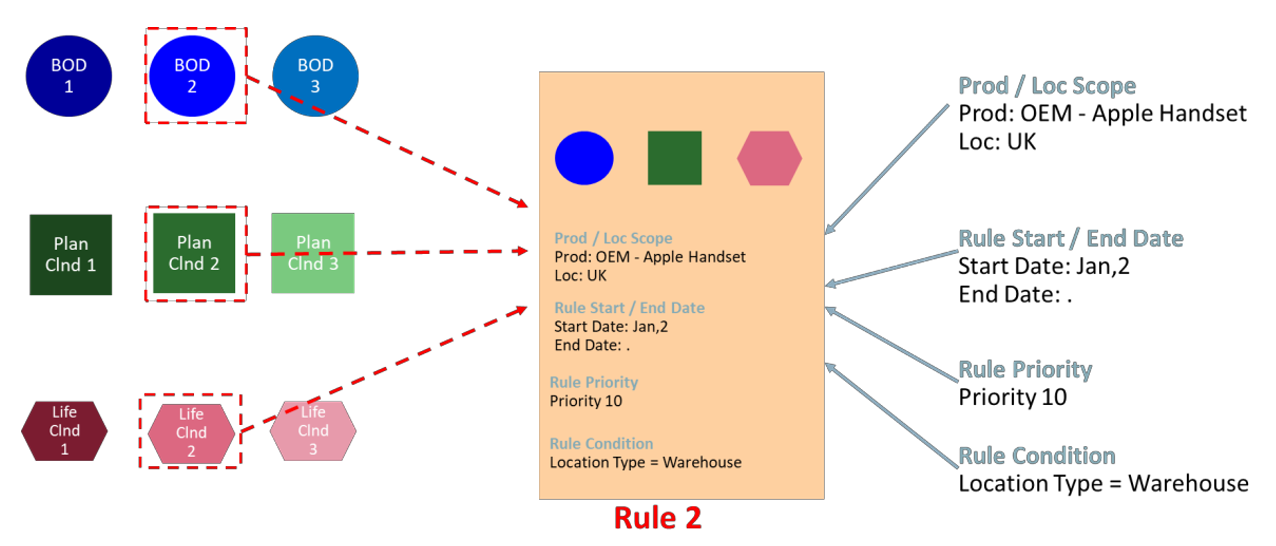

-

Rule 2

This rule should be configured to apply the Bill of distribution BOD2, the planning calendar PLC2 and the lifecycle calendar Clnd2.

-

The scope of the rule is the scope of the rule group where it is being configured (for example, Apple Handset products and the country UK).

-

The condition where the rule applies is for all items in the scope and for all locations where the type is STORE.

-

Note:

The condition is used by the IPOCS-Lifecycle Allocation and Replenishment Rule Engine to apply the set up to the product and location combinations that match the condition within the rule scope. The rule scope is defined by the Product Groups and Location Groups associated with the rule’s rule group.

Figure 18-24 Illustration for Rule 1

Figure 18-25 Illustration for Rule 2

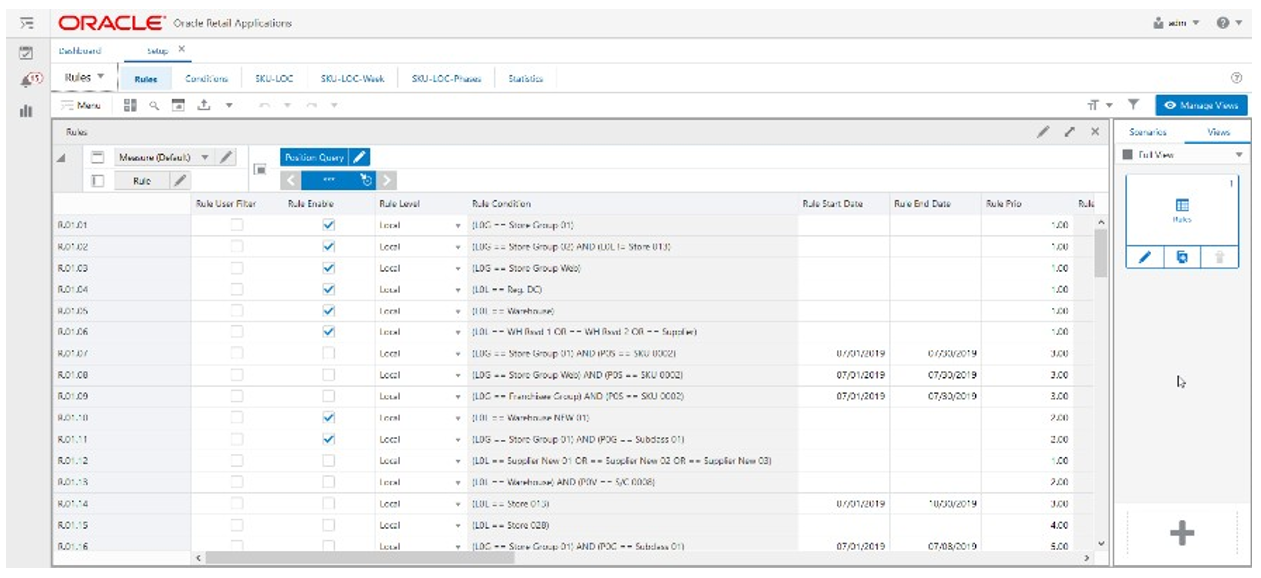

Rules View

The Rules View, under the Rules tab, allows you to configure the rules by enabling them and defining the rule start date, end date and priority for each one. Once configured you can set up the rule by selecting the bill of distribution, the planning calendar, and the lifecycle calendar that the rule uses. The product and locations that apply the rule set up are based on the scope of the rule’s rule group (Product Scope and Location Scope views) and the rule’s condition that is set up and managed in the Conditions view.

Figure 18-26 Rules View

Rules View - Measure Profiles

The Rules View contains the following profiles to change the measures that are visible in the view:

-

Default

This profile is used as default by the view. All the available or visible measures are listed and described in the section Measure: Default Profile.

-

BOD

This profile displays a subset of measures from the default profile. It focuses on the rule and on the BOD measures only. The Planning Calendar and Lifecycle calendar-related measures are left out of the visible measures.

