13 Warehousing

Performing Inventory Transactions

Topics in this part: This part describes how to perform inventory transactions.

- Working with Inventory Transactions (WITI) tells you how to perform transactions which change inventory immediately.

- Working with Inventory Transaction Errors (WITE) allows you to review all of the errors that have occurred while performing inventory transactions.

- Finished Good Work Order Processing (WWOR) allows you to reserve component items while you assemble a finished good.

Transaction History

Topics in this part: The following topics describe the history information maintained for inventory transactions and how to display and print this information.

-

Display Inventory Transaction History (DITH) describes the amount of history available, describes the inventory transaction history scan screen, and tells you how to display a specific record.

-

Print Inventory Transaction History (PITH) tells you how to use the selection screen and how to print inventory transaction history. It also describes a sample report.

Inventory Transaction Setup

Topics in this part: The following topics describe the setup required to perform inventory transactions.

-

Work with Inventory Transaction Codes (WITC) explains the purpose of transaction codes, tells you how to work with the code scan screen, and tells you how to create, change, display, delete, and print transaction codes.

-

Work with Inventory Transaction Reason Codes (WIT1) explains how to use the Transaction Reason Code scan screen, and how to create, change, display, delete, and print a list of reason codes.

-

Verifying Inventory Sharing (VISH) explains how to generate the Verify Inventory Sharing Report, which lists the items in the sharing warehouse that are not setup correctly for inventory sharing.

Item Where Used

Topics in this part: The following topics describe the finished good explosion functions and the reports they produce.

-

Finished Good/Component On Hand (MFGO) defines the terms used in this topic.

-

Explode Finished Good Items (MKEX) defines the purpose of this function, describes the Finished Good Explosion screen, and describes a sample report.

-

Where Finished Good Component Item Usage (MKCU) defines the purpose of this function, displays the Where F. Good Component Item Usage screen, and explains the sample report.

-

Where Set Component Item Usage (MSCU) defines the purpose of this function, displays the Where Set Component Item Usage screen, and explains the sample report.

-

Where Variable Set Component Item Usage (MVCU) defines the purpose of this function, displays the Where Variable Set Component Item Usage screen, and describes the sample report.

Purchase Order Receipts

Topics in this part: The following topics describe the functions available when using receiving merchandise from your vendors.

-

Purchase Order Receiving Overview describes the options available when receiving purchase orders, explains how the system determines the cost of an item and how the Suggest Warehouse Placement function works, and shows you how to locate the function.

-

Working with P/O In Transit Information (MPIT) shows you how to quickly update a purchase order with shipping information.

-

Selecting Purchase Orders for Receipt (PORC) shows you how to enter the purchase order number you want to post receipts against, and how to scan for open purchase orders.

-

Receiving Purchase Orders (PORC) describes the various methods of posting receipts to a purchase order, shows you how to post receipts using each of the available methods, and describes each of the options available in PO receipts.

-

Placing Suspended Stock (SUSP) shows you how to transfer merchandise from suspense to inventory.

Purchase Order Receiving Overview

Purpose: Use purchase order receipts to record the receipt of inventory on open purchase orders.

You can record receipt:

-

in the warehouse, to record stock receipts immediately as merchandise is being brought into the warehouse.

-

as an office function, where receipts are entered after the merchandise is put away.

Purchase Order Receipt In API: You can use the Purchase Order Receipt In API to process PO receipts received from another system, such as a warehouse management system. See the Purchase Order Receipt In API for an overview and the required setup.

PO download triggers: The setting of the Create Generic PO Download Trigger for PO Receipt (K27) system control value determines whether the system creates a purchase order download (POH) trigger when a purchase order line is received. See Generic Outbound Purchase Order API for an overview.

For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1).

In this topic:

For more information:

Docking Stock

You have the option of recording a purchase order as "docked" before you receive it. A docked status indicates that you have received inventory associated with the purchase order, but have not yet confirmed items or quantities. You can dock a purchase order just once or many times for different deliveries. Until you actually receive the purchase order, inventory inquires do not indicate that any of the associated inventory is on-hand in your warehouse.

A standard process might include:

-

dock the purchase order

-

count the merchandise and perform quality control

-

receive the purchase order

Docking stock provides a record of when the inventory actually arrived at your warehouse, as opposed to when you completed quality control and recorded the receipt. This can be helpful if there is a question on whether the vendor delivered the merchandise on time.

If you dock stock, the system assigns a purchase order receipt control number at the time you dock it.

For more information: See Docking Purchase Orders.

Receiving Merchandise into Suspense

Receiving merchandise into suspense gives you the opportunity to inspect the merchandise before it becomes part of your inventory. Once the inventory has been inspected, you can transfer the inventory to its final destination. See Receiving into Suspense for more information.

Receiving Merchandise into a Pending Warehouse

Pending warehouses are warehouses where you can place inventory that is on its way to its final destination, for example, a staging area.

Use a pending putaway warehouse to temporarily store saleable inventory on its way to its final destination warehouse. Inventory received into a pending putaway warehouse retains its on order status so that the inventory is visible in PO Layering, yet the system recognizes the inventory as being in a warehouse location so that you can manipulate it.

You can define a warehouse as a pending warehouse using the Working with Default Warehouse Locations (WWDL) menu option.

When you place stock in a pending putaway warehouse, the system creates a record in the Pending Putaway Detail table. See Pending Putaway Overview for more information.

Suggest Location Placement

Use Suggest Location Placement to have the system recommend the locations where the inventory should be placed.

Values in the System Control table determine how this feature works. If you use a staging warehouse to receive inventory before you put it away, the system would suggest locations within your staging warehouse; the staging location indicates where the stock should ultimately be placed. See Working with Default Warehouse Locations (WWDL) for information on using a staging warehouse.

Additional Functions During Purchase Order Receiving

During Purchase Order Receiving, you can also add, change or view the messages associated with the purchase order, a line item on the purchase order, or with the vendor.

Warning about Conflicting Jobs

A warning pop-up window opens automatically when you select this option if Pick Slip Generation is active (in the Active Procedures table).

Reason: The warning pop-up window opens because each of these options affect inventory at the location level in the warehouse, as does the current option you are trying to use.

Responding to the Warning: Select OK to use the option anyway or select Exit to receive the items into inventory at a later time when the other jobs are finished running.

Note:

The warning pop-up window(s) opens again if you selected OK at the first warning window to perform the receipt, then selected Accept to accept your entries. You can select OK to continue or Exit to wait to receive the inventory until the conflicting job has finished.Receipt Cost Calculation

The system does not recalculate standard cost at purchase order receipt. You enter and maintain all cost information; the system does not update any cost information automatically.

The system retains the standard cost for each item, the cost at receiving for each receipt, and the cost at payables for each item invoiced. Overhead charges for a purchase order or a vendor/item are not included in the cost at receiving.

You can update the standard cost with the landed cost (primary vendor price + additional charges) through:

-

the Update Standard Cost periodic function (see Working with Periodic Functions (WPER))

-

creating your own query reports to compare the standard cost of an item against its current cost, and making any necessary adjustments manually.

The system includes the following in the receipt cost calculation:

-

cost of item

-

discounts: You can include the following discounts in the receipt cost calculation:

-

primary vendor discount: (from the Discount % (Primary discount percentage) field.

-

additional vendor discounts: Discounts in Work with Vendors.

