20 Review and Approve

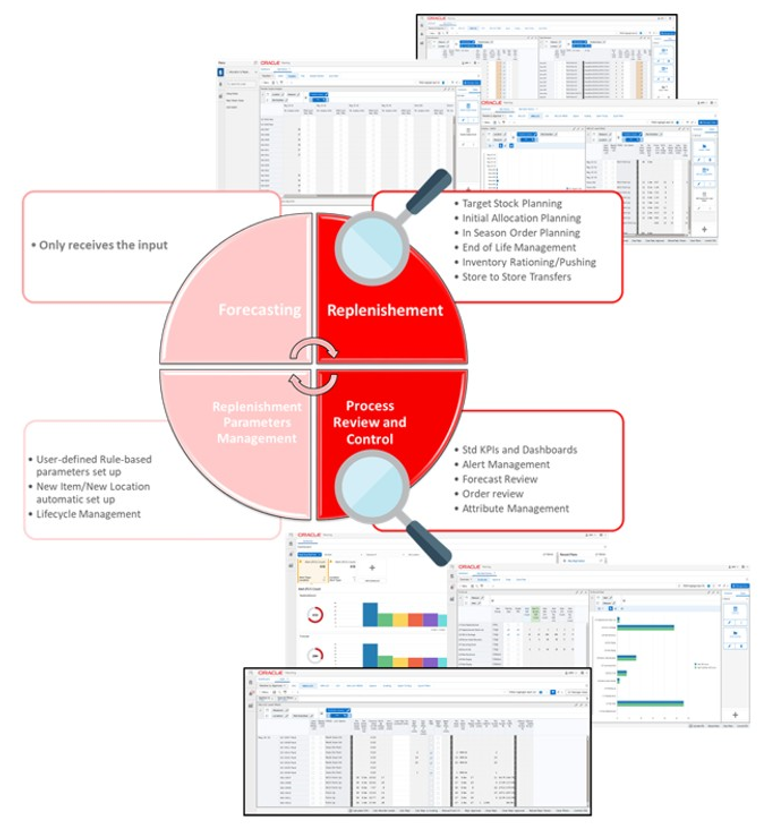

This chapter describes the functionality that allows you to review and approve the latest system-calculated point-in-time orders and time-phased orders. This is the workspace where you analyze the suggested replenishment and allocations and perform the necessary actions. The following are some examples of typical tasks to perform in this workspace.

-

Future store opening or store closing impacts

-

What-if scenarios to simulate changes in the replenishment parameters

-

Review critical alerts and do the necessary amendments

-

Approve orders that are not approved automatically due to critical alerts

Figure 20-1 Review and Approve Task

Review and Approve Workspace, Steps, and Views

The following table lists the workspaces, steps, and views of the Review and Approve task.