-

Calendars

This profile displays a subset of measures from the default profile. It focuses on the rule and in the Planning Calendar measures only. BOD and Lifecycle calendar-related measures are left out of the visible measures.

-

Lifecycle

This profile displays a subset of measures from the default profile. It focuses on the rule and on the lifecycle calendar only. The BOD and Planning calendar-related measures are left out of the visible measures.

Rules View - Default Profile Measures

The Rules View contains the following measures.

Rule User Filter

The Rule User Filter is an editable measure to select the rule to filter the views by the selected rule. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Setup Rules workspace.

Rule Enable

The Rule Enable is an editable measure to enable or disable a rule. Each row (or list) represents a different rule.

Rule Condition

The Rule Condition is a calculated measure used to indicate the condition for which the rule is valid. The condition is the result of the set up completed in the Conditions view.

Rule Start Date

The Rule Start Date is an editable measure for you define a start date for the rule (when the rule should become active). When the rule is valid and the start date is empty, then IPOCS-Lifecycle Allocation and Replenishment applies it. When the rule is valid, and the start date is populated, IPOCS-Lifecycle Allocation and Replenishment starts to apply it only when the start date is reached.

Rule End Date

The Rule End Date is an editable measure for you define an end date for the rule (when the rule should become inactive). When empty IPOCS-Lifecycle Allocation and Replenishment assumes that the rule has no end date and if it is valid then IPOCS-Lifecycle Allocation and Replenishment applies it. When the rule is valid, and the end date is populated, IPOCS-Lifecycle Allocation and Replenishment stops applying it starting from the defined date.

Rule Priority

The Rule Priority is an editable measure for you define the rule’s priority. The higher that the number is, then the higher the priority of the rule. This rule priority is important to IPOCS-Lifecycle Allocation and Replenishment as it is used when rules overlap each other. IPOCS-Lifecycle Allocation and Replenishment uses the rule priority to select which one to apply.

Rule Valid

The Rule Valid is a calculated measure used to indicate if the set up of the rule is valid or not. For example, if the BOD, Planning Calendar, and Lifecycle Calendar are missing then the rule is not valid for IPOCS-Lifecycle Allocation and Replenishment. IPOCS-Lifecycle Allocation and Replenishment needs at least one of them to be assigned for the rule to be considered valid.

PL Ass. Count

The Product and Location Associated Count is a calculated measure to display the total number of product and location combinations that are associated with the rule based on the rule’s condition.

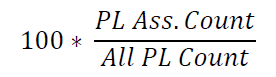

PL Ass. %

The Product and Location Associated Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule is applicable, represent the total of product and location combinations within the rule group scope. The value of this measure is the result of the formula:

Figure 18-27 Calculation

Rule BOD

The Rule Bill of Distributions is an editable measure to select the bill of distribution to be applied by the rule. This measure is a picklist populated with all valid BODs that were set up in the Bill of Distributions view.

PL BOD App. Count

The Product and Location Bill of Distributions Applied Count is a calculated measure to display the total number of product and location combinations that apply this rule’s BOD. The calculations take into account all the valid rules where the product and location combinations fall into and based on the priority calculates the count of product and location that applies the selected BOD.

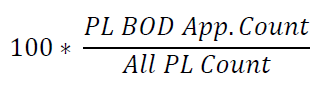

PL BOD App. %

The Product and Location Bill of Distributions Applied Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule’s BOD is applicable, represent the total of product and location combinations within the rule group scope. The value of this measure is the result of the formula:

Figure 18-28 Calculation

Rule Plc.

The Rule Planning Calendar is an editable measure to select the planning calendar to be applied by the rule. This measure is a picklist populated with all valid planning calendars that were set up in the Planning Calendars view.

PL Plc. App. Count

The PL Planning Calendar Applied Count is a calculated measure to display the total number of product and location combinations that apply this rule’s planning calendar. The calculations take into account all the valid rules where the product and location combinations fall into and based on the priority calculates the count of product and location that apply to the selected planning calendar.

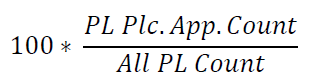

PL Plc. App. %

The PL Planning Calendar Applied Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule’s planning calendar is applicable, represent the total of product and location combinations within the rule group scope. The value of this measure is the result of the formula:

Figure 18-29 Calculation

Rule Lfc.

The Rule Lifecycle Calendar is an editable measure to select the lifecycle calendar to be applied by the rule. This measure is a picklist populated with all valid lifecycle calendars that were set up in the Lifecycle Calendars view.

PL Lfc. App. Count

The Product and Location Lifecycle Calendar Applied Count is a calculated measure to display the total number of product and location combinations that apply this rule’s lifecycle calendar. The calculations take into account all the valid rules where the product and location combinations fall into and based on the priority calculates the count of product and location that apply to the selected lifecycle calendar.

PL Lfc. App. %

The Product and Location Lifecycle Calendar Applied Percentage is a calculated measure used to indicate, in percentage, how many of the product and location combinations, where the rule’s lifecycle calendar is applicable, represent the total of product and location combinations within the rule group scope. The value of this measure is the result of the formula:

Figure 18-30 Calculation

Copy and Paste

The Copy and Paste is an editable measure to select whether the rule is the source or destination for the copy and paste rules functionality (Copy-Paste Rules action button). Valid values are:

-

Copy

Option to select in the rule to be used as the source of the copy.

-

Paste

Option to select in the rule to be used as the destination of the copy.

-

-

Option selected to clear the measure.

Note:

Only one rule should be selected as a source ( Copy) but multiple rules can be selected as a destination (Paste).

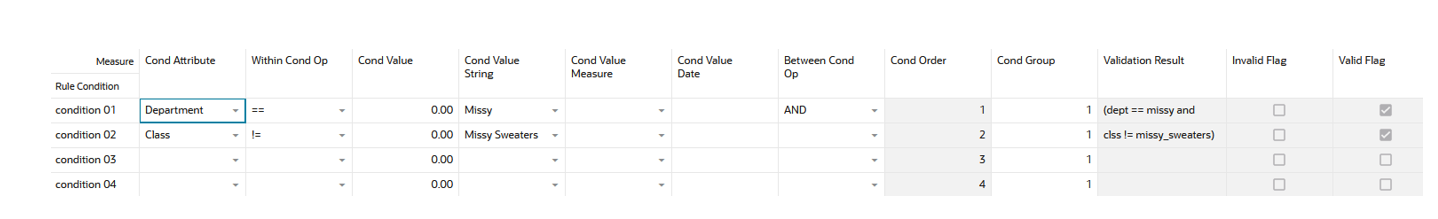

Conditions View

This view allows you to define the conditions for the rules based in product, location, and product-location attributes. A rule condition is what allows the engine to find the product and location combinations where the rule is applicable.