-

vendor terms discount: from the Terms field. The Vendor Discount % to Costing at Receiving (D76) system control value must be selected in order for the system to include the vendor terms discount.

-

-

additional charges. You can include the following additional charges in the receipt cost calculation:

-

purchase order additional charges: You can define purchase order additional charges at the Work with PO Header Estimated Charges Screen and Work with PO Detail Estimated Charges Screen.

-

vendor item additional charges: You can define vendor item additional charges at the Work with Vendor Item Add’l Charges Screen.

-

-

costing calculation method: The system calculates the receipt cost using the item cost plus any additional charges and discounts.

Distributing Overhead Costs

Overhead costs: When you receive a shipment, you might incur additional costs that you want to distribute across the cost of all items received. These costs might include freight charges, duty charges, import charges, brokerage fees, commissions, surcharges or any other user-defined costs.

You can include overhead costs in the cost of an item by applying them to items:

-

received on a single purchase order

-

purchased from specific vendors

When the Allow Additional Costs to P/O Receipts (A60) system control value is selected, the system allows you to advance to the Work with Additional Charges, where you can enter the overhead costs associated with the purchase order.

Additional PO estimated charges: You can also define overhead costs to apply to each detail line on a purchase order or to a specific detail line on a purchase order if the Include PO Estimated Charges in Receipt Cost Calculation (G29) system control value is selected.

Additional charge calculation guidelines: The table below presents the guidelines the system uses in determining the purchase order additional charges to factor into the cost of an item at purchase order receipt when using receipt controls.

| Standard PO Receipt Cost Calculation Method | Vendor Item Additional Charges (Charges in WVNI) | PO Additional Estimated Charges (Est charges when creating the PO or Estimated charges when maintaining) |

|---|---|---|

|

NA |

All, whether unit or percentage, if Default Vendor Item Additional Charges (I21) is selected and Include PO Estimated Charges in Receipt Cost Calculation (G29) is selected |

All, whether unit or percentage, if Include PO Estimated Charges in Receipt Cost Calculation (G29) is selected |

Which costs are updated? The Average cost and the Last purchase cost in the SKU table are always updated when you receive a purchase order.

The standard cost is not updated at purchase order receipt.

Note:

Additional charges you enter by selecting Add’l Charges when receiving a specific purchase order do not update any of the costs in the SKU table.Additional costing factors: The following system control values control the discounts you factor into the Last purchase cost in the SKU table based on purchase order receiving:

-

Vendor Discount % to Costing at Receiving (D76): If this field is selected, the system applies the terms code assigned to the vendor through Working with Vendors (WVEN), and subtracts the related discount percentage from the cost at receiving.

-

Apply Discount To Manual Cost (D96): If this field is selected, the system subtracts any discounts assigned to the vendor.

Receiving Inventory

Receiving choices: You can receive merchandise:

-

Directly into inventory: the system updates inventory immediately, and the merchandise is available to be reserved and picked. See Receiving into Inventory.

-

Into suspense: inventory is not updated until the merchandise is transferred from suspense to inventory. Suspended merchandise is not available for reservation and picking. You control whether merchandise can be received into suspense by completing the Allow Receipt to Suspense (A59) system control value. You can receive an entire purchase order into suspense, or only specific items. You determine how the inventory will be received during purchase order receipts. See Receiving into Suspense.

-

Into a pending putaway warehouse: the system creates a record in the Pending Putaway Detail table and creates a PO layering record for the “final destination” warehouse. The pending putaway detail record indicates the quantity to be placed in the “final destination” warehouse and the expected due date when the inventory will be moved. See Receiving into a Pending Warehouse.

-

Into a staging warehouse: you would normally define the staging warehouse as non-allocatable, and the staging locations as non-pickable, to prevent the system from attempting to reserve or pick from the staging area. See Receiving into a Staging Warehouse.

When the entire quantity of the item is received, the purchase order detail line is closed. When the entire purchase order is received, the purchase order is closed. See Receiving Overages and Underages for information on special receipt quantities.

Receiving into Inventory

When merchandise is received directly into inventory, it is available for reservation and picking immediately.

If you receive merchandise directly into inventory, the following system updates occur at receiving:

-

The on-order quantity for the item is decreased

-

The on-hand quantity of the item is increased in the item warehouse and the item location.

-

Vendor item analysis is performed

All or part of a purchase order can be received into inventory.

You can use the Suggest Location Placement function to recommend the locations where the items should be placed when the inventory is received. See Suggest Warehouse/Location Placement.

Receiving into Suspense

Placing merchandise into suspense can help you quickly move merchandise from the loading dock to a secured setting where it can be processed for quality control.

When merchandise is received into suspense:

-

It is not available for order fulfillment.

-

Inventory is not updated until the merchandise is transferred from suspense to inventory.

-

Suspended merchandise is not available for reservation and picking.

To receive into suspense: You can receive merchandise into suspense only if the Allow Receipt to Suspense (A59) system control value is selected.

Inventory can be received into suspense using the Work with P/O Receipt Detail Screen:

-

You can receive the entire balance of the purchase order into suspense using the Receive Suspense option. In this situation, the quantity due for each item on the purchase order is placed into suspense and the purchase order is closed. See Receiving an Entire Purchase Order Into Suspense for instructions.

-

You can receive a purchase order line into suspense using the Suspense On/Off option: Select this option for an item on a purchase order to change the suspense receiving status of the line. The word

Suspensedisplays next to the Location field and indicates the line item will be placed into suspense when the purchase order is accepted. If the wordSuspenseis not displayed, the quantity received for the line will be placed into inventory. A Location is not required if you are placing the item into suspense. See Using the Direct Entry Method or Using the Change Purchase Order Details Method for instructions on working with individual line items during PO Receipts.

Suspense updates: The system performs the following updates when merchandise is received into suspense:

-

Creates a record in the PO Suspense table for each purchase order line indicating the quantity received into suspense.

-

Creates a record in the PO Receipt table for each purchase order line, with the Suspense flag set to Y.

-

Updates the Received quantity for each purchase order line on the Purchase Order History screen by the quantity received into suspense.

-

Decreases the Quantity Due for each purchase order line on the First Display Purchase Order Detail Screen by the quantity received into suspense.

-

Updates the Suspense quantity on the Display Item/Warehouse Information Screen by the quantity received into suspense.

The following updates do not occur when merchandise is received into suspense:

-

The on-hand quantity for the item is not changed.

-

The costing calculation is not performed.

-

Vendor Item analysis is not performed.

These updates occur when the merchandise is transferred from suspense to inventory using the Placing Suspended Stock (SUSP) menu option.

Receiving into a Pending Warehouse

Pending warehouses are warehouses where you can place inventory that is on its way to its final destination, for example, a staging area. Inventory in a pending warehouse is not available for reservation and picking.

Use a pending putaway warehouse to temporarily store saleable inventory on its way to its final destination warehouse. Inventory received into a pending putaway warehouse retains its on order status so that the inventory is visible in PO Layering, yet the system recognizes the inventory as being in a warehouse location so that you can manipulate it.

You can define a warehouse as a pending warehouse using the Working with Default Warehouse Locations (WWDL) menu option.