Table 20-1 Review and Approve Workspace, Steps, and Views

| Workspace | Step | Tab | Views |

|---|---|---|---|

|

To-Do List |

|||

|

By Prod |

|||

|

By Location |

|||

|

Space |

|||

|

OTB |

|||

|

Inventory Plan |

|||

|

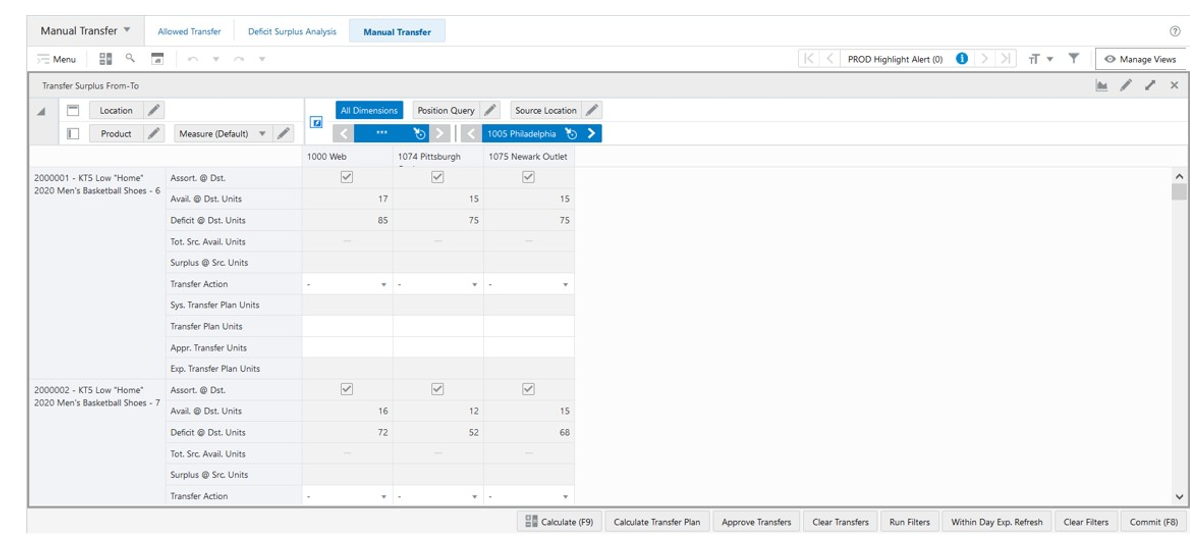

Allowed Transfer |

|||

|

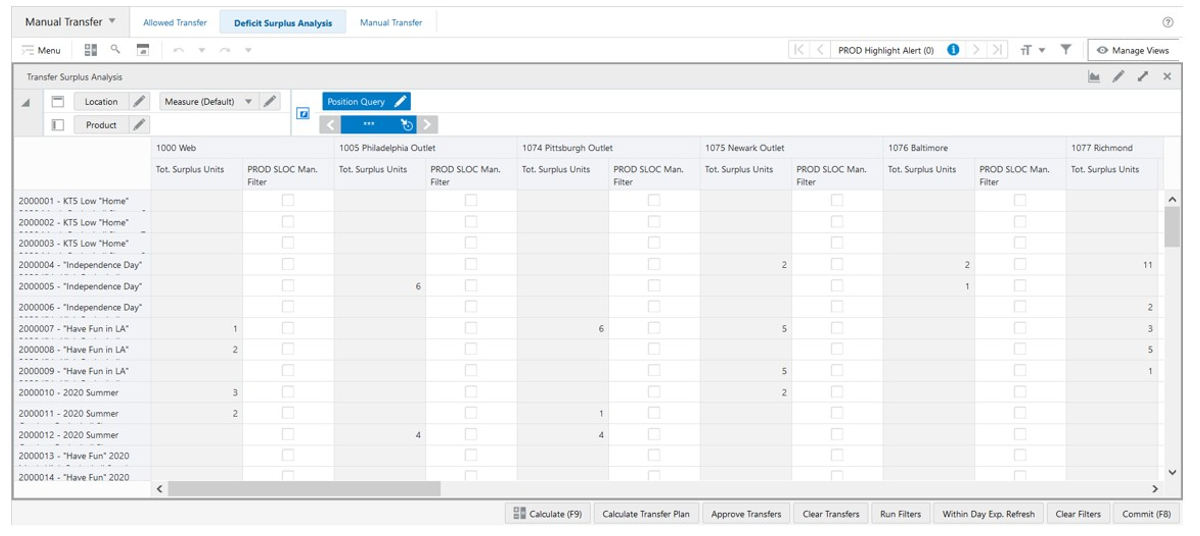

Deficit Surplus Analysis |

|||

|

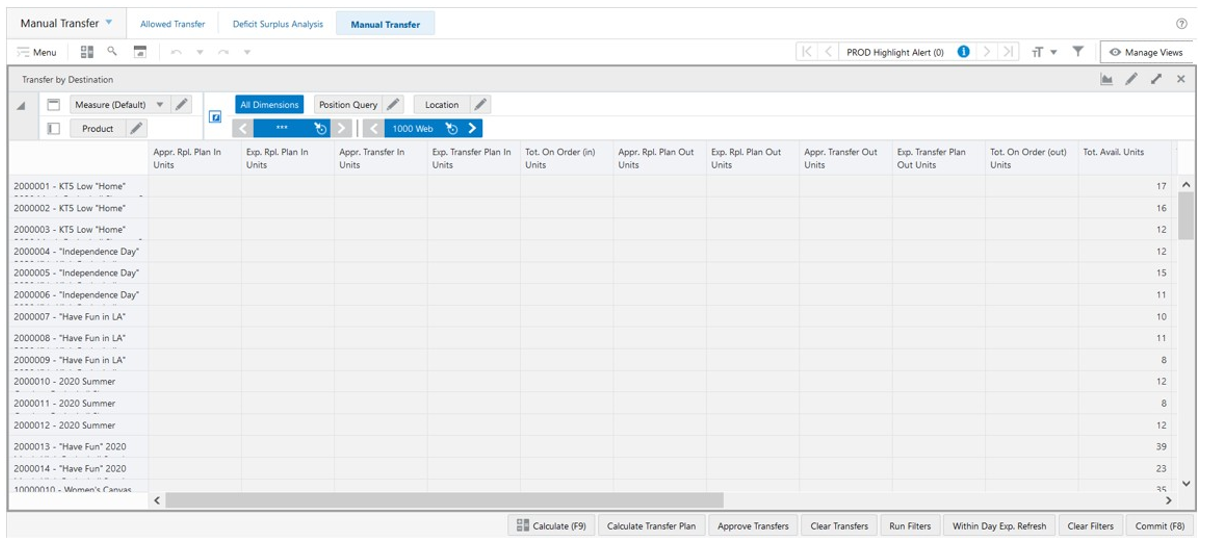

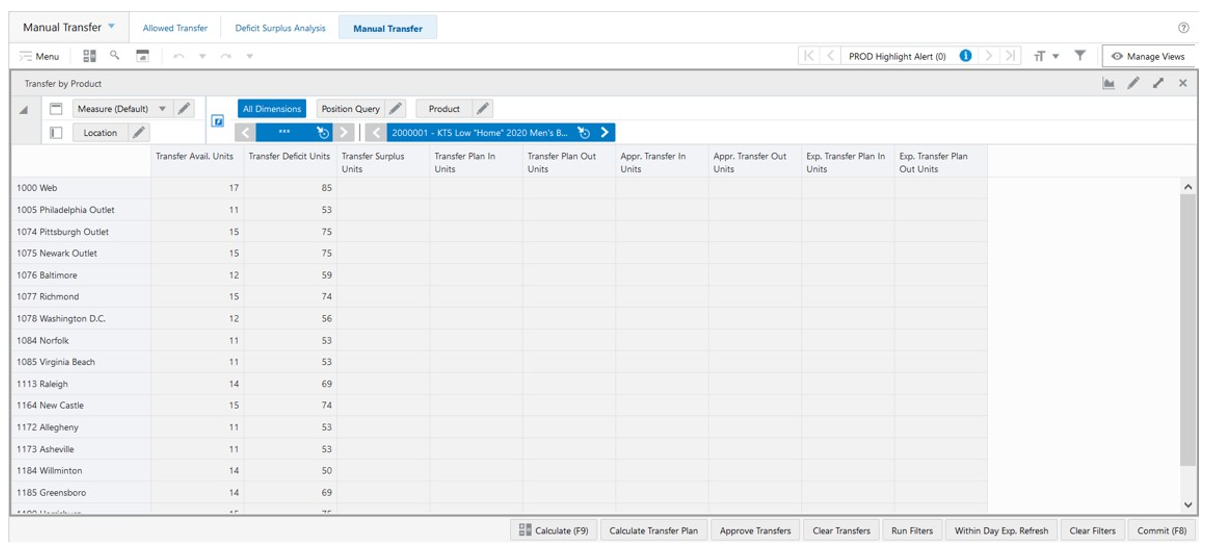

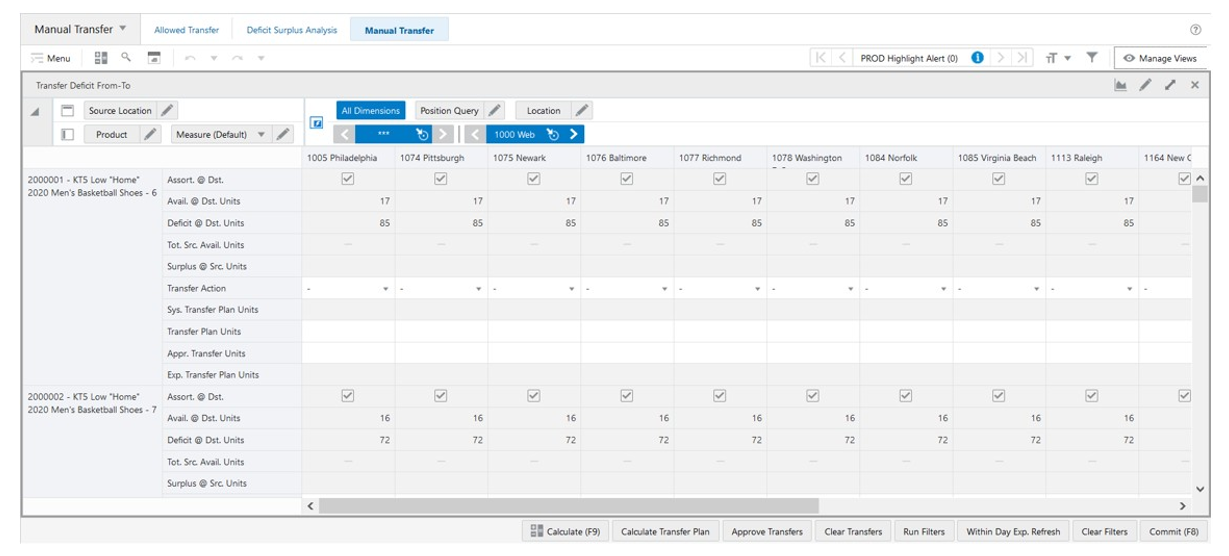

Manual Transfer |

|||

|

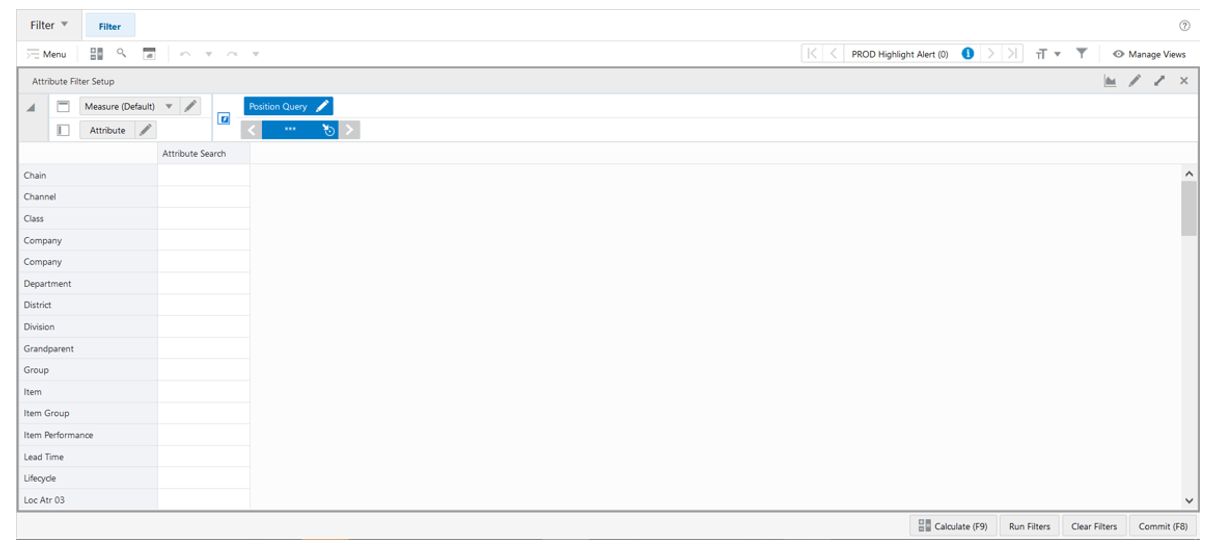

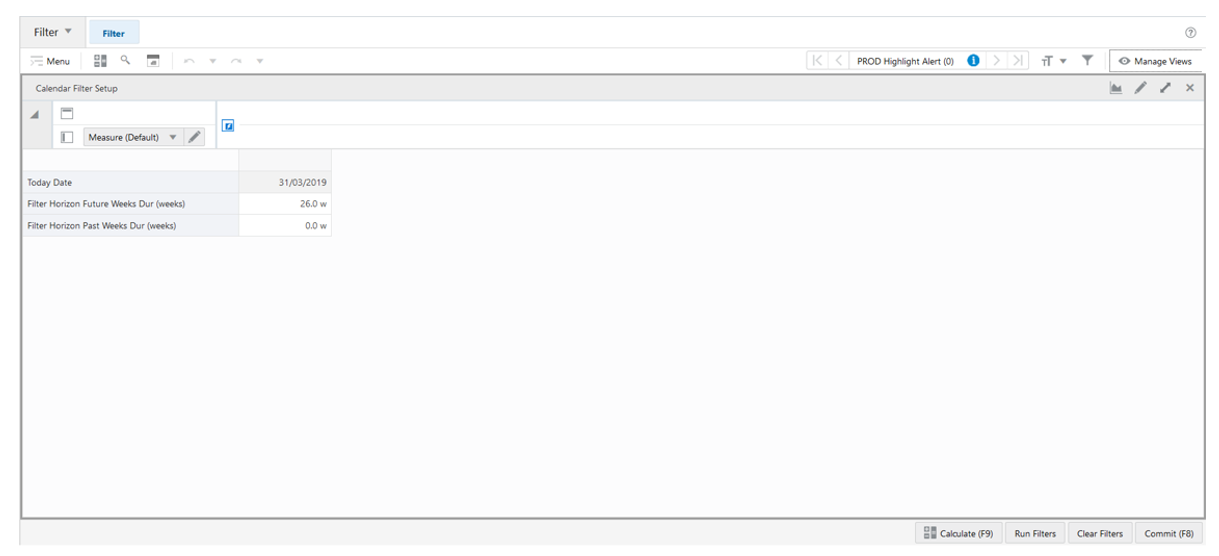

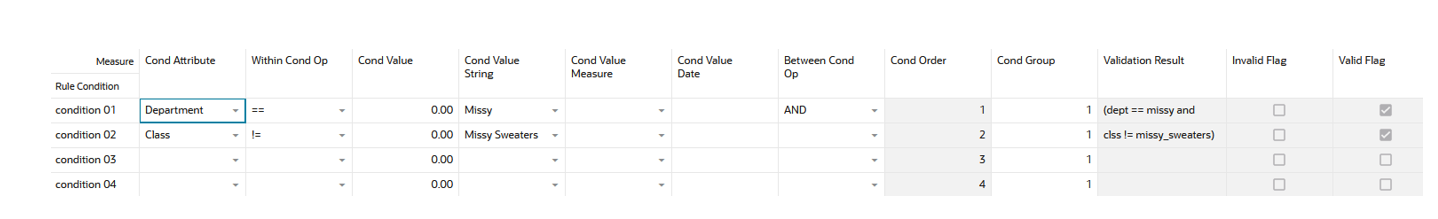

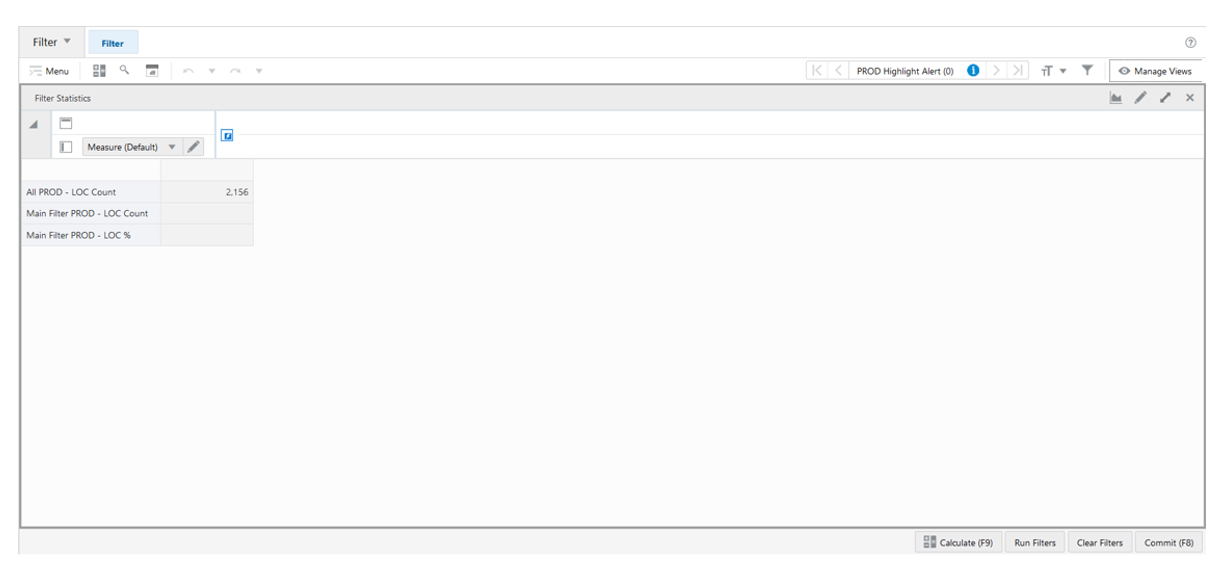

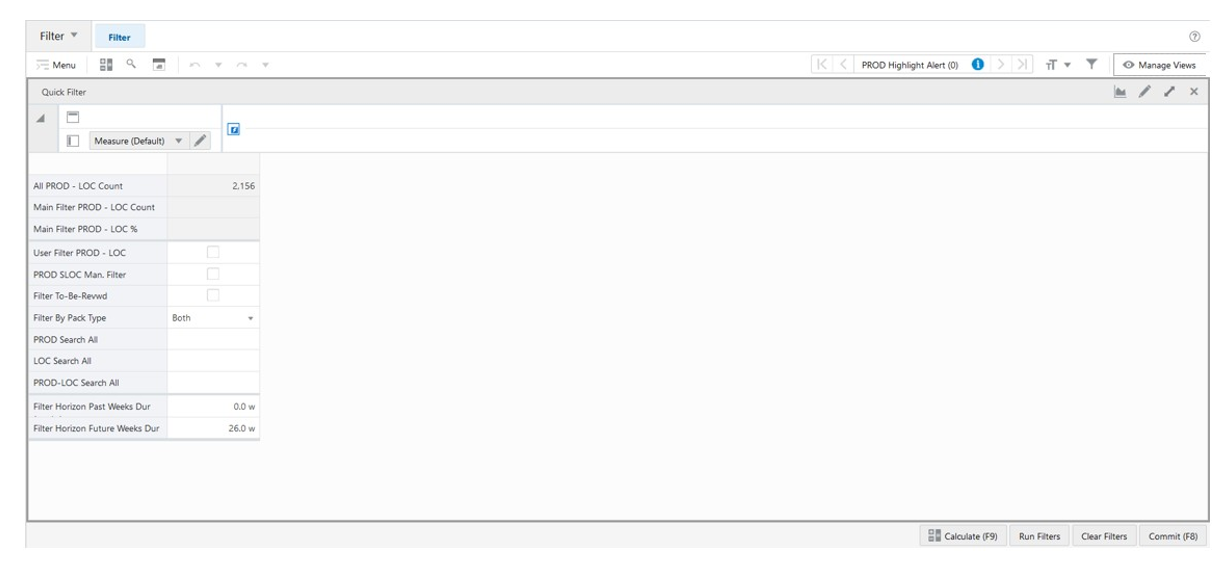

Filter |

|||

Review and Approve Workspace

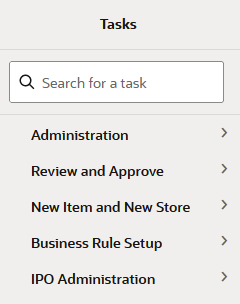

The Review and Approve workspace allows you to access all views listed in the Review and Approve Workspace, Steps, and Views. To build the Review and Approve workspace, perform these steps:

-

From the left sidebar menu, click the Task Module to view the available tasks.

Figure 20-2 Task Module

-

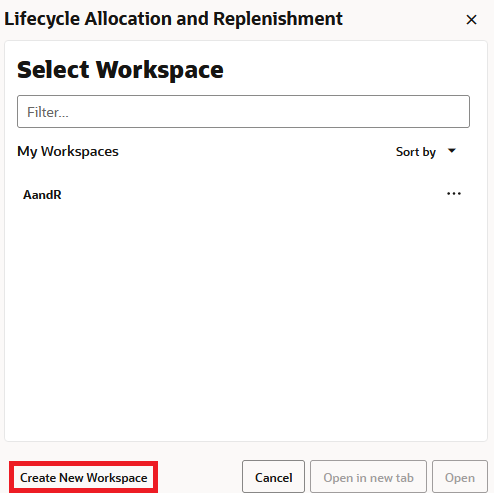

Click the Review and Approve activity to access the available workspaces.

-

Click Lifecycle Allocation and Replenishment. The wizard opens. You can open an existing workspace, but to create a new workspace, click Create New Workspace.

Figure 20-3 Lifecycle Review and Approve Wizard

-

Enter a name for your new workspace in the label text box and click OK.

Figure 20-4 Enter Workspace Label

-

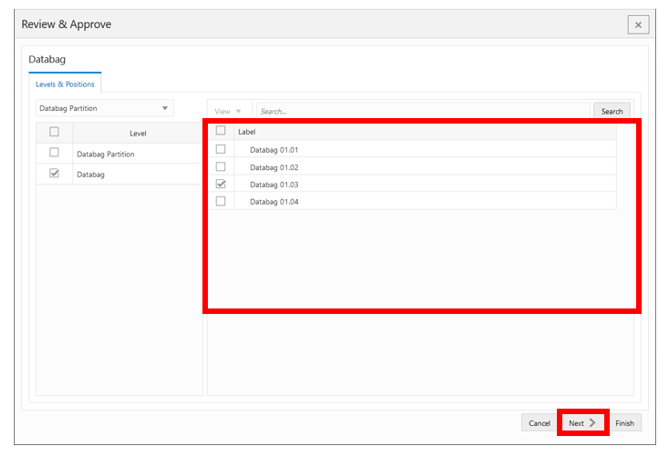

The workspace wizard opens. Select the databag you want to work with and click Next.

Figure 20-5 Workspace Wizard: Databag

-

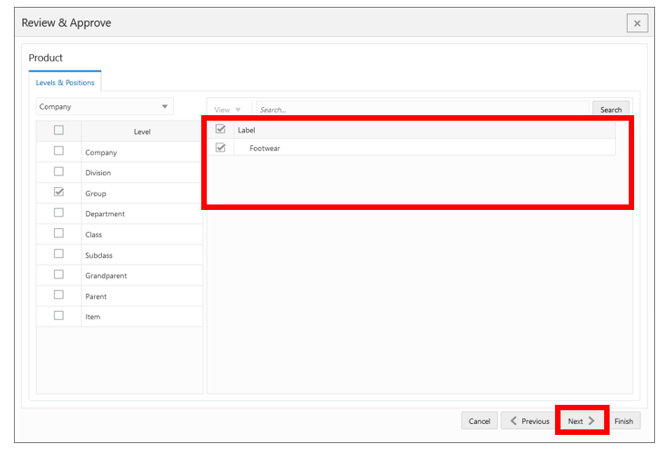

Select the product you want to work with and click Next.

Figure 20-6 Workspace Wizard: Product

-

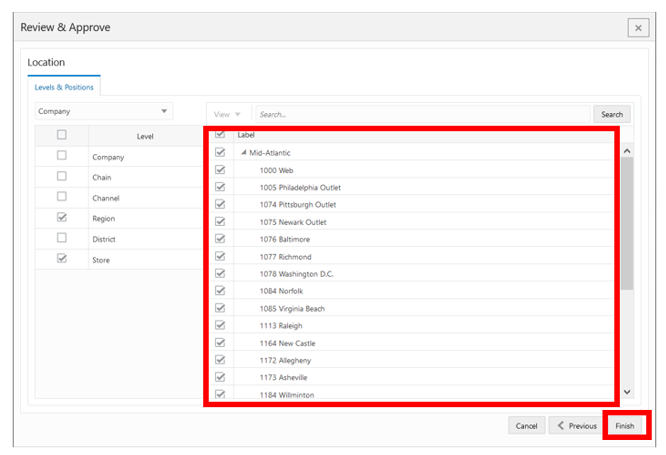

Select the locations you want to work with and click Finish.

Figure 20-7 Workspace Wizard: Locations

-

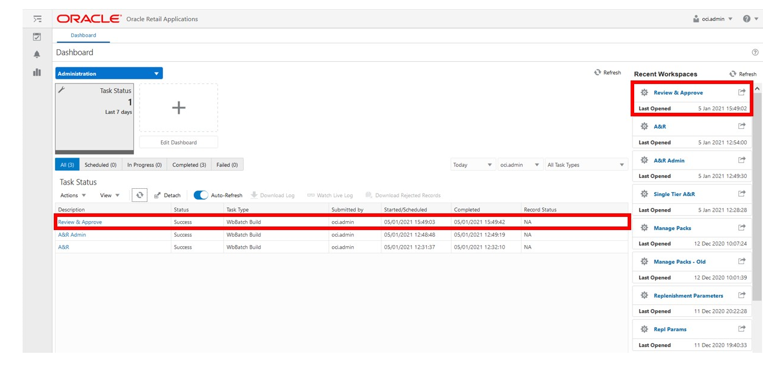

The wizard notifies you that your workspace is being prepared. Successful workspaces are available from the Dashboard.

Figure 20-8 Successful Workspace Build

Note:

The workspace is built using the selected databag scope. The products, locations, source locations, alerts, and attributes available in the workspace are in the databag scope that is managed in the Manage Databag workspace.

Overview Step

This step contains these views:

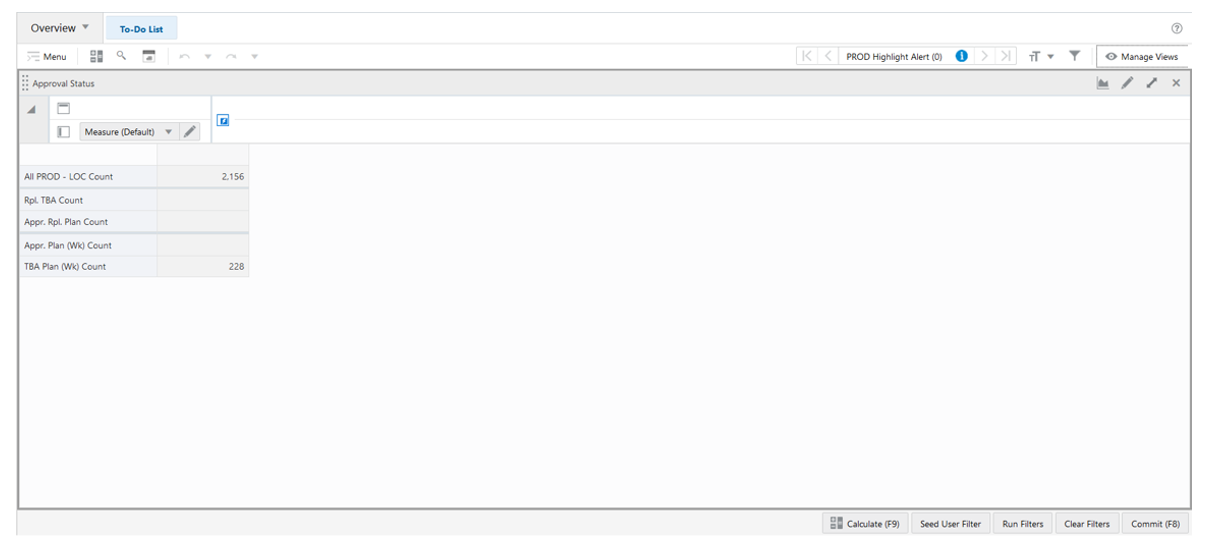

Approval Status View

The Approval Status View, under the To-Do List tab, allows you to review approval statistics like the number of product and location combinations that were automatically approved and the ones that still require your approval.

Figure 20-9 Approval Status View

Approval Status View - Default Profile Measures

The Approval Status view contains the following measures.

Rpl TBA Count

The Rpl TBA Count is a calculated measure used to indicate the total number of assorted product and location combinations that need the orders to be approved manually.

Appr. Rpl. Plan Count

The Approved Rpl. Plan Count is a calculated measure used to indicate the total number of assorted product and location combinations with approved orders.

Appr. Plan (Wk) Count

The Approved Plan (Week) Count is a calculated measure used to indicate the total number of assorted product and location combinations with approved orders for the current week.

TBA Plan (Wk) Count

The TBA Plan (Week) Count is a calculated measure used to indicate the total number of assorted product and location combinations that need the orders to be approved manually for the current week.

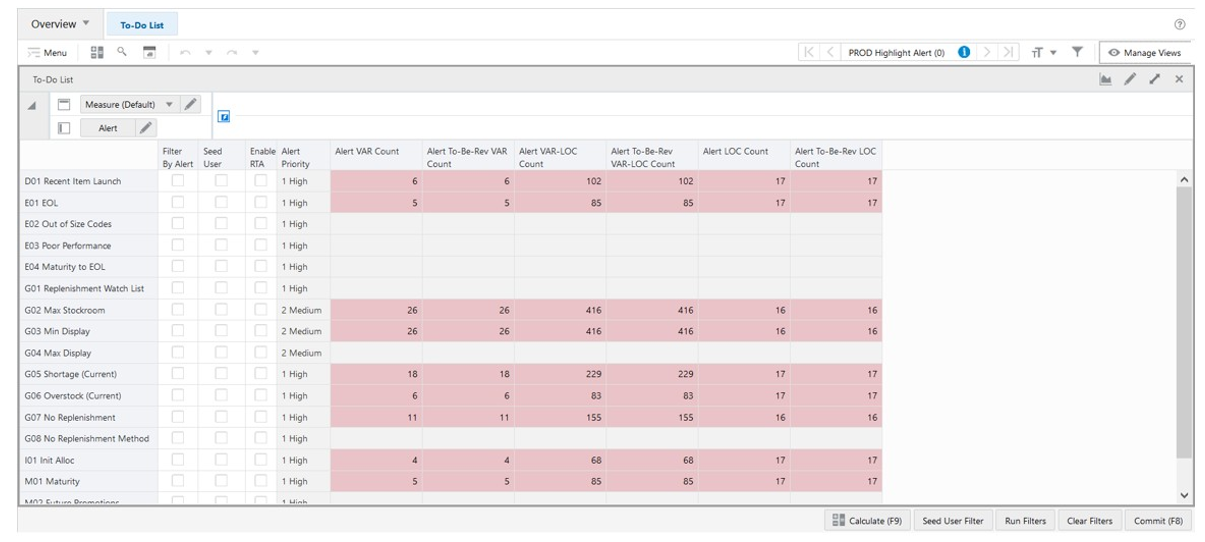

To-Do List View

The To-Do List View, under the To-Do List tab, allows you to review the number of alert hits that have been triggered as well as their types (all alerts available in IPOCS-Lifecycle Allocation and Replenishment). Within this view, you can also select the alerts to focus the review and leverage IPOCS-Lifecycle Allocation and Replenishment filter capabilities. If alerts are used as a filter, then the views under the Review & Approve steps are filtered based on the alert hits only. The alerts can be added or removed as a filter at any time by you.