Figure 18-31 Conditions View

Conditions View - Default Profile Measures

The Conditions view contains the following measures.

Condition Attribute

The Condition Attribute measure allows you to select the attribute for the condition, The attributes for the rules are assigned in the Attribute Review workspace.

Within Cond Op

The Within Cond Op measure allows you to specify the operator to be used inside the condition.

Table 18-2 Within Cond Op Measure Available Operators

| Available Operators | Description | Example |

|---|---|---|

|

= = |

Checks if the attribute value is equal with the Condition Value |

brand == Private Label |

|

!= |

Checks if the attribute value is different from the Condition Value |

Average sales !=0 |

|

> |

Checks if the attribute value is larger than the Condition Value |

Average sales >5 |

|

< |

Checks if the attribute value is less than the Condition Value |

Standard deviation of sales <6 |

|

>= |

Checks if the attribute value is larger or equal than the Condition Value |

|

|

<= |

Checks if the attribute value is less or equal than the Condition Value |

|

|

contain |

||

|

Not contain |

||

|

Match |

||

|

Not match |

Cond Value

The Cond Value measure is used when the type of the attribute is numeric. Example: average sales > 10

Cond Value String

The Cond Value String measure is used when the type of the attribute is a string. Example: brand == Private Label

Cond Value Measure

The value of the Cond Value measure is a measure name, which is populated by an expression that let’s you refine the condition value. For instance private label versus non-private label.

This measure is used when you want to refine the condition value.

For instance, for the coffee items, except Private Label, you want to assign items to the rule that sell more than 50 per week. For Private Label items you may want the value to be 100. You need to populate your Condition measure with a value of 100 for all Private Label items, and the rest of the coffee items with 50.

Cond Value Date

The Cond Value Date measure is used when the type of the attribute is a date. Example: today >= 02/30/2024"

Between Cond Op

Within a rule there can be multiple conditions and also multiple condition groups. This is specified in the Cond Group measure. Conditions with the same Cond Group value belong to the same group.

For example, if a rule has 4 conditions, Conditions 1 and 2 can belong to condition group 1, and conditions 3 and 4 can belong to the condition group 2. Also, the Cond Order measure gives the ranking of the conditions inside the group.

The following table is an assumed use case:

Table 18-3 Between Cond Op Assumed Use Case

| Condition | Between Con Op | Cond Order | Cond Group |

|---|---|---|---|

|

Condition 1 |

AND |

1 |

1 |

|

Condition 2 |

OR |

2 |

1 |

|

Condition 3 |

OR |

3 |

2 |

|

Condition 4 |

4 |

2 |

The value for the Between Cond Op can be the logical operators AND or OR.

The conditions are evaluated first inside a condition group and then between groups. In the previous case, the resulting condition is:

(Condition 1 AND Condition 2) OR (Condition 3 OR Condition 4)

Here is an example where all conditions belong to the same condition group:

Table 18-4 Example: All Conditions Belong to the Same Condition Group

| Condition | Between Con Op | Cond Order | Cond Group |

|---|---|---|---|

|

Condition 1 |

AND |

1 |

1 |

|

Condition 2 |

OR |

2 |

1 |

|

Condition 3 |

OR |

3 |

1 |

|

Condition 4 |

4 |

1 |

The resulting condition for the rule is given by:

Condition 1 AND Condition 2 OR Condition 3 OR Condition 4

Note that the conditions are evaluated in the order given by the values in the Cond Order measure.

Cond Order

The Cond Order measure displays the order in which conditions are evaluated, wither independently or inside a condition group.

Cond Group

The Cond Group measure allows you to group conditions. This is useful when you want to evaluate conditions in a two-step process. First, the conditions are evaluated inside groups. In the second step, the group results are evaluated .

Validation Result

The Validation Result measure displays the condition expressions that are validated.

Invalid Flag

The Invalid Flag measure indicates if a condition is invalid.

Valid Flag

The Valid Flag measure indicates if a condition is valid.

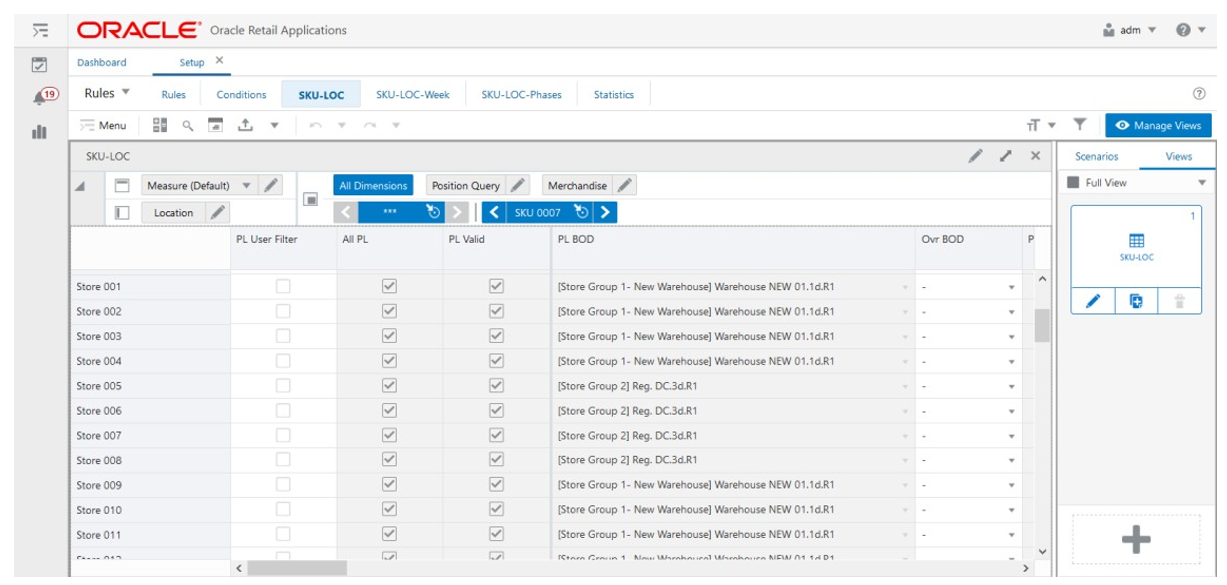

SKU-LOC View

The SKU-LOC View, under the SKU-LOC tab, allows you to review the results of the IPOCS-Lifecycle Allocation and Replenishment Rule Engine calculation based on the rules set up in the workspace. In this view, you have to review to the results at the lowest level, item, and location levels, and you can also create exceptions, at the item-location level, to overwrite the replenishment set up calculated by the IPOCS-Lifecycle Allocation and Replenishment Rule Engine (for example, a particular item and location that should apply a different planning calendar from all the other item locations in the same rule).