When you receive merchandise into a pending warehouse, the system performs the following updates at receiving time:

-

Creates a pending putaway detail record. If a pending putaway detail record already exists for the purchase order and item/SKU, the system adds the receipt quantity to the existing pending putaway detail record. The pending putaway detail record indicates:

-

The quantity of the item in the pending warehouse for this receipt. The on hand quantity for the item at the item warehouse level indicates the total pending putaway quantity for the item.

-

The “final destination” warehouse where the inventory will be placed.

-

The expected due date of the inventory; this due date is displayed in order entry, order maintenance, standard or streamlined order inquiry, inventory inquiry, and item availability for the “final destination” warehouse.

-

-

Creates a PO layering record for the “final destination” warehouse.

-

Decreases the on-order quantity for the item in the “final destination” warehouse.

-

Creates an inventory transaction history record for the pending warehouse.

The following updates do not occur when merchandise is received into a pending warehouse.

-

The on-hand quantity for the item in the "final destination" warehouse is not changed.

-

The costing calculation is not performed.

-

Vendor Item analysis is not performed

These updates occur when the merchandise is transferred from the pending putaway warehouse to the "final destination" warehouse.

See Pending Putaway Overview for an overview of the updates the system performs when you place inventory into a pending warehouse.

Receiving into a Staging Warehouse

When you receive into a staging warehouse, the same updates take place at receiving as when you receive into inventory. However, you normally define the staging warehouse to be non-allocatable and non-viewable in Order Entry, and define each location to be non-pickable; the result is that the inventory is not generally available or visible on the system until you place it in your main warehouse.

See Working with Default Warehouse Locations (WWDL) for an overview of defining default locations within a staging warehouse.

Suggest Warehouse/Location Placement

Purpose: Use the Suggest Location Placement function to have the system determine where merchandise should be placed. The system searches through the available locations in your warehouse to determine where you should place the merchandise. You can accept, reject or change any of the system suggested placements for an item.

When suggest placement is used: Suggest Location Placement can be used during the following functions:

-

Receiving Purchase Orders (PORC): when merchandise is being received into inventory

-

Placing Suspended Stock (SUSP): when merchandise is being transferred from suspense to inventory

-

Suggest Location Placement (MSLO): when you are placing items in locations independent of the Purchase Order Receipts and Place Suspended Stock functions.

Standard Warehouse/Location Placement

Purpose: The system will attempt to place the merchandise in a single location where the item is currently stored, if possible. If a single location cannot be found, the system will spread the merchandise across as many locations where the item is stored as is necessary. If the full quantity cannot be placed in existing item locations, the system will search for any suitable location (e.g., a location class compatible with the item type, a location that is not frozen, etc.) that can hold the placement quantity.

Note:

The Suggest Location Placement function searches existing warehouse locations only; new warehouse locations will not be created using this function.Your company decides the criteria for how locations are suggested and the order in which the system will search for available locations.

System Control Values

The following values in the System Control table allow you to define whether to use suggest placement, and how the system will search for available locations when recommending stock placements. The following values are used:

-

Suggest Location Placement (A27), which controls whether the function is used.

-

Type of Location to Search First during Suggest Location Placement (C40), which defines the location type that will be searched first.

-

Type of Location to Search Second during Suggest Location Placement (C41), which defines the location type that will be searched second.

-

Type of Location to Search Third during Suggest Location Placement (C42), which defines the location type that will be searched last.

-

Suggest Multiple Items in a Location during Suggest Location Placement (C43), which determines whether the merchandise can be placed in a location the contains other merchandise when the system is searching for any available location.

-

Location Capacity Method (A31), which determines how the system determines when a location is full.

Suggest Location Placement searches primary, secondary and bulk locations in the sequence you define. You do not have to include all three location types. For example, you can choose to suggest only primary locations, or only bulk and secondary locations for item placements. Temporary locations cannot be recommended for placements.

Searching for Locations

The Suggest Location Placement program searches for a location as follows:

-

First, search locations whose Location type code matches the Type of Location to Search First during Suggest Location Placement (C40) in location code sequence until it finds a single location for the placement; otherwise,

-

Search locations whose Location type code matches the Type of Location to Search Second during Suggest Location Placement (C41) until it finds a single location for the placement; otherwise,

-

Search locations whose Location type code matches the Type of Location to Search Third during Suggest Location Placement (C42) until it finds a single location for the placement; otherwise,

-

If the full quantity cannot be placed in one location, search through all applicable locations again, in the same sequence, and fill each eligible location to capacity until the full quantity has been placed; otherwise,

-

If the full quantity cannot be placed in the existing locations where the item is stored, search for any available location in the warehouse that can hold the full placement quantity. If the Suggest Multiple Items in a Location during Suggest Location Placement (C43) value is selected, the program places two different items in the same location if it can hold the full capacity; otherwise, if the value is unselected, the program evaluates only empty locations.

Determining Location Capacity

The system evaluates the location capacity when determining whether the placement quantity can fit in a location. The location capacity can be evaluated by units, by cubic volume, or by weight. The unit capacity, cubic capacity, and weight capacity for a location are defined in the Location table. See Creating and Maintaining Locations (WLOC).

Determining Location Capacity by Units

When determining capacity by units, the system evaluates the number of units currently on hand in the location against the placement quantity to determine if the quantity can fit in the location. The total quantity cannot exceed maximum number of units from the Item Location table or the Location table.

In addition, the system checks the combined item weight to ensure that the location can support the on-hand quantity and the proposed placement quantity.

Determining Location Capacity by Volume

When determining capacity by volume, the system evaluates the cubic volume of the units currently on hand in the location against the cubic volume of the placement quantity to determine if the quantity can fit in the location. The Fill factor defined for the location is used to determine the total cubic volume that can fit in the location. See Creating and Maintaining Locations (WLOC).

If item dimensions (height, length, and width) are defined in the Item/SKU table, the item dimensions will be used to calculate the cubic volume. If item dimensions are not defined, the Cube factor is used.

In addition, the system checks the combined item weight to ensure that the location can support the on-hand quantity and the proposed placement quantity.

Receiving Overages and Underages

Overages: At times, a vendor may overship an item. The Over Receipt % (A61) value in the System Control table allows you to receive more than the quantity ordered for an item if the quantity received is within the tolerance limit.

If a vendor ships you more merchandise than you ordered, the system allows you to record the receipt if the overage is within an acceptable tolerance limit. For example, if you set the Over Receipt % (A61) to 10%, you can receive a quantity up to ten percent above the amount that was ordered. If the overage exceeds the tolerance amount, the following message indicates:

Invalid over receipt quantity

The Override Tolerance (A18) value in the Security table lets you accept any overage amount the vendor may ship. When this option is allowed, the system accepts any receipt quantity you enter without displaying a message.

Underages: At times, a vendor may under-ship an item and may not be able to fulfill the entire purchase request. The Under Receipt % (A62) value in the System Control table allows the system to close a purchase order line if only a certain percentage of the order quantity is received.

If a vendor short-ships an item and the quantity received is within the defined tolerance, the purchase order line will be closed even if the full order quantity was not received. This allows you to close purchase order lines when vendors short-ship merchandise and are unable to complete the shipment.

For example, if you define the Under Receipt % (A62) at 10%, a purchase order line will be closed when at least 90% of the merchandise is received. If you order 100 units and receive 92 units, the line will be closed when the receipt for 92 units is accepted.