Figure 20-10 To-Do List View

To-Do List View - Default Profile Measures

The To-Do List view contains the following measures.

Filter By Alert

The Filter By Alert is an editable measure used to select what alerts should be used to filter the views under the Review & Approve Step. When alerts are selected, IPOCS-Lifecycle Allocation and Replenishment uses the calculated alert hits for the selected alerts to filter the views. The views are filtered as soon as you run the workspace calculation, (either Calculate or F9). In order to disable the alert as a filter you need to clear the alerts and re-run the workspace calculation (either Calculate or F9).

Seed User

The Seed User is an editable measure used to select which alerts should be used to populate the User-filtered Boolean measure. You can use this alert to first seed the User-filtered measure and then either add additional positions or reduce the positions by simply selecting or clearing the item/location combination. This is used for the filtering functionality.

Enable RTA

The Enable Real-Time Alerts is an editable measure used to select alerts that should be used as Real-Time Alerts (RTA) within the workspace. When alerts are selected, IPOCS-Lifecycle Allocation and Replenishment uses the calculated alert hits for the selected alerts to enable the RTA. The RTA hits and navigation capabilities are available as soon as you run the workspace calculation (either Calculate or F9). To disable the alert as RTA you need to clear the alert and re-run the workspace calculation (either Calculate or F9).

Alert Priority

The Alert Priority is a calculated measure used to indicate the alert’s priority.

Alert VAR Count

The Alert Variant Count is a calculated measure used to indicate the total number of variants that have hits for the alert. For example, if 12 different variants were added to the replenishment watch list, regardless of the stores, then this measure indicates the number 12 in the replenishment watch list alert.

Alert To-Be-Rev VAR Count

The Alert To-Be-Reviewed Variant Count is a calculated measure used to indicate the number of variants that have not been reviewed yet, out of the total number of variants that have hits for the alert.

Alert VAR-LOC Count

The Alert Variant-Location Count is a calculated measure used to indicate the total number of variant and location combinations that have hits for the alert. For example, if 12 different variants are added to the replenishment watch list, for only two stores, then this measure indicates the number 24 in the replenishment watch list alert.

Alert To-Be-Rev VAR-LOC Count

The Alert To-Be-Reviewed Variant-Location Count is a calculated measure used to indicate the number of variant and location combinations that have not been reviewed yet, out of the total number of variant and location combinations that have hits for the alert.

Alert LOC Count

The Alert Location Count is a calculated measure used to indicate the total number of locations that have hits for the alert. For example, if 12 different variants were added to the replenishment watch list, for only two stores, then this measure indicates the number 2 in the replenishment watch list alert.

Alert To-Be-Rev LOC Count

The Alert To-Be-Reviewed Location Count is a calculated measure used to indicate the number of locations that have not been reviewed yet, out of the total number of locations that have hits for the alert.

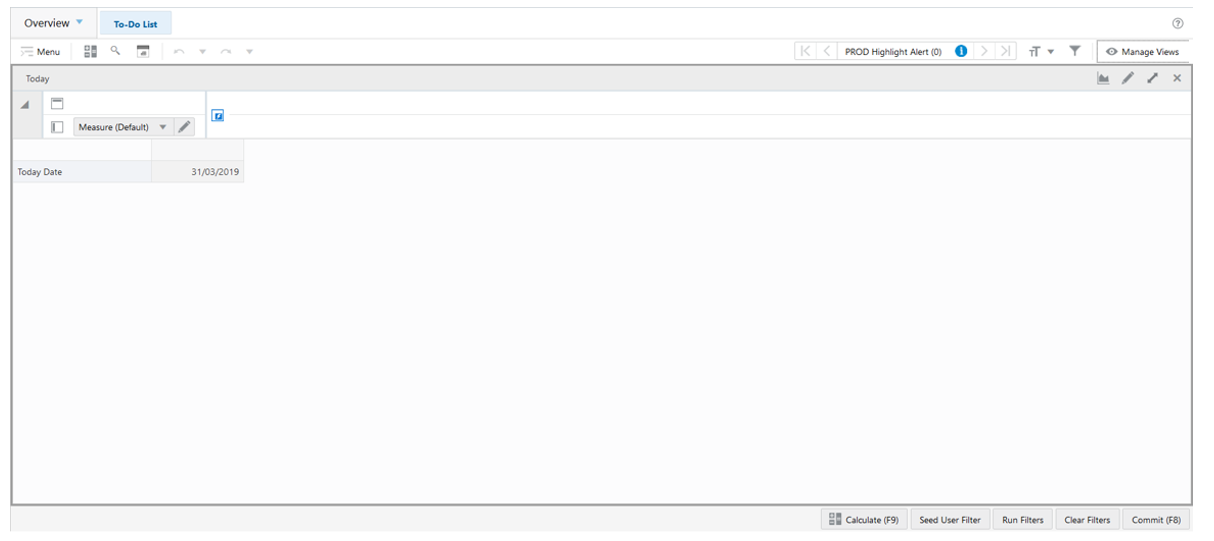

Today View

The Today View, under the Today View List tab, allows you to check IPOCS-Lifecycle Allocation and Replenishment's Today date.

Figure 20-11 Today View

Today View - Default Profile Measures

The Today view contains the following measure.

Today Date

The Today Date is a loaded read-only measure to display the system date that is calculated by IPOCS-Lifecycle Allocation and Replenishment batch.

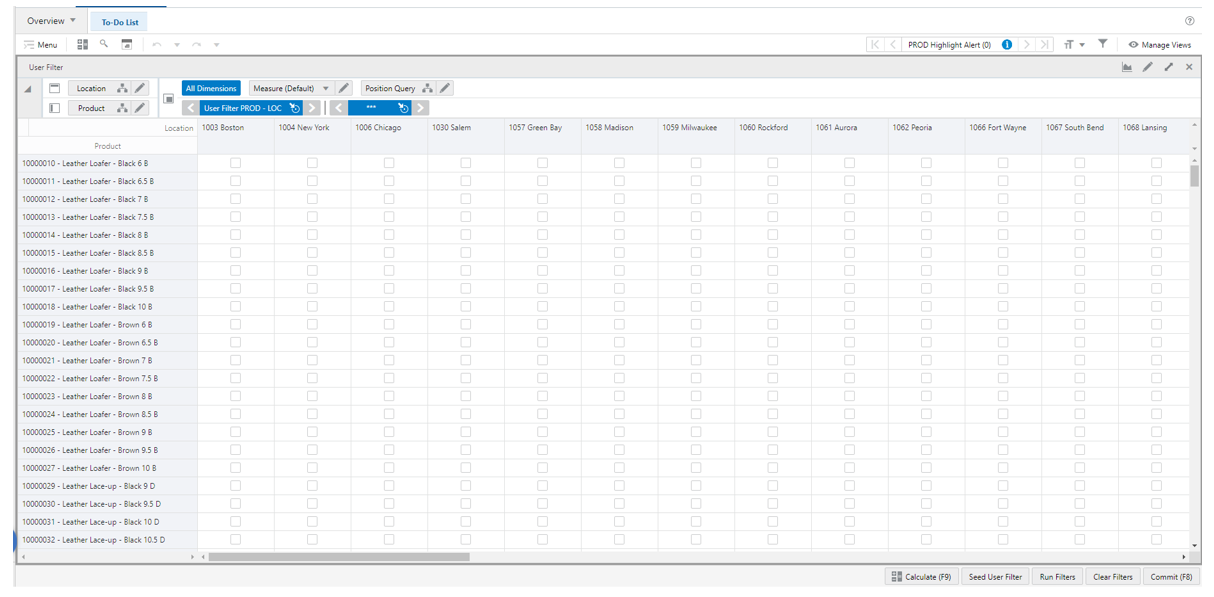

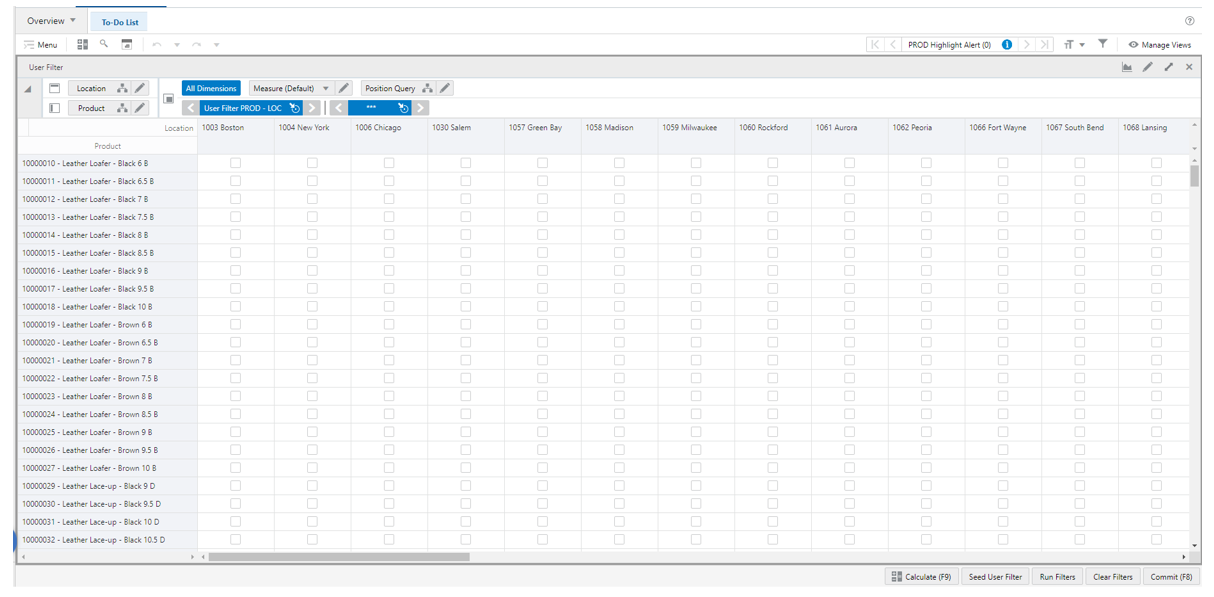

User Filter View

The User Filter View, under the To-Do List tab, allows you to configure the filter to be applied to the views within the Review & Approve workspace. In this view you can configure the filter to be applied to the product and location hierarchies. Once a change is performed it is applied after running the workspace calculation (either Calculate or F9).

Figure 20-12 User Filter View

User Filter View - Default Profile Measures

The User Filter view contains the following measure.

User Filter PROD-LOC

User Filter Product and Location is an editable measure to restrict the filter by the product and location combinations when the measure User Filter PROD-LOC is selected.

Review & Approve Step

In this step you can review at different levels, the orders calculated by IPOCS-Lifecycle Allocation and Replenishment and approve them. This step contains these views:

By Prod Tab

By Location Tab

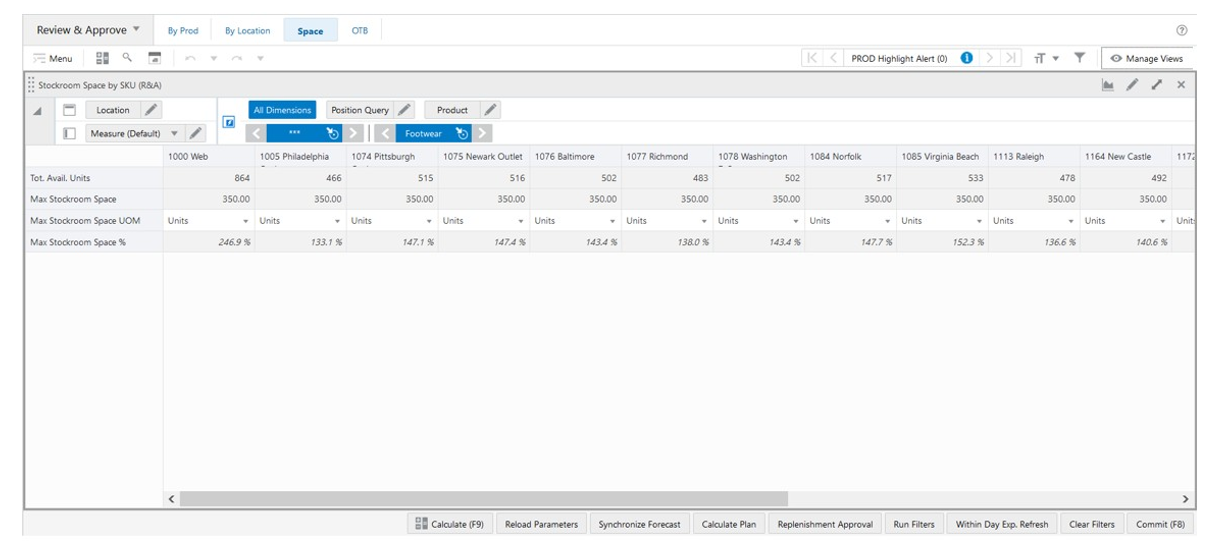

Space Tab

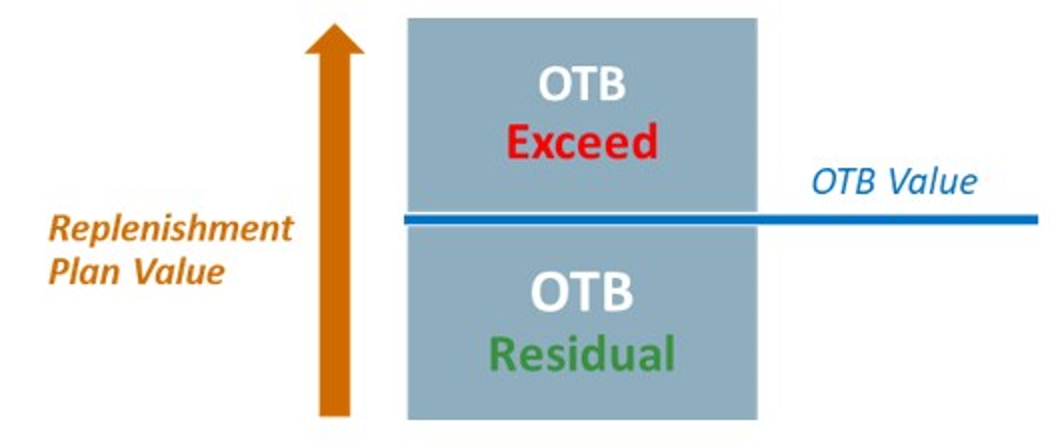

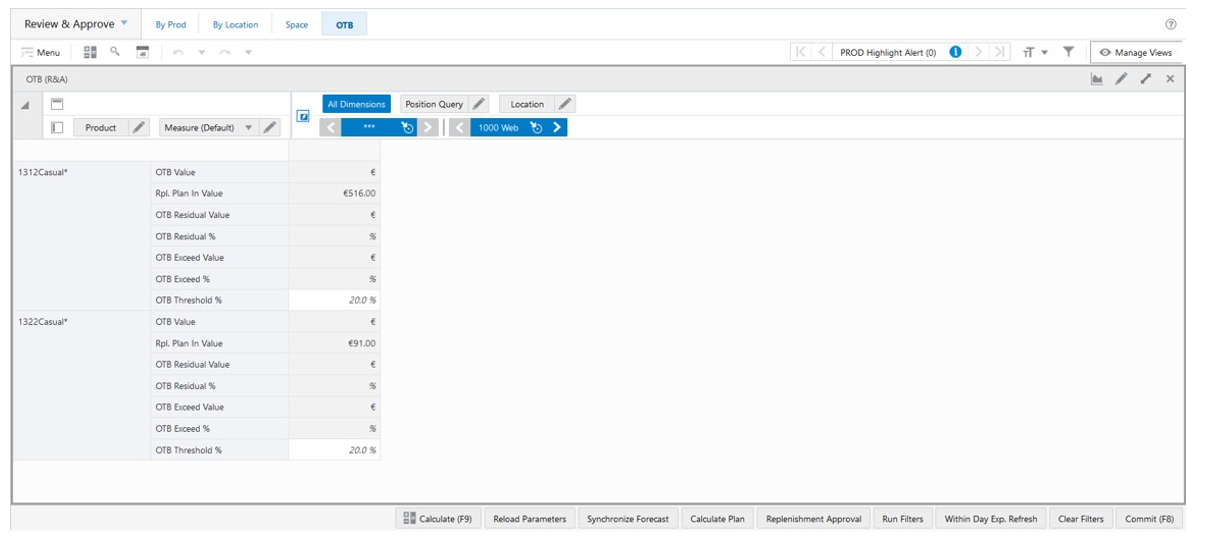

OTB Tab

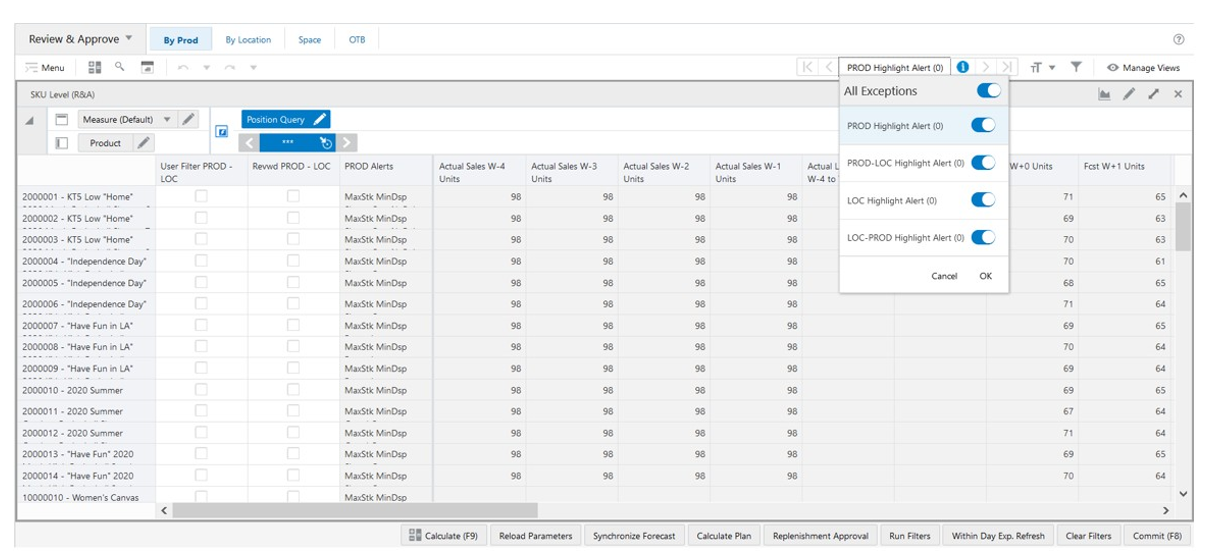

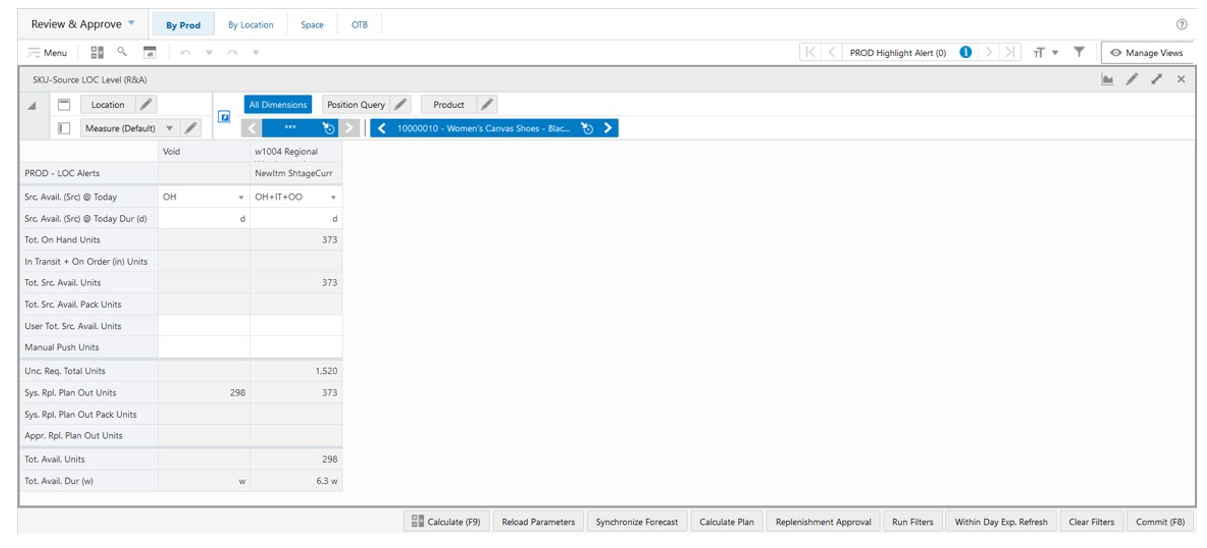

SKU Level (R & A) View

The SKU Level (R & A) View, under the By Prod tab, allows you to review the replenishment and allocation calculated values at the product level only (no location). Additionally, the sales and forecast for the previous and forthcoming four weeks are also available.

The navigation of this view is driven by real-time alerts or workspace alerts. To leverage the real-time alert navigation in this workspace the desired alerts should be enabled as RTA (measure Enable RTA) in the To-Do List view.

Figure 20-13 SKU Level (R & A) View

Note:

The measures being displayed in this view, regardless of the measure profile, are supported by their counterparts defined at the product and location level. Therefore, the calculated measures in this view are the result of aggregating the ones at the product and location intersection.

SKU Level (R & A) View - Default Profile Measures

The Default measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is an editable measure used to include specific product and location combinations into the quick filter. When selected, by clicking the Run Filters action menu, the quick filter restricts the condition to search only for the product and location combinations selected. When clear, the product and location combinations are not included in the filter condition.

Revwd PROD - LOC

The Revwd PROD - LOC is an editable measure used to indicate that the product and location combination alerts have been reviewed.

PROD Alerts

The PROD Alerts is a calculated measure used to display the Alert Short Descr. of all alerts that were triggered for the product.

Actual Sales W-4 Units

The Actual Sales W-4 Units is a calculated measure used to display the accumulated daily sales units at the system date week - 4 weeks. The system date is available in the Today view.

Actual Sales W-3 Units

The Actual Sales W-3 Units is a calculated measure used to display the accumulated daily sales units at the system date week - 3 weeks. The system date is available in the Today view.

Actual Sales W-2 Units

The Actual Sales W-2 Units is a calculated measure used to display the accumulated daily sales units at the system date week - 2 weeks. The system date is available in the Today view.

Actual Sales W-1 Units

The Actual Sales W-1 Units is a calculated measure used to display the accumulated daily sales units at the system date week - 1 week. The system date is available in the Today view.

Actual Lost Sales W-4 to W-1 Units

The Actual Lost Sales W-4 to W-1 Units is a calculated measure used to display the accumulated lost sales units from the system date week – 4 until the previous week (from the system date week). The system date is available in the Today view.

Actual Sales W+0 Units

The Actual Sales W+0 Units is a calculated measure used to display the accumulated daily sales units for the current system date week. The system date is available in the Today view.

Fcst W+0 Units

The Fcst W+0 Units is a calculated measure used to display forecast units for the current system date week. The system date is available in the Today view.

Fcst W+1 Units

The Fcst W+1 Units is a calculated measure used to display forecast units at the system date week +1 week. The system date is available in the Today view.

Fcst W+2 Units

The Fcst W+2 Units is a calculated measure used to display forecast units at the system date week +2 weeks. The system date is available in the Today view.

Fcst W+3 Units

The Fcst W+3 Units is a calculated measure used to display forecast units at the system date week + 3 weeks. The system date is available in the Today view.

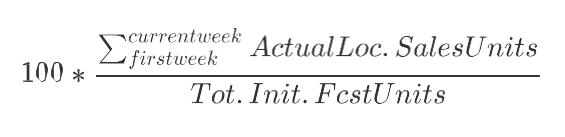

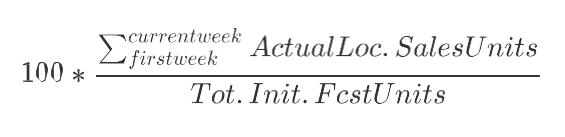

Lifecycle Sales To-Date %

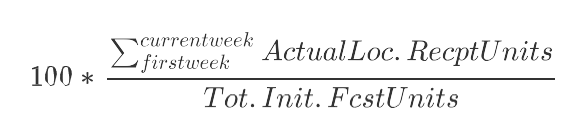

The Lifecycle Sales To-Date % is a calculated measure used to indicate the percentage of actual sales up to date against the total initial forecast.

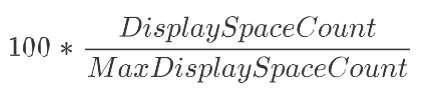

Figure 20-14 Calculation

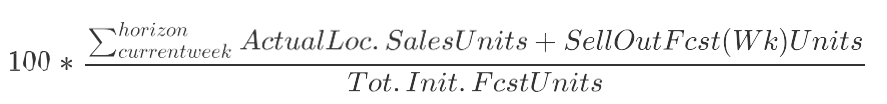

Lifecycle Sales To-Go %

The Lifecycle Sales To-Go % is a calculated measure used to indicate the percentage of sales to complete the total initial forecast.

Figure 20-15 Calculation

Asst. Prod-Loc Start Date

The Asst. Prod-Loc Start Date is a loaded measure used to indicate the assortment start date for the assorted product and location combinations.

Asst. Prod-Loc End Date

The Asst. Prod-Loc End Date is a loaded measure used to indicate the assortment end date for the assorted product and location combinations.

Asst. Prod-Loc Active Count

The Asst. Prod-Loc Active Count is a calculated measure used to indicate the total number of product and location combinations assorted and still active. If the assortment end date has not been reached yet then, it is active. Otherwise, it is inactive; meaning that the assortment has stopped already.

RUTL @Today Units

The RUTL @Today Units is a calculated measure used to indicate the Reorder Up-to Level (RUTL) value in units for the product and location combination at the system date. In this view, the value is the total of all locations for the product.

Tot. Dest. Avail. Units

The Tot. Dest. Avail. Units is a calculated measure used to indicate the total quantity of units available at the destination location. In this view, the value is the total of all locations where there is available inventory for the product.

Unc Need Total Units

The Unc Need Total Units is a calculated measure used to indicate the total unconstrained quantity, in units, needed for the location. In this view, the value is the total of all locations for the product.

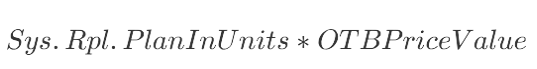

Sys. Rpl. Plan In Units

The Sys. Rpl. Plan In Units is a calculated measure used to indicate the order quantity for the location based on the location’s needs. This value is calculated based on the replenishment rules and the location forecast. In this view, the value is the total of all locations for the product.

Sys. Rpl. Plan In Pack Units

The Sys. Rpl. Plan In Pack Units is a calculated measure used to indicate the order quantity, in pack order quantity, for the location based on the location needs. This value is calculated based on the replenishment rules and the location forecast. In this view, the value is the total of all locations for the product.

Rpl. TBA Count

The Rpl. TBA Count is a calculated measure used to indicate the total number of assorted product and location combinations that need the orders to be approved manually. In this view, the value is the total of all locations for the product.

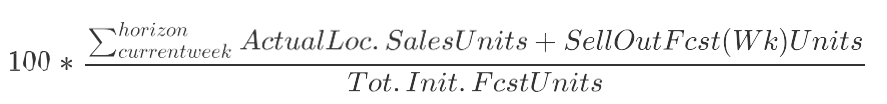

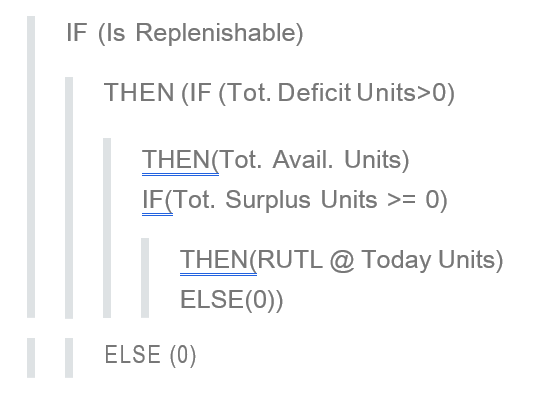

Tot. Deficit Units

The Tot. Deficit Units is a calculated measure used to indicate the product inventory deficit using the total available inventory and Reorder Up-to Level (RUTL) value.

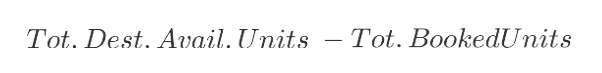

Figure 20-16 Calculation

Tot. Surplus Units

The Tot. Surplus Units is a calculated measure used to indicate the product inventory surplus using the total available inventory and Reorder Up-to Level (RUTL) value.

Figure 20-17 Calculation

SKU Level (R & A) View - Actuals Profile Measures

The Actuals measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

Actual PL Sales Wk Units

The Actual PL Sales Wk Units is a calculated measure used to indicate the weekly sales, aggregated from the daily sales, for the product and location combination. In this view, the value is the total of all locations and all weeks for the product.

Actual Loc. Sales Units

The Actual Loc. Sales Units is a calculated measure used to indicate the weekly sales, aggregated from the daily sales, for the product and location combinations. In this view, the value is the total of all locations and all weeks for the product.

Actual Loc.Recpt Units

The Actual Loc.Recpt Units is a calculated measure used to indicate the weekly receipts for the product and location combination. In this view, the value is the total of all locations and all weeks for the product.

Actual Loc. Shipmt Units

The Actual Loc. Shipmt Units is a calculated measure used to indicate the weekly shipments for the product and location combinations. In this view, the value is the total of all locations and all weeks for the product.

Actual Sales W-4 Units

The Actual Sales W-4 Units is the same as the one in the default profile. Refer to the measure, Actual Sales W-4 Units, in the Default Profile Measures.

Actual Sales W-3 Units

The Actual Sales W-3 Units is the same as the one in the default profile. Refer to the measure, Actual Sales W-3 Units in the Default Profile Measures.

Actual Sales W-2 Units

The Actual Sales W-2 Units is the same as the one in the default profile. Refer to the measure, Actual Sales W-2 Units, in the Default Profile Measures.

Actual Sales W-1 Units

The Actual Sales W-1 Units is the same as the one in the default profile. Refer to the measure, Actual Sales W-1 Units, in the Default Profile Measures.

Actual Sales W+0 Units

Actual Sales W+0 Units is the same as the one in the default profile. Refer to the measure, Actual Sales W+0 Units, in the Default Profile Measures.

Actual Sales W-1 + W+0 Units

The Actual Sales W-1 + W+0 Units is a calculated measure used to display the accumulated sales units from the system date week – 1 until the system current week. The system date is available in the Today view.

Actual Sales W-2 + W+0 Units

The Actual Sales W-2 + W+0 Units is a calculated measure used to display the accumulated sales units from the system date week – 2 until the system current week. The system date is available in the Today view.

Actual Sales W-3 + W+0 Units

The Actual Sales W-3 + W+0 Units is a calculated measure used to display the accumulated sales units from the system date week – 3 until the system current week. The system date is available in the Today view.

Actual Sales W-4 + W+0 Units

The Actual Sales W-4 + W+0 Units is a calculated measure used to display the accumulated sales units from the system date week – 4 until the system current week. The system date is available in the Today view.

Actual Lost Sales W-4 to W-1 Units

Actual Lost Sales W-4 to W-1 Units is the same as the one in the default profile. Refer to the measure, Actual Lost Sales W-4 to W-1 Units, in the Default Profile Measures.

Actual Sales D-7 Units

The Actual Sales D-7 Units is a calculated measure used to display the accumulated daily sales units for the last 7 days (from the system date - 7 days until system date). The system date is available in the Today view.

Actual Sales D-15 Units

The Actual Sales D-15 Units is a calculated measure used to display the accumulated daily sales units for the last 15 days (from the system date - 15 days until system date). The system date is available in the Today view.

Actual Sales D-30 Units

The Actual Sales D-30 Units is a calculated measure used to display the accumulated daily sales units for the last 30 days (from the system date - 30 days until system date). The system date is available in the Today view.

Actual Avg Inv. W-1 Units

The Actual Avg Inv. W-1 Units is a calculated measure used to display the average inventory units at the previous week (system date week - 1 week). The system date is available in the Today view.

Actual Avg Inv. W-2 Units

The Actual Avg Inv. W-2 Units is a calculated measure used to display the average inventory units at the system date week - 2 weeks. The system date is available in the Today view.

Actual Avg Inv. W-3 Units

The Actual Avg Inv. W-3 Units is a calculated measure used to display the average inventory units at the system date week - 3 weeks. The system date is available in the Today view.

Actual Avg Inv. W-4 Units

The Actual Avg Inv. W-4 Units is a calculated measure used to display the average inventory units at the system date week - 4 weeks. The system date is available in the Today view.