Figure 18-32 SKU-LOC View

SKU-LOC View - Measure Profiles

The SKU-LOC View contains the following profiles to change the measures that are visible in the view:

-

Default

This profile is used as default by the view. All the available or visible measures are listed and described in SKU-LOC View - Default Profile Measures.

-

BOD

This profile displays a subset of measures from the default profile. It focuses on the rule and in the BOD measures only. Planning Calendar and Lifecycle calendar-related measures are left out of the visible measures.

-

Planning

This profile displays a subset of measures from the default profile to focus on the Planning Calendar measures. BOD and Lifecycle calendar-related measures are left out of the visible measures.

-

Lifecycle

This profile displays a subset of measures from the default profile. It focuses on the rule and in the lifecycle calendar only. BOD and Planning calendar-related measures are left out of the visible measures.

SKU-LOC View - Default Profile Measures

The SKU-LOC View contains the following measures.

PL User Filter

The Product and Location User Filter is an editable measure to select the product and location combinations to filter the views by the selected product and location combinations. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Setup Rules workspace.

All PL

The All Product and Location is a calculated measure used to indicate if a product and location combination is valid or not. A selected measure indicates the combination is valid, meaning it has a lifecycle phase value. A clear measure indicates that it is not valid.

PL Valid

The Product and Location Valid is a calculated measure used to indicate if a product and location combination has a valid rule from where the IPOCS-Lifecycle Allocation and Replenishment Rule Engine calculates the replenishment set up. The measure is selected when the item and location combinations have at least one valid rule that applies. A clear measure indicates that it does not have at least one valid rule that applies.

PL BOD

The Product and Location Bill of Distribution is a calculated measure used to indicate that the bill of distribution is applied to the product and location combination. The bill of distribution displayed is the one calculated by the IPOCS-Lifecycle Allocation and Replenishment Rule Engine using the rules set up.

Ovr BOD

The Override Bill of Distributions is an editable measure that allows you to create exceptions at the item-location level. You can select the bill of distribution to override the assigned bill of distribution (measure PL BOD). This measure is a picklist populated with all valid BODs that were set up in the Bill of Distributions view.

PL BOD Prio

The Product and Location Bill of Distributions Priority is a calculated measure used to indicate the priority of the rule from where the bill of distribution was calculated for the product and location combination.

PL BOD End Date

The Product and Location Bill of Distributions End Date is a calculated measure used to indicate the end date of the rule from where the bill of distribution was calculated for the product and location combination.

PL BOD Rule Count

Product and Location Bill of Distributions Rule Count is a calculated measure used to indicate the total number of BOD that are assigned to the product and location combination based on the set up rules. Note that a product and location combination can only have one BOD active. The active one is the one from the rule with the highest priority or has an exception override.

PL Plc.

The Product and Location Planning Calendar is a calculated measure used to indicate the planning calendar applied to the product and location combination. The planning calendar displayed is the one calculated by the IPOCS-Lifecycle Allocation and Replenishment Rule Engine using the rules set up.

Ovr Plc.

The Override Planning Calendar is an editable measure that allows you to create exceptions at the item-location level. You can select the planning calendar to override the assigned planning calendar (measure PL Plc.). This measure is a picklist populated with all valid planning calendars that were set up in the Planning Calendars view.

PL Plc. Prio

The Product and Location Planning Calendar Priority is a calculated measure used to indicate the priority of the rule from where the planning calendar was calculated for the product and location combination.

PL Plc. End Date

Product and Location Planning Calendar End Date is a calculated measure used to indicate the end date of the rule from where the planning calendar was calculated for the product and location combination.

PL Plc. Rule Count

The Product and Location Planning Calendar Rule Count is a calculated measure used to indicate the total number of PLC that are assigned to the product and location combination based on the set up rules. Note that a product and location combination can only have one PLC active. The active one is the one from the rule with the highest priority or has an exception override.

PL Lfc.

The Product and Location Lifecycle Calendar is a calculated measure used to indicate the lifecycle calendar applied to the product and location combination. The lifecycle calendar displayed is the one calculated by the IPOCS-Lifecycle Allocation and Replenishment Rule Engine using the rules set up.

Ovr Lfc.

The Override Lifecycle Calendar. is an editable measure that allows you to create exceptions at the item-location level. You can select the lifecycle calendar to override the assigned lifecycle calendar (measure PL Lfc.). This measure is a picklist populated with all valid lifecycle calendars that were set up in the Lifecycle Calendars view.

PL Lfc. Prio

The Product and Location Lifecycle Calendar Priority is a calculated measure used to indicate the priority of the rule from where the lifecycle calendar was calculated for the product and location combination.

PL Lfc. End Date

The Product and Location Lifecycle Calendar End Date is a calculated measure used to indicate the end date of the rule from where the lifecycle calendar was calculated for the product and location combination.

PL Lfc. Rule Count

The Product and Location Lifecycle Calendar Rule Count is a calculated measure used to indicate the total number of lifecycle calendars that are assigned to the product and location combination based on the set up rules. Note that a product and location combination can only have one lifecycle calendar active. The active one is the one from the rule with the highest priority or has an exception override.

Primary Source @ Today

The Primary Source at Today is a calculated measure used to indicate the applied primary source for the product and location combination at the system date. The primary source is calculated from the current BOD assigned to the product and location combination.