If the vendor ships you the balance of the merchandise at a later time, you can add a line to the purchase order during Purchase Order Receipts to record the additional receipt, if you have the proper authority. The Add PO Detail Line during PO Receipts (A21) value in the Security table determines whether you can add lines to a purchase order at receiving.

Managing Warehouses

Topics in this part: The following topics describe the functions available from the Warehouse Management menu. These functions are used to define your warehouses, establish warehouse locations and assign inventory, and analyze your current warehouse utilization.

-

Creating and Maintaining Warehouses (WWHS) shows you how to establish each of your warehouses on the system. In addition, this topic explains how to define the warehouse sequence to use when you fulfill customer orders from more than one warehouse.

-

Creating and Maintaining Location Classes (WLCL) explains how location classes can be used to define the type of merchandise that will be stored in a warehouse location.

-

Creating and Maintaining Locations (WLOC) shows you how to define the locations in the warehouse where merchandise is stored. Warehouse locations can be comprised of a series of zone, aisle, shelf, and bin indicators, or they can be free-form user-defined location codes.

-

Using the Location Generator (MLOC) explains how to use the automated location generator to create multiple warehouse locations at the same time.

-

Creating Item Warehouse/Locations (MIWL) shows you how to assign an item to a warehouse location or change existing item location information, or change existing item warehouse information.

-

Suggest Location Placement (MSLO) describes how to use the Suggest Warehouse Placement function to have the system determine the warehouse location where an item should be stored.

-

Creating and Maintaining Item Warehouses describes how to assign items to a warehouses and how inventory history is captured for each item at the warehouse level.

-

Working with Default Warehouse Locations (WWDL) describes how to create and work with the default locations the system checks automatically for certain inventory transactions.

-

Pending Putaway Overview describes the updates the system performs when you place inventory into a pending putaway warehouse.

Creating and Maintaining Item Warehouses

Purpose: Work with Item Warehouses is used to change, delete, display, or create item warehouse records. An item warehouse record must exist for each item/SKU that is stocked in the warehouse. These records also provide the ability to capture inventory history for each item/SKU in the warehouse.

Item warehouse records are created automatically during item setup using the Work with Items function or the SKU Generator if you specify a warehouse for the item/SKU. Use the Work with Item Warehouse function to assign an item to a warehouse manually, if the item was not stocked in the warehouse at the time of setup.

In this topic:

Reset On-Order PO Quantity Periodic Function

You can use the PORST periodic function to reset the open PO quantities in the Item Warehouse table based on purchase order detail lines that are open or held, or received into suspense or into a pending putaway warehouse location.

Sample setup: Enter the following at the Create Periodic Function Screen:

-

Function: PORST

-

Description: PO On Order Reset

-

Company parameter: Y

-

Appl area: ALL

-

Program name: OER1018

Add to periodic process: You can, optionally, add this periodic function to a periodic process at the Work with Periodic Processes Screen, select Functions.

You can also run the on-order reset through the Unlock Purchase Order (MUPO) menu option.

Inventory Extract Periodic Function

Use the Inventory Extract INVEXT periodic function (program name URR0003) to create records in the Inventory Extract table for each item location in your company. You can use the Inventory Extract table to determine the on-hand inventory for each item/SKU in your company.

No on-hand quantity: If all of the item locations for an item/SKU have an on-hand quantity equal to or less than zero, the system creates only 1 record in the Inventory Extract table for the item/SKU. This 1 record indicates that the item/SKU does not have any on-hand inventory.

-

The location for this inventory extract record is the primary primary location for the item.

-

If a primary primary location has not been defined for the item, the location for this inventory extract record is blank.

Note:

The “primary primary” location is stored in the Primary location field in the SKU table.Records remain in the Inventory Extract table until they are downloaded to another system. It is your responsibility to delete the records in the Inventory Extract table. Each time you run the On-Hand by Location Extract program, the system appends records to this table; because of this, duplicate records may exist in the table.

Work with Item Warehouse Screen

Purpose: Use this screen to create, change, delete, or display records that define the items that are stocked in the warehouse. An item/warehouse record must exist for each item/SKU in the warehouse.

How to display this screen:

-

Select Items for the desired warehouse at the Work with Warehouses Screen.

-

Select Warehouse for the item at the Work with Items Screen.

| Field | Description |

|---|---|

|

Item |

The number of the item assigned to the warehouse. Alphanumeric, 12 positions; optional. |

|

SKU |

The Split SKU codes associated with the item. The three elements (color, size, and width) are used to further identify the item. Note: The SKU elements are defined in the System Control table.Alphanumeric, three 4-position fields; optional. |

|

On-hand |

The number of units of this item across all locations in the warehouse. Numeric, 7 positions; optional. |

|

On order |

The total quantity of this item in this warehouse that is due to be received through purchase orders. Numeric, 7 positions; optional. |

|

Protected |

An amount of inventory that cannot be reserved using immediate or batch reservation for this item or SKU across all locations in this warehouse. Numeric, 7 positions; optional. |

|

Reservation freeze |

Indicates whether the item or SKU in this warehouse is on hold, or frozen. Valid values are:

If an item or SKU warehouse is frozen:

|

| Screen Option | Procedure |

|---|---|

|

Create an item warehouse record |

Select Create to advance to the Create Item Warehouse Screen. |

|

Change item warehouse information |

Select Change for an Item Warehouse record to advance to the Change Item Warehouse Screen. See the Create Item Warehouse Screen for field descriptions. |

|

Delete item warehouse information |

Select Delete for an Item Warehouse to delete it. Note: You cannot delete an item warehouse record if there are any on-hand quantities, open purchase order quantities, or backordered or reserved quantities for the item in the selected warehouse. If there are any Item Location records or Item Warehouse History records associated with this item and warehouse, the system will display a warning message:

|

|

Display item warehouse information |

Select Display for an Item Warehouse record to advance to the Display Item Warehouse Screen. |

|

Work with locations |

Select Locations for an Item Warehouse record to advance to the Work with Item Locations Screen. |

|

Display Pending Put away Details |

Select Pend Putaway for an Item Warehouse record to advance to the Display Pending Putaway Details Screen. |

Create Item Warehouse Screen

Purpose: Use this screen to create an item warehouse.

The Work with Items function and the SKU generator automatically create Item Warehouse records if you enter a warehouse code, and Item Location records if you enter a location code during item setup. See Creating Item Warehouse/Locations (MIWL).