Actual PL Avg Inv. Wk Units

The Actual PL Avg Inv. Wk Units is a calculated measure to display the average holding inventory of the assortment period.

SKU Level (R & A) View - Availability Profile Measures

The Availability measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

RUTL Mask

The RUTL Mask is a calculated measure used to indicate whether the product and location combination is eligible for replenishment. When selected, then it is eligible. When clear, it is not eligible. In this view, if at least one location is eligible then the product is eligible.

Rpl. Dest. Mask

The Rpl. Dest. Mask is a calculated measure used to indicate whether the product and location combination is eligible for replenishment and the constraint parameter at the system date indicates that replenishment is enabled (measure Rpl. Active (Dst) @ Today). When selected, then it is eligible. When clear, it is not eligible. In this view, if at least one location is eligible then the product is eligible.

Rpl. Src. Mask

The Rpl. Src. Mask is a calculated measure used to indicate whether the product and source location combination is eligible for replenishment. When selected, then it is eligible. When clear, it is not eligible. In this view, if at least one location is eligible then the product is eligible.

Tot. On Hand Units

The Tot. On Hand Units is a calculated measure used to indicate the total on-hand inventory units. The total on-hand units include the on-hand inventory loaded into IPOCS-Lifecycle Allocation and Replenishment plus the on-hand inventory units for the replacement or phase-out product, if any.

In Transit over LT+RT Units

The In Transit over LT+RT Units is a calculated measure used to indicate the total in transit units over the lead time plus the review time.

On Order (in) over LT+RT Units

The On Order (in) over LT+RT Units is a calculated measure used to indicate the total on orders (in) units over the lead time plus the review time.

Exp. Rpl. Plan In Units

The Exp. Rpl. Plan In Units is a calculated measure used to indicate the replenishment planned units to be exported from the batch for the product and location combination. In this view, the value is the total of all destination locations for the product.

Appr. Rpl. Plan In Units

The Appr. Rpl. Plan In Units is a calculated measure used to indicate the approved replenishment planned units for the product and location combination. In this view, the value is the total of all destination locations for the product.

Appr. Rpl. Plan In Pack Units

The Appr. Rpl. Plan In Pack Units is a calculated measure used to indicate the approved replenishment planned packs units for the product and location combination. In this view, the value is the total of all destination locations for the product.

Sys. Rpl. Plan In Units

The Sys. Rpl. Plan In Units is the same as the one in the default profile. Refer to the measure, Sys. Rpl. Plan In Units, in the Default Profile Measures.

Transfer Plan In Units

The Transfer Plan In Units is a calculated measure used to indicate the transfer units planned for the product and location combination. In this view, the value is the total of all destination locations for the product.

Appr. Transfer In Units

The Appr. Transfer In Units is a calculated measure used to indicate the transfer units approved for the product and location combination. In this view, the value is the total of all destination locations for the product.

Exp. Transfer Plan In Units

The Exp. Transfer Plan In Units is a calculated measure used to indicate the transfer units to be exported from the batch for the product and location combination. In this view, the value is the total of all destination locations for the product.

On Order (out) over LT+RT Units

The On Order (out) over LT+RT Units is a calculated measure used to indicate the total on orders (out) units over the lead time plus the review time.

Exp. Rpl. Plan Out Units

The Exp. Rpl. Plan Out Units is a calculated measure used to indicate the source location (for example, warehouse) replenishment planned units to be exported from the batch for the product and location combination. In this view, the value is the total of all source locations for the product.

Appr. Rpl. Plan Out Units

Appr. Rpl. Plan Out Units is a calculated measure used to indicate the source location approved replenishment units for the product and location combination. In this view, the value is the total of all source locations for the product.

Sys. Rpl. Plan Out Units

The Sys. Rpl. Plan Out Units is a calculated measure used to indicate the order quantity for the source location based on the source location needs. This value is calculated based on the replenishment rules and the source location demand. In this view, the value is the total of all source locations for the product.

Transfer Plan Out Units

The Transfer Plan Out Units is a calculated measure used to indicate the source location’s transfer units planned for the product and location combination. In this view, the value is the total of all locationss for the product.

Appr. Transfer Out Units

The Appr. Transfer Out Units is a calculated measure used to indicate the source location’s transfer units approved for the product and location combination. In this view, the value is the total of all locationss for the product.

Exp. Transfer Plan Out Units

The Exp. Transfer Plan Out Units is a calculated measure used to indicate the source location’s transfer units to be exported from the batch for the product and location combination. In this view, the value is the total of all locations for the product.

Tot. Dest. Avail. Units

The Tot. Dest. Avail. Units is the same as the one in the default profile. Refer to the measure, Tot. Dest. Avail. Units, in the Default Profile Measures.

Tot. Dest. Avail Dur (w)

The Tot. Dest. Avail Dur (w) is a calculated measure used to indicate the number of weeks that the Tot. Dest. Avail. Units can cover the demand for the product and location combination.

Tot. Physical Avail. Units

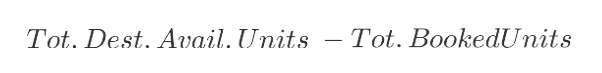

The Tot. Physical Avail. Units is a calculated measure used to indicate the total quantity of units’ physically available at the destination location. The physically available units differ from the available units as the booked inventory is taken into consideration. In this view, the value is the total of all locations for the product.

Figure 20-18 Calculation

Tot. Physical Avail. Dur (w)

The Tot. Physical Avail. Dur (w) is a calculated measure used to indicate the number of weeks that the Tot. Physical Avail. Units can cover the demand for the product and location combination.

Up To Dest. Avail Units

The Up To Dest. Avail Units is the same as Tot. Dest. Avail Units grouped by source.

Up To Dest. Avail Dur (w)

The Up To Dest. Avail Dur (w) is the same as Tot. Dest. Avail Units grouped by source displayed by duration (weeks).

Tot. Src. Avail. Units

The Tot. Src. Avail. Units is a calculated measure used to indicate the total quantity of units available at the source location.

Tot. Src. Avail. Pack Units

The Tot. Src. Avail. Pack Units is a calculated measure used to indicate the total quantity of pack units available at the source location.

Tot. Dest. Avail. (incl. Rpl. & Trsf. Out)

The Tot. Dest. Avail. (incl. Rpl. & Trsf. Out) is the Total Destination Available stock, which is calculated as the sum of all inbound deliveries following replenishment, plus stock on hand but excluding all planned and approved outbound shipments – this measure provides the location net inventory following replenishment calculation.

Tot. Avail. Units

The Tot. Avail. Units is a calculated measure used to indicate the total quantity of units available for the product considering all inventory (booked, on-hand, transit, and on-order) plus all orders (approved, planned, and exported) plus all transfers (approved, planned, and exported).

Tot. Avail. Dur (w)

The Tot. Avail. Dur (w) is a calculated measure used to indicate the number of weeks that the Tot. Avail. Units can cover the demand for the product and location combination.

SKU Level (R & A) View - Forecast Profile Measures

The Forecast measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

Fcst W+0 Units

The Fcst W+0 Units is the same as the one in the default profile. Refer to the measure, Fcst W+0 Units, in the Default Profile Measures.

Fcst W+1 Units

The Fcst W+1 Units is the same as the one in the default profile. Refer to the measure, Fcst W+1 Units, in the Default Profile Measures.

Fcst W+2 Units

The Fcst W+2 Units is the same as the one in the default profile. Refer to the measure, Fcst W+2 Units, in the Default Profile Measures.

Fcst W+3 Units

The Fcst W+3 Units is the same as the one in the default profile. Refer to the measure, Fcst W+3 Units, in the Default Profile Measures.

Fcst W+0 to W+1 Units

The Fcst W+0 to W+1 Units is a calculated measure used to display the accumulated forecast from the current system date week until the system current week + 1. The system date is available in the Today view.

Fcst W+0 to W+2 Units

The Fcst W+0 to W+2 Units is a calculated measure used to display the accumulated forecast from the current system date week until the system current week + 2. The system date is available in the Today view.

Fcst W+0 to W+3 Units

The Fcst W+0 to W+3 Units is a calculated measure used to display the accumulated forecast from the current system date week until the system current week + 3. The system date is available in the Today view.

Forecast Overt LT+RT Units

The Forecast Overt LT+RT Units is a calculated measure used to display the daily Forecast Demand, in units, from the system date up to number of days of Lead Time plus Review Time. The system date is available in the Today view.

Final Fcst PL Wk Units

The Final Fcst PL Wk Units is a calculated measure used to display the final weekly forecast after being spread from the variant level.

Sell-Out Fcst (Wk) Units

The Sell-Out Fcst (Wk) Units is an editable measure used to enter product demand at the destination locations. In this view, the measure is aggregated and when changed, the value is spread proportionally across the locations and weeks within the workspace (you can check the spread value in the SKU-LOC-WEEK Level (InvPlan) view).

Sell-In Fcst (Wk) Units

The Sell-In Fcst (Wk) Units is an editable measure used to enter the weekly demand at the source location for the product and location combination.

Tot. Demand (Wk) Units

The Tot. Demand (Wk) Units is a calculated measure used to indicate the total weekly demand for the product. In this view, the measure is aggregated (you can check the weekly value in the SKU-LOC-WEEK Level (InvPlan) view).

Up To Sell-Out Fcst Units

The Up To Sell-Out Fcst Units is a calculated measure used to indicate the sell-out Forecast from the source location perspective for the products.

SKU Level (R & A) View - Inventory Profile Measures

The Inventory measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

Tot. On Hand Units

The Tot. On Hand Units is the same as the one in the availability profile. Refer to the measure, Tot. On Hand Units, in the in the Availability Profile Measures.

Tot. Booked Units

The Tot. Booked Units is a calculated measure used to indicate the total inventory booked in units.

In Transit over LT+RT Units

The In Transit over LT+RT Units is the same as the one in the availability profile. Refer to the measure, In Transit over LT+RT Units, in the Availability Profile Measures.

Tot. In Transit Units

The Tot. In Transit Units is a calculated measure used to indicate the total inventory units in transit.

Tot. In Transit

The Tot. In Transit is a calculated measure used to display your comment for the in-transit inventory and your comment for the phase-out item’s inventory, if any.

Tot. On Order (in) Units

The Tot. On Order (in) Units is a calculated measure used to indicate the total on-order inventory units. The total on-order units include the on-order inventory loaded into IPOCS-Lifecycle Allocation and Replenishment plus the on-order inventory units for the replacement/phase-out product, if any.

On Order (in) over LT+RT Units

The On Order (in) over LT+RT Units is the same as the one in the availability profile. Refer to the measure, On Order (in) over LT+RT Units, in the Availability Profile Measures.

In Transit + On Order (in) Units

The In Transit + On Order (in) Units is a calculated measure used to indicate the accumulated on-order and in-transit inventory units at the locations for the product.

Tot. on Order (out) Units

The Tot. on Order (out) Units is a calculated measure used to indicate the total on-order inventory units out from the source locations (for example, warehouse. The total on-order (out) units include the on-order inventory loaded into IPOCS-Lifecycle Allocation and Replenishment plus the on-order (out) inventory units for the replacement/phase-out product, if any.

On Order (out) over LT+RT Units

The On Order (out) over LT+RT Units is the same as the one in the availability profile. Refer to the measure, On Order (out) over LT+RT Units, in the Measures: Availability Profile in the Default Profile Measures.

Tot. Cust. Order Units

The Tot. Cust. Order Units is a calculated measure used to indicate the total customer orders units. The total customer orders include the customer orders loaded into IPOCS-Lifecycle Allocation and Replenishment plus the customer orders for the replacement/phase-out product, if any.

Loc. On Hand Units

The Loc. On Hand Units is a loaded measure used to indicate the on-hand inventory units for the product and location combinations. In this view, the displayed value is for the product considering all locations.

Loc. Booked Units

The Loc. Booked Units is a loaded measure used to indicate the booked or reserved inventory units for the product and location combinations. In this view, the displayed value is for the product considering all locations.

Loc. In Transit Units

The Loc. In Transit Units is a loaded measure used to indicate the in-transit inventory units for the product and location combinations. In this view, the displayed value is for the product considering all locations.

Loc In Transit

vLoc In Transit is a loaded measure used to indicate whether the product and location combination has in-transit inventory or not. When selected, there is in-transit inventory. When clear, there is no in-transit inventory. In this view, a product has in-transit inventory if there is at least one location with in-transit inventory.

Loc. On Order (in) Units

The Loc. On Order (in) Units is a loaded measure used to indicate the in-transit inventory units for the product and location combinations. In this view, the displayed value is for the product considering all locations.

Loc. On Order (out) Units

The Loc. On Order (out) Units is a loaded measure used to indicate the on-order inventory units (into the destination locations) for the product and location combinations. In this view, the displayed value is for the product considering all locations.

Cust. Order Units

The Cust. Order Units is a loaded measure used to indicate the on-order inventory units (out from source locations) for the product and location combinations. In this view, the displayed value is for the product considering all locations.

Ph. Out On Hand Units

The Ph. Out On Hand Units is a calculated measure used to indicate the on-hand inventory units for the phased-out item, if any.

Ph. Out Booked Units

The Ph. Out Booked Units is a calculated measure used to indicate the booked or reserved inventory units for the phased-out item, if any.

Ph. Out In Transit Units

The Ph. Out In Transit Units is a calculated measure used to indicate the in-transit inventory units for the phased-out item, if any.

Ph. Out In Transit

The Ph. Out In Transit is a calculated measure used to indicate whether the phased-out item has in-transit inventory or not. When selected, there is in-transit inventory. When clear, there is no in-transit inventory.

Ph. Out On Order (in) Units

The Ph. Out On Order (in) Units is a calculated measure used to indicate the on-order inventory units (into the destination locations) for the phased-out item, if any.

Ph. Out On Order (out) Units

The Ph. Out On Order (out) Units is a calculated measure used to indicate the on-order inventory units (out from source locations) for the phased-out item, if any.

Ph. Out Cust. Order Units

The Ph. Out Cust. Order Units is a calculated measure used to indicate the customer orders for the phased-out item, if any.

Pack Type

The Pack Type is a loaded measure used to indicate the product’s pack type. Either simple or complex.

Pack Desc.

The Pack Desc. is a loaded measure used to indicate the product’s pack description.

Pack - SKU Ass. Count

The Pack - SKU Ass. Count is a calculated measure used to indicate the total number of products (SKU) in the pack.

Pack - SKU Ass. Units

The Pack - SKU Ass. Units is an editable measure used to indicate the total number of units that the product (SKU) has in the pack.

SKU Level (R & A) View - Parameters Profile Measures

The Parameters measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

Asst. Prod-Loc

The Asst. Prod-Loc is a loaded measure used to indicate whether the product and location combinations are assorted or not. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Asst. Prod-Loc Count

The Asst. Prod-Loc Count is a loaded measure used to indicate the total number of product and location combinations assorted. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Asst. Prod-Loc Active

The Asst. Prod-Loc Active is a loaded measure used to indicate whether the product and location combinations are assorted and still active or not. For more details check the same measure in the view Product- Location within the Manage Assortment workspace.

Asst. Prod-Loc Active Count

The Asst. Prod-Loc Active Count is a loaded measure used to indicate the total number of product and location combinations assorted and still active. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Asst. Prod-Loc Start Date

The Asst. Prod-Loc Start Date is a loaded measure used to indicate the assortment start date for the assorted product and location combinations. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Asst. Prod-Loc End Date

The Asst. Prod-Loc End Date is a loaded measure used to indicate the assortment end date for the assorted product and location combinations. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Lfc. Prod-Loc

The Lfc. Prod-Loc is a loaded measure used to indicate whether the product and location combination has a valid lifecycle or not. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Lfc. Prod-Loc Count

The Lfc. Prod-Loc Count is a calculated measure used to indicate the number of locations where the product has a valid lifecycle.

Lfc. Active @ Today

The Lfc. Active @ Today is a loaded measure used to indicate whether the product and location combination has a valid lifecycle or not at the system date. In this view, the product has an active lifecycle if there is at least one location with an active lifecycle.

Lfc. Active @ Today

The Lfc. Active @ Today is a loaded measure used to indicate the lifecycle phase string for the product and location combination when the product and location combination has a valid lifecycle at the system date. In this view, the values are aggregated to the product level only using the ambig aggregation.

Display Qty Units

The Display Qty Units is a loaded measure used to indicate the Display Quantity for the product and location combination used by IPOCS-Lifecycle Allocation and Replenishment for the RUTL calculation. In this view, the value is the total for the product.

Min Order Qty Units

The Min Order Qty Units is an editable measure used to indicate the minimum order quantity for the product and location combination. In this view, the value is the total for the product.

Mult. Order Qty Units

The Mult. Order Qty Units is an editable measure used to indicate the number of multiple order quantities for the product and location combination. In this view, the value is the total for the product.

Fixed TS 1 Units

The Fixed TS 1 Units is a loaded measure used to indicate the initial allocation for the product and location combination. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Fixed TS 2 Units

The Fixed TS 2 Units is an editable measure used to indicate an initial allocation for the product and location combination. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Fixed TS 3 Units

The Fixed TS 3 Units is an editable measure used to indicate an initial allocation for the product and location combination. For more details, refer to the same measure in the Product-Location view within the Manage Assortment workspace.