Lead Time @ Today Dur (d)

The Lead Time at Today Duration (day) is a calculated measure used to indicate the applied lead time, in days, for the product and location combination at the system date. The lead time is calculated from the current BOD assigned to the product and location combination.

Reserved Source 1 @ Today

The Reserved Source 1 at Today is a calculated measure used to indicate the applied reserved source 1 for the product and location combination at the system date. The reserved source 1 is calculated from the current BOD assigned to the product and location combination.

Reserved Source 2 @ Today

The Reserved Source 2 at Today is a calculated measure used to indicate the applied reserved source 2 for the product and location combination at the system date. The reserved source 2 is calculated from the current BOD assigned to the product and location combination.

Alternative Source @ Today

The Alternative Source at Today is a calculated measure used to indicate the applied alternative source for the product and location combination at the system date. The alternative source is calculated from the current BOD assigned to the product and location combination.

LLC @ Today

The Low-level Code at Today is a calculated measure used to indicate the low-level code applied to the product and location combination at the system date. The low-level code is calculated from the current BOD assigned to the product and location combination and the valid values are:

-

0

The location is a store

-

1

The location is a warehouse

-

2

The location is a supplier

-

–1

The location is invalid

Network Loop @ Today

The Network Loop at Today is a calculated measure used to indicate if there are Network Loop errors caused by the BOD set up for the rule group at the system date. When selected, there are Network Loop errors. Otherwise, there are no errors.

Revw @ Today

The Review at Today is a calculated measure used to indicate if today (current system date) is a review day for the product and location combination. The review day is calculated from the current planning calendar assigned to the product and location combination.

Next Revw @ Today Date

The Next Review at Today Date is a calculated measure used to indicate the next review date for the product and location combination. The next review date is calculated from the current planning calendar assigned to the product and location combination.

Next Revw @ Today Dur (d)

The Next Review at Today Duration (day) is a calculated measure used to indicate the number of days to the next review date for the product and location combination. The calculation of the number of days uses the current system date and the Next Revw @ Today Date.

Avg Revw Time @ Today Dur (d)

The Average Review Time at Today Duration (day) is a calculated measure used to indicate the average number of days between each review period (planning period) for the product and location combination. The value is calculated using the review periods from the current planning calendar assigned to the product and location combination.

Asst. Prod-Loc

The Assorted Product and Location is a loaded measure used to indicate whether the product and location combinations are assorted or not.

Asst. Prod-Loc Start Date

The Assorted Product and Location Start Date is a loaded measure used to indicate the assortment start date for the assorted product and location combinations.

Asst. Prod-Loc End Date

The Assorted Product and Location End Date is a loaded measure used to indicate the assortment end date for the assorted product and location combinations.

Asst. Prod-Loc Active

Assorted Product and Location Active is a loaded measure used to indicate whether the product and location combinations are assorted and still active or not. If the assortment end date has not been reached yet then it is active. Otherwise, the product and location combination is assorted but not active.

Lfc. Prod-Loc Def.

The Lifecycle Calendar Product and Location Default is a loaded measure to identify whether the product and location combination has a valid lifecycle by default or not.

Lfc. Prod-Loc Exc.

The Lifecycle Calendar Product and Location Exception is a loaded measure used to indicate whether the lifecycle is an exception for the product and location combination. Check the measure Lfc. Prod-Loc Exc. in the Assortment Admin workspace for more detail on the valid values.

Lfc. Prod-Loc Validity Start Date

The Lifecycle Calendar Product and Location Validity Start Date is a loaded measure used to indicate the lifecycle start date exception for the product and location combination when there is an exception.

Lfc. Prod-Loc Validity End Date

The Lifecycle Calendar Product and Location Validity End Date is a loaded measure used to indicate the lifecycle end date exception for the product and location combination when there is an exception.

Lfc. Prod-Loc

The Lifecycle Calendar Product and Location is a loaded measure to identify whether the product and location combination has a valid lifecycle or not.

Lfc. Anchor Exc. Date

The Lifecycle Calendar Anchor Exception Date is a loaded measure to identify the lifecycle anchor date exception for the product and location combination when there is an exception.

Lfc. End Exc. Date

The Lifecycle Calendar End Exception Date is a loaded measure to identify the lifecycle’s exception end date for the product and location combination when there is an exception.

Actual Loc. Sales Units

The Actual Location Sales Units is a loaded measure to display the actual sales for the product and location combination. The value displayed for the product and location combination is the aggregation of all the weeks that are in the scope of the workspace.

Tot. Init. Fcst Units

The Total Initial Forecast Units is a loaded measure to display the total initial forecast for the product and location combination. The value displayed for the product and location combination is the aggregation of all the weeks from the current week up to the forecast horizon.

Lfc. Active @ Today

The Lifecycle Calendar Active at Today is a loaded measure used to indicate whether the product and location combination has a valid lifecycle or not at the system date.

Lfc. Active @ Today

The Lifecycle Calendar Active at Today is a loaded measure used to indicate the lifecycle phase string for the product and location combination when the product and location combination has a valid lifecycle at the system date.