How to display this screen: At the initial Work with Item Warehouse Screen, select Create.

| Field | Description |

|---|---|

|

Item |

The item number you are assigning to the warehouse. The item number is validated against the Item/SKU table. Alphanumeric, 12 positions. Create screen: required. Change screen: display-only. |

|

Colo/Styl/Size |

The Split SKU codes associated with the item. The three elements (color, style, and size) are used to further identify the item. The SKU codes entered are validated against the SKU tables. Note: The SKU elements are defined in the System Control Table.Alphanumeric, three 4-position fields. Create screen: required, if applicable. Change screen: display-only. |

|

Reservation freeze |

Indicates whether the item or SKU in this warehouse is on hold, or frozen. Valid values are:

If an item or SKU warehouse is frozen:

|

|

Protected qty |

An amount of inventory that cannot be reserved (using immediate or batch reservation) for this item/ SKU across all locations in this warehouse. The system will only use this inventory in Interactive Reservation. Numeric, 7 positions; optional. |

|

Min qty |

The least amount of inventory on hand for this item/ SKU. An error message indicates if you try to enter a minimum quantity and you do not have authority to the Maintain Item Warehouse Minimum/Maximum Quantity (A92) secured feature:

Numeric, 7 positions; optional. |

|

Protect min/max (Protect minimum and maximum quantities) |

This field is not currently implemented. This field is included only if the Use Store File (G15) system control value is selected. An error message indicates if you try to change this value and you do not have authority to the Maintain Item Warehouse Minimum/Maximum Quantity (A92) secured feature:

|

|

Max qty |

The maximum amount of inventory on hand for this item/SKU. An error message indicates if you try to enter a maximum quantity and you do not have authority to the Maintain Item Warehouse Minimum/Maximum Quantity (A92) secured feature:

Numeric, 7 positions; optional. |

|

Economic order qty |

The recommended optimum ordering quantity for this item/SKU, based on a set of criteria such as cost. Used for inventory reporting purposes. Numeric, 7 positions; optional. |

|

Reorder qty |

Defines the quantity of this item/ SKU that should be ordered when the item/ SKU reaches the minimum stock level. Numeric, 7 positions; optional. |

|

Original retail price |

The original price of this item in the retail store. You can use this field to track the original retail price for the item if the warehouse represents a retail store. This field is included only if the Use Store File (G15) system control value is selected. An error message indicates if you try to enter a price and you do not have authority to the Maintain Item Warehouse Retail Price (A91) secured feature:

Numeric, 13 positions with a 2-place decimal; optional. |

|

Protect price (Protect current price) |

This field is not currently implemented. This field is included only if the Use Store File (G15) system control value is selected. An error message indicates if you try to change this value and you do not have authority to the Maintain Item Warehouse Retail Price (A91) secured feature:

|

|

Current retail price |

The current price of this item in the retail store. You can use this field to track the current retail price for the item if the warehouse represents a retail store. This field is included only if the Use Store File (G15) system control value is selected. An error message indicates if you try to enter a price and you do not have authority to the Maintain Item Warehouse Retail Price (A91) secured feature:

Numeric, 13 positions with a 2-place decimal; optional. |

|

User field 1 |

An informational field where you can enter additional item warehouse information. Alphanumeric, 10 positions; optional. |

|

User field 2 |

An informational field where you can enter additional item warehouse information. Alphanumeric, 10 positions; optional. |

Display Item Warehouse Screen

To display: Select Display for an item warehouse at the Work with Item Warehouse Screen to advance to the Display Item Warehouse screen. You cannot change any fields on this screen.

| Field | Description |

|---|---|

|

Item |

The item number assigned to the warehouse. Alphanumeric, 12 positions. |

|

SKU |

The SKU associated with the item. Alphanumeric, three 4-position fields. |

|

Warehouse |

The code and description of the warehouse where the item is located. Code: Numeric, 3 positions. Description: Alphanumeric, 30 positions. |

|

Reservation freeze |

Indicates whether the item or SKU in the warehouse is on hold, or frozen. Valid values are:

If an item or SKU warehouse is frozen:

|

|

Economic order qty |

The recommended optimum ordering quantity for this item/SKU, based on a set of criteria such as cost. Used for inventory reporting purposes. Numeric, 7 positions. |

|

Backorder qty |

The quantity of the item/SKU in this warehouse that is currently on open orders but not available in your warehouse. Numeric, 7 positions. |

|

Protected qty |

The amount of inventory that cannot be reserved (using immediate or batch reservation) for this item/ SKU across all locations in this warehouse. The system will only use this inventory in Interactive Reservation. Numeric, 7 positions. |

|

Min qty |

The least amount of inventory on hand for this item/ SKU. Numeric, 7 positions. |

|

Max qty |

The maximum amount of inventory on hand for this item/SKU. Numeric, 7 positions. |

|

Reorder qty |

Defines the quantity of this item/SKU that should be ordered when the item/ SKU reaches the minimum stock level. Numeric, 7 positions. |

|

Reserve quantity |

The quantity of this item/SKU in this warehouse that is reserved for existing orders. This total increases through immediate, batch, and interactive reservation, and decreases through confirmation or pick void/reprint. Numeric, 7 positions. |

|

On hand quantity |

The number of units of this item in all locations in this warehouse. Numeric, 7 positions. |

|

On order quantity |

The total quantity of this item in this warehouse that is due to be received on open purchase orders. This quantity increases when you enter a purchase order and decreases when you receive a purchase order. If you receive purchase orders into suspense, the suspended quantity remains in this total until you place the suspended stock. Numeric, 7 positions. |

|

S/H reserve qty |

The quantity of this item/SKU in this warehouse that is reserved for existing orders and requires special handling. This total increases through immediate, batch, and interactive reservation, and decreases through confirmation or pick void/reprint. Numeric, 7 positions. |

|

Reserve transfer qty |

The quantity of this item/SKU in this warehouse that is set to be transferred to another warehouse through replenishment. Numeric, 7 positions. |

|

Protect min/max |

This field is not currently implemented. This field is included only if the Use Store File (G15) system control value is selected. |

|

Cost of goods |

The total cost of units shipped from this warehouse, based on the defined unit cost of the item or SKU. Note: The Display Cost in Inventory (A38) secured feature controls the display of this field.Numeric, 13 positions with a four-place decimal. |

|

Picks generated |

This field is not currently implemented. |

|

Dollars returned |

The total dollar value of units returned to this warehouse, based on the actual selling price of each unit. Numeric, 20 positions with a 2-place decimal. |

|

Units returned |

The total number of units returned to this warehouse by customers. Numeric, 9 positions. |

|

Dollars sold |

The total dollar value of units shipped and billed from this warehouse, based on the actual selling price of each unit. Numeric, 20 positions with a 2-place decimal. |

|

Units sold |

The total number of units shipped and billed from this warehouse. Numeric, 9 positions. |

|

Original retail price |

The original price of this item in the retail store. You can use this field to track the original retail price for the item if the warehouse represents a retail store. This field is included only if the Use Store File (G15) system control value is selected. Numeric, 13 positions with a 2-place decimal. |

|

Current retail price |

The current price of this item in the retail store. You can use this field to track the current retail price for the item if the warehouse represents a retail store. This field is included only if the Use Store File (G15) system control value is selected. Numeric, 13 positions with a 2-place decimal. |

|

Protect price |

This field is not currently implemented. This field is included only if the Use Store File (G15) system control value is selected. |

|

User field 1 |

An informational field where you can enter additional item warehouse information. Alphanumeric, 10 positions. |

|

User field 2 |

An informational field where you can enter additional item warehouse information. Alphanumeric, 10 positions. |

Work with Item Locations Screen

Purpose: Use this screen to create, change, delete, or display a location for an item/SKU within a warehouse. Essential user-defined and system-updated quantity information is kept at the item/SKU location level.