Tot. Init. Fcst Units

The Tot. Init. Fcst Units is a loaded measure used to display the total initial forecast for the product and location combination.

Conversion UOM 1

The Conversion UOM 1 is an editable measure used to indicate a value to be used when converting units into a specific unit of measure based on the Constraint UOM 1 for scaling. In this view, the value is the total for the product.

Conversion UOM 2

The Conversion UOM 2 is an editable measure used to indicate a value to be used when converting units into a specific unit of measure based on the Constraint UOM 1 for scaling. In this view, the value is the total for the product.

Conversion UOM 3

The Conversion UOM 3 is an editable measure used to indicate a value to be used when converting units into a specific unit of measure based on the Constraint UOM 1 for scaling. In this view, the value is the total for the product.

Avg. Cost €

The Avg. Cost € is an editable measure used to indicate the average cost for the product and location combination. In this view, the value is the average for the product considering all the locations.

Price (excl.VAT) €

The Price (excl.VAT) € is an editable measure used to indicate the price excluding VAT for the product and location combination. In this view, the value is the average for the product considering all the locations.

Primary Source @ Today

The Primary Source @ Today is a loaded measure used to indicate the applied primary source for the product and location combination at the system date and can be overridden. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Reserved Source 1 @ Today

The Reserved Source 1 @ Today is a calculated measure used to indicate the applied reserved source 1 for the product and location combination at the system date and can be overridden. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Reserved Source 2 @ Today

The Reserved Source 2 @ Today is a calculated measure used to indicate the applied reserved source 2 for the product and location combination at the system date and can be overridden. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Alternative Source @ Today

The Alternative Source @ Today is a calculated measure used to indicate the applied alternative source for the product and location combination at the system date and can be overridden. .

LLC @ Today

The LLC @ Today is a calculated measure used to indicate the low level code applied to the product and location combination at the system date and can be overridden. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Lead Time @ Today Dur (d)

The Lead Time @ Today Dur (d) is a calculated measure used to indicate the applied lead time, in days, for the product and location combination at the system date and can be overridden. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Revw @ Today

The Revw @ Today is a calculated measure used to indicate if Today (current system date) is a review day for the product and location combination and can be overridden. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Next Revw @ Today Date

The Next Revw @ Today Date is a calculated measure used to indicate the next review date for the product and location combination. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Next Revw @ Today Dur (d)

The Next Revw @ Today Dur (d) is a calculated measure used to indicate the number of days to the next review date for the product and location combination. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Avg Revw Time @ Today Dur (d)

The Avg Revw Time @ Today Dur (d) is a calculated measure used to indicate the average number of days between each review period (planning period) for the product and location combination. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

RUTL Mask

The RUTL Mask is the same as the one in the availability profile. Refer to the measure, RUTL Mask, in the Availability Profile Measures.

Min Cred. Qty @ Today Units

The Min Cred. Qty @ Today Units is a calculated measure used to indicate the Minimum Credible Quantity applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

ROL Meth. @ Today

The ROL Meth. @ Today is a calculated measure used to indicate the ROL method applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Min Qty @ Today Units

The Min Qty @ Today Units is a calculated measure used to indicate the ROL minimum quantity units applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Min TS @ Today Dur (d)

The Min TS @ Today Dur (d) is a calculated measure used to indicate the ROL minimum time supply (in days) applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Tgt. SL @ Today %

The Tgt. SL @ Today % is a calculated measure used to indicate the Target Service Level % applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Volatility @ Today %

The Volatility @ Today % is a calculated measure used to indicate the Volatility % applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

ROL Sft. Time @ Today Dur (d)

The ROL Sft. Time @ Today Dur (d) details the Reorder level safety time duration applicable today based on rules association and used in replenishment calculations where RUTL method is not Target Stock. The ROL level is determined as lead time + review time + ROL Sft Time @ Today Dur (d).

RUTL Meth. @ Today

The RUTL Meth. @ Today is a calculated measure used to indicate the RUTL method applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Max Qty @ Today Units

The Max Qty @ Today Units is a calculated measure used to indicate the RUTL maximum quantity units applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Max TS @ Today Dur (d)

The Max TS @ Today Dur (d) is a calculated measure used to indicate the RUTL maximum time supply (in days) applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Tgt. DoS @ Today Dur (d)

The Tgt. DoS @ Today Dur (d) is a calculated measure used to indicate the Target Days of Supply (in days) applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

TS Meth. @ Today

The TS Meth. @ Today is a calculated measure used to indicate the target stock method applied to the product and location combination at the system date (when the RUTL method is target stock). For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

TS Seas. Fcst @ Today %

TS Seas. Fcst @ Today % is a calculated measure used to indicate the percentage of the Seasonal Forecast applied to the product and location combination at the system date (to be used when the RUTL method is target stock). For more details about the measure, refer to the same measure description in the view SKU- LOC within the Network workspace.

TS Sft. Time @ Today Dur (d)

The TS Sft. Time @ Today Dur (d) is a calculated measure used to indicate the number of days for the stock safety applied to the product and location combination at the system date (to be used when the RUTL method is target stock). For more details about the measure, refer to the same measure description in the view SKU- LOC within the Network workspace.

Order Rounding Threshold @ Today

The Order Rounding Threshold @ Today is a calculated measure used to indicate the percentage to round up the orders applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Repl. Status @ Today

The Repl. Status @ Today is a calculated measure used to indicate whether the product and location combination at the system date is replenishable or not. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

ROL Chng @ Today %

The ROL Chng @ Today % is a calculated measure used to indicate the percentage to increase or decrease the system-generated ROL value applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

RUTL Chng @ Today %

The RUTL Chng @ Today % is a calculated measure used to indicate the percentage to increase or decrease the system-generated RUTL value applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Rpl. Dest. Mask

The Rpl. Dest. Mask is the same as the one in the availability profile. Refer to the measure, Rpl. Dest. Mask, in the Measures: Availability Profile in the Default Profile Measures.

Rpl. Src. Mask

The Rpl. Src. Mask is the same as the one in the availability profile. Refer to the measure, Rpl. Src. Mask, in the Measures: Availability Profile in the Default Profile Measures.

Avail. Constr. (Src) @ Today

The Avail. Constr. (Src) @ Today is a calculated measure used to indicate whether a constraint is enabled or disabled (at the source location) for the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Src. Avail. (Src) @ Today

The Src. Avail. (Src) @ Today is a calculated measure used to indicate which stock units to be used from the source locations are applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Src. Avail. (Src) @ Today Dur (d)

The Src. Avail. (Src) @ Today Dur (d) is a calculated measure used to indicate the number of days to get the in-transit and on-order stock applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Rpl. Active (Dst) @ Today

The Rpl. Active (Dst) @ Today is a calculated measure used to indicate for the product and location combination at the system date if the location has the replenishment active or not. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Fulfill Till Layer (Dst) @ Today

The Fulfill Till Layer (Dst) @ Today is a calculated measure used to indicate the layer applied to the product and location combination at the system date (layer until which IPOCS-Lifecycle Allocation and Replenishment should fulfill the demand). For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Ration. Prio (Dst) @ Today

The Ration. Prio (Dst) @ Today is a calculated measure used to indicate the rationing priority applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

SubLayer (Dst) @ Today

The SubLayer (Dst) @ Today is a calculated measure used to indicate the sublayers applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Assign Pack (Dst) @ Today

The Assign Pack (Dst) @ Today is a calculated measure used to indicate the pack types assignment applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace workspace.

Min Pack Fill Rate 1 (Dst) @ Today %

The Min Pack Fill Rate 1 (Dst) @ Today % is a calculated measure used to indicate the minimum pack fill rate percentage for the 1st round of complex pack assignments applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

Min Pack Fill Rate 2 (Dst) @ Today %

The Min Pack Fill Rate 2 (Dst) @ Today % is a calculated measure used to indicate the minimum pack fill rate percentage for the 2nd round of complex pack assignments applied to the product and location combination at the system date. For more details about the measure, refer to the same measure description in the SKU-LOC view within the Network workspace.

SKU Level (R & A) View - Plan Profile Measures

The Plan measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

RUTL Mask

The RUTL Mask is the same as the one in the availability profile. Refer to the measure, RUTL Mask, in the Availability Profile Measures.

Rpl. Dest. Mask

The Rpl. Dest. Mask is the same as the one in the availability profile. Refer to the measure, Rpl. Dest. Mask, in the Availability Profile Measures.

Rpl. Src. Mask

The Rpl. Src. Mask is the same as the one in the availability profile. Refer to the measure, Rpl. Src. Mask, in the Availability Profile Measures.

Pack Partition

The Pack Partition is a calculated measure used to indicate a partition (identifier) for the products that belong to the same pack. For example, if pack 001 has sku001, sku002 and sku003 then all 3 SKUs have the same pack partition value.

Tot. Physical Avail. Units

The Tot. Physical Avail. Units is the same as the one in the availability profile. Refer to the measure, Tot. Physical Avail. Units, in the Availability Profile Measures.

Tot. Physical Avail. Dur (w)

The Tot. Physical Avail. Dur (w) is the same as the one in the availability profile. Refer to the measure, Tot. Physical Avail. Dur (w), in the Availability Profile Measures.

Tot. Dest. Avail. Units

The Tot. Dest. Avail. Units is the same as the one in the default profile. Refer to the measure, Tot. Dest. Avail. Units, in the Default Profile Measures.

Tot. Dest. Avail. Dur (w)

Tot. Dest. Avail. Dur (w) is a calculated measure used to indicate the number of weeks that the Tot. Dest. Avail. Units can cover the demand for the product and location combination.

Tot. Src. Avail. Units

The Tot. Src. Avail. Units is a calculated measure used to indicate the total quantity of units available at the source location for the product and location combination. In this view, the value is the total for the product.

Tot. Src. Avail Pack Units

The Tot. Src. Avail Pack Units is a calculated measure used to indicate the total quantity of pack units available at the source location for the product and location combination. In this view, the value is the total for the product.

User Tot. Src. Avail. Units

The User Tot. Src. Avail. Units is an editable measure you can use to enter the total quantity of units available at the source location for the product. The value of this measure overrides the measure Tot. Src. Avail. Unit.

Manual Push Units

The Manual Push Units is an editable measure you can use to enter the total quantity of units to be manually pushed from the source location to the destination locations for the product. The value is spread proportionally between all the product’s destination locations.

ROL @ Today Units

The ROL @ Today Units is a calculated measure used to indicate the Reorder level (ROL) value in units for the product and location combination at the system date. In this view, the value is the total of all locations for the product.

RUTL @ Today Units

The RUTL @ Today Units is the same as the one in the default profile. Refer to the measure, RUTL @ Today Units, in the Default Profile Measures.

Forecast Over LT+RT Units

The Forecast Over LT+RT Units is the same as the one in the forecast profile. Refer to the measure, Forecast Over LT+RT Units, in the Forecast Profile Measures.

Unc. Need Total Units

The Unc. Need Total Units is the same as the one in the default profile. Refer to the measure, Unc. Need Total Units, in the Default Profile Measures.

Min Unc. Need Pack Units

The Min Unc. Need Pack Units is a measure that indicates the minimum unit of Packs needed regardless of Pack Fill Rate.

Max Unc. Need Pack Units

The Max Unc. Need Pack Units is a measure that indicates the maximum unit of Packs needed regardless of Pack Fill Rate.

User Rpl. Fix Locked Units

The User Rpl. Fix Locked Units is an editable measure you can use to enter fixed replenishment units (order quantity) for the product. This measure overrides the product’s system-calculated replenishment units. The entered value is spread proportionally between all the product’s destination locations.

Sys. Rpl. Plan In Units

The Sys. Rpl. Plan In Units is the same as the one in the default profile. Refer to the measure, Sys. Rpl. Plan In Units, in the Default Profile Measures.

Sys. Rpl. Plan In Pack Units

The Sys. Rpl. Plan In Pack Units is the same as the one in the default profile. Refer to the measure, Sys. Rpl. Plan In Pack Units, in the Default Profile Measures.

Unc. Req. Total Units

The Unc. Req. Total Units is a calculated measure used to indicate the total unconstrained quantity, in units, needed for the source location (for example, warehouse). In this view, the value is the total for the product.

Sys. Rpl. Plan Out Units

The Sys. Rpl. Plan Out Units is the same as the one in the default profile. Refer to the measure, Sys. Rpl. Plan Out Units, in the Default Profile Measures.

Sys. Rpl Plan Out Pack Units

The Sys. Rpl Plan Out Pack Units is a calculated measure used to indicate the pack order quantity (either simple or complex packs) for the source location based on the source location needs. This value is calculated based on the replenishment rules and the source location demand. In this view, the value is the total of all source locations for the product.

Tot. Avail Units

The Tot. Avail Units is the same as the one in the availability profile. Refer to the measure, Tot. Avail. Units, in the Availability Profile Measures.

Tot. Avail Dur (w)

The Tot. Avail Dur (w) is the same as the one in the availability profile. Refer to the measure, Tot. Avail. Dur (w), in the Availability Profile Measures.

Tot. Regular Units

The Tot. Regular Units is a calculated measure used to indicate the total regular units for the product. The calculation is based on the deficit and surplus units.

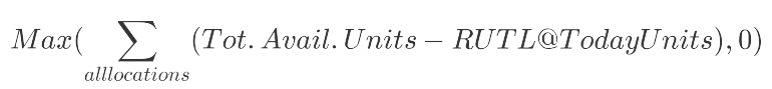

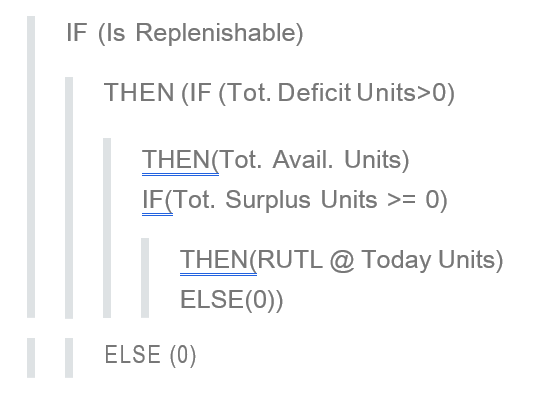

Figure 20-19 Calculation

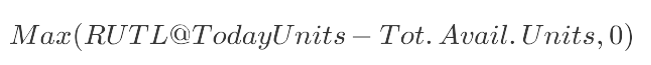

Tot. Deficit Units

The Tot. Deficit Units is the same as the one in the default profile. Refer to the measure, Tot. Deficit Units, in the Default Profile Measures.

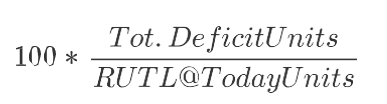

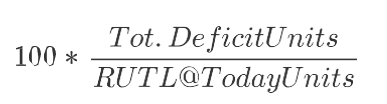

Tot. Deficit %

The Tot. Deficit % is a calculated measure used to indicate the percentage that the deficit units represent in the RUTL units.

Figure 20-20 Calculation

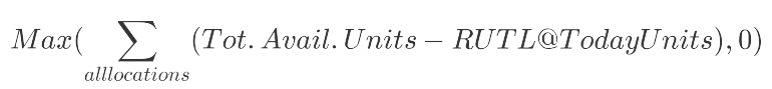

Tot. Surplus Units

The Tot. Surplus Units is the same as the one in the default profile. Refer to the measure, Tot. Surplus Units, in the Default Profile Measures.

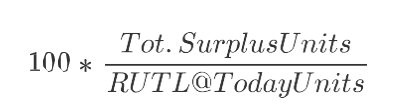

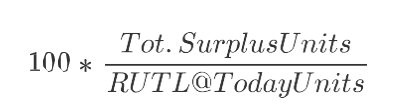

Tot. Surplus %

The Tot. Surplus % is a calculated measure used to indicate the percentage that the surplus units represent in the RUTL units.

Figure 20-21 Calculation

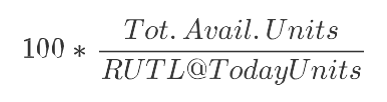

Tot. Fulfil. %

The Tot. Fulfil. % is a calculated measure used to indicate the percentage that the total available stock fulfills the RUTL.

Rpl. TBA

The Rpl. TBA is a calculated measure used to indicate whether the product and location combination needs the order to be approved manually. In this view, the value is the total of all locations for the product.

Appr. Rpl. Plan

The Appr. Rpl. Plan is an editable measure used to indicate whether the product’s order should or should not be approved by the approval process. The Replenishment Approval action button approves all orders when this measure is selected.

Appr. Rpl Plan User ID

The Appr. Rpl Plan User ID is a calculated measure used to audit the Replenishment Approval action button. It is populated with the user-identifier that last ran the Replenishment Approval.

Appr. Rpl. Plan Date

Appr. Rpl. Plan Date is a calculated measure used to audit the Replenishment Approval action button. It is populated with the date and time that the replenishment approval was last run.

Appr. Rpl. Plan In Units

The Appr. Rpl. Plan In Units is the same as the one in the availability profile. Refer to the measure, Appr. Rpl. Plan In Units, in the Availability Profile Measures.