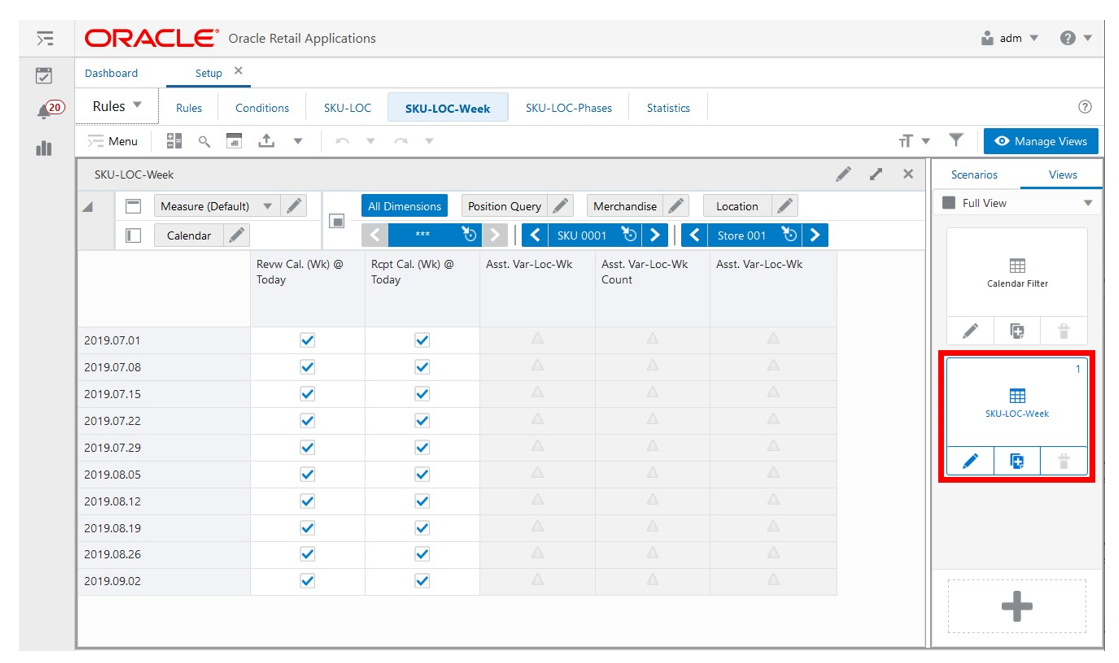

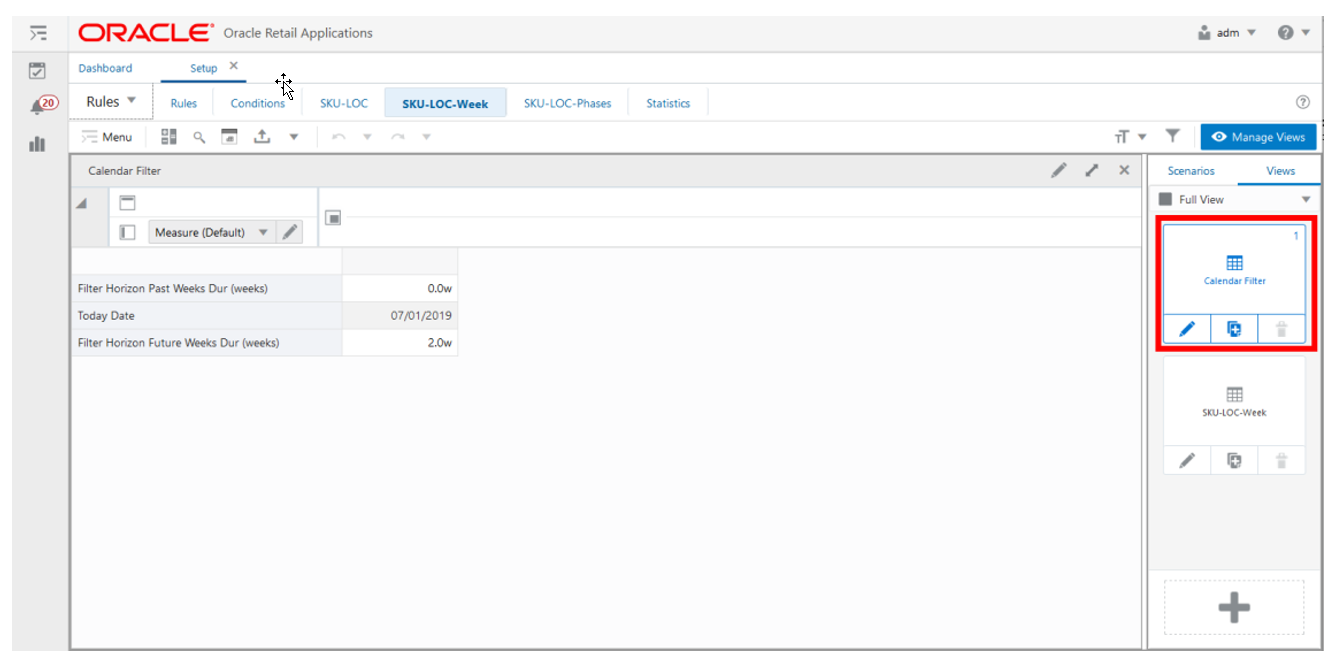

SKU-LOC-Week View

The SKU-LOC-Week View, under the Review tab, allows you to review and overwrite the review weeks and receipt weeks. Any overrides are on top of the review weeks and receipt weeks that the IPOCS-Lifecycle Allocation and Replenishment calculates using the planning calendar set up for the product and location combination.

Figure 18-33 SKU-LOC-Week View

SKU-LOC-Week View - Default Profile Measures

The SKU-LOC-Week View contains the following measures.

Revw Cal. (Wk) @ Today

The Review Calendar (Week) at Today is an editable measure used to indicate whether the week is a review week or not based on the planning calendar set up for the product and location combination at the system date. You can override the calculated value.

Rcpt Cal. (Wk) @ Today

The Receipt Calendar (Week) at Today is an editable measure used to indicate whether the week is a receipt week or not based on the planning calendar set up for the product and location combination at the system date. You can override the calculated value.

Asst. Var-Loc-Wk

The Assorted Variant-Location-Week is a calculated measure used to indicate whether a Var-Location is assorted or not for the given week. (Note if one item under the Variant is assorted then this is indicated as true).

Asst. Var-Loc-Wk Count

The Assorted Variant-Location-Week Count is a calculated measure used to indicate whether a Var-Location is assorted or not for the given week. (Note if one item under the Variant is assorted then this is indicated as true).

Asst. Var-Loc-Wk

The Assorted Variant-Location-Week is an image measure that aligns with the Asst. Var-Loc-Wk Count.

Note:

The location group measures display if the Location Group level (or higher) is available in the view. Otherwise, the measures display the following warning sign to inform you that the measure is not available at that level.