How to display this screen: At the Work with Item Warehouse Screen, select Locations for an item warehouse.

| Field | Description |

|---|---|

|

Location |

A code that identifies a location for an item/SKU within the warehouse. Numeric, 7 positions; optional. |

|

On-hand |

The number of units for this item in this location. Numeric, 7 positions; optional. |

|

Pending |

The quantity of an item for which a batch inventory transaction has been entered, but not processed. A negative quantity in this field indicates component items picked from this location for a finished good work order. This field is cleared once you process the work order. See Finished Good Work Order Processing (WWOR). Numeric, 7 positions; optional. |

|

Min |

The least amount of units to stock in this location. Numeric, 7 positions; optional. |

|

Max |

The maximum amount of units to stock in this location. Numeric, 7 positions; optional. |

|

Reservation freeze |

Indicates whether the item location or SKU location is frozen. Valid values are:

Note: Even though a pick slip does not print for an item from a frozen item location, the system still reserves the item on the Order Lines Fields in Order Entry. |

| Screen Option | Procedure |

|---|---|

|

Create an item location |

Select Create to advance to the Create Item Location Screen. |

|

Change an item location |

Select Change for an item location to advance to the Change Item Location Screen. |

|

Delete an item location |

Select Delete for an item location to delete it. Note: The system will prevent you from deleting Item Locations if the quantity on-hand for the item in this location is greater than zero, or if there are any pending Inventory Transactions for the item in this location. |

|

Display an item location |

Select Display for an item location to advance to the Display Item Location Screen. You cannot change any information at this screen. See the Change Item Location Screen for field descriptions. |

Create Item Location Screen

Purpose: Use this screen to create an item location.

Temporary location: If the item is assigned to a temporary location, the system automatically deletes the location when the on-hand quantity reaches zero. Order Administration does not allocate merchandise from a temporary location even if the location is defined as pickable. In order to allocate stock, you must move the merchandise to a non-temporary, pickable location.

How to display this screen:

-

Select Create at the Work with Item Locations Screen.

-

Select Create Loc at the Work with Inventory Transactions Screen.

| Field | Description |

|---|---|

|

Location |

The code representing the area within the warehouse that contains the item or SKU. An error message indicates if you enter a location whose

location class does not match the location class for the item and

the Allow Location Class Edit in Inventory Transaction

(F86) system control value is selected: Typically the location code is composed of a single alphanumeric character for Zone, and two numbers each for Aisle, Shelf, and Bin. For instance, the location A010201 indicates:

Free-form location codes can also be used. The location code entered is validated against the Location table. Alphanumeric, 7 positions; required. |

|

Reservation freeze |

Indicates whether the item location or SKU location is frozen. Valid values are:

Note: Even though a pick slip does not print for an item from a frozen item location, the system still reserves the item on the Order Lines Fields in Order Entry. |

|

Min qty |

The desired least amount of inventory on hand for this item/SKU in this warehouse location. Numeric, 7 positions; optional. |

|

Max qty |

The desired highest amount of inventory on hand for this item or SKU in this warehouse location. Numeric, 7 positions; optional. |

Change Item Location Screen

Purpose: Use this screen to change the item location’s reservation freeze status, minimum quantity and maximum quantity, and to view inventory transaction information.

How to display this screen: Select Change for an item location at the Work with Item Locations Screen.

See the Create Item Location Screen for the field descriptions not shown below.

| Field | Description |

|---|---|

|

On-hand quantity |

The number of units of the item in this location. Alphanumeric, 7 position; display-only. |

|

Pending transfer quantity |

The quantity of an item for which an inventory transaction has been entered, but not processed. A positive quantity reflects that inventory is in the process of being transferred to this location while a negative quantity indicates inventory is in the process of being transferred from this location. Reflects an adjustment, transfer, or finished good work order, and is not included in the on-hand quantity. Numeric, 7 positions; display-only. |

|

Printed quantity |

The number of units currently “allocated” for the item in this location, determined by the total quantity of the item on printed pick slips. When determining the locations from which to reserve items during pick slip generation, the printed quantity is subtracted from the on-hand quantity in the location to determine the quantity available for reservation. Numeric, 7 positions; display-only. |

|

Placement date |

The date when you first placed the item in this location, for example through purchase order receiving, customer returns, transfers, or adjustments. Numeric, 6 positions (user date format); display-only. |

|

Item transfer pending |

Indicates whether an inventory transaction is pending for the item in this location. For example, the system selects this field if you enter a finished good work order, but do not approve or process the request. See Finished Good Work Order Processing (WWOR). |

Pending Putaway Overview

Purpose: A pending putaway warehouse is a warehouse where you keep stock that still needs to be moved to its final destination: for example, a staging area.

Use a pending putaway warehouse to temporarily store saleable inventory on its way to its final destination warehouse. Inventory received into a pending putaway warehouse is included in the on-hand quantity for that warehouse, but also retains its on-order status; the inventory is also visible in PO Layering. Stock moved into or out of a pending putaway warehouse increases or decreases the on-order quantity in the pending putaway item warehouse.

How do I create a pending warehouse? You can define a warehouse as a pending putaway warehouse using the Working with Default Warehouse Locations (WWDL) menu option.

Note:

Inventory in a pending putaway warehouse should not be available for reservation and picking. You should leave the Allocatable flag for the warehouse unselected.In this topic:

Pending Putaway Processing

Purpose: When you place stock into a pending putaway warehouse, the system performs the following steps.

-

Creates a record in the Pending Putaway Detail table. You can review inventory in a pending putaway warehouse on the Display Pending Putaway Details Screen.

The pending putaway detail record indicates:

-

PO # = The purchase order number on which the inventory was originally received. If the inventory is not associated with a purchase order, the system uses 9999999 as the purchase order number.

-

PO detail = The purchase order line number on the purchase order on which the inventory was originally received. If the inventory is not associated with a purchase order, this field remains blank.

-

PO warehouse = The “final destination” warehouse where the inventory will be placed.

-

Due date = The expected due date of the inventory; this due date will display in order entry, order maintenance, order inquiry, inventory inquiry, and item availability for the “final destination” warehouse.

-

Pending qty = The quantity of the item in the pending putaway warehouse for this transaction. The on hand quantity and on order quantity for the item at the item warehouse level indicates the total pending quantity for the item.

-

Offer = The offer associated with the pending putaway detail record. If the inventory is associated with a purchase order, this is the offer on the purchase order.

-

-

For inventory placed in a pending putaway warehouse, the system creates a PO layering record for the “final destination” warehouse. The Open quantity field represents the quantity placed in pending putaway for the transaction.

-

Decreases the on order quantity for the item in the “final destination” warehouse.

-

Creates an inventory transaction history record for the pending warehouse.

Determining the “final destination” warehouse: The “final destination” warehouse is the warehouse where the inventory will eventually be placed. The system determines which warehouse is the “final destination” warehouse by looking at:

-

the warehouse on the purchase order, or

-

the warehouse associated with the inventory transaction, or

-

the Primary warehouse for the item/SKU.

Moving stock from a pending warehouse: When you move stock from a pending warehouse, the system performs the following steps.

-

Decreases the quantity of the item in the pending warehouse. If the inventory quantity associated with the pending putaway detail record reaches zero, the system also deletes the pending putaway detail record.

-

Increases the on hand quantity of the item in the “final destination” warehouse.

-

Creates an inventory transaction history record for the pending warehouse and the “final destination” warehouse.

-

Performs vendor item analysis.

Other Async Processing: The Other Async performs updates to inventory placed in a pending warehouse.

-

If a pending putaway detail record associated with a purchase order exists, the system keeps the associated PO layering record in an open status until the pending putaway detail record is deleted. The system deletes pending putaway detail records when the associated pending quantity is moved to another warehouse.

In addition, for inventory placed in a pending putaway warehouse:

-

If enough backorders exist to use up the pending quantity, the system updates the status of the PO layering record to closed.