Appr. Rpl. Plan In Pack Units

The Appr. Rpl. Plan In Pack Units is the same as the one in the availability profile. Refer to the measure, Appr. Rpl. Plan In Pack Units, in the Availability Profile Measures.

Appr. Rpl. Plan Out Units

The Appr. Rpl. Plan Out Units is the same as the one in the availability profile. Refer to the measure, Appr. Rpl. Plan Out Units, in the Measures: Availability Profile in the Default Profile Measures.

Exp. Rpl. Plan Date

The Exp. Rpl. Plan Date is a calculated measure used to audit the replenishment export. It is populated with the date and time that the replenishment was exported by the batch, if exported by the last batch run. Otherwise, it is empty.

Exp Rpl. Plan In Units

The Exp Rpl. Plan In Units is the same as the one in the availability profile. Refer to the measure, Exp. Rpl. Plan In Units, in the Availability Profile Measures.

Exp. Rpl. Plan Out Units

The Exp. Rpl. Plan Out Units is the same as the one in the availability profile. Refer to the measure, Exp. Rpl. Plan Out Units, in the Availability Profile Measures.

SKU Level (R & A) View - Replacement Profile Measures

The Replacement measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

Phs. Out PROD

The Phs. Out PROD is an editable measure used to select the phase-out product for the current product. You can select the product from a picklist populated with all available products within the workspace.

Phs. Out Subst. Date

The Phs. Out Subst. Date is an editable measure used to select the substitution date for the phased-out product.

Tot. On Hand Units

The Tot. On Hand Units is the same as the one in the availability profile. Refer to the measure, Tot. On Hand Units, in the Availability Profile Measures.

Tot. Booked Units

The Tot. Booked Units is the same as the one in the inventory profile. Refer to the measure, Tot. Booked Units, in the Inventory Profile Measures.

Tot. In Transit Units

The Tot. In Transit Units is the same as the one in the inventory profile. Refer to the measure, Tot. In Transit Units, in the Inventory Profile Measures.

Tot. In Transit

The Tot. In Transit is the same as the one in the inventory profile. Refer to the measure, Tot. In Transit, in the Inventory Profile Measures.

Tot. On Order (in) Units

The Tot. On Order (in) Units is the same as the one in the inventory profile. Refer to the measure, Tot. On Order (out) Units, in the Inventory Profile Measures.

Tot. On Order (out) Units

The Tot. On Order (out) Units is the same as the one in the inventory profile. Refer to the measure, Tot. On Order (out) Units, in the Inventory Profile Measures.

Tot. Cust. Order Units

The Tot. Cust. Order Units is the same as the one in the inventory profile. Refer to the measure, Tot. Cust. Order Units, in the Inventory Profile Measures.

Loc. On Hand Units

The Loc. On Hand Units is the same as the one in the inventory profile. Refer to the measure, Loc. On Hand Units, in the Inventory Profile Measures.

Loc. Booked Units

The Loc. Booked Units is the same as the one in the inventory profile. Refer to the measure, Loc. Booked Units, in the Inventory Profile Measures.

Loc. In Transit Units

The Loc. In Transit Units is the same as the one in the inventory profile. Refer to the measure, Loc. In Transit Units, in the Inventory Profile Measures.

Loc. In Transit

The Loc. In Transit is the same as the one in the inventory profile. Refer to the measure, Loc. In Transit in the Inventory Profile Measures.

Loc. On Order (in) Units

The Loc. On Order (in) Units is the same as the one in the inventory profile. Refer to the measure, Loc. On Order (in) Units, in the Inventory Profile Measures.

Loc. On Order (out) Units

Loc. On Order (out) Units is the same as the one in the inventory profile. Refer to the measure, Loc. On Order (out) Units, in the Inventory Profile Measures.

Cust. Order Units

The Cust. Order Units is the same as the one in the inventory profile. Refer to the measure, Cust. Order Units, in the Inventory Profile Measures.

Ph. Out On Hand Units

The Ph. Out On Hand Units is the same as the one in the inventory profile. Refer to the measure, Ph. Out On Hand Units, in the Inventory Profile Measures.

Ph. Out Booked Units

The Ph. Out Booked Units is the same as the one in the inventory profile. Refer to the measure, Ph. Out Booked Units, in the Inventory Profile Measures.

Ph. Out In Transit Units

The Ph. Out In Transit Units is the same as the one in the inventory profile. Refer to the measure, Ph. Out In Transit Units, in the Inventory Profile Measures.

Ph. Out In Transit

The Ph. Out In Transit is the same as the one in the inventory profile. Refer to the measure, Ph. Out In Transit in the Inventory Profile Measures.

Ph. Out On Order (in) Units

The Ph. Out On Order (in) Units is the same as the one in the inventory profile. Refer to the measure, Ph. Out On Order (in) Units, in the Inventory Profile Measures.

Ph. Out On Order (out) Units

The Ph. Out On Order (out) Units is the same as the one in the inventory profile. Refer to the measure, Ph. Out On Order (out) Units, in the Inventory Profile Measures.

Ph. Out Cust. Order Units

The Ph. Out Cust. Order Units is the same as the one in the inventory profile. Refer to the measure, Ph. Out Cust. Order Units, in the Inventory Profile Measures.

SKU Level (R & A) View - YTDYTG Profile Measures

The Year-To-Date Year-To-Go (YTDYTG) measure profile available in the SKU Level (R & A) view contains the following measures.

User Filter PROD - LOC

The User Filter PROD - LOC is the same as the one in the default profile. Refer to the measure User Filter PROD-LOC in the Default Profile Measures.

Tot. Init. Fcst Units

The Tot. Init. Fcst Units is the same as the one in the parameters profile. Refer to the measure, Tot. Init. Fcst Units, in the Parameters Profile Measures.

Actual Loc. Sales Units

The Actual Loc. Sales Units is the same as the one in the actuals profile. Refer to the measure, Actual Loc. Sales Units, in the Actuals Profile Measures.

Sell-Out Fcst (Wk) Units

The Sell-Out Fcst (Wk) Units is the same as the one in the forecast profile. Refer to the measure, Sell-Out Fcst (Wk) Units, in the Forecast Profile Measures.

Lifecycle Sales To-Date %

The Lifecycle Sales To-Date % is the same as the one in the default profile. Refer to the measure, Lifecycle Sales To-Date %, in the Default Profile Measures.

Lifecycle Sales To-Go %

The Lifecycle Sales To-Go % is the same as the one in the default profile. Refer to the measure, Lifecycle Sales To-Go %, in the Default Profile Measures.

Actual Loc. Recpt Units

The Actual Loc. Recpt Units is the same as the one in the actuals profile. Refer to the measure, Actual Loc. Recpt Units, in the Actuals Profile Measures.

Actual Loc. Shipmt Units

The Actual Loc. Shipmt Units is the same as the one in the actuals profile. Refer to the measure, Actual Loc. Shipmt Units, in the Actuals Profile Measures.

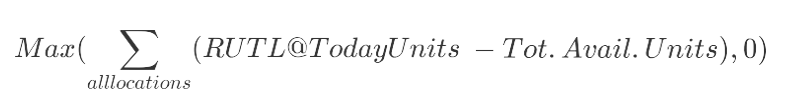

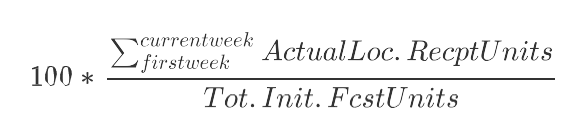

Lifecycle Receipt To-Date %

The Lifecycle Receipt To-Date % is a calculated measure used to indicate the percentage of actual receipts up to date against the total initial forecast.

Figure 20-22 Calculation

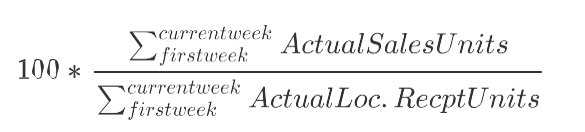

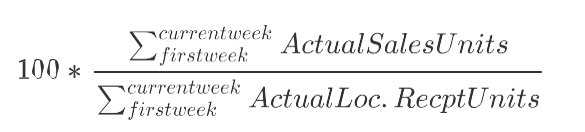

Lifecycle Sell-Thru %

The Lifecycle Sell-Thru % is a calculated measure used to indicate the percentage of lifecycle product’s sell-through.

Figure 20-23 Calculation

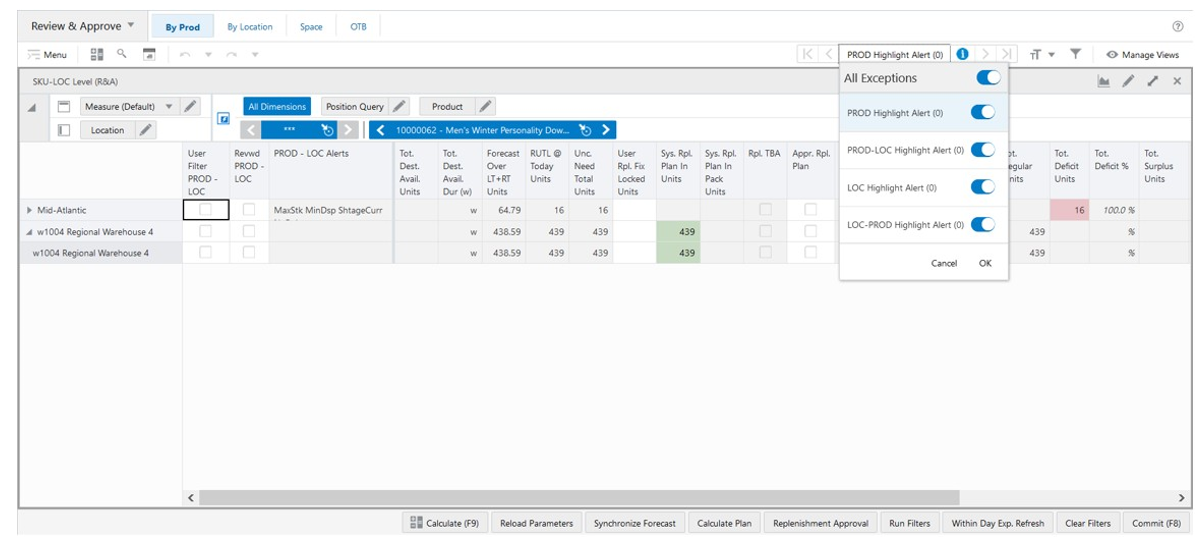

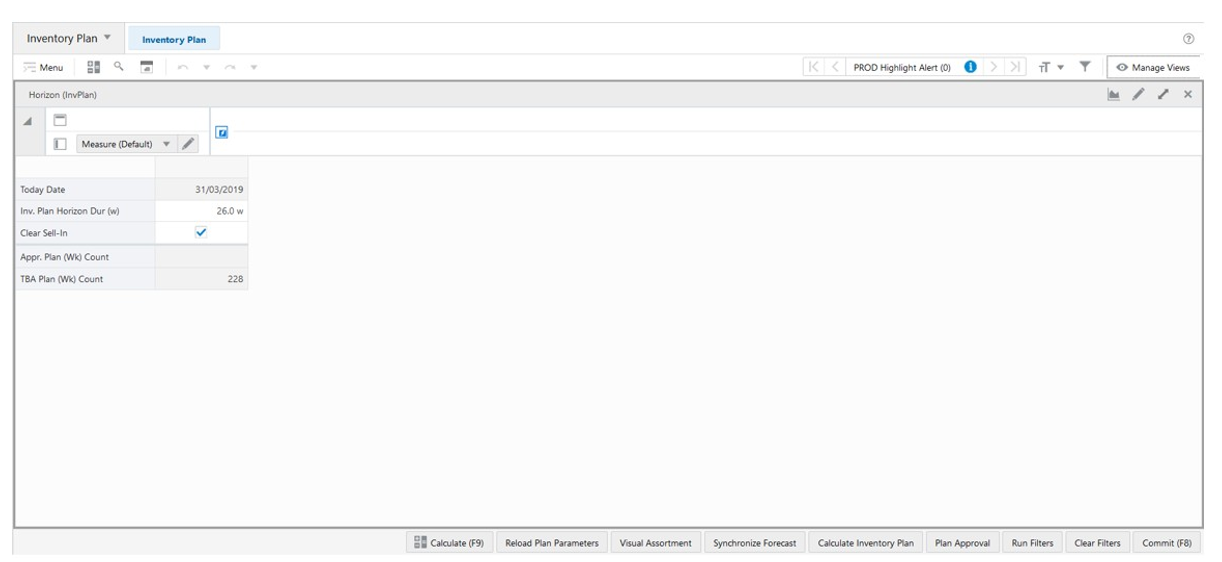

SKU-LOC Level (R & A) View

The SKU-LOC Level (R & A) View, under the By Prod tab, is similar to the view SKU Level (R & A) but allows you to do the review at the product and location levels.

The navigation of this view is driven by real-time alerts or workspace alerts. To leverage the real-time alert navigation in this workspace the desired alerts should be enabled as RTA (measure Enable RTA) in the To-Do List view.

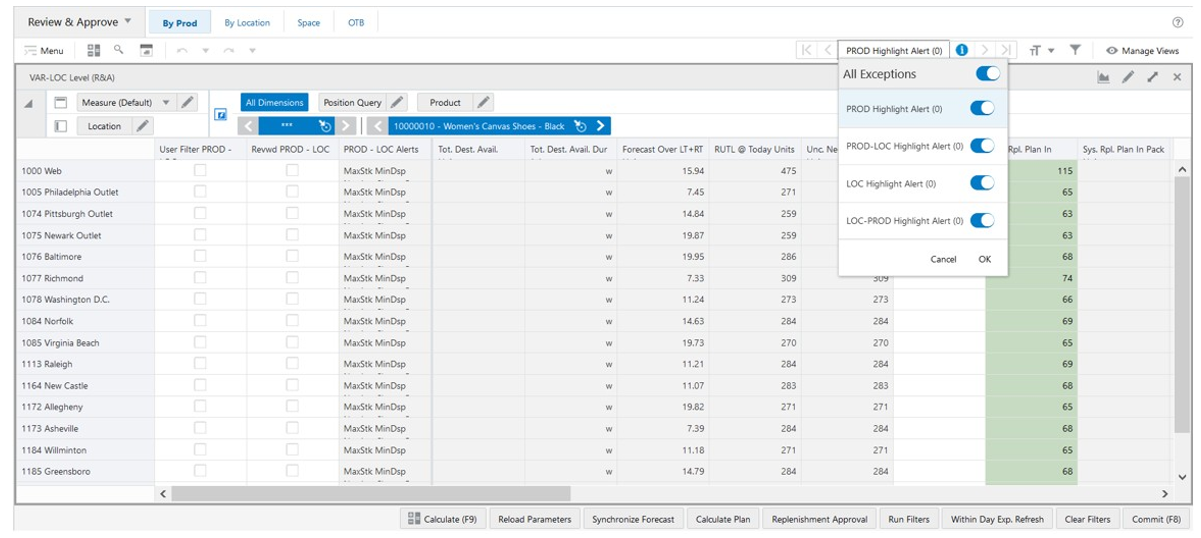

Figure 20-24 SKU-LOC Level (R & A) View

SKU-LOC Level (R & A) View - Default Profile Measures

The Default measure profile available in the SKU-LOC Level (R & A) view contains the following measures.

User Filter PROD-LOC

The User Filter PROD-LOC is an editable measure used to include specific product and location combinations into the quick filter. When selected, the quick filter restricts the condition to search only for the product and location combinations selected. When clear, the product and location combinations are not included in the filter condition.

Revwd PROD - LOC

The Revwd PROD - LOC is an editable measure used to indicate that the product and location combination alerts have been reviewed.

PROD - LOC Alerts

The PROD - LOC Alerts is a calculated measure used to display the Alert Short Descr. for all alerts that were triggered for the product and location combination.

Tot. Dest. Avail. Units

The Tot. Dest. Avail. Units is a calculated measure used to indicate the total quantity of units available at the location for the product and location combination.

Tot. Dest. Avail. Dur (w)

The Tot. Dest. Avail. Dur (w) is a calculated measure used to indicate the number of weeks that the Tot. Dest. Avail. Units can cover the demand for the product and location combination.

Forecast Over LT+RT Units

The Forecast Over LT+RT Units is a calculated measure to display the daily Forecast Demand for the product and location combination, in units, from the system date up to the number of days of Lead Time plus Review Time. The system date is available in the Today view.

RUTL @ Today Units

The RUTL @ Today Units is a calculated measure used to indicate the Reorder Up-to Level (RUTL) value in units for the product and location combination at the system date.

Unc. Need Total Units

The Unc. Need Total Units is a calculated measure used to indicate the total unconstrained quantity, in units, needed at the location for the product and location combination.

User Rpl. Fix Locked Units

The User Rpl. Fix Locked Units is an editable measure used to enter fixed replenishment units (order quantity) for the product and location combination. This measure overrides the product’s system-calculated replenishment units.

Sys. Rpl. Plan In Units

The Sys. Rpl. Plan In Units is a calculated measure used to indicate the order quantity for the product and location combination based on the location needs. This value is calculated based on the replenishment rules and the available forecast.