Figure 18-34 Warning Icon

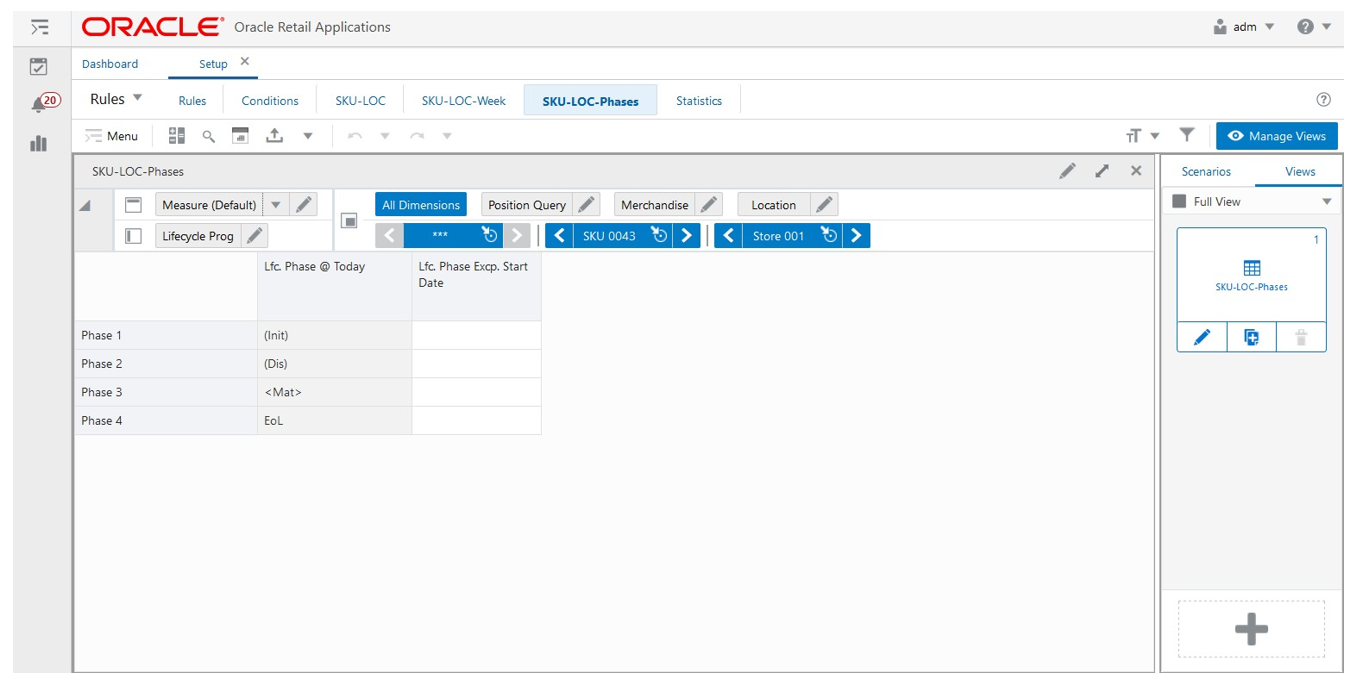

SKU-LOC-Phases View

The SKU-LOC-Phases View, under the Review tab, allows you to review the lifecycle phases for the product and location combinations. In addition, you are allowed to overwrite the start date of each lifecycle phase at the product and location combination level.

Figure 18-35 SKU-LOC-Phases View

SKU-LOC-Phases View - Default Profile Measures

The SKU-LOC-Phases View contains the following measures.

Lfc. Phase @ Today

The Lifecycle Calendar Phase at Today is a loaded measure used to indicate the list of lifecycle phases for the product and location combination based on the lifecycle calendar set up at the system date. The phase names are prefixed and suffixed to provide you with additional information, the logic is as follows:

-

< >

When the phase name is prefixed and suffixed this way, it means that the phase is the current lifecycle phase (for example, <Maturity>

-

( )

When the phase name is prefixed and suffixed this way, it means that the phase is an elapsed/previous lifecycle phase (for example, (Discovery)

-

When the phase name has no prefix and suffix, it means the lifecycle phase has not been reached yet (for example, EOL)

Lfc. Phase Excp. Start Date

The Lifecycle Calendar Phase Exception Start Date is an editable measure that allows you to override the phase start date set up in the lifecycle calendar assigned to the product and location combination.

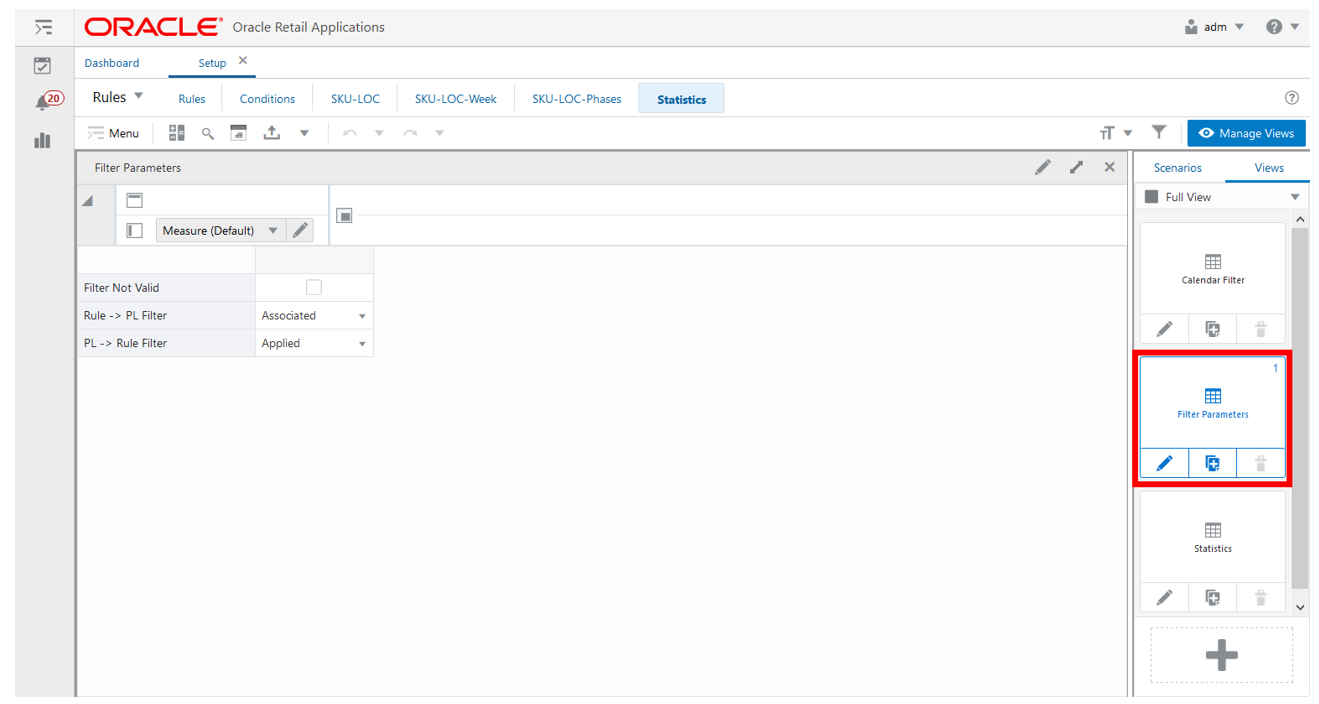

Filter Step

This step contains these views:

Filter Parameters View

The Filter Parameters View, under the Filter tab, allows you to set up the filter that can change the scope of the products and locations displayed in all relevant views under the Rules Step within the Setup Rules Workspace.