-

If the pending quantity is less than the open quantity on the PO layering record, the system updates the PO layering open quantity to equal the pending quantity.

-

If the pending quantity is equal to or greater than the open quantity on the PO layering record, the system does not update the PO layering open quantity.

Print backorder reports (PBOR): The on order quantity on the backorder reports does not include the quantity in a pending putaway warehouse.

Soldout control processing: The calculation the system uses to determine when an item with a soldout control status of 2 should be sold out now includes the on order quantity for pending putaway detail records that are associated with a pending putaway warehouse and whose “final destination” warehouse is allocatable. An item with a soldout control status of 2 is sold out when this condition is met:

(on order + on order in pending putaway warehouse + on-hand)

- reserved < 0

Reset On-Order PO Quantity periodic function: The Reset On-Order PO Quantity periodic function updates the on order quantity in a pending putaway warehouse, regardless if the “final destination” warehouse is allocatable or non-allocatable.

Purchase Order Receipt Transactions

When you receive inventory into a pending warehouse through Purchase Order Receipts, the system looks for an existing pending putaway detail record for this purchase order and item/SKU (indicating the item/SKU on this purchase order has already been partially received).

-

If a pending putaway detail record does not already exist for the purchase order and item/SKU, the system creates a pending putaway detail record in the pending warehouse.

-

If a pending putaway detail record already exists for the purchase order and item/SKU, the system adds the receipt quantity to the existing pending putaway detail record. The system looks at these fields in the Pending Putaway Detail table to determine if a record already exists for this purchase order and item/SKU:

-

Company: the company where you performed the PO receipt.

-

Item number: the item you received into the pending putaway warehouse.

-

SKU code: the SKU of the item.

-

Warehouse: the pending putaway warehouse.

-

PO #: the number of the purchase order associated with the item you received.

-

Sequence #: the system uses the next available number.

-

PO layering warehouse: the “final destination” warehouse; this is the warehouse on the purchase order line.

-

PO Maintenance: If you cancel a purchase order line after it has been partially received in a pending warehouse, the system keeps the pending putaway detail record until the inventory in the pending warehouse is placed in its “final destination” warehouse.

Warehouse Transfer Transactions

For a warehouse transfer (T) from one pending warehouse to another pending warehouse, the system:

For the “from” warehouse:

-

decreases the on order quantity and the on hand quantity on the item warehouse for the “from” warehouse. If the on order quantity and on hand quantity is adjusted to a negative quantity, the quantities are set to 0.

-

decreases the pending quantity on the pending putaway detail record with the oldest due date for the “from” warehouse.

-

pending quantity - transfer quantity = new pending quantity.

-

If the pending quantity for the record is reduced to 0, the record is deleted.

-

For the “to” warehouse:

-

increases the on order quantity and the on hand quantity on the item warehouse for the “to” warehouse.

-

checks for existing pending putaway detail records in the “to” warehouse from the same item, SKU, PO number, and PO detail sequence number found in the “from” warehouse pending putaway detail record.

-

if a pending putaway detail record is found, then the system increases the pending quantity with the transfer quantity. Pending quantity + transfer quantity = new pending putaway quantity.

-

if a pending putaway detail record does not exist, then the system creates a pending putaway detail record, using the information from the “from” pending putaway detail record. In this case, the pending quantity represents the transfer quantity.

-

-

The system does not adjust PO layering since the PO layering record does not contain the pending putaway warehouse.

Positive Inventory Adjustments Transactions

The system:

-

increases the on order quantity and on hand quantity on the item warehouse by the adjustment quantity.

-

creates a pending putaway detail record in the pending warehouse. If a pending putaway detail record already exists for the same transaction date and PO # 9999999, the system adds the adjustment quantity to the pending quantity of the existing pending putaway detail record.

-

Item number: the item against which you performed the adjustment.

-

SKU code: the SKU of the item.

-

Warehouse: this is the pending putaway warehouse.

-

PO #: when a pending putaway quantity is not associated with a purchase order, the system displays 9999999.

-

PO detail sequence #: the system assigns the next available number.

-

PO warehouse: this is the “final destination” warehouse.

-

Due date: the system uses this calculation to determine the due date:

date the inventory adjustment was performed + number in the Pending Putaway Due Date Days system control value = due date -

Pending quantity: the adjustment quantity.

-

-

creates a PO layering record. If a PO layering record exists, the system adds the adjustment quantity to the open quantity on the PO layering record.

-

Company: the company where you performed the adjustment.

-

Item number: the item against which you performed the adjustment.

-

SKU code: the SKU of the item.

-

Warehouse: the “final destination” warehouse.

-

PO #: 9999999

-

Sequence #: the sequence number for the pending putaway detail record.

-

Due date: the due date for the pending putaway detail record.

-

Open quantity: the adjustment quantity.

-

Note:

When you process an overlay transaction, the system uses the difference between the original on hand quantity and the overlay quantity as the adjustment quantity.Negative Inventory Adjustments Transactions

The system:

-

decreases the on order quantity and on hand quantity on the item warehouse by the adjustment quantity.

-

decreases the pending quantity on the pending putaway detail record that has the oldest due date.

pending putaway quantity - adjustment quantity = new pending putaway quantity -

updates the PO layering record associated with the pending putaway detail record whose pending quantity was decreased.

-

Open quantity: reduced by the adjustment quantity. If the open quantity reaches 0, the system updates the PO layering status to closed.

-

Note:

When you process an overlay transaction, the system uses the difference between the original on hand quantity and the overlay quantity as the adjustment quantity.Display Pending Putaway Details Screen

Purpose: Use this screen to review inventory information for items that have been placed in a pending putaway (PP) warehouse.

How to display this screen: At the Work with Item Warehouse Screen, when accessed through the Creating and Maintaining Item Warehouses menu option, select Pend Putaway for an item warehouse.

| Field | Description |

|---|---|

|

Item |

The code and description for the item that has inventory in a pending putaway warehouse. Item code: Alphanumeric, 12 positions; display-only. Item description: Alphanumeric, 120 positions; display-only. |

|

SKU |

The code and description for the unique attributes of the item that has inventory in a pending putaway warehouse. SKU code: Alphanumeric, three 4-position fields; display-only. |

|

Warehouse |

A code and description for the warehouse that represents the pending putaway warehouse. Pending warehouses are areas where you place inventory before the inventory is placed in its final destination, such as a staging area. Warehouse code: Numeric, 3 positions; display-only. Warehouse description: Alphanumeric, 30 positions; display-only. |

|

PO # |

The number of the purchase order associated with the inventory that has been placed in a pending putaway warehouse. If the inventory is not associated with a purchase order, for example the inventory is associated with an inventory transaction, the purchase order # is shown as 9999999. Numeric, 7 positions; display-only. |

|

PO dtl (PO detail line number) |

The purchase order line number associated with the inventory that has been placed in a pending putaway warehouse. If the inventory is not associated with a purchase order, for example the inventory is associated with an inventory transaction, the purchase order line number is the next available purchase order detail sequence number from the Pending Putaway Detail table. Numeric, 3 positions; display-only. |

|

PO warehouse |

The code for the warehouse where the inventory that is located in the pending putaway warehouse will finally be placed.