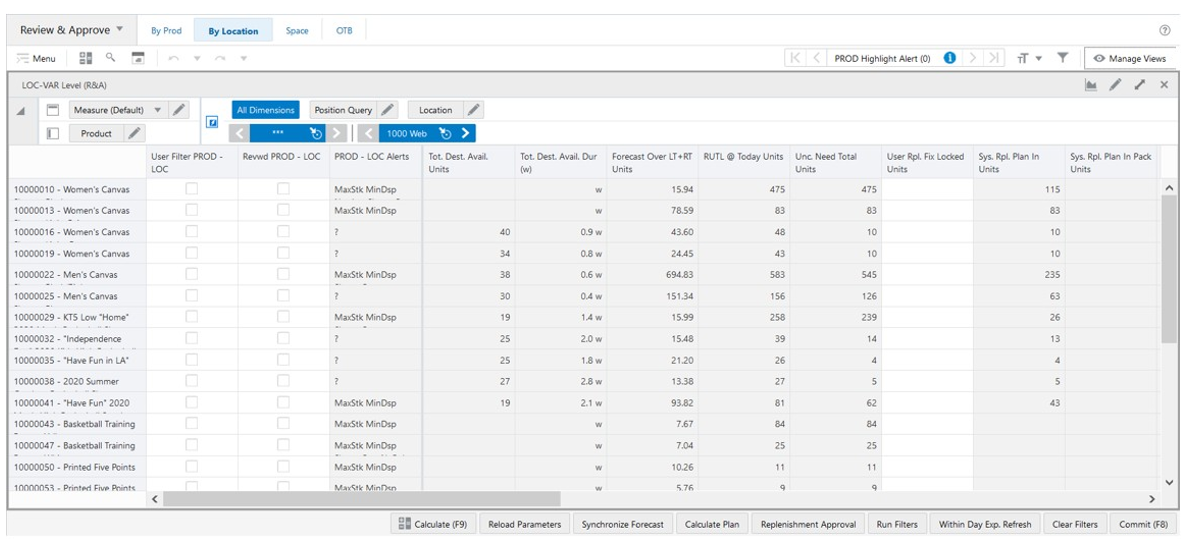

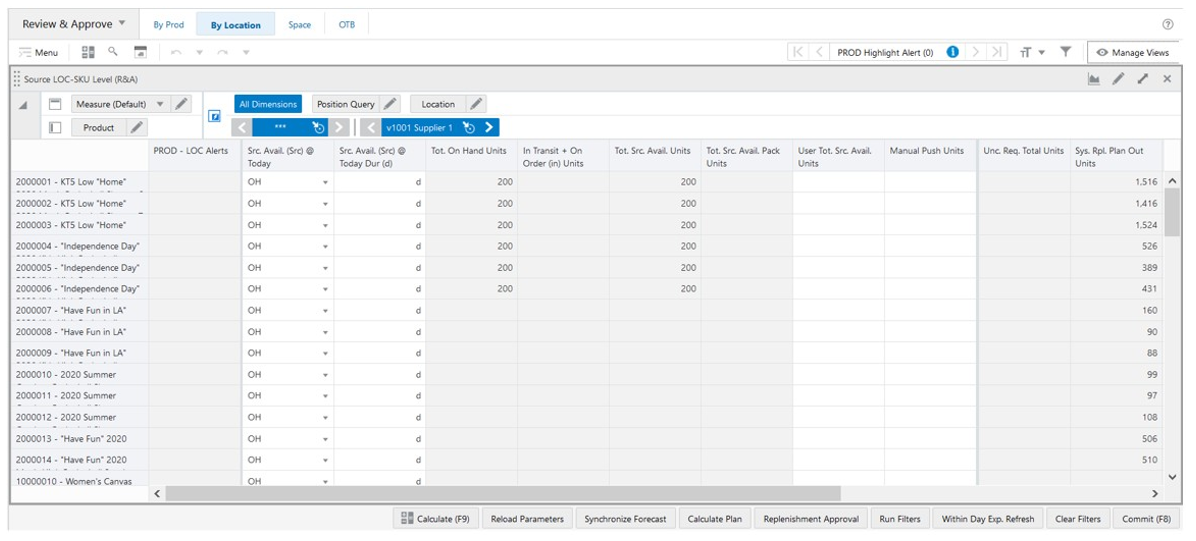

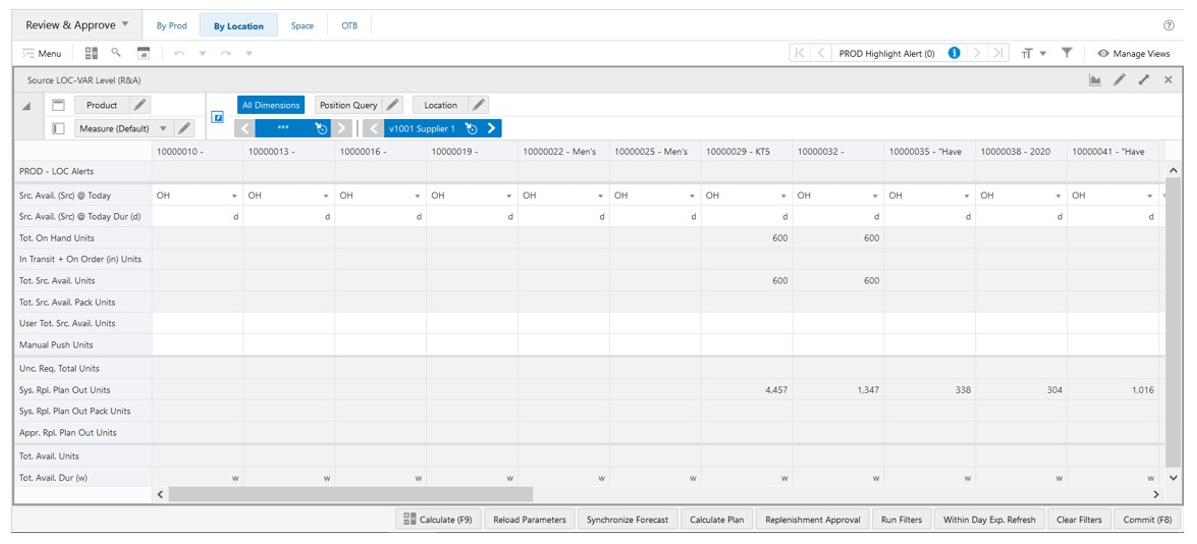

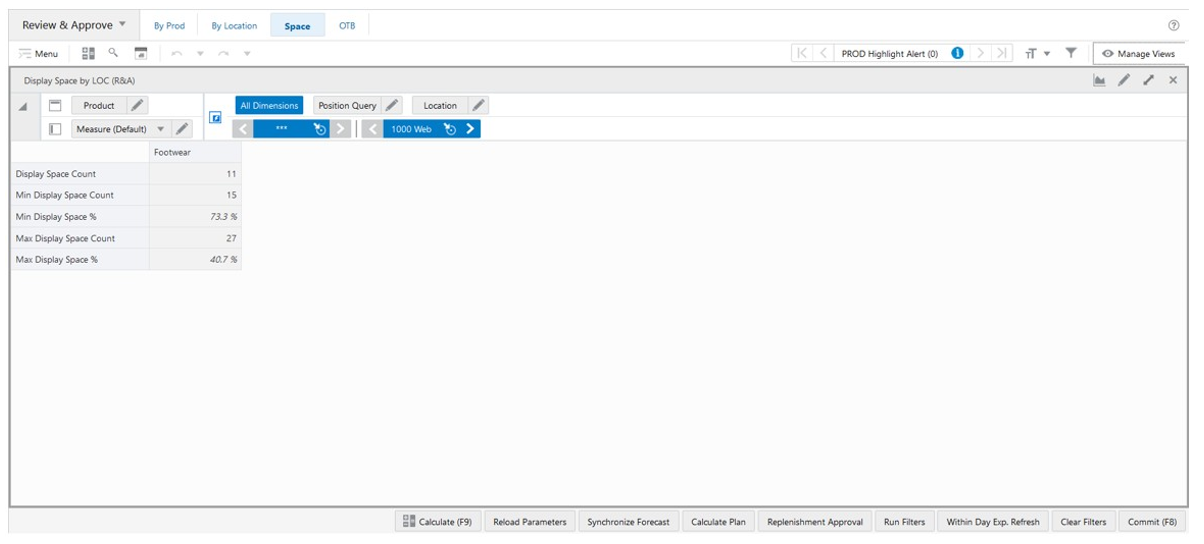

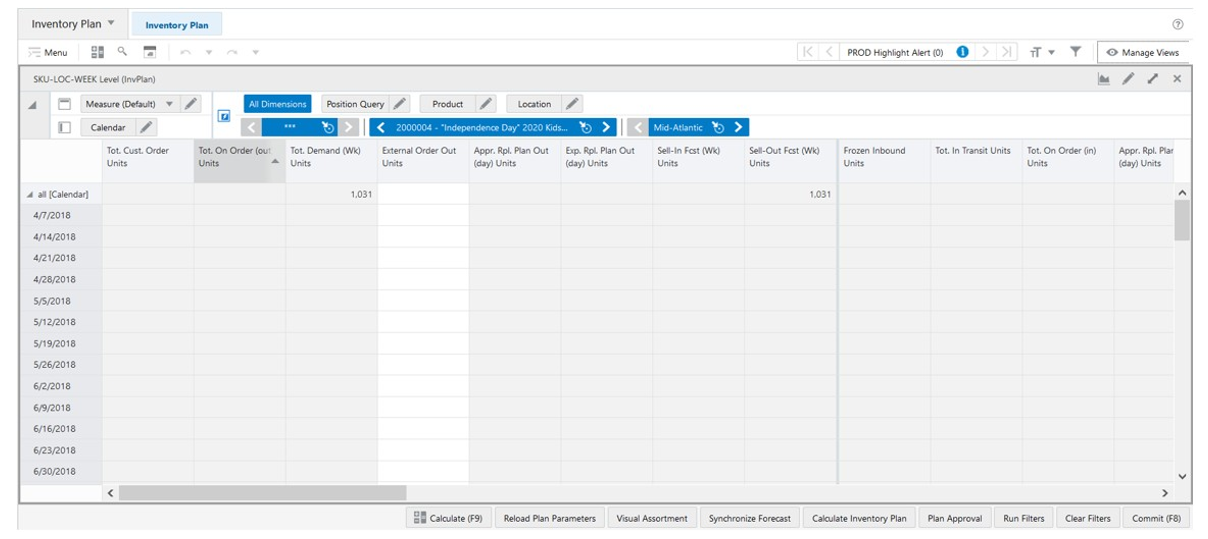

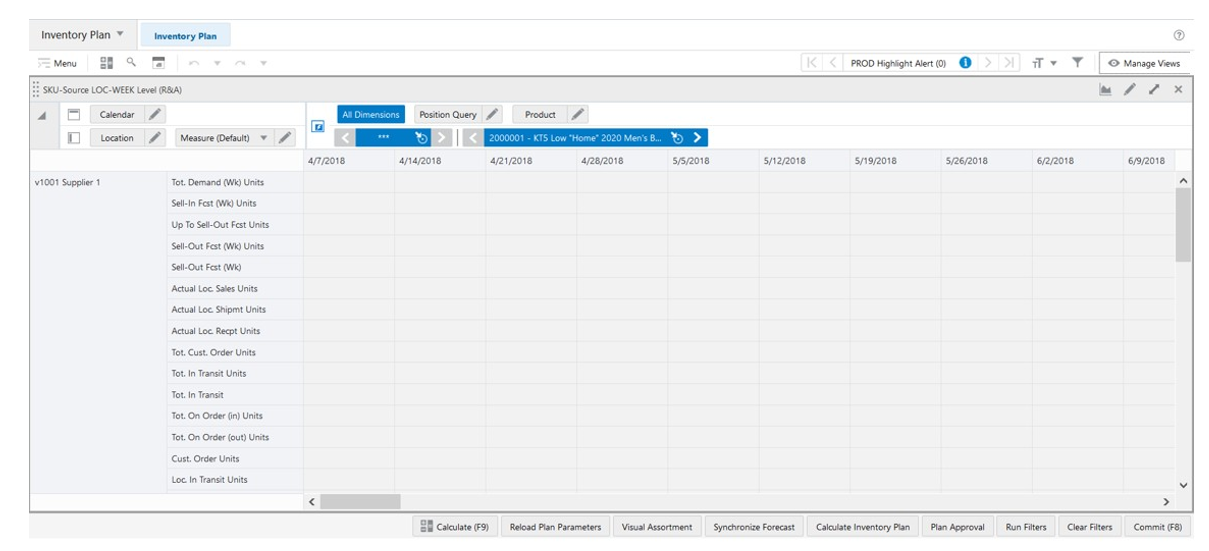

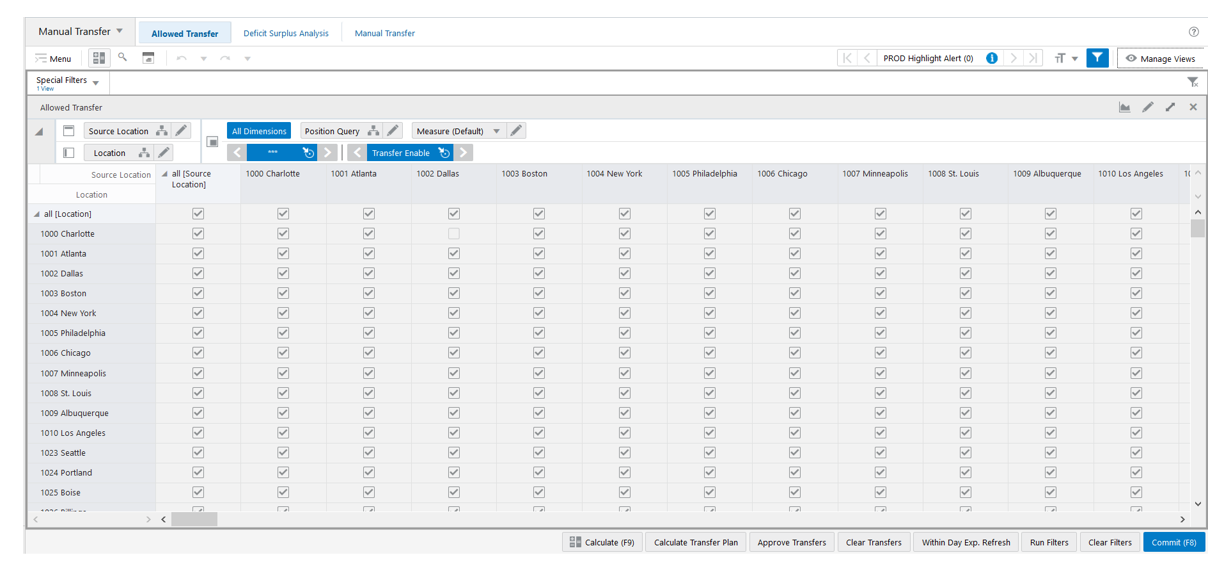

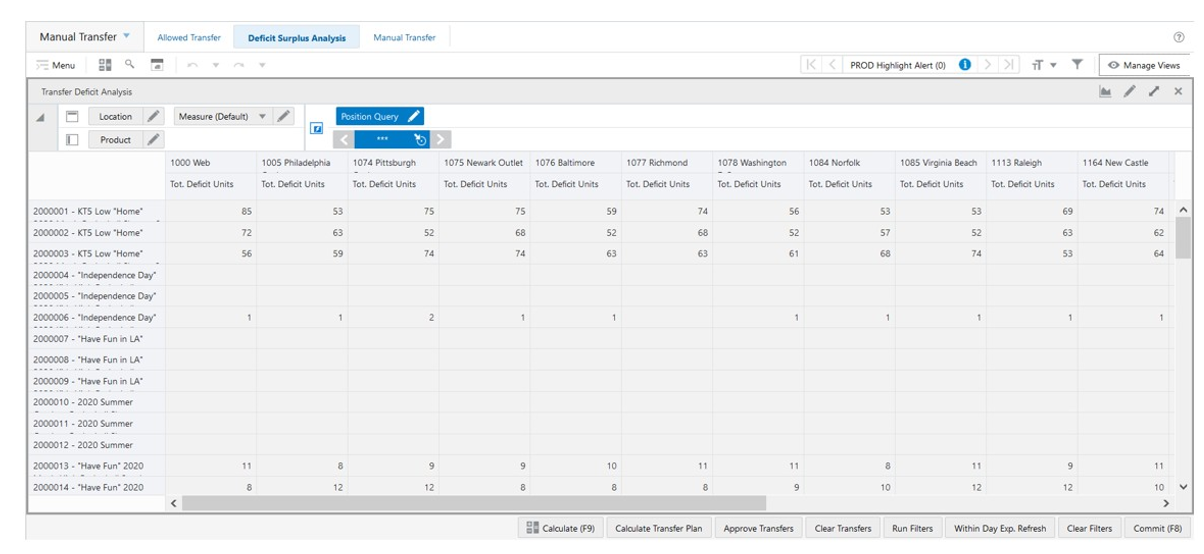

Sys. Rpl. Plan In Pack Units