Figure 18-36 Filter Parameters View

Filter Parameters View - Default Profile Measures

The Filter Parameters View contains the following measures.

Filter Not Valid

The Filter Not Valid is an editable measure to change the scope of the products and locations displayed in all relevant views under the Rules Step. If the measure is selected the Run Filter action button is responsible to calculate the filters only displayed as non-valid product and location combinations. When clear the filter only displays valid product and location combinations. By default, the measure is clear. The measure PL Valid identifies whether a product and location combination is valid or not.

Rule -> PL Filter

Rule -> Product and Location Filter is an editable measure to select how the filter should work in the SKU- LOC view. Valid values are:

-

Associated

The view is filtered to display the product and location combinations that are associated with the rules selected in the Rules view (measure Rule User Filter). Note that product and location combinations can fit within more than one rule. When they fit into a rule, they are associated regardless of whether that rule is the actual one to be applied.

-

Applied

The view is filtered to display the product and location combinations that apply the rules selected in the Rules view (measure Rule User Filter). The rule is considered applied when the IPOCS-Lifecycle Allocation and Replenishment Rule Engine sets the replenishment set up for the product and location combination based on the rule (for example, BOD, PLC, and so on.).

PL -> Rule Filter

The Product and Location -> Rule Filter is an editable measure to select how the filter should work in the Rules view. Valid values are:

-

Associated

The view is filtered to display rules that are associated with the product and location combinations selected in the SKU-LOC view (measure PL User Filter). Note that product and location combinations can fit into more than one rule. When they fit in a rule they are associated regardless of whether that rule is the actual one to be applied.

-

Applied

The view is filtered to display rules that are associated with the product and location combinations selected in the SKU-LOC view (measure PL User Filter). The rule is considered applied when the IPOCS-Lifecycle Allocation and Replenishment Rule Engine sets the replenishment set up for the product and location combination based on the rule (for example, BOD, PLC, and so on.).

Calendar Filter View

The Calendar Filter View, under the SKU-LOC-Week tab and Statistics tab, allows you to choose the number of weeks to filter based on the weeks displayed in the SKU-LOC view- Week. This view is the same as the Calendar Filter view under the Planning Calendar Step. For more details on the measures, check the Calendar Filter view measures in the Planning Calendar Step.

Figure 18-37 Calendar Filter View

Setup Rules Action Buttons

The Setup Rules workspace has the following action buttons available:

-

Copy-Paste Exceptions

Use the Copy-Paste Exceptions action button to copy the planning daily exceptions from the planning calendar selected as the source of the copy and paste into all planning calendars selected as the destination of the copy. This action only copies the daily exceptions. It does not copy any other planning calendar (for example, weekdays).

-

Copy-Paste LFC

Use the Copy-Paste Lifecycle Calendar action button to copy the lifecycle calendar information from the lifecycle calendar selected as the source of the copy and paste it into all the lifecycle calendars selected as the destination of the copy. This action copies all the information in the lifecycle calendar view and lifecycle phase view.

-

Copy-Paste Rules

Use the Copy-Paste Rules action button to copy all rule information from the rule selected as the source of the copy and paste it into all rules selected as the destination of the copy. This action copies all the information in the Rules view and Conditions view.

-

Rule Conditions

Use the Rule Conditions action button for the calculation of the rule's conditions based on the set up completed in the Conditions view. The result of the calculation is written into the measure Rule Condition in the Rules view.

-

Rule Engine

Use the Rule Engine action button for running the IPOCS-Lifecycle Allocation and Replenishment Rules Engine to calculate which rule’s replenishment set up would be applied to the product and location combination level. The results of the run are visible in the statistic measures of the Rules view as they are updated with the run results. To ensure that the IPOCS-Lifecycle Allocation and Replenishment Rules Engine is run with the right conditions for all the rules, this action button runs the Rule Conditions first, as part of its process.

-

Rule Apply

Use the Rule Apply action button for applying the rule’s replenishment set up, from the last Rule Engine run, down to the product and location combination level. The results of the run are visible in the SKU-LOC view as the measures are updated with the run results.

-

Rule Engine + Apply

Use the Rule Engine + Apply action button to run the Rule Engine action button followed by the run of the Rule Apply action button. As a result, the IPOCS-Lifecycle Allocation and Replenishment Rule Engine is run, and the results are applied down to the product and location combination level immediately.

-

Clear Filter

Use the Clear Filter action button to remove all filters applied in the Setup Rules view and clear all User Filter measures within the workspace.

-

Run Filter

Use the Run Filter action button to apply the filters in the Setup Rules views based on the filter set up completed within the workspace. For example, the calendar horizon or check the filtered measures.

-

Reload Attributes

Use the Reload Attributes action button to load the product, location, and product-location attributes from the domain into the workspace. It refreshes the measures available for all the views under the Attributes Step.

-

Commit Attributes

Use the Commit Attributes action button to save the domain, product, location, and product-location attributes. This functionally ensures that any user changes to the attributes within the workspace are saved and committed to the domain.

Note:

When product, location and product-location attributes are interfaced into IPOCS-Lifecycle Allocation and Replenishment your changes are overridden by the interface values during the batch run.

-

Calc. Visual Assort.

Use the Calculate Visual Assortment action button to display a visual representation of your assortment.

-

Reload Valid Intersections

Use the Reload Valid Intersections action button to load the assortment information from the domain into the workspace. It refreshes all assortment and lifecycle related information. You can use this option when changes are performed in the Assortment Admin workspace and should be refreshed in the Setup Rules workspace.

Figure 18-38 Setup Rules Action Buttons