Numeric, 3 positions; display-only. |

|

Due date (Pending putaway due date) |

The date inventory in the pending putaway warehouse is due to be received into the “final destination” warehouse. The purchase order has already been received in the pending putaway warehouse, but the system retains this information until the inventory is placed in the PO warehouse. Determining the pending putaway due date when a PO is not associated with the inventory If the inventory is not associated with a purchase order, such as when you perform an inventory transaction, the system determines the due date based on the Pending Putaway Due Date Days (G92).

Example: You perform an inventory adjustment for item A123 in the pending putaway warehouse on 6/20. The Pending Putaway Due Date Days system control value is 6.

Numeric, 6 positions (user date format); display-only. |

|

Pending qty |

The quantity of the item that is currently placed in the pending putaway warehouse for a specific transaction. This is the quantity to place in the PO warehouse. Numeric, 7 positions; display-only. |

|

Offer |

The offer on the purchase order, if any. Alphanumeric, 3 positions; display-only. |

Docking Purchase Orders

Topics in this part: The following topics describe the functions available when using the Dock Purchase Orders function.

-

Docking Purchase Orders (MDPO) shows you how to record a purchase order as “docked” before you receive it.

-

Printing the Purchase Orders in Docked Status Report (PDPO) shows you how to print the Docked Purchase Order Report and describes the information on the report.

-

Printing the Docked but Past Due Purchase Order Report (PDPD) shows you how to create and print the Past Due Docked Purchase Order Report and describes the information on the report.

Warehouse Management Integration

In this part: This part includes the following topics:

-

Warehouse Management System Integration Overview: Provides an overview of the Warehouse Management Integration.

-

Generic Outbound Purchase Order API: Describes how to send purchase order information to an external system.

-

Purchase Order Receipt In API: Describes how to process PO receipts received through the generic API.

-

Generic Pick In API (Shipments, Voids, and Backorders): Describes how to confirm shipments or void pick slips through the generic API.

For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1).

Warehouse Management System Integration Overview

Warehouse management systems control inventory movement, such as receiving merchandise, inventory transactions, picking and packing, and shipping merchandise to a customer.

The Warehouse Management System integration allows Order Administration and a warehouse management system (WMS) to pass inventory information in order to keep inventory information in both systems accurate. The WMS is where the actual inventory is located, but Order Administration needs to keep track of the changes to inventory that occur in the WMS so that the data in Order Administration remains accurate. For example, if the WMS adjusts the inventory for an item and does not notify Order Administration, orders placed in Order Administration may reserve items that do not have enough inventory in the warehouse.

The warehouse management system integration creates a bridge between Order Administration and a WMS. This bridge allows Order Administration and a WMS to pass data between the two systems using XML messages transmitted via a queue or web service.

In this topic:

-

What Does Order Administration Send to the Warehouse Management System?

-

What Does the Warehouse Management System Send to Order Administration?

What Does Order Administration Send to the Warehouse Management System?

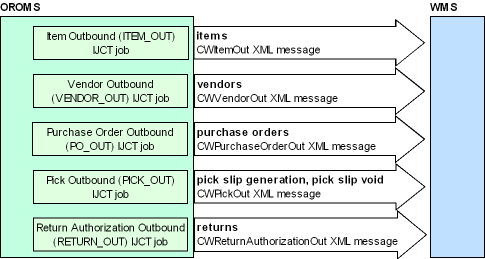

Order Administration controls item information, vendor information, purchase order information, pick slip information, and return information. Any time you create or modify information in these areas, Order Administration sends the information to the warehouse management system.

What Does the Warehouse Management System Send to Order Administration?

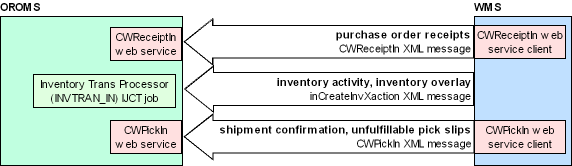

The warehouse management system controls changes to inventory, such as purchase order receipts, inventory transactions, and shipping merchandise to customers. Any time the warehouse management system adds or removes inventory in a warehouse, the WMS sends the information to Order Administration.

Warehouse Integration Summary

| Function | Performed By: |

|---|---|

|

Items: Order Administration sends new or changed items to the warehouse management system (WMS) |

Generic Item Download API For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Vendors: Order Administration sends new or changed vendors to the WMS |

Generic Vendor Download API For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Purchase orders: Order Administration sends new or changed purchase orders to the WMS |

Generic Outbound Purchase Order API For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Purchase order receipts: Order Administration receives information on purchase order receipts sent from the WMS |

Purchase Order Receipt In API For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Inventory activity: Order Administration receives information on inventory activity, such as transfers or adjustments, from the WMS |

Generic Inventory Transaction Upload For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Inventory overlay: Order Administration receives updated inventory information from the WMS |

Generic Inventory Transaction Upload For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Pick slip generation: Order Administration sends information on generated pick slips to the WMS |

Generic Pick Out API For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Pick slip void: Order Administration sends information on voided pick slips to the WMS |

Generic Pick Out API For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Shipment confirmation: Order Administration receives information on full or partial shipments; information on carton contents can also be included |

Generic Pick In API (Shipments, Voids, and Backorders) For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Unfulfillable pick slips: Order Administration receives information on pick slip voids from the WMS |

Generic Pick In API (Shipments, Voids, and Backorders) For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

|

Returns: Order Administration sends updates on customer returns to the WMS |

NA |

Receiving Purchase Orders (PORC)

Purpose: Use the Purchase Order Receiving function to update the system when you receive inventory from open purchase orders from your vendors. When you receive inventory, you can:

-

receive the entire purchase order in one step, or you can receive the items one line at a time.

-

receive items directly into your on-hand inventory, or into suspense for placement at a later time.

-

place items in more than one location or warehouse.

-

have the system suggest where to place the items.

-

add items to the purchase order if the vendor shipped you merchandise you did not order. This addition allows you to record the receipt for tracking purposes, and process a return-to-vendor transaction on the system at a later time.

If you are receiving a serial numbered item, you will need to enter the serial number of each unit at the time you place the merchandise in the warehouse. See Enter Serial Numbers Screen.

If you are receiving a drop ship purchase order, you can also print a drop ship invoice if the Print Drop Ship Invoice at time of Purchase Order Receiving (F10) system control value is selected.

Note:

You should not confirm shipment through this menu option of a drop ship purchase order processed automatically through the Order Orchestration Drop Ship Integration. This updates the status of the purchase order in Order Administration to X (Closed) but does not affect the Order Orchestration status of a purchase order. The item is still displayed on your Order Orchestration Vendor Portal screens, and your Order Orchestration functionality is not affected; however, vendor actions subsequent to receiving the purchase order are not recorded in Order Administration.Purchase Order Receipt In API: You can use the Purchase Order Receipt In API to process PO receipts received from another system, such as a warehouse management system. See the Purchase Order Receipt In API in the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1) for an overview and the required setup.

PO download triggers: The setting of the Create Generic PO Download Trigger for PO Receipt (K27) system control value determines whether the system creates a purchase order download (POH) trigger when a purchase order line is received. See Generic Outbound Purchase Order API for an overview.

For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1).

In this topic:

Work with P/O Receipt Detail Screen

Purpose: This screen displays each open line on the purchase order you have selected and is used to enter the receipt information for the purchase order or to view information from prior receipts against the purchase order for lines that are still